Abstract

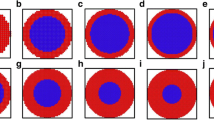

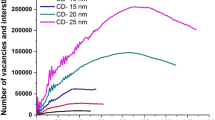

The mechanical properties of core–shell bimetallic composite nanowires, forming the bases of nanoporous metallic foams, have been investigated and compared with pure metal nanowires using molecular dynamics simulations. In the current study, pure copper and gold nanowires under uniaxial loading were tested at room temperature and compared to composite nanowires of the same materials (core) with a nickel coating (shell). The core radius ranged from 1 to 15 nm, and the shell thickness ranged from 0.1 to 5 nm. The tension strain was performed along the [001] direction under room temperature. Both coherent and semi-coherent composite nanowires were studied, and the effect of coating layer thickness was investigated. The strengthening mechanisms of the core–shell structures due to the presence of the two different types of interfaces were investigated for various nickel thicknesses. The atomistic simulation results revealed that the addition of the nickel shell strengthens the structure when the layer thickness exceeds a critical value.

Similar content being viewed by others

References

Y. Xue, J. Liu, H. Chen, R. Wang, D. Li, J. Qu, and L. Dai: Nitrogen-doped graphene foams as metal-free counter electrodes in high-performance dye-sensitized solar cells. Angew. Chem., Int. Ed. 51, 12124 (2012).

S. Bhaviripudi, E. Mile, S.A. Steiner, A.T. Zare, M.S. Dresselhaus, A.M. Belcher, and J. Kong: CVD synthesis of single-walled carbon nanotubes from gold nanoparticle catalysts. J. Am. Chem. Soc. 129, 1516 (2007).

A.C. Patel, S. Li, C. Wang, W. Zhang, and Y. Wei: Electrospinning of porous silica nanofibers containing silver nanoparticles for catalytic applications. Chem. Mater. 19, 1231 (2007).

S.F. Corbin, R.M.C. Clemmer, and Q. Yang: Development and characterization of porous composites for solid oxide fuel cell anode conduction layers using ceramic-filled highly porous Ni foam. J. Am. Ceram. Soc. 92, 331 (2009).

C-J. Tseng, Y-J. Heush, C-J. Chiang, Y-H. Lee, and K-R. Lee: Application of metal foams to high temperature PEM fuel cells. Int. J. Hydrogen Energy 41, 16196 (2016).

R. Shinde and M. Tayade: Remarkable hydrogen storage on beryllium oxide clusters: First-principles calculations. J. Phys. Chem. C 118, 17200 (2014).

S. Mellouli, H. Dhaou, F. Askri, A. Jemni, and S. Ben Nasrallah: Hydrogen storage in metal hydride tanks equipped with metal foam heat exchanger. Int. J. Hydrogen Energy 34, 9393 (2009).

J. Biener, G.W. Nyce, A.M. Hodge, M.M. Biener, A.V. Hamza, and S.A. Maier: Nanoporous plasmonic metamaterials. Adv. Mater. 20, 1211 (2008).

J. Biener, A.M. Hodge, and A.V. Hamza: Microscopic failure behavior of nanoporous gold. Appl. Phys. Lett. 87, 121908 (2005).

Q. Zhou, J.Y. Xie, F. Wang, P. Huang, K.W. Xu, and T.J. Lu: The mechanical behavior of nanoscale metallic multilayers: A survey. Acta Mech. Sin. 31, 319 (2015).

I.N. Mastorakos, H.M. Zbib, and D.F. Bahr: Deformation mechanisms and strength in nanoscale multilayer metallic composites with coherent and incoherent interfaces. Appl. Phys. Lett. 94, 173114 (2009).

R.G. Hoagland, R.J. Kurtz, and C.H. Henager, Jr.: Slip resistance of interfaces and the strength of metallic multilayer composites. Scr. Mater. 50, 775 (2004).

N. Abdolrahim, H.M. Zbib, and D.F. Bahr: Multiscale modeling and simulation of deformation in nanoscale metallic multilayer systems. Int. J. Plast. 52, 33 (2014).

A. Misra, M. Verdier, Y.C. Lu, H. Kung, T.E. Mitchell, M. Nastasi, and J.D. Embury: Structure and mechanical properties of Cu-X (X = Nb, Cr, Ni) nanolayered composites. Scr. Mater. 39, 555 (1998).

I.N. Mastorakos, N. Abdolrahim, and H.M. Zbib: Deformation mechanisms in composite nano-layered metallic and nanowire structures. Int. J. Mech. Sci. 52, 295 (2010).

R.G. Hoagland, T.E. Mitchell, J.P. Hirth, and H. Kung: On the strengthening effects of interfaces in multilayer fee metallic composites. Philos. Mag. A 82, 643 (2002).

S. Shao and S.N. Medyanik: Dislocation–interface interaction in nanoscale fcc metallic bilayers. Mech. Res. Commun. 37, 315 (2010).

D. Mitlin, A. Misra, T.E. Mitchell, J.P. Hirth, and R.G. Hoagland: Interface dislocation structures at the onset of coherency loss in nanoscale Ni–Cu bilayer films. Philos. Mag. 85, 3379 (2005).

S. Shao and J. Wang: Relaxation mechanisms, structure and properties of semi-coherent interfaces. Metals 5, 1887 (2015).

J. Wang, R.G. Hoagland, J.P. Hirth, and A. Misra: Atomistic modeling of the interaction of glide dislocations with “weak” interfaces. Acta Mater. 56, 5685 (2008).

R.G. Hoagland, J.P. Hirth, and A. Misra: On the role of weak interfaces in blocking slip in nanoscale layered composites. Philos. Mag. 86, 3537 (2006).

N. Abdolrahim, I.N. Mastorakos, and H.M. Zbib: Deformation mechanisms and pseudoelastic behaviors in trilayer composite metal nanowires. Phys. Rev. B 81, 054117 (2010).

P. Li, Y. Yang, X. Luo, N. Jin, G. Liu, and Y. Gao: Structural evolution of copper–silver bimetallic nanowires with core–shell structure revealed by molecular dynamics simulations. Comput. Mater. Sci. 137 (Suppl. C), 289 (2017).

X-Y. Sun, Y. Xu, G-F. Wang, Y. Gu, and X-Q. Feng: Effects of surface atomistic modification on mechanical properties of gold nanowires. Phys. Lett. A 379, 1893 (2015).

N. Abdolrahim, D.F. Bahr, B. Revard, C. Reilly, J. Ye, T.J. Balk, and H.M. Zbib: The mechanical response of core–shell structures for nanoporous metallic materials. Philos. Mag. 93, 736 (2013).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1 (1995).

M.S. Daw and M.I. Baskes: Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29, 6443 (1984).

M.S. Daw, S.M. Foiles, and M.I. Baskes: The embedded-atom method: A review of theory and applications. Mater. Sci. Rep. 9, 251 (1993).

A.F. Voter and S.P. Chen: Accurate interatomic potentials for Ni, Al, and Ni3Al. MRS Online Proc. Libr. 82, 175–180 (1986).

X.W. Zhou, R.A. Johnson, and H.N.G. Wadley: Misfit-energy-increasing dislocations in vapor-deposited CoFe/NiFe multilayers. Phys. Rev. B 69, 144113 (2004).

L. Ward, A. Agrawal, K.M. Flores, and W. Windl: Rapid production of accurate embedded-atom method potentials for metal alloys. ArXiv12090619 Cond-Mat Physicsphysics (2012).

J.A. Zimmerman, H. Gao, and F.F. Abraham: Generalized stacking fault energies for embedded atom FCC metals. Modell. Simul. Mater. Sci. Eng. 8, 103 (2000).

J. Davoodi, S. Dadashi, and M. Yarifard: Molecular dynamics simulations of the melting of Al–Ni nanowires. Philos. Mag. 96, 2300 (2016).

S. Divi and A. Chatterjee: Understanding segregation behavior in AuPt, NiPt, and AgAu bimetallic nanoparticles using distribution coefficients. J. Phys. Chem. C 120, 27296 (2016).

T. Zientarski and D. Chocyk: Structure and stress in Cu/Au and Fe/Au systems: A molecular dynamics study. Thin Solid Films 562 (Suppl. C), 347 (2014).

P. Hirel: Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 197, 212 (2015).

J.D. Honeycutt and H.C. Andersen: Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. J. Phys. Chem. 91, 4950 (1987).

D. Faken and H. Jónsson: Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 2, 279 (1994).

A. Stukowski, V.V. Bulatov, and A. Arsenlis: Automated identification and indexing of dislocations in crystal interfaces. Modell. Simul. Mater. Sci. Eng. 20, 085007 (2012).

A. Stukowski: Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2010).

J. Marian and J. Knap: Breakdown of self-similar hardening behavior in Au nanopillar microplasticity. Int. J. Multiscale Comput. Eng. 5, 287–294 (2007).

Y. Gan and J.K. Chen: Molecular dynamics study of size, temperature and strain rate effects on mechanical properties of gold nanofilms. Appl. Phys. A 95, 357 (2009).

A. Misra and R.G. Hoagland: Plastic flow stability of metallic nanolaminate composites. J. Mater. Sci. 42, 1765 (2007).

A. Misra, J.P. Hirth, and R.G. Hoagland: Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 53, 4817 (2005).

J.P. Hirth and X. Feng: Critical layer thickness for misfit dislocation stability in multilayer structures. J. Appl. Phys. 67, 3343 (1990).

I.N. Mastorakos, A. Bellou, D.F. Bahr, and H.M. Zbib: Size-dependent strength in nanolaminate metallic systems. J. Mater. Res. 26, 1179 (2011).

H.J. Chu, J. Wang, C.Z. Zhou, and I.J. Beyerlein: Self-energy of elliptical dislocation loops in anisotropic crystals and its application for defect-free core/shell nanowires. Acta Mater. 59, 7114 (2011).

A. Misra and H. Krug: Deformation behavior of nanostructured metallic multilayers. Adv. Eng. Mater. 3, 217 (2001).

Acknowledgments

This work was supported by the National Science Foundation under Grant No. CMMI-1634640.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Ke, H., Mastorakos, I. Deformation behavior of core–shell nanowire structures with coherent and semi-coherent interfaces. Journal of Materials Research 34, 1093–1102 (2019). https://doi.org/10.1557/jmr.2018.491

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.491