Abstract

Independent control of particle velocity and temperature in the HVOF process has been achieved in this research, allowing these variables to change by 170 m/s and 200 °C, respectively. The independence was achieved using a specially designed nozzle with multiple powder injection ports and by an inert diluent added to the oxygen stream feeding the combustion. Within the available range, notable changes in splat morphology, porosity, and coating oxidation of sprayed 316L stainless steel are readily apparent. Increased particle velocity generally correlates with improved splat deformation but has a weak effect on porosity and no effect on oxidation. Particle temperature, on the other hand, correlates strongly with highly deformed splats, porosity, and oxidation. In fact, highly dense coatings having little oxidation can be formed with relatively low velocity particles if the average particle temperature is kept in the vicinity of the material melting point. This result suggests that particle temperature control is the key to creating dense, low-oxide HVOF-sprayed corrosion-control coatings. Because commercial HVOF equipment currently lacks this capability, the research indicates a useful direction for future development.

Similar content being viewed by others

References

C.M. Hackett: “The Gas Dynamics of High-Velocity Oxy-Fuel Thermal Sprays,” Ph.D. Thesis, Dept. of Mechanical and Nuclear Engineering, UMI Order Number 9628094, Pennsylvania State University, 1996.

H.F. Voggenreiter, S. Huber, S. Beyer, and H-J. Spies: “Influence of Particle Velocity and Molten Phase on the Chemical and Mechanical Properties of HVOF-Sprayed Structural Coatings of Alloy 316L” in Advances in Thermal Spray Science and Technology, C.C. Berndt and S. Sampath, ed., ASM International, Materials Park, OH, 1995, pp. 303–08.

H.F. Voggenreiter, H. Huber, H-J. Spies, and H. Baum: “HVOF-Sprayed Alloy In718 — The Influence of Process Parameters on the Microstructure and Mechanical Properties” in Forum for Scientific and Technological Advances, C.C. Berndt, ed., ASM International, Materials Park, OH, 1997.

K.H. Dobler, H. Kreye, and R. Schwetzke: “Oxidation of Stainless Steel in the High Velocity Oxy-Fuel Process,” J. Therm. Spray Technol, 2000, 9(3), pp. 407–13.

A.J. Sturgeon and D.C. Buxton: “The Electrochemical Corrosion Behavior of HVOF Sprayed Coatings” in Thermal Spray Surface Engineering via Applied Research. C.C. Berndt, ed., ASM International, Materials Park, OH, 2000, pp. 1011–15.

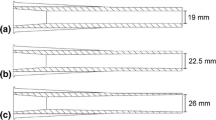

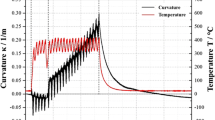

T.C. Hanson, C.M. Hackett, and G.S. Settles: “Independent Control of HVOF Particle Velocity and Temperature,” J. Therm. Spray Technol., 2002, 11(1), pp. 75–85.

A.P. Alkhimov, V.F. Kosarev, and A.N. Papyrin: “A Method of ‘Cold’ Gas-Dynamic Deposition,” Dokl. Akad. Nauk SSSR, 1990, 315, pp. 1062–65.

R.C. McCune, W.T. Donlon, O.O. Popoola, and E.L. Cartwright: “Characterization of Copper Layers Produced by Cold Gas-Dynamic Spraying,” J. Therm. Spray Technol., 2000, 9(1), pp. 73–82.

R.C. Dykhuizen and M.F. Smith: “Gas Dynamic Principles of Cold Spray,” J. Therm. Spray Technol., 1998, 7(2), pp. 205–12.

E.E. Underwood: Quantitative Stereology. Addison-Wesley, Reading, MA, 1970.

R.C. McCune, W.T. Donlon, E.L. Cartwright, A.N. Papyrin, E.F. Rybicki, and J.R. Shadley: “Characterization of Copper and Steel Coatings Made by the Cold Gas-Dynamic Spray Method” in Thermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 397–403.

T.C. Hanson: “Independent Control of Particle Velocity and Temperature in the High-Velocity Oxy-Fuel Spray Process,” Masters Thesis, Department of Mechanical and Nuclear Engineering, Pennsylvania State University, State College, PA, 2001.

J.A. Browning: “Hypervelocity Impact Fusion — A Technical Note,” J. Therm. Spray. Technol, 1992, 1(4), pp. 289–92.

J.A. Browning: “HVIF/Cold Spray?,” Spraytime, 4th Quarter 2001, p. 7.

M.F. Smith, R.C. Dykhuizen, and R.A. Neiser: “Oxidation in HVOF-Sprayed Steel” in Thermal Spray: A United Forum, C.C. Berndt, ed., ASM International, Materials Park, OH, 1997, pp. 885–93.

R.A. Neiser, M.F. Smith, and R.C. Dykhuizen: “Oxidation in Wire HVOF-Sprayed Steel,” J. Therm. Spray Technol. 7(4), 1998, pp. 537–45.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hanson, T.C., Settles, G.S. Particle temperature and velocity effects on the porosity and oxidation of an HVOF corrosion-control coating. J Therm Spray Tech 12, 403–415 (2003). https://doi.org/10.1361/105996303770348276

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996303770348276