Abstract

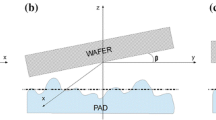

Physical forces control particle deposition on wafers in virtually all manufacturing environments: open air, liquid baths, and subatmospheric chambers. Physical forces also often dominate particle adhesion and removal. In aerosol systems, gravity and diffusion are important universal mechanisms contributing to particle deposition velocity (≡particle flux to a surface/particle concentration adjacent to that surface). Under appropriate conditions, electrical and thermal forces are also important and sometimes dominating. Both these conditional mechanisms can be introduced so as to minimize particle deposition velocity and thus protect wafers from particulate contamination.

In liquid systems where particle and liquid densities are similar, gravity is a less important particle deposition mechanism. Convective diffusion remains an important mechanism but typically contributes a much lower deposition velocity than in aerosol systems (particle diffusion coefficients are smaller in liquids than in gases). In many liquid systems, electrical forces, arising from particle and surface charging by ion adsorption from the liquid or ionization of surface groups, dominate particle deposition by introducing electrostatic double layer repulsion.

The primary force binding a particle to a surface is van der Waals attraction which is universal and dominating when separation distances between a particle and a surface decrease below 1 to 2 nm. Van der Waals attractive forces are lower in liquids than in gases so particles are easier to remove in liquids, partly because of this reduced adhesion.

Physical forces—centrifugal, hydrodynamic, vibrational—typically dominate particle removal technology as well. These forces depend directly on fluid density and hence are larger in liquid systems than in gases, another reason why liquid systems remain more successful at particle removal than dry methods.

Similar content being viewed by others

References

B.Y.H. Liu and K.H. Ahn, “Particle Deposition on Semiconductor Wafers” J. Aerosol Sci. and Tech 6, 215–244 (1987).

T.W. Peterson, K.M. Scanners, F. S tratmann, and H. Fissan, “Particle Deposition of Wafers: A Comparison Between Two Modeling Approaches,” J. Aerosol Sci. 19 (7):1409–12 (1988).

D.W. Cooper, R.J. Miller, J.J. Wu, and M.N. Peters, “Deposition of Submicron Aerosol Particles During Integrated Circuit Manufacturing: Theory,” Particulate Sci. and Tech. 8, 209–224 (1990).

R.P. Donovan, T. Yamamoto, R. Periasamy, and A.C. Clayton, “Mechanisms of Particle Transport in Process Equipment” pp. 21–41 in Contamination Control and Defect Reduction in Semiconductor Manufacturing 1, PV 92-21, edited by D.N. Schmidt (The Electrochemical Society, Inc., 10 South Main St, Pennington, NJ 08534-2896, 1992).

B.Y.H. Liu, B. Fardi, and K.H. Ahn, “Deposition of Charged and Uncharged Aerosol Particles on Semiconductor Wafers” pp. 461–465 in 1987 Proceedings of the 33rd ATM of the IES (IES, 940 E. Northwest Hghwy, Mt. Propect, IL 60065).

G.K. Batchelor and C. Shen, “Thermophoretic Deposition in Gas Flowing over Cold Surface” J. Colloid Interface Sci. 107, 21–37 (1985).

D.J. Riley and R.G. Carbonell, “Mechanisms of Particle Deposition from Ultrapure Chemicals onto Semiconductor Wafers: Deposition from Bulk Liquid during Wafer Submersion,” J. Colloid Interface Sci., to be published (1993).

M.B. Ranade, “Adhesion and Removal of Fine Particles on Surfaces,” Aerosol Sci. and Tech. 7(2), 161–176 (1987).

K. Christenson, “HF Last Performance in Centrifugal Spray Processors,” pp. 286–293, in Cleaning Technology in Semiconductor Device Manufacturing, PV 92-12, edited by J. Ruzyllo and R.A. Novak (The Electrochemical Society, Inc., 10 South Main St, Pennington, NJ 08534-2896, 1992).

J.N. Israelachvili, Intermolecular and Surface Forces, Academic Press (1985).

R.A. Bowling, “An Analysis of Particle Adhesion on Semiconductor Surfaces,” J. Electrochem Soc. 132(9), 2208–2214 (1985).

N.A. Burnham and R.J. Colton, “Measuring the nanomechnical properties and surface forces of materials using an atomic force microscope,” J. Vac. Sci. Technol. A7(4), 2906–2913 (Jul/Aug. 1989).

J.H. Hoh, J.P. Cleveland, C.B. Prater, J.P. Revel, and P.K. Hansma, “Quantized Adhesion Detected with the Atomic Force Microscope,” J. Am. Chem. Soc. 114, 4917–4918 (1992).

G. Higashi, private communication, reports that the separation force of the AFM is a measure of room relative humidity when force curves are carried out in the open air. He also pointed out to the authors the value of the AFM in measuring surface adhesion forces. (1992).

U. Landman, W.D. Luedtke, N.A. Burnham and R.J. Colton, “Atomistic Mechanisms and Dynamics of Adhesion, Nanoindentation, and Fracture,” Science 248, 454–461 (April 1990).

N.A. Burnham, R.J. Colton, and H.M. Pollock, “Interpretation Issues in Force Microscopy” J. Vac. Sci. Technol A9 (4), 2548–2556 (July/August 1991).

N. Kallay, “Adhesion of Fine Particles at Solid/Solution Interfaces,” MRS Bulletin XV(1), 41–47 (January 1990).

V.B. Menon and R.P. Donovan, “Review of Particle Control Methods during Wet Chemical Cleaning of Silicon Wafers,” in Semiconductor Cleaning Technology/1989, PV90-9, edited by J. Ruzyllo and R.E. Novak (The Electrochemical Society, Inc., 10 S. Main St., Pennington, NJ 08534-2896, 1990), pp. 167–181.

W.A. Syverson, MJ. Fleming, and P.J. Schubring, “The Benefits of SC-l/SC-2 Megasonic Wafer Cleaning,” in Cleaning Technology in Semiconductor Device Manufacturing, PV92-12, edited by J. Ruzyllo and R.E. Novak (The Electrochemical Society, Inc., 10 S. Main St., Pennington, NJ 08534-2896, 1992), pp. 10–17.

C.J. Gow, R.E. Smith, W.A. Syverson, R.F. Kunesh, E.D. Buker, K.B. Albaugh, and L.S. Whittingham, “A Method for Evaluating Cleaning Techniques for the Removal of Particulates from Semiconductor Surfaces” in Cleaning Technology in Semiconductor Device Manufacturing, PV 92-12, edited by J. Ruzyllo and R.E. Novak (The Electrochemical Society, Inc. 10 S. Main St., Pennington, NJ 08534-2896, 1992), pp. 366–371.

W.H. Whitlock, “Dry Surface Cleaning with CO2 Snow,” Fine Particle Society Mtg. Boston, MA, August 22, 1989.

W.T. McDermott, R.C. Ockovic, J.J. Wu, and R.J. Miller, “Surface Cleaning by a Cryogenic Argon Aerosol,” in 1991 Proceedings of the IES (IES, 940 E. Northwest Highway, Mt. Prospect, EL 60065, 1991), pp. 882–885.

I. Kanno, T. Ohmori, T. Fukumoto, T. Noguchi, and Y. Maeda, “Surface and Back Surface Simultaneous Cleaning by Ice Scrubber Cleaning,” in Microcontamination 91 Proceedings (Canon Communications, Inc., 3340 Ocean Park Blvd, Suite 1000, Santa Monica, CA 90405, 1991), pp. 625–630.

A.F.M. Leenaars, “A New Approach to the Removal of Submicron Particles from Solid (Silicon) Substrates,” in Particles on Surfaces 1, edited by K.L. Mittal (Plenum Press, 1988), pp. 361–372.

A.F.M. Leenaars and S.B.G. O’Brien, “Particle Removal from Silicon Substrates Using Surface Tension Forces,” Philips J. Res. 44, 183–209 (1989).

A.C. Tarn, W.P. Leung, W. Zapka, and W. Ziemlich, “Laser-Cleaning Techniques for Removal of Surface Particulates,” J. Appl. Phys. 71 (1)}, 3515–3523 (April 1992).

Acknowledgment

This work was sponsored by the Semiconductor Research Corporation, Manufacturing Process Sciences, under Contracts 91-MJ-199 and 92-MJ-199.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Donovan, R.P., Yamamoto, T. & Periasamy, R. Particle Deposition, Adhesion, and Removal. MRS Online Proceedings Library 315, 3–22 (1993). https://doi.org/10.1557/PROC-315-3

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-315-3