Abstract

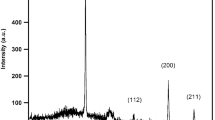

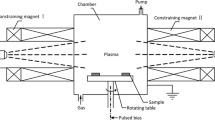

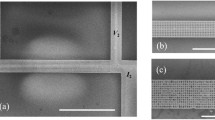

Density modulated tungsten (W) thin films with nanoscale porosity contents of 7% to 40% by volume were grown on Si substrates through magnetron sputter deposition. Process parameters were selected according to the structure zone model, which resulted in film thicknesses between 105 nm and 520 nm. Nanomechanical properties of samples were investigated by means of instrumented nanoindentation. Reduced-χ2 analysis was carried out to assess four models formulated through differential effective medium approach. The model that factored in both the crowding effect and the maximum random packing of pores successfully captured the experimental trends. Attempts to breach the auxetic barrier resulted in large-scale pulverization or spontaneous conversion into WO3. Porosity corrected yield strength calculations underlined the possibility of defining a porosity threshold beyond which the compressive yield strength of density modulated nanoporous metallic thin films would drop abruptly due to aggravated geometric slenderness effects in agreement with earlier hypotheses.

Similar content being viewed by others

References

J.P. Singh, T. Karabacak, D.X. Ye, D.L. Liu, R.C. Picu, T.M. Lu, and G.C. Wang: Physical properties of nanostructures grown by oblique angle deposition. J. Vac. Sci. Technol., B 23 (5), 2114 (2005).

J.A. Thornton: High rate thick film growth. Annu. Rev. Mater. Sci. 7, 239 (1977).

J.A. Thornton: The microstructure of sputter-deposited coatings. J. Vac. Sci. Technol., A 4 (6), 3059 (1986).

D.C. Meyer, A. Klingner, T. Holz, and P. Paufler: Self-organized structuring of W/C multilayers on Si substrate. Appl. Phys. A: Mater. Sci. Process. 69 (6), 657 (1999).

L.B. Freund and S. Suresh: Thin Film Materials: Stress, Defect Formation and Surface Evolution, 1st ed. (Cambridge University Press, Cambridge, England, 2004); pp. 60–72.

A.M. Haghiri-Gosnet, F.R. Ladan, C. Mayeux, H. Launois, and M.C. Joncour: Stress and microstructure in tungsten sputtered thin films. J. Vac. Sci. Technol., A 7 (4), 2663 (1989).

H. Windischmann: Intrinsic stress in sputtered thin films. J. Vac. Sci. Technol., A 9 (4), 2431 (1991).

A.M. Haghiri-Gosnet, F.R. Ladan, C. Mayeux, and H. Launois: Stresses in sputtered tungsten thin films. Appl. Surf. Sci. 38 (1–4), 295 (1989).

M. Yonezawa, T. Yamazaki, and T. Kikuta: Porosity Assessment of NiO sputtered film and NO2 sensing property. J. Vac. Soc. Jpn. 53 (3), 226 (2010).

D. Ren, Y. Zou, C.Y. Zhan, and N.K. Huang: Study on the porosity of TiO2 films prepared by using magnetron sputtering deposition. J. Korean Phys. Soc. 58 (4), 883 (2011).

R. Messier, A.P. Giri, and R.A. Roy: Revised structure zone model for thin film physical structure. J. Vac. Sci. Technol., A 2 (2), 500 (1984).

T. Karabacak, C.R. Picu, J.J. Senkevich, G.C. Wang, and T.M. Lu: Stress reduction in tungsten films using nanostructured compliant layers. J. Appl. Phys. 96 (10), 5740 (2004).

T. Karabacak, J.J. Senkevich, G.C. Wang, and T.M. Lu: Stress reduction in sputter deposited films using nanostructured compliant layers by high working-gas pressures. J. Vac. Sci. Technol., A 23 (4), 986 (2005).

J.W. Hutchinson: Mechanics of Thin Films and Multilayers: Course Notes (Technical University of Denmark, Technical Report, 1996).

M. Ohring: Materials Science of Thin Films, 2nd ed. (Academic Press, San Diego, CA, 2002); pp. 641–742.

A.G. Evans and J.W. Hutchinson: The thermomechanical integrity of thin films and multilayers. Acta Metall. Mater. 43, 2507 (1995).

I. Petrov, P. Barna, L. Hultman, and J. Greene: Microstructural evolution during film growth. J. Vac. Sci. Technol., A 21, S117 (2003).

D.L. Smith: Thin-Film Deposition: Principles and Practice, 1st ed. (McGraw-Hill Professional, New York, NY, 1995); pp. 307–318.

T. Karabacak, Y.P. Zhao, G.C. Wang, and T.M. Lu: Growth front roughening in amorphous silicon films by sputtering. Phys. Rev. B 64 (8), 085323 (2001).

R. Liu and A. Antoniou: A relationship between the geometrical structure of a nanoporous metal foam and its modulus. Acta Mater. 61 (7), 2390 (2013).

C. Lu, X. Shun, and O. Lewis: Investigation of film-thickness determination by oscillating quartz resonators with large mass load. J. Appl. Phys. 43 (11), 4385 (1972).

M.T. Demirkan, L. Trahey, and T. Karabacak: Cycling performance of density modulated multilayer silicon thin film anodes in Li-ion batteries. J. Power Sources 273 (6), 52 (2015).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7 (4), 1564 (1992).

A.C. Fischer-Cripps: Nanoindentation, 3rd ed. (Springer, New York, NY, 2011); pp. 1–29.

R. Pal: Porosity-dependence of effective mechanical properties of pore–solid composite materials. J. Compos. Mater. 39 (13), 1147 (2005).

A. Chatterjee, N. Kumar, J.R. Abelson, P. Bellon, and A.A. Polycarpou: Nanoscratch and nanofriction behavior of hafnium diboride thin films. Wear 265, 921 (2008).

P.C. Meier and R.E. Zund: Statistical Methods in Analytical Chemistry, 2nd ed. (John Wiley & Sons, New York, NY, 2000); p. 76.

E. Lassner and W-D. Schubert: Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds, 1st ed. (Kluwer Academic/Plenum Publishers, New York, NY, 1999); pp. 11–85.

K.K. Shih, D.A. Smith, and J.R. Crow: Properties of hard tungsten films prepared by sputtering. J. Vac. Sci. Technol. A 6 (3), 1681 (1988).

J. Bernardini and D.L. Beke: Diffusion in nanomaterials. In Nanocrystallinen Metals and Oxides, 1st ed., P. Knauth and J. Schoonman eds.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; pp. 41–79.

T. Ozkan, D. Shaddock, D.M. Lipkin, and I. Chasiotis: Mechanical strengthening, stiffening, and oxidation behavior of pentatwinned Cu nanowires at near ambient temperatures. Mater. Res. Express 1 (3), 035020–035021 (2014).

A. Warren, A. Nylund, and I. Olefjord: Oxidation of tungsten and tungsten carbide in dry and humid atmospheres. Int. J. Refract. Met. Hard Mater. 14, 345 (1996).

F. Huth, M. Schnell, J. Wittborn, N. Ocelic, and R. Hillenbrand: Infrared-spectroscopic nanoimaging with a thermal source. Nat. Mater. 10, 352 (2011).

C. Li, J.H. Hsieh, M-T. Hung, and B.Q. Huang: The deposition and microstructure of amorphous tungsten oxide films by sputtering. Vacuum 118, 125 (2015).

A.F. Bower: Applied Mechanics of Solids, 1st ed. (CRC Press, Boca Raton, FL, 2010); pp. 85–87.

Y. Li and A. Antoniou: Synthesis of transversely isotropic nanoporous platinum. Scr. Mater. 66, 503 (2012).

M.O. Jensen and M.J. Brett: Porosity engineering in glancing angle deposition thin films. Appl. Phys. A 80 (4), 763 (2005).

Y. Ding and Z. Zhang: Nanoporous metals. In Springer Handbook of Nanomaterials, 1st ed., R. Vajtai ed.; Springer Science: New York, NY, 2013; pp. 799–802.

L. Wang: Structural tailoring of nanoporous metals and study of their mechanical behavior (University of Kentucky Theses and Dissertations in Chemical and Materials Engineering, Louisville, KY, 2013); pp. 5–131.

C. Ma, S.C. Wang, R.J.K. Wood, J. Zekonyte, Q. Luo, and F.C. Walsh: Hardness of porous nanocrystalline Co–Ni electrodeposits. Met. Mater. Int. 19 (6), 1187 (2013).

N. Huber, R.N. Viswanath, N. Mameka, J. Markmann, and J. Weissmuller: Scaling laws of nanoporous metals under uniaxial compression. Acta Mater. 67, 252 (2014).

K.L. Johnson: Contact Mechanics, 1st ed. (Cambridge University Press, Cambridge, England, 2001); pp. 171–179.

K.M. Lee, C-D. Yeo, and A.A. Polycarpou: Relationship between scratch hardness and yield strength of elastic perfectly plastic materials using finite element analysis. J. Mater. Res. 23 (8), 2229 (2008).

A. Giri, J. Tao, M. Kirca, and A.C. To: Mechanics of nanoporous metals. In Handbook of Micromechanics and Nanomechanics, 1st ed., S. Li and X-L. Gao eds.; Pan Stanford Publishing: Singapore, Singapore, 2013; pp. 827–867.

X-Y. Sun, G-K. Xu, X. Li, X-Q. Feng, and H. Gao: Mechanical properties and scaling laws of nanoporous gold. J. Appl. Phys. 113, 023505–1 (2013).

A.M. Hodge, J. Biener, J.R. Hayes, P.M. Bythrow, C.A. Volkert, and A.V. Hamza: Scaling equation for yield strength of nanoporous open-cell foams. Acta Mater. 55, 1343 (2007).

D. Lydzba and J.F. Shao: Modeling of plastic deformation of saturated porous materials: Effective stress concept. In Applied Micromechanics of Porous Materials, 1st ed., L. Dormieux and F-J. Ulmedited eds.; Springer: Udine, Italy, 2005; pp. 187–204.

ACKNOWLEDGMENTS

Authors Tanil Ozkan and Andreas A. Polycarpou gratefully acknowledge the support of the National Science Foundation under grant no. NSF CMMI 1030657. Film growth and structural analyses of films were carried out in the laboratories of the University of Arkansas at Little Rock. Nanoindentation, SPM and AFM analyses were performed in the Frederick Seitz Materials Research Laboratory Central Research Facilities, University of Illinois. Authors gratefully acknowledge Dr. Tobias Gokus at Neaspec GmbH for nano-FTIR analysis. Authors also express their gratitude for the constructive feedback they received from the reviewers of the JMR, which enhanced the scope and the depth of analysis provided in the revised version of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ozkan, T., Demirkan, M.T., Walsh, K.A. et al. Density modulated nanoporous tungsten thin films and their nanomechanical properties. Journal of Materials Research 31, 2011–2024 (2016). https://doi.org/10.1557/jmr.2016.197

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.197