Abstract

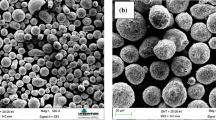

Thermal spray processes are widely used to deposit high-chromium, nickel-chromium coatings to improve high temperature oxidation and corrosion behavior. However, despite the efforts made to improve the present spraying techniques, such as high-velocity oxyfuel (HVOF) and plasma spraying, these coatings may still exhibit certain defects, such as unmelted particles, oxide layers at splat boundaries, porosity, and cracks, which are detrimental to corrosion performance in severe operating conditions. Because of the process temperature, only mechanical bonding is obtained between the coating and substrate. Laser remelting of the sprayed coatings was studied in order to overcome the drawbacks of sprayed structures and to markedly improve the coating properties. The coating material was high-chromium, nickel-chromium alloy, which contains small amounts of molybdenum and boron (53.3% Cr, 42.5% Ni, 2.5% Mo, 0.5% B). The coatings were prepared by HVOF spraying onto mild steel substrates. A high-power, fiber-coupled, continuous-wave Nd:YAG laser equipped with large beam optics was used to remelt the HVOF-sprayed coating using different levels of scanning speed and beam width (10 or 20 mm). Coating that was remelted with the highest traverse speed suffered from cracking because of the rapid solidification inherent to laser processing. However, after the appropriate laser parameters were chosen, nonporous, crack-free coatings with minimal dilution between coating and substrate were produced. Laser remelting resulted in the formation of a dense oxide layer on top of the coatings and full homogenization of the sprayed structure. The coatings as sprayed and after laser remelting were characterized by optical and electron microscopy (OM, SEM, respectively). Dilution between coating and substrate was studied with energy dispersive spectrometry (EDS). The properties of the laser-remelted coatings were directly compared with properties of as-sprayed HVOF coatings.

Similar content being viewed by others

References

Y. Kawahara: “Development and Application of High Temperature Corrosion-Resistant Materials and Coatings for Advanced Waste-to-Energy Plants,” Mater. High Temp., 1997, 14(3), pp. 261–68.

E.J. Morgan-Warren: “Thermal Spraying for Boiler Tube Protection,” Welding Met. Fabric., 1992, January/February, pp. 25–31.

G.C. Irons: “Laser Fusing of Flame Sprayed Coatings,” Welding J., 1978, December, pp. 29–32.

K.L. Wang, Y.M. Zhu, and W.M. Steen: “Laser Remelting of Plasma Sprayed Coatings,” J. Laser Appl., 2000, 12(4), pp. 175–78.

X.C. Yang, Y.H. Han, X.K. Wang, and H.W. Gu: “Microstructure and Performance of Laser Cladding NiCrBSi Alloy,” in Applications of Lasers and Electro-Optics, Proceedings of ICALEO 87, San Diego, CA, 1987, Laser Institute of America, Orlando, FL, pp. 209–20.

Y. Longa and M. Takemoto: “Laser Processing of High-Chromium Nickel-Chromium Coatings Deposited by Various Thermal Spraying Methods,” Corrosion, 1994, 50(11), pp. 827–37.

Y. Longa and M. Takemoto: “High-temperature Corrosion of Laser-Glazed Alloys in Na2SO4-V2O5,” Corrosion, 1992, 48(7), pp. 599–607.

T.A. Mahank, J. Singh, and A.K. Kulkarni: “Laser Glazing of Plasma Sprayed Ni-Cr-Al-Y Alloy,” Mater. Manuf. Process., 1998, 13(6), pp. 829–39.

A.H. Dent, A.J. Horlock, D.G. McCartney, and S.J. Harris: “The Corrosion Behavior and Microstructure of High-Velocity Oxy-Fuel Sprayed Nickel-Base Amorphous/Nanocrystalline Coatings,” J Thermal Spray Technol., 1999, 8(3), pp. 399–404.

H. Edris, D.G. McCartney, and A.J. Sturgeon: “Microstructural Characterization of High-Velocity Oxy-Fuel Sprayed Coatings of Inconel 625,” J. Mater. Sci. 1997, 32, pp. 863–72.

S. Tobe, Y. Andoh, K. Hidaka, K. Tanaka, S. Nishimura, K. Kawaharada and K. Shirai: “High Temperature Corrosion Resistance of Newly Developed Cr-Based Alloy Coatings,” Proceedings of UTSC’99, E. Lugsheider and P.A. Kammer, ed., ASM Thermal Spray Society, DVS German Welding Society, Düsseldorf, Germany, 1999, pp. 296–300.

ASM Metals Handbook—Properties and Selection: Stainless Steels, Tool Materials and Special-Purpose Metals, 9th ed., Vol. 3, ASM, Metals Park, OH, USA, 1980, p. 145.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tuominen, J., Vuoristo, P., Mäntylä, T. et al. Corrosion behavior of HVOF-sprayed and Nd-YAG laser-remelted high-chromium, nickel-chromium coatings. J Therm Spray Tech 11, 233–243 (2002). https://doi.org/10.1361/105996302770348899

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996302770348899