Abstract

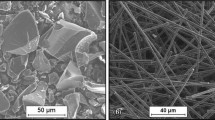

A vacuum stir casting process is developed to produce SiCp reinforced cast magnesium matrix composites. This process can eliminate the entrapment of external gas onto melt and oxidation of magnesium during stirring synthesis. Two composites with Mg-Al9Zn and Mg-Zn5Zr alloys as matrices and 15 vol.% SiC particles as reinforcement are obtained. The microstructure and mechanical properties of the composites and the unreinforced alloys in as-cast and heat treatment conditions are analyzed and evaluated. In 15 vol.% SiCp reinforced Mg-Al9Zn alloy-based composite (Mg-Al9Zn/15SiCp), SiC particles distribute homogenously in the matrix and are well bonded with magnesium. In 15 vol.% SiCp reinforced Mg-Zn5Zr alloy-based composite (Mg-Zn5Zr/15SiCp), some agglomerations of SiC particles can be seen in the microstructure. In the same stirring process conditions, SiC reinforcement is more easily wetted by magnesium in the Mg-Al9Zn melt than in the Mg-Zn5Zr melt. The significant improvement in yield strength and elastic modulus for two composites has been achieved, especially for the Mg-Al9Zn/15SiCp composite in which yield strength and elastic modulus increase 112 and 33%, respectively, over the unreinforced alloy, and increase 24 and 21%, respectively, for the Mg-Zn5Zr/15SiCp composite. The strain-hardening behaviors of the two composites and their matrix alloys were analyzed based on the microstructure characteristics of the materials.

Similar content being viewed by others

References

V. Laurent, P. Jarry, G. Regazzoni, and D. Apelian: “Processing-Microstructure Relationships in Compocast Magnesium/SiC,” J. Mater. Sci., 1992, 27, pp. 4447–59.

A. Martin and J. Llorca: “Mechanical Behavior and Failure Mechanisms of a Binary Mg-6%Zn Alloy Reinforced With SiC Particulates,” Mater. Sci. Eng., 1995, A201, pp. 77–87.

R.A. Saravanan and M.K. Surappa: “Fabrication and Characterization of Pure Magnesium-30 Vol.% SiCp Particulate Composite,” Mater. Sci. Eng., 2000, A276, pp. 108–16.

S.C. Sharma, B. Anand, and M. Krishna: “Evaluation of Sliding Wear Behavior of Feldspar Particle-Reinforced Magnesium Alloy Composites,” Wear, 2000, 241, pp. 33–40.

C. Mayencourt and R. Schaller: “Mechanical-Stress Relaxation in Magnesium-Based Composites,” Mater. Sci. Eng., 2002, A325, pp. 286–91.

A. Bochenek and K.N. Braszczynska: “Structural Analysis of the MgAl5 Matrix Cast Composites Containing SiC Particles,” Mater. Sci. Eng., 2000, 290A, pp. 122–27.

Y. Cai, M.J. Tan, G.J. Shen, and H.Q. Su: “Microstructure and Heterogeneous Nucleation Phenomena in Cast SiC Particles Reinforced Magnesium Composite,” Mater. Sci. Eng., 2000, 282A, pp. 232–39.

H. Hu: “Grain Microstructure Evolution of Mg (AM50A)/SiCp Metal Matrix Composites,” Scripta Mater., 1998, 39, pp. 1015–22.

T. Imai, S.W. Lim, D. Jiang, Y. Nishida, and T. Imura: “Superplasticity of Ceramic Particulate Reinforced Magnesium Alloy Composite Made by a Vortex Method,” Mater. Sci. Forum, 1999, 304/306, pp. 315–20.

A. Luo: “Processing, Microstructure, and Mechanical Behavior of Cast Magnesium Metal Matrix Composites,” Metall. Mater. Trans., 1995, 26A, pp. 2445–55.

H. Ferkel and B.L. Mordike: “Magnesium Strengthened by SiC Nanoparticles,” Mater. Sci. Eng., 2001, 298, pp. 193–99.

B.W. Chua, L. Lu, and M.O. Lai: “Influence of SiC Particles on Mechanical Properties of Mg Based Composite,” Compos. Struct., 1999, 47, pp. 595–601.

M. Yoshida, S. Takeuchi, J. Pan, G. Sasaki, N. Fuyama, T. Fujii, and H. Fukunaga: “Preparation and Characterization of Aluminum Borate Whisker Reinforced Magnesium Alloy Composites by Semi-solid Process,” Adv. Compos. Mater., 1999, 8, pp. 258–68.

L. Hu and E. Wang: “Fabrication and Mechanical Properties of SiCw/ZK51A Magnesium Matrix Composite by Two-step Squeeze Casting,” Mater. Sci. Eng., 2000, 278A, pp. 267–71.

M.Y. Zheng, K. Wu, and C.K. Yao: “Effect of Interfacial Reaction on Mechanical Behavior of SiCw/AZ91 Magnesium Matrix Composites,” Mater. Sci. Eng., 2001, 318A, pp. 50–56.

Y. Cai, D. Taplin, M.J. Tan, and W. Zhou: “Nucleation Phenomenon in SiC Particulate Reinforced Magnesium Composite,” Scripta Mater., 1999, 41, pp. 967–71.

A. Luo: “Development of Matrix Grain Structure During the Solidification of an Mg (AZ91)/SiCp Composite,” Scripta Metall. Mater., 1994, 31, pp. 1253–58.

P.M. Singh, and J.J. Lewandowki: “Effects of Heat Treatment and Reinforcement Size on Reinforcement Fracture During Tension Testing of a SiCp Discontinuously Reinforced Aluminum Alloy,” Metall. Trans. A, 1993, 24A, pp. 2531–43.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gui, M., Li, P. & Han, J. Fabrication and characterization of cast magnesium matrix composites by vacuum stir casting process. J. of Materi Eng and Perform 12, 128–134 (2003). https://doi.org/10.1361/105994903770343259

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994903770343259