Abstract

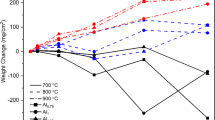

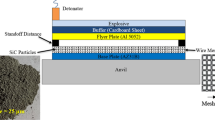

In this study, a powder blend representing 6061 Al-alloy was first mixed with Al2O3 ceramic particles and then foamed by using the powder compact melting method. 6061-Al2O3 foams and control specimens 6061 foams (without ceramic reinforcement) were produced. The effects of both different ratios of Al2O3 particle addition and different kinds of heat treatment on hardenability, structure and mechanical behavior of the final foams were investigated. Foams that were fully heat treated had the highest hardness values, and they performed best with an increase in collapse strength up to 100% over the untreated samples. Improved cell structure and decreased drainage were obtained when the Al2O3 addition was not more than 5 vol%. The compression test results were interpreted in terms of the foam’s microstructure, and correlations were made relating to the unloading modulus and compression strength of the foams to the relative density.

Similar content being viewed by others

References

J. Banhart: Manufacture, characterization and application of cellular metals and metal foams. Prog. Mater. Sci. 46, 559 (2001).

J. Banhart: Metal foams: Production and stability. Adv. Eng. Mater. 8, 781 (2006).

V. Gergely and B. Clyne: The FORMGRIP process: Foaming of reinforced metals by gas release in precursors. Adv. Eng. Mater. 2, 175 (2000).

J. Baumeister and H. Schrader: Methods for manufacturing foamable metal bodies. U.S. Patent 5 151 246, 1992.

C. Körner, M. Arnold, and R.F. Singer: Metal foam stabilization by oxide network particles. Mater. Sci. Eng., A. 396, 28 (2005).

D. Lehmhus and M. Busse: Potential new matrix alloys for production of PM aluminium foams. Adv. Eng. Mater. 6, 391 (2004).

F. Von Zeppelin, M. Hirscher, H. Stanzick, and J. Banhart: Desorption of hydrogen from blowing agents used for foaming metals. Compos. Sci. Technol. 63, 2293 (2003).

B. Matijasevic and J. Banhart: Improvement of aluminium foam technology by tailoring of blowing agent. Scr. Mater. 54, 503 (2005).

B. Matijasevic-Lux, J. Banhart, S. Fiechter, O. Görke, and N. Wanderka: Modification of titanium hydride for improved aluminium foam manufacture. Acta Mater. 54, 1887 (2006).

A.R. Kennedy: The effect of TiH2 heat treatment on gas release and foaming in Al-TiH2 preforms. Scr. Mater. 47, 763 (2002).

A.R. Kennedy and S. Asavavisithchai: Effect of ceramic particle additions on foam expansion and stability in compaced Al-TiH2 powder precursors. Adv. Eng. Mater. 6, 400 (2004).

S. Elbir, S. Yilmaz, A.K. Toksoy, M. Guden, and I.W. Hall: SiC-particulate aluminum composite foams produced by powder compacts: Foaming and compression behavior. J. Mater. Sci. 38, 4745 (2003).

A.R. Kennedy and S. Asavavisithchai: Effects of TiB2 particle addition on the expansion, structure and mechanical properties of PM Al foams. Scr. Mater. 50, 115 (2004).

S. Asavavisithchai and A.R. Kennedy: The effect of Mg addition on the stability of Al-Al2O3 foams made by a powder metallurgy route. Scr. Mater. 54, 1331 (2006).

S. Esmaeelzadeh, A. Simchi, and D. Lehmhus: Effect of ceramic particle addition on the foaming behavior, cell structure and mechanical properties of P/M AlSi7 foam. Mater. Sci. Eng., A 424, 290 (2006).

M. Haesche, J. Weise, F. Garcia-Moreno, and J. Banhart: Influence of particle additions on the foaming behavior of AlSi11/TiH2 composites made by semi-solid processing. Mater. Sci. Eng., A. 480, 283 (2008).

D. Lehmhus and J. Banhart: Properties of heat-treated aluminium foams. Mater. Sci. Eng., A 349, 98 (2003).

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, and H.N.G. Wadley: Metal Foams: A Design Guide (Butterworth Heineman, MA, 2000).

H.P. Degischer and B. Kriszt: Handbook of Cellular Metals: Production, Processing, Applications (Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, 2002).

C. Körner: Foam formation mechanisms in particle suspensions applied to metal foams. Mater. Sci. Eng., A. 495, 227 (2008).

A. Dudka, F. Garcia-Moreno, N. Wanderka, and J. Banhart: Structure and distribution of oxides in aluminium foam. Acta Mater. 56, 3990 (2008).

L.J. Gibson and M.F. Ashby: Cellular Solids: Structure and Properties, 2nd ed. (Cambridge Solid State Science Series, Cambridge, England, 1999).

M.F. Ashby: Criteria for selecting the components of composites. Acta Metall. Mater. 41, 1313 (1993).

K.Y.G. McCullough, N.A. Fleck, and M.F. Ashby: Uniaxial stress-strain behavior of aluminium alloy foams. Acta Mater. 47, 2323 (1999).

Acknowledgments

This work was supported in part by the Turkish State Planning Agency (DPT-03K120250) and Bogazici University Scientific Research Projects (BAP-07A603D).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahmutyazicioglu, N., Albayrak, O., Ipekoglu, M. et al. Effects of alumina (Al2O3) addition on the cell structure and mechanical properties of 6061 foams. Journal of Materials Research 28, 2509–2519 (2013). https://doi.org/10.1557/jmr.2013.187

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.187