Abstract

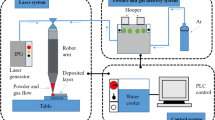

This study investigates the influence of laser cladding parameters on the geometry and composition of metalmatrix composite (MMC) coatings. Composite coatings are made of a Ni-Cr-B-Si metallic matrix and of WC reinforcement with a volume fraction of 50%. Optical microscopy is used to characterize the coating geometry (height, width, and penetration depth) and to determine the real volumetric content of WC. Laser cladding on low-carbon steel substrate is carried out using a cw neodymium:yttrium-aluminum-garnet (Nd:YAG) laser, a coaxial powder injection system, and a combination of Taguchi and EM methods to design the experiments. This combination explores efficiently the multidimensional volume of laser cladding parameters. The results, which express the interrelationship between laser cladding parameters and the characteristics of the clad produced, can be used to find optimum laser parameters, to predict the responses, and to improve the understanding of laser cladding process.

Similar content being viewed by others

References

Y. Li, H. Yang, X. Lin, W. Huang, J. Li, and Y. Zhou, The Influences of Processing Parameters on Forming Characterizations During Laser Rapid Forming,Mater. Sci. Eng. A, 2003,360(1–2), p 18–25

J. Lin and W.M. Steen, Design Characteristics and Development of a Nozzle for Coaxial Laser Cladding,J. Laser Appl., 1998,10(2), p 55–63

K. Van Acker, D. Vanhoyweghen, R. Persoons, and J. Vangrunderbeek, Influence of Tungsten Carbide Particle Size and Distribution on the Wear Resistance of Laser Clad WC/Ni Coatings,Wear, 2005,258, p 194–202

A. Yakovlev, Ph. Bertrand, and I. Smurov, Laser Cladding of Wear Resistant Metal Matrix Composite Coatings,Thin Solid Films, 2004,453–454, p 133–138

D.K. Das, K.S. Prasad, and A.G. Paradkar, Evolution of Microstructure in Laser Surface Alloying of Aluminium with Nickel,Mater. Sci. Eng. A, 1994,174, p 75–84

W.J. Tomlinson and A.S. Bransden, Sliding Wear of Laser Alloyed Coatings on Al-12Si,J. Mater. Sci. Lett., 1994,13, p 1086–1088

L. Dubourg, H. Pelletier, D. Vaissiere, F. Hlawka, and A. Cornet, Mechanical Characterisation of Laser Surface Alloyed Aluminium-Copper Systems,Wear, 2002,253, p 1077–1085

Y.Y. Qiu, A. Almeida, and R. Vilar, Structure Characterization of a Laser-Processed Al-Mo Alloy,J. Mater. Sci., 1998,33, p 2639–2651

Y.Y. Qiu, A. Almeida, and R. Vilar, Microstructure of Al 4,3%at Cr Alloy Produced by Laser Surface Alloying,Scr. Met. Mater., 1995,33(6), p 863–870

Y.T. Pei and J.Th.M. De Hosson, Functionally Graded Materials Produced by Laser Cladding,Acta Mater., 2000,48, p 2617–2624

L. Dubourg, D. Ursescu, F. Hlawka, and A. Cornet, Laser Cladding of MMC Coatings on Aluminium Substrate: Influence of Composition and Microstructure on Mechanical Properties,Wear, 2005,258(11–12), p 1745–1754

S. Ignat, P. Sallamand, D. Grevey, and M. Lambertin, “Magnesium Alloys Laser Cladding with Side Injection of Aluminium Based Powder,”23rd International Congress on Applications of Lasers and Electro-Optics ICALEO, Oct 4–7, 2004 (San Francisco, CA), Laser Institute of America

L. Dubourg, A. Ott, F. Hlawka, and A. Cornet, Wear Behaviour of Al-Based Composite Coatings Obtained by Laser Cladding and Reinforced with WC, TiC and SiC Particles,Surface Modification Technologies 18, SMT 18 (Dijon, France), T.S. Sudarshan, M. Jeandin, and J.J. Stiglich, ASM International, 2004

L. Dubourg, B. Des Roches, A. Couture, D. Bouchard, and H.R. Shakeri, “Optimization of Aluminium Laser Welding Using Taguchi and EM Methods,”23rd International Congress on Applications of Lasers and Electro-Optics ICALEO, Oct 4–7, 2004 (San Francisco, CA), Laser Institute of America

L. Dubourg, Experimental Differences between Aluminium Welding of Tee and Lap Joints by a cw/Nd:YAG Laser,Trends in Welding Research, May 16–19, 2005 (Pine Mountain, GA)

Author information

Authors and Affiliations

Corresponding author

Additional information

This article was originally published inBuilding on 100 Years of Success, Proceedings of the 2006 International Thermal Spray Conference (Seattle, WA), May 15–18, 2006, B.R. Marple, M.M. Hyland, Y.-Ch. Lau, R.S. Lima, and J. Voyer, Ed., ASM International, Materials Park, OH, 2006.

Rights and permissions

About this article

Cite this article

Dubourg, L., St-Georges, L. Optimization of laser cladding process using taguchi and EM methods for MMC coating production. J Therm Spray Tech 15, 790–795 (2006). https://doi.org/10.1361/105996306X146785

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996306X146785