-

摘要:

为满足光学行业的市场需求,非球面光学元件的快速制造技术是实现低成本、批量化、高精度生产的最佳解决方案之一。本文主要介绍了非球面光学元件的快速制造技术,包括精密光学玻璃模压成型技术和精密光学塑料注射成型技术,并对两种技术与其他非球面光学元件的制造技术进行了对比,阐述了模具材料种类、模具加工方法、成型材料、成型过程等内容。最后总结了近年来非球面光学元件的快速制造技术的发展现状,并对未来发展进行了展望。

Abstract:In order to meet the market demand of the optical industry, the rapid manufacturing technology of aspheric optical elements is one of the best solutions to realize low cost, mass production, and high precision production. This paper mainly introduces the rapid manufacturing technology of aspheric optical elements, including precision optical glass molding technology and precision optical plastic injection molding technology, and compares the two technologies with the manufacturing technology of other aspheric optical elements. This paper also expounds on the types of mold materials, mold processing methods, molding materials, molding process, etc. Finally, the development status of rapid manufacturing technology of aspheric optical elements in recent years is summarized, and future development has prospected.

-

Overview: Aspheric optical elements are widely used in various optical systems because they can eliminate spherical aberration, coma, astigmatism, field distortion, and other unfavorable factors. This type of lens can also reduce the loss of light energy and obtain high-quality images and optical properties. With the rapid development of the optical industry, the demand for aspheric optical elements is also increasing. At the same time, the optical components in the system need to ensure high surface accuracy and low optical birefringence to improve the user experience, which puts forward higher requirements and challenges for the manufacturing method of optical components. The traditional manufacturing methods of aspheric optical elements often have problems such as high manufacturing costs, long processing cycles, and difficulty in ensuring manufacturing accuracy, which limits the wide application of aspheric optical elements. In order to overcome these constraints, researchers have conducted in-depth research on the manufacturing technology of aspheric optical components, aiming to achieve efficient, economical, and accurate manufacturing methods. With the development and popularization of computers in recent years, advanced optical manufacturing technology has gradually begun to be applied to the processing of optical components, and is gradually replacing traditional processing techniques such as classical polishing that have been used for decades. It includes ultra-precision cutting technology, ultra-precision grinding technology, ultra-precision polishing technology, precision glass molding technology, and precision injection molding technology. This paper first introduces the advanced optical manufacturing technology of various aspheric optical components and compares them horizontally. Among them, ultra-precision cutting technology, ultra-precision grinding technology, and ultra-precision polishing technology have high precision of machining components. However, due to the high precision of machining components, ultra-precision machining technology usually requires a slower feed rate, so the machining speed is relatively slow, which leads to the increased manufacturing cost of components. In order to meet the market demand, the rapid manufacturing technology of aspheric optical components is one of the best solutions to achieve low-cost, high-volume, and high-precision production. Then we introduce the precision glass molding technology and precision injection molding technology in detail. The two technologies are compared with the manufacturing technology of other aspheric optical components, and the types of mold materials, mold processing methods, molding materials, molding process and so on are described. Finally, the development status of rapid manufacturing technology of aspheric optical elements in recent years is summarized, and the future development is prospected.

-

-

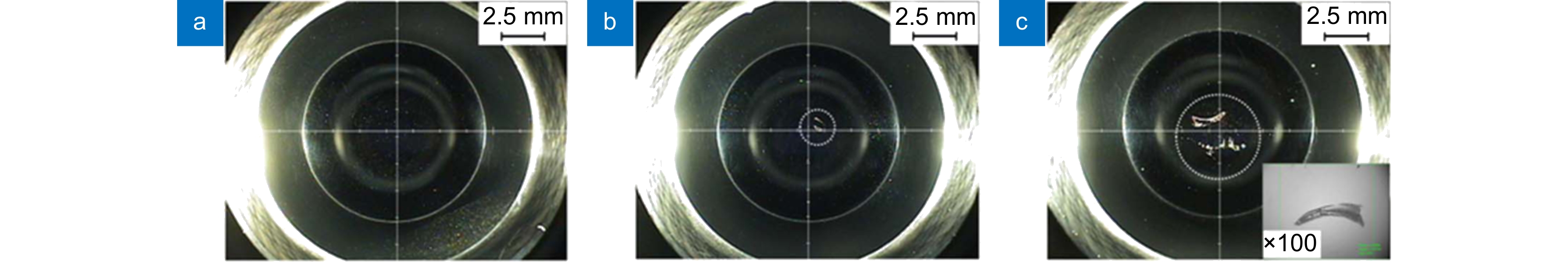

图 15 硫系玻璃与镀有Re–Ir的模具表面粘附[42]。(a)模压成型前的模具表面;(b) 330 ℃模压成型后的模具表面;(C) 340 ℃模压成型后的模具表面

Figure 15. Adhesion of sulfide glass to the surface of a mold coated with Re-Ir[42]. (a) Mold surface before molding; (b) The surface of the mold after molding at 330 ℃ ; (C) The surface of the mold after molding at 340 ℃

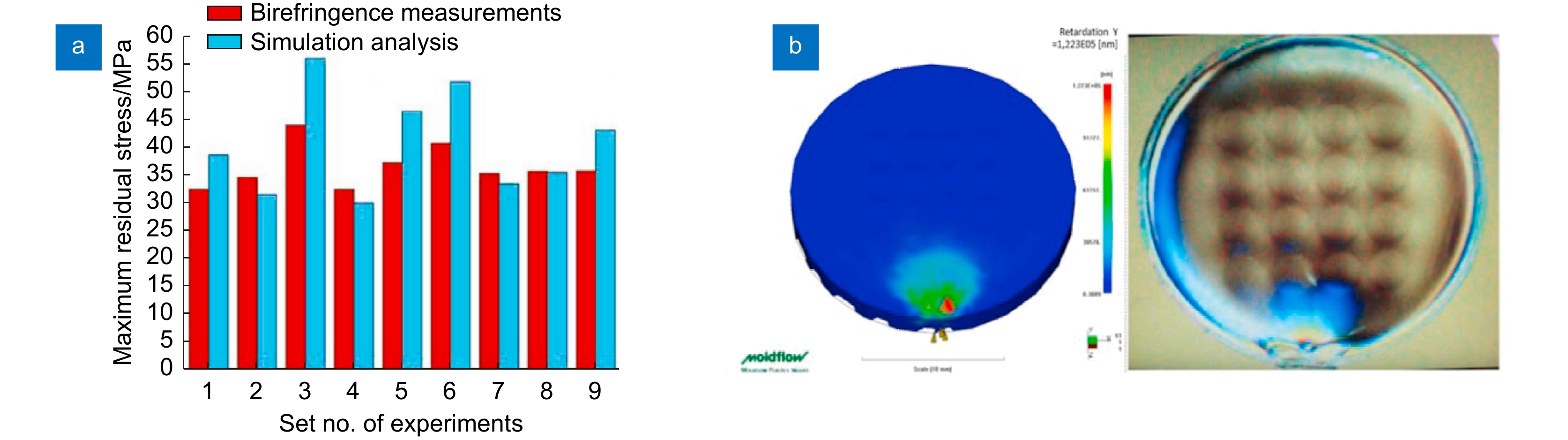

图 30 光学元件的残余应力和双折射分布[74]。(a) PC光学元件最大残余应力的仿真与实验数据比较; (b)光学元件的残余应力分布模拟和实验对比

Figure 30. Residual stress and birefringence distribution of optical components[74]. (a) Simulation and comparison of maximum residual stress of PC optics; (b) Simulation and experimental comparison of residual stress distribution of optical components

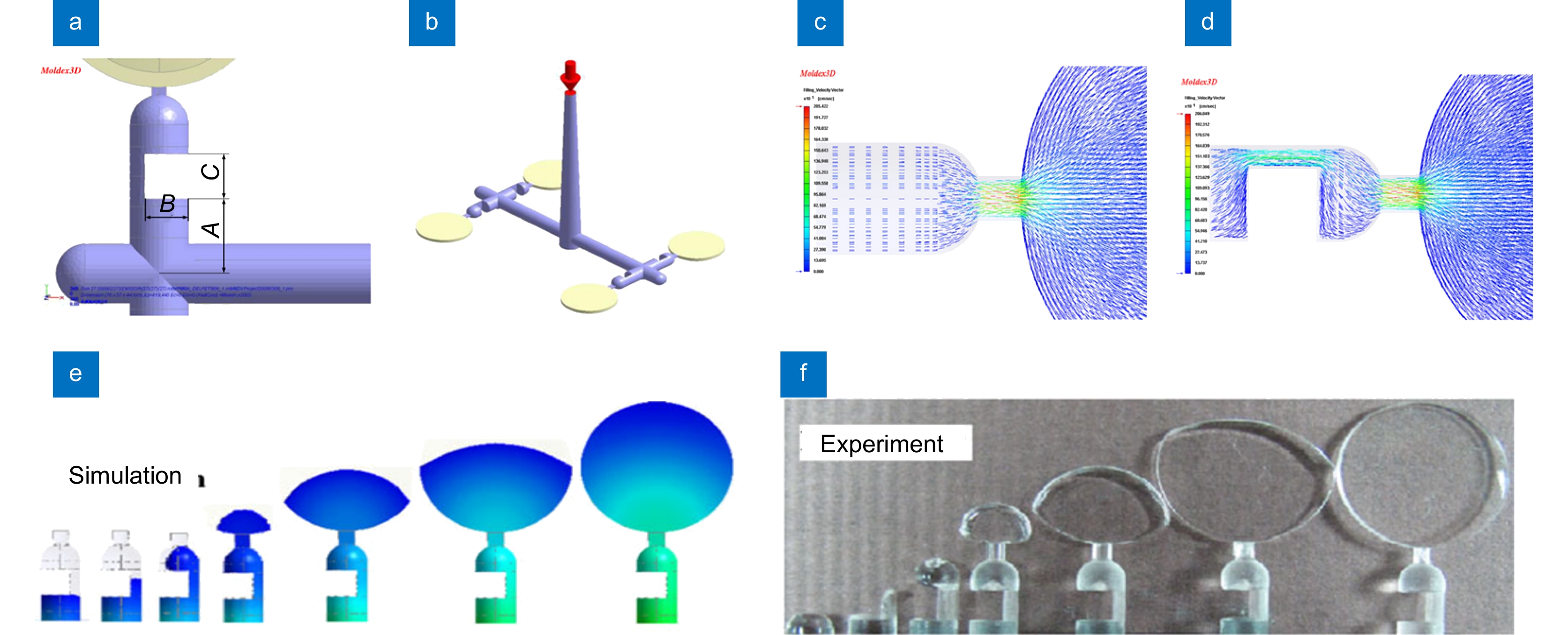

图 32 仿真模型的限流器设计及短射实验[77]。(a)限流器尺寸参数;(b) 带限流器的流道;(c) 原始流道的速度场图;(d) 带限流器的流道的速度场图;(e)短射模拟仿真;(f)短射实验结果

Figure 32. Simulation model current limiter design and short-shot experiment [77]. (a) Dimensional parameters of restrictor; (b) Runner with restrictor for 4-cavity mold; (c) Velocity field plot for original runner; (d) Velocity field plot for runner with restrictor; (e) Short-shot simulation; (f) Results of short-shot experiments

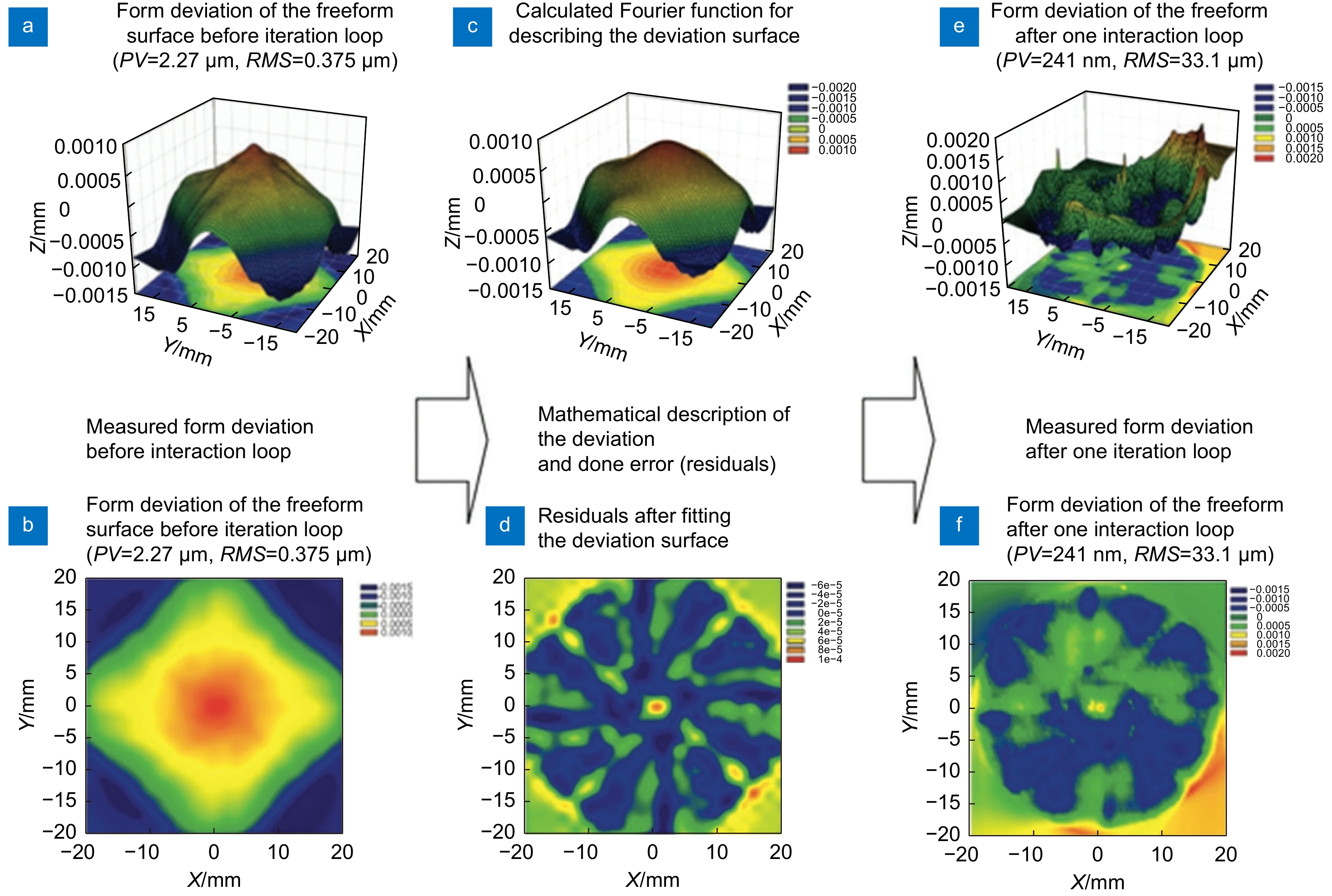

图 34 在模具上加工高精度自由曲面的迭代循环细节[79]。(a)迭代循环前的曲面偏差,三维视图;(b)迭代循环前的曲面偏差,俯视图;(c)拟合的傅里叶函数作为曲面偏差的误差描述;(d)拟合的偏差和发现的数学描述之间的误差;(e)一个迭代循环后的曲面偏差,三维视图;(f)一个迭代循环后的曲面偏差,俯视图

Figure 34. Details of the iteration loop for machining a high precision freeform surface on the mold[79]. (a) Surface deviation before iteration loop, 3D view; (b) Surface deviation before iteration loop, top view; (c) Fitted Fourier function as error description of the surface deviation; (d) Error between fitted deviation and found mathematical description; (e) Surface deviation after one iteration loop, 3D view; (f) Surface deviation after one iteration loop, top view

表 1 单个非球面光学元件的不同制造技术对比

Table 1. Comparison of manufacturing techniques of aspherical optical elements

精磨玻璃模压技术 精密注塑成型技术 超精密切削技术 超精密磨削技术 超精密抛光技术 加工周期 70 s~150 s 15 s~75 s 1000 s以上 1000 s以上 3000 s以上 加工精度 1 μm 3 μm 0.5 μm以下 0.5 μm以下 0.1 μm以下 表 2 精密模压成型技术加工元件种类

Table 2. Precision glass molding technology processing components

非球面透镜 超细内窥镜的物镜 非球面微透镜阵列 非球面柱面镜片 非球面柱面镜阵列 外观尺寸 Φ1 mm~Φ30 mm Φ0.35 mm Φ7 mm以下 5 mm×15 mm 8 mm×8 mm 中心厚度 0.5 mm~20 mm 0.2 mm~5 mm 0.3 mm以上 3 mm 0.7 mm 形状精度 0.5 μm 1 μm以下 1 μm以下 1 μm 1 μm 表 3 精密注塑成型技术加工元件种类

Table 3. Precision injection molding technology processing components

非球面透镜 非球面衍射元件 非球面微透镜阵列 外观尺寸 Φ1 mm~Φ50 mm Φ0.35 mm Φ7 mm以下 中心厚度 0.5 mm~20 mm 0.2 mm~5 mm 0.3 mm以上 形状精度 3 μm 5 μm以下 5 μm以下 -

[1] 焦松峰, 谢启明, 刘尧, 等. 光学非球面面形轮廓检测技术[J]. 红外技术, 2023, 45(5): 534−540.

Jiao S F, Xie Q M, Liu Y, et al. Optical aspheric surface profile testing technology[J]. Infrared Technol, 2023, 45(5): 534−540.

[2] Yin S H, Jia H P, Zhang G H, et al. Review of small aspheric glass lens molding technologies[J]. Front Mech Eng, 2017, 12(1): 66−76. doi: 10.1007/s11465-017-0417-2

[3] 梁子健, 杨甬英, 赵宏洋, 等. 非球面光学元件面型检测技术研究进展与最新应用[J]. 中国光学, 2022, 15(2): 161−186. doi: 10.37188/CO.2021-0143

Liang Z J, Yang Y Y, Zhao H Y, et al. Advances in research and applications of optical aspheric surface metrology[J]. Chin Opt, 2022, 15(2): 161−186. doi: 10.37188/CO.2021-0143

[4] Ding Y, Liu X, Zheng Z R, et al. Freeform LED lens for uniform illumination[J]. Opt Express, 2008, 16(17): 12958−12966. doi: 10.1364/OE.16.012958

[5] Qandil H, Wang S P, Zhao W H. Application-based design of the Fresnel lens solar concentrator[J]. Renewables Wind Water Solar, 2019, 6(1): 3. doi: 10.1186/s40807-019-0057-8

[6] Lee S W, Joh H H, Hong J S, et al. Birefringent analysis of plastic lens injection molding for mobile phone camera[J]. Trans Mater Process, 2011, 20(1): 54−59. doi: 10.5228/KSTP.2011.20.1.54

[7] Heiney A J, Jiang C L, Reysen W H. Polymer molded lenses for optoelectronics[C]//1995 Proceedings. 45th Electronic Components and Technology Conference, Las Vegas, 1995: 170‒176. https://doi.org/10.1109/ECTC.1995.514379.

[8] Milster T D, Upton R S, Luo H. Objective lens design for multiple-layer optical data storage[J]. Proc SPIE, 1997, 3109: 142−149. doi: 10.1117/12.280685

[9] La M, Park S M, Kim W, et al. Injection molded plastic lens for relay lens system and optical imaging probe[J]. Int J Precis Eng Manuf, 2015, 16(8): 1801−1808. doi: 10.1007/s12541-015-0235-6

[10] Hatefi S, Abou-El-Hossein K. Review of single-point diamond turning process in terms of ultra-precision optical surface roughness[J]. Int J Adv Manuf Technol, 2020, 106(5): 2167−2187. doi: 10.1007/s00170-019-04700-3

[11] Yuan J L, Lyu B H, Hang W, et al. Review on the progress of ultra-precision machining technologies[J]. Front Mech Eng, 2017, 12(2): 158−180. doi: 10.1007/s11465-017-0455-9

[12] 聂兰舰, 王玉芬, 向在奎, 等. 高性能光学合成石英玻璃的制备和应用[J]. 光学 精密工程, 2016, 24(12): 2916−2924. doi: 10.3788/OPE.20162412.2916

Nie L J, Wang Y F, Xiang Z K, et al. Preparation and application of high-performance synthetic optical fused silica glass[J]. Opt Precision Eng, 2016, 24(12): 2916−2924. doi: 10.3788/OPE.20162412.2916

[13] 花宁, 李怀阳, 王友军, 等. 石英玻璃晶圆的加工工艺[J]. 红外与激光工程, 2016, 45(S2): S221003. doi: 10.3788/IRLA201645.S221003

Hua N, Li H Y, Wang Y J, et al. Processing techniques of quartz glass wafer[J]. Infrared Laser Eng, 2016, 45(S2): S221003. doi: 10.3788/IRLA201645.S221003

[14] 汪志斌, 李军琪, 张峰, 等. 硫系红外玻璃精密模压模具有限元仿真设计[J]. 光电工程, 2016, 43(5): 53−58. doi: 10.3969/j.issn.1003-501X.2016.05.009

Wang Z B, Li J Q, Zhang F, et al. The design of mold with simulation for chalcogenide glass precision molding[J]. Opto-Electron Eng, 2016, 43(5): 53−58. doi: 10.3969/j.issn.1003-501X.2016.05.009

[15] 成都光明光电股份有限公司[EB/OL]. [2023-10-14]. http://www.cdgmgd.com/.

[16] Zhang A Z, Youngworth R N. Review of Optical Manufacturing 2000 to 2020[M]. Bellingham: SPIE, 2021: 223–224. https://doi.org/10.1117/3.2599940.ch1.

[17] Masuda J, Yan J W, Tashiro T, et al. Microstructural and topographical changes of Ni-P plated moulds in glass lens pressing[J]. Int J Surf Sci Eng, 2009, 3(1-2): 86−102. doi: 10.1504/IJSURFSE.2009.024363

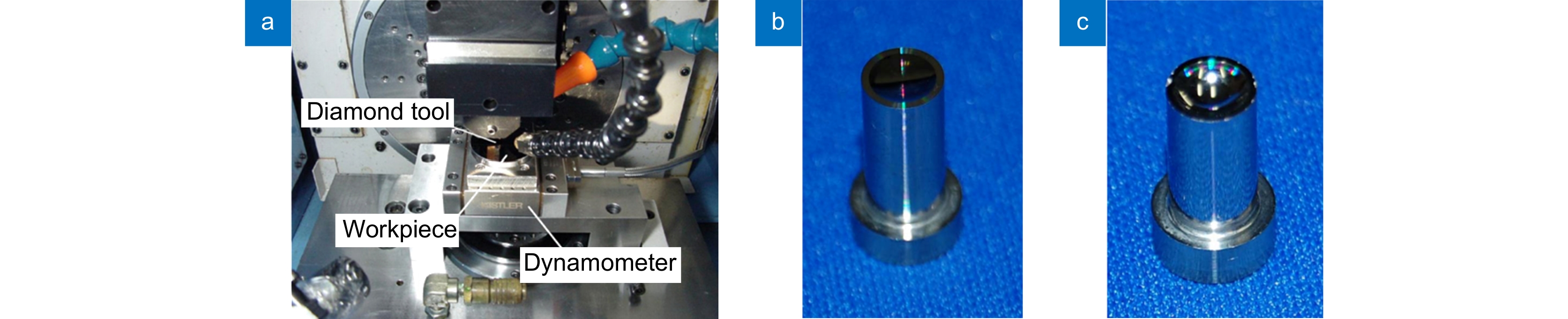

[18] Zhang Z Y, Peng H M, Yan J W. Micro-cutting characteristics of EDM fabricated high-precision polycrystalline diamond tools[J]. Int J Mach Tools Manuf, 2013, 65: 99−106. doi: 10.1016/j.ijmachtools.2012.10.007

[19] Yan J W, Oowada T, Zhou T F, et al. Precision machining of microstructures on electroless-plated NiP surface for molding glass components[J]. J Mater Process Technol, 2009, 209(10): 4802−4808. doi: 10.1016/j.jmatprotec.2008.12.008

[20] Yan J W, Zhang Z Y, Kuriyagawa T. Mechanism for material removal in diamond turning of reaction-bonded silicon carbide[J]. Int J Mach Tools Manuf, 2009, 49(5): 366−374. doi: 10.1016/j.ijmachtools.2008.12.007

[21] He P, Li L K, Li H, et al. Compression molding of glass freeform optics using diamond machined silicon mold[J]. Manuf Lett, 2014, 2(2): 17−20. doi: 10.1016/j.mfglet.2013.12.002

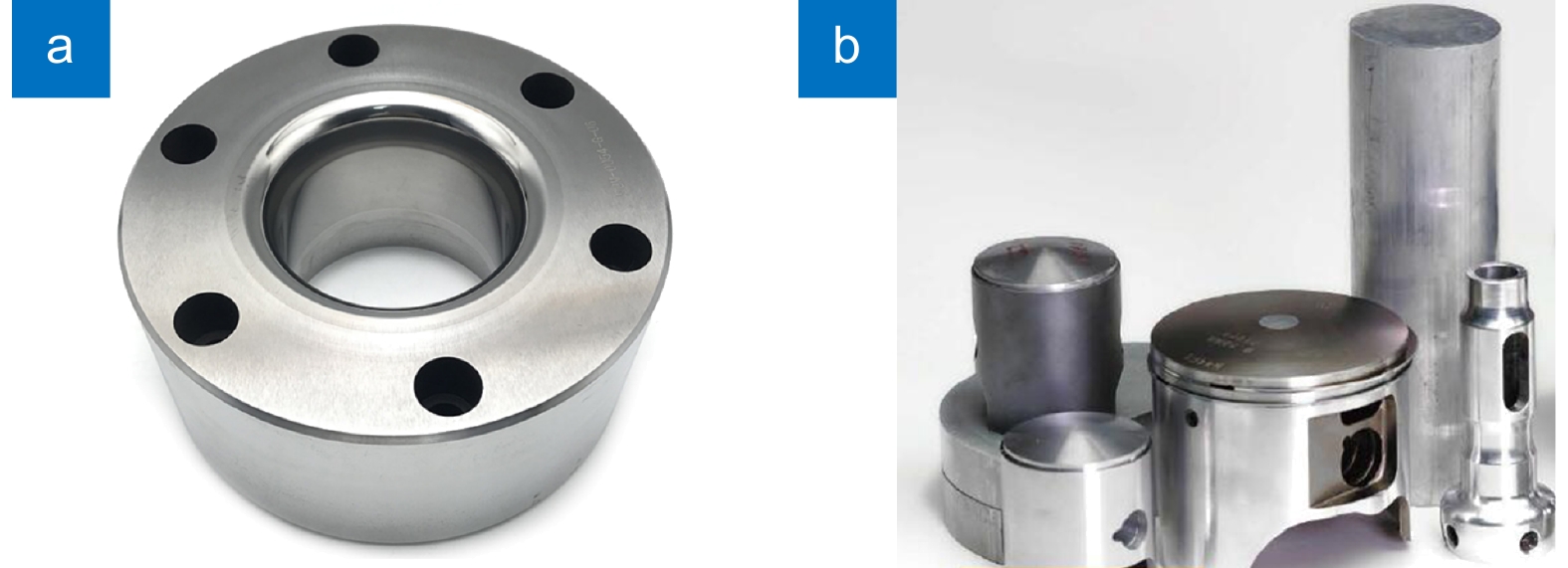

[22] 尹韶辉, 唐昆, 朱勇建, 等. 小口径玻璃透镜热压成形模具的超精密微细磨削加工[J]. 中国机械工程, 2008, 19(23): 2790−2792. doi: 10.3321/j.issn:1004-132X.2008.23.005

Yin S H, Tang K, Zhu Y J, et al. Fabrication of micro glass lens mould by using ultra-precision micro-grinding process[J]. China Mech Eng, 2008, 19(23): 2790−2792. doi: 10.3321/j.issn:1004-132X.2008.23.005

[23] 范亚卓, 鞠鹤, 蔡天晓, 等. Pt-Ir涂层阳极的制备及在电解水中的应用[J]. 湿法冶金, 2009, 28(2): 109−111. doi: 10.3969/j.issn.1009-2617.2009.02.012

Fan Y Z, Ju H, Cai T X, et al. Preparation of Pt-Ir coating anode and its application in electrolyzed water[J]. Hydrometall China, 2009, 28(2): 109−111. doi: 10.3969/j.issn.1009-2617.2009.02.012

[24] Ren X, Leng L, Cao Y Q, et al. Enhanced recycling performance of bimetallic Ir-Re/SiO2 catalyst by amberlyst-15 for glycerol hydrogenolysis[J]. Chin J Chem Eng, 2022, 45(5): 171−181. doi: 10.1016/j.cjche.2021.07.015

[25] Yi A Y, Jain A. Compression molding of aspherical glass lenses–a combined experimental and numerical analysis[J]. J Am Ceram Soc, 2005, 88(3): 579−586. doi: 10.1111/j.1551-2916.2005.00137.x

[26] Jain A, Yi A Y. Numerical modeling of viscoelastic stress relaxation during glass lens forming process[J]. J Am Ceram Soc, 2005, 88(3): 530−535. doi: 10.1111/j.1551-2916.2005.00114.x

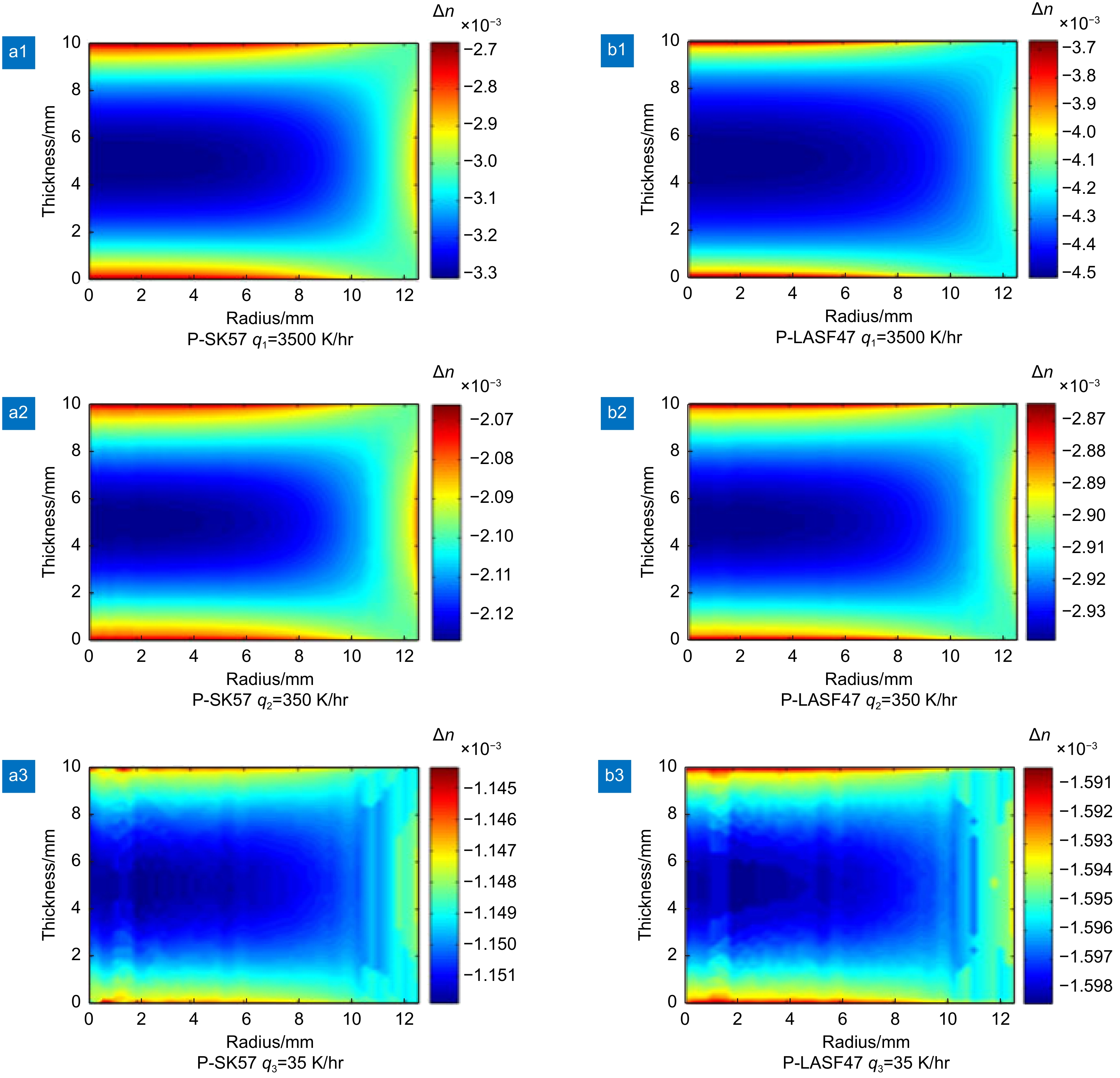

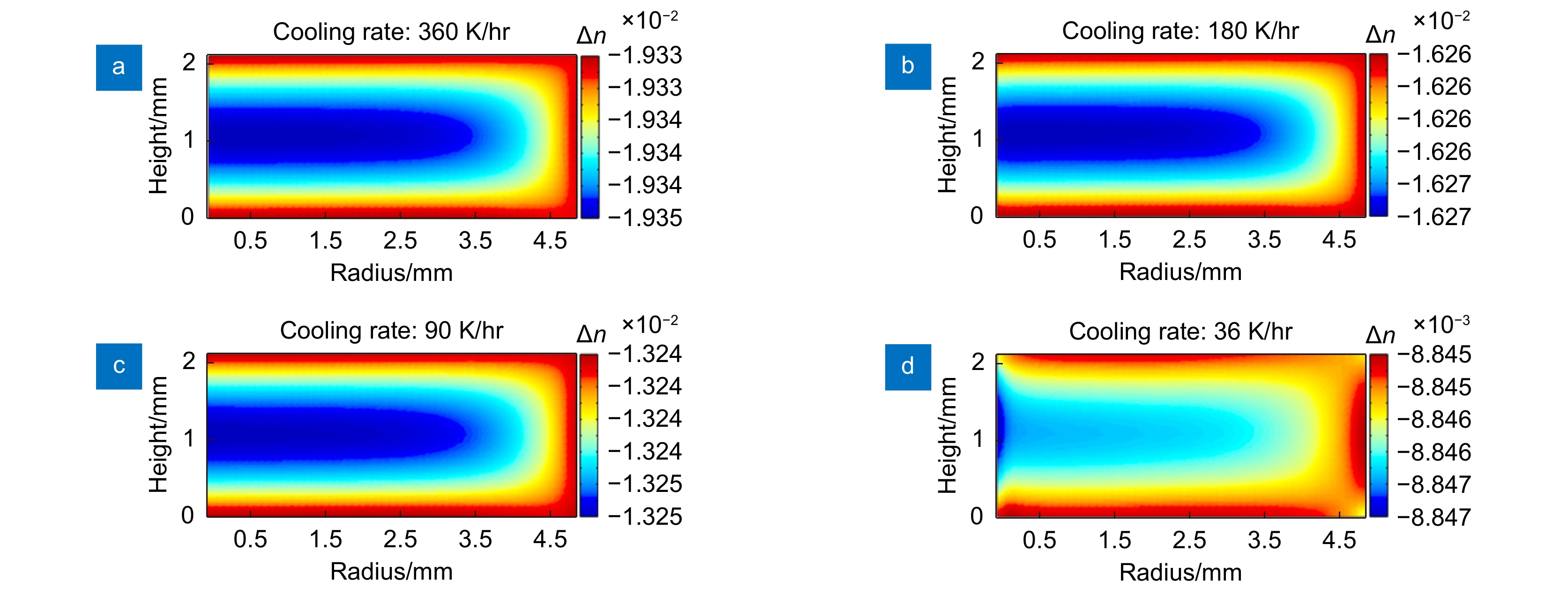

[27] Su L J, Yi A Y. Finite element calculation of refractive index in optical glass undergoing viscous relaxation and analysis of the effects of cooling rate and material properties[J]. Int J Appl Glass Sci, 2012, 3(3): 263−274. doi: 10.1111/j.2041-1294.2011.00074.x

[28] Su L J, Wang F, He P, et al. An integrated solution for mold shape modification in precision glass molding to compensate refractive index change and geometric deviation[J]. Opt Lasers Eng, 2014, 53: 98−103. doi: 10.1016/j.optlaseng.2013.08.016

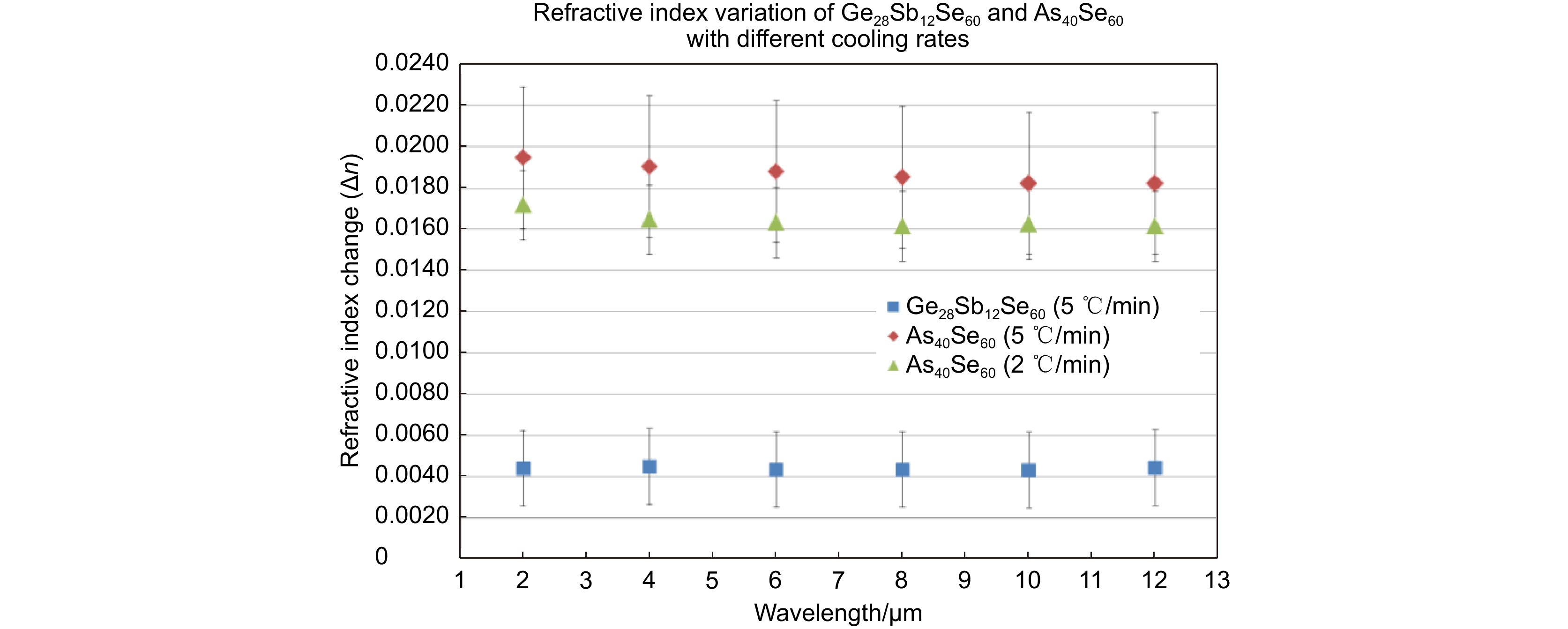

[29] Zhang L, Zhou W C, Naples N J, et al. Investigation of index change in compression molding of As40Se50S10 chalcogenide glass[J]. Appl Opt, 2018, 57(15): 4245−4252. doi: 10.1364/AO.57.004245

[30] Zhou J, Yu J F, Lee L J, et al. Stress relaxation and refractive index change of As2S3 in compression molding[J]. Int J Appl Glass Sci, 2017, 8(3): 255−265. doi: 10.1111/ijag.12244

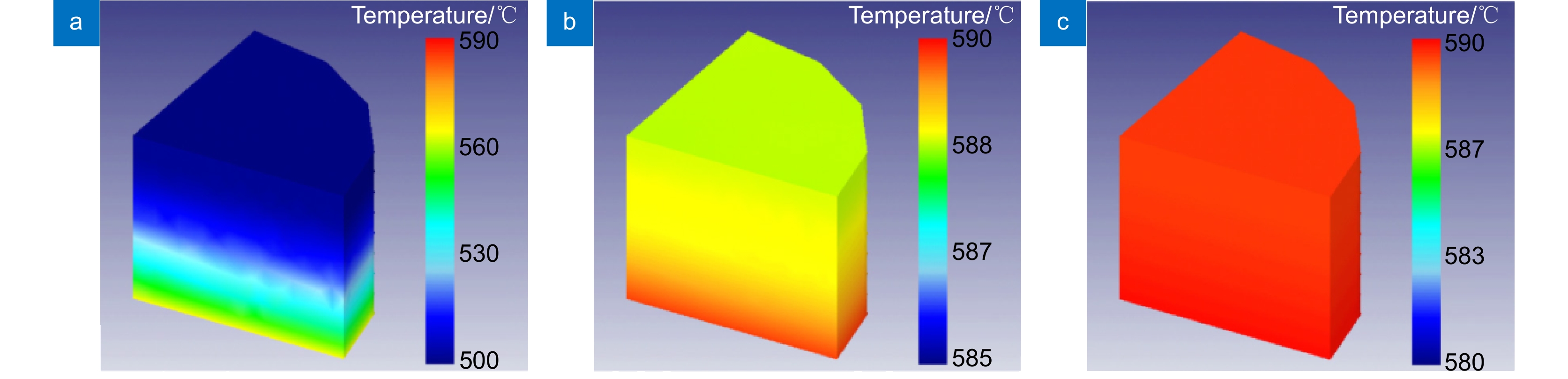

[31] Yan J W, Zhou T F, Masuda J, et al. Modeling high-temperature glass molding process by coupling heat transfer and viscous deformation analysis[J]. Precis Eng, 2009, 33(2): 150−159. doi: 10.1016/j.precisioneng.2008.05.005

[32] Yin S H, Zhu K J, Wang Y F, et al. Numerical simulation on two-step isothermal glass lens molding[J]. Adv Mater Res, 2010, 126–128: 564−569. doi: 10.4028/www.scientific.net/AMR.126-128.564

[33] Liu Y, Xing Y T, Li C, et al. Analysis of lens fracture in precision glass molding with the finite element method[J]. Appl Opt, 2021, 60(26): 8022−8030. doi: 10.1364/AO.436359

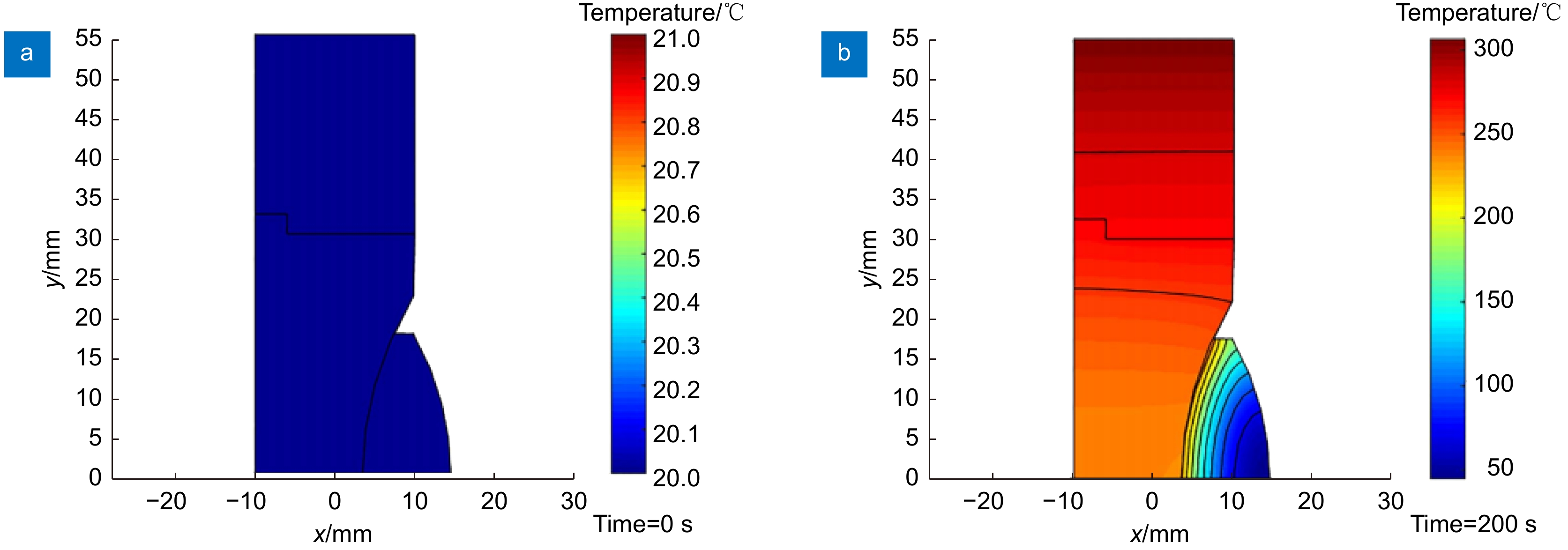

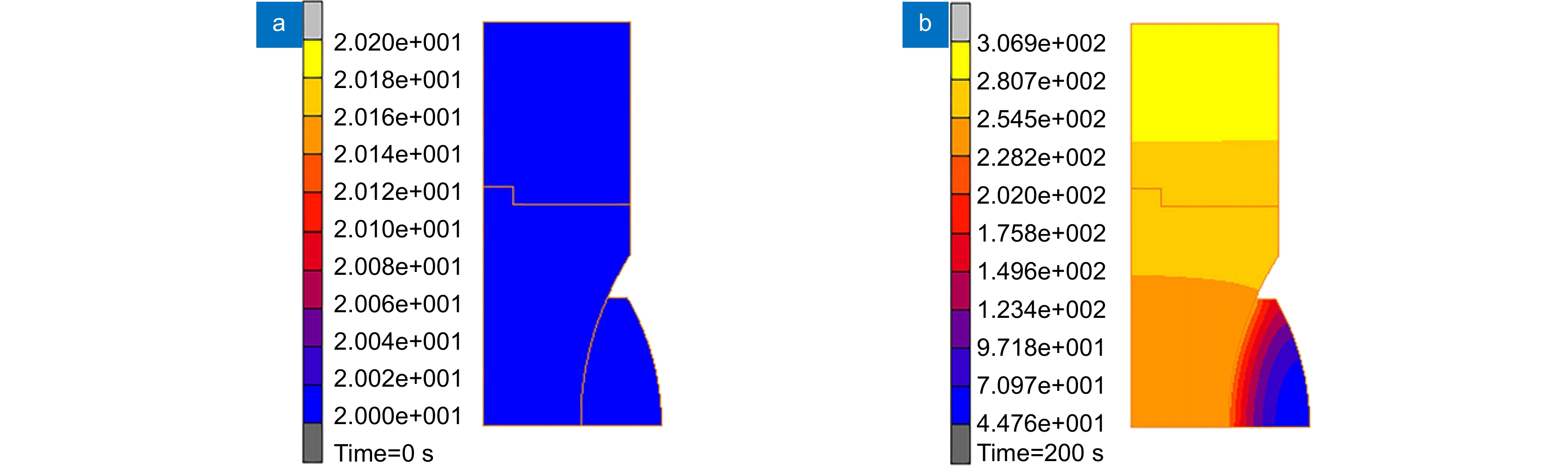

[34] Liu Y, Xing Y T, Yang C, et al. Simulation of heat transfer in the progress of precision glass molding with a finite element method for chalcogenide glass[J]. Appl Opt, 2019, 58(27): 7311−7318. doi: 10.1364/AO.58.007311

[35] Fu H, Xue C X, Liu Y, et al. Prediction model of residual stress during precision glass molding of optical lenses[J]. Appl Opt, 2022, 61(5): 1194−1202. doi: 10.1364/AO.448010

[36] Narayanaswamy O S. A model of structural relaxation in glass[J]. J Am Ceram Soc, 1971, 54(10): 491−498. doi: 10.1111/j.1151-2916.1971.tb12186.x

[37] Angle M A, Blair G E, Maier C C. Method for molding glass lenses: US3833347A[P]. 1974-09-03.

[38] Budinski M K, Pulver J C, Nelson J J, et al. Glass mold material for precision glass molding: US6363747B1[P]. 2002-04-02.

[39] Yao H H, Lv K Y, Zhang J R, et al. Effect of elastic modulus on the accuracy of the finite element method in simulating precision glass molding[J]. Materials, 2019, 12(22): 3788. doi: 10.3390/ma12223788

[40] Su L J, Yi A Y. Investigation of the effect of coefficient of thermal expansion on prediction of refractive index of thermally formed glass lenses using FEM simulation[J]. J Non-Cryst Solids, 2011, 357(15): 3006−3012. doi: 10.1016/j.jnoncrysol.2011.04.005

[41] Luo H, Yu J W, Hu J Z, et al. Effects of uniform/nonuniform interface friction on mold-filling behavior of glass microarray: a numerical-experimental study[J]. Tribol Lett, 2022, 70(1): 20. doi: 10.1007/s11249-022-01563-w

[42] Cha D H, Kim H J, Park H S, et al. Effect of temperature on the molding of chalcogenide glass lenses for infrared imaging applications[J]. Appl Opt, 2010, 49(9): 1607−1613. doi: 10.1364/AO.49.001607

[43] Jain A, Firestone G C, Yi A Y. Viscosity measurement by cylindrical compression for numerical modeling of precision lens molding process[J]. J Am Ceram Soc, 2005, 88(9): 2409−2414. doi: 10.1111/j.1551-2916.2005.00477.x

[44] Jain A, Yi A Y. Finite element modeling of structural relaxation during annealing of a precision-molded glass lens[J]. J Manuf Sci Eng, 2006, 128(3): 683−690. doi: 10.1115/1.2163362

[45] Jain A, Yi A Y, Xie X P, et al. Finite element modelling of stress relaxation in glass lens moulding using measured, temperature-dependent elastic modulus and viscosity data of glass[J]. Modell Simul Mater Sci Eng, 2006, 14(3): 465−477. doi: 10.1088/0965-0393/14/3/009

[46] Li H, He P, Yu J F, et al. Localized rapid heating process for precision chalcogenide glass molding[J]. Opt Lasers Eng, 2015, 73: 62−68. doi: 10.1016/j.optlaseng.2015.04.007

[47] Zhou T F, Yan J W, Masuda J, et al. Investigation on the viscoelasticity of optical glass in ultraprecision lens molding process[J]. J Mater Process Technol, 2009, 209(9): 4484−4489. doi: 10.1016/j.jmatprotec.2008.10.030

[48] Wang T, Zhou T F, Chen J, et al. Study the formation process of cuboid microprotrusion by glass molding process[J]. Micromachines, 2017, 8(3): 66. doi: 10.3390/mi8030066

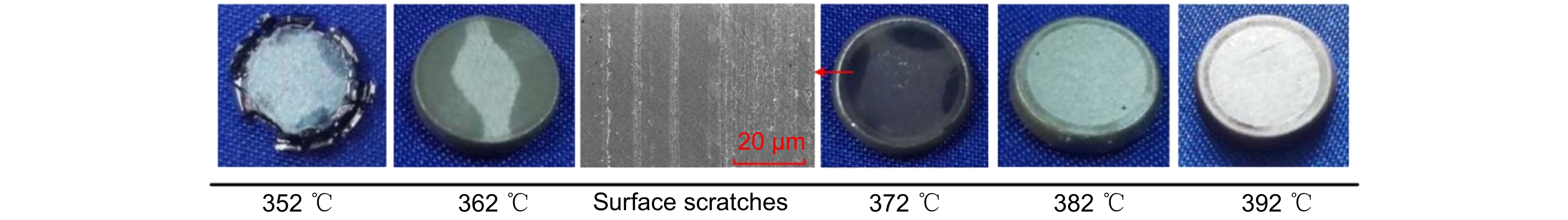

[49] Zhou T F, Zhou Q, Xie J Q, et al. Surface defect analysis on formed chalcogenide glass Ge22Se58As20 lenses after the molding process[J]. Appl Opt, 2017, 56(30): 8394−8402. doi: 10.1364/AO.56.008394

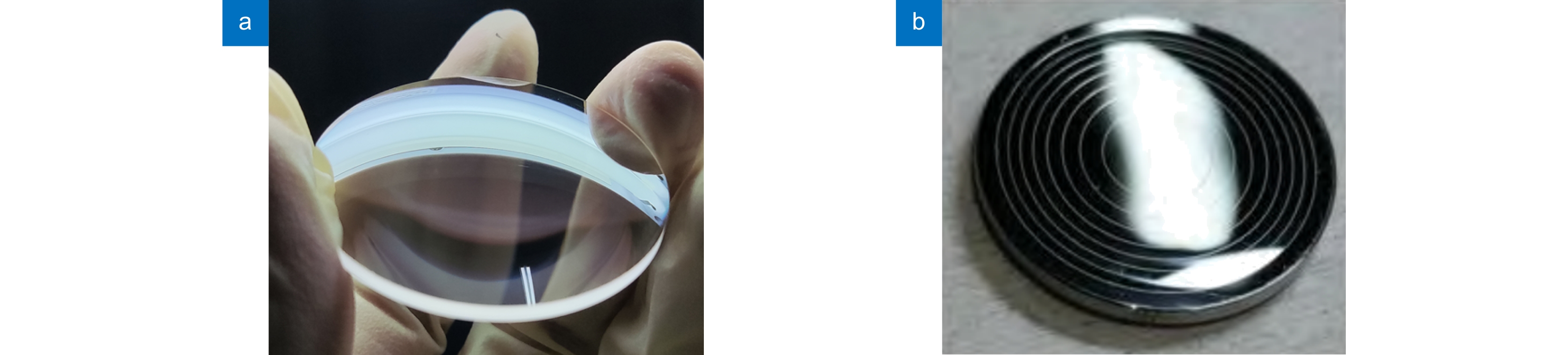

[50] Cha D H, Kim H J, Hwang Y, et al. Fabrication of molded chalcogenide-glass lens for thermal imaging applications[J]. Appl Opt, 2012, 51(23): 5649−5656. doi: 10.1364/AO.51.005649

[51] 付航. AR中的非球面透镜模压成型技术研究[D]. 长春: 长春理工大学, 2022: 30‒50. https://doi.org/10.26977/d.cnki.gccgc.2022.000650.

Fu H. Precision glass molding technology of aspheric lens in AR[D]. Changchun: Changchun University of Science and Technology, 2022: 30‒50. https://doi.org/10.26977/d.cnki.gccgc.2022.000650.

[52] 陈津平, 刘悦, 李闯, 等. 硫系玻璃衍射面模压成型仿真分析与实验研究[J]. 光学学报, 2023, 43(8): 0822024. doi: 10.3788/AOS221885

Chen J P, Liu Y, Li C, et al. Simulation analysis and experimental study on compression molding of chalcogenide-glass diffractive surface[J]. Acta Opt Sin, 2023, 43(8): 0822024. doi: 10.3788/AOS221885

[53] Novak J, Pini R, Moreshead W V, et al. Investigation of index of refraction changes in chalcogenide glasses during molding processes[J]. Proc SPIE, 2013, 8896: 889602. doi: 10.1117/12.2028902

[54] Fotheringham U, Baltes A, Fischer P, et al. Refractive index drop observed after precision molding of optical elements: a quantitative understanding based on the Tool–Narayanaswamy–Moynihan model[J]. J Am Ceram Soc, 2008, 91(3): 780−783. doi: 10.1111/j.1551-2916.2007.02238.x

[55] Zhou T F, Yan J W, Yoshihara N, et al. Study on nonisothermal glass molding press for aspherical lens[J]. J Adv Mech Design, Syst, Manuf, 2010, 4(5): 806−815. doi: 10.1299/jamdsm.4.806

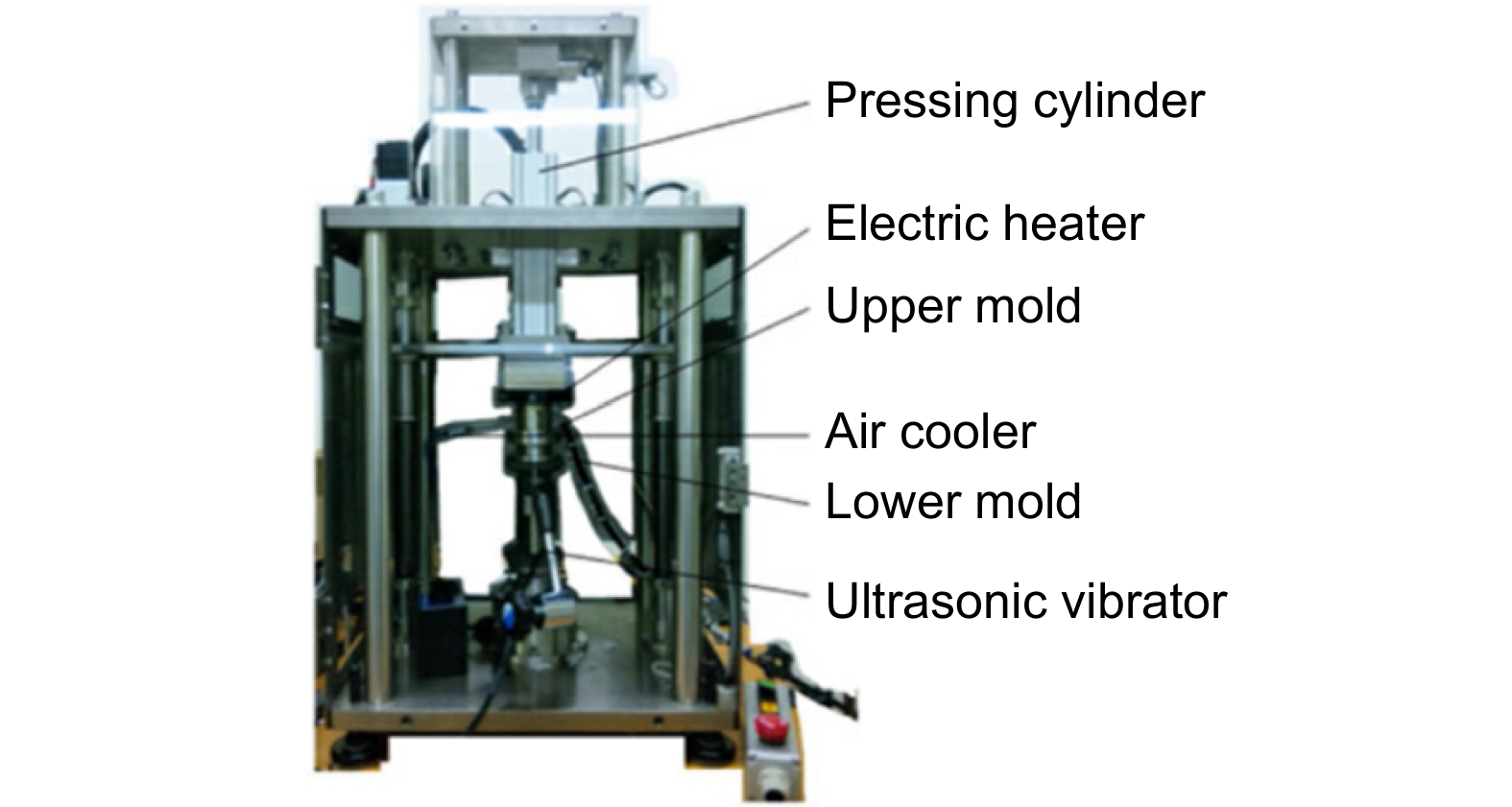

[56] Zhou T F, Xie J Q, Yan J W, et al. Improvement of glass formability in ultrasonic vibration assisted molding process[J]. Int J Precis Eng Manuf, 2017, 18(1): 57−62. doi: 10.1007/s12541-017-0007-6

[57] 李婵. 超声振动辅助微光学玻璃元件模压仿真和实验研究[D]. 长沙: 湖南大学, 2018: 20‒40.

Li C. Experimental research and simulation analysis on ultrasonic vibration-assisted molding press for optical microstructures[D]. Changsha: Hunan University, 2018: 20‒40.

[58] Bobba D, Morgan C. Reduction of cycle time during press molding of glass lenses[J]. Proc SPIE, 2022, 12219: 1221904. doi: 10.1117/12.2633380

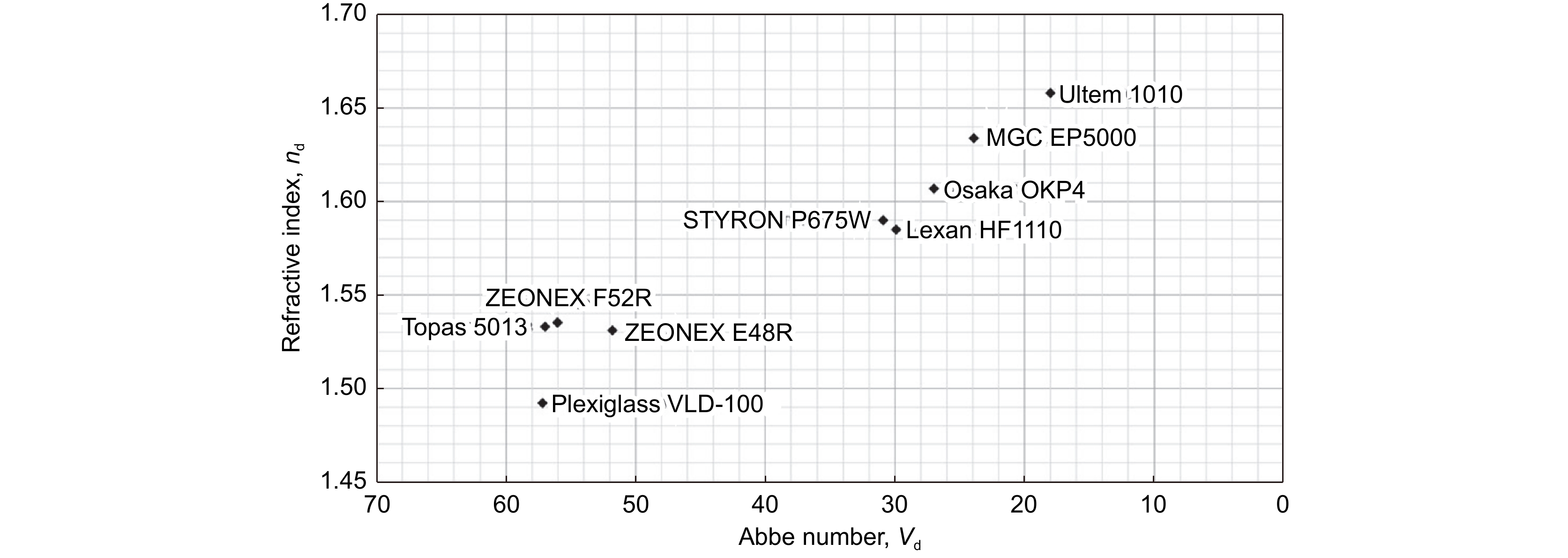

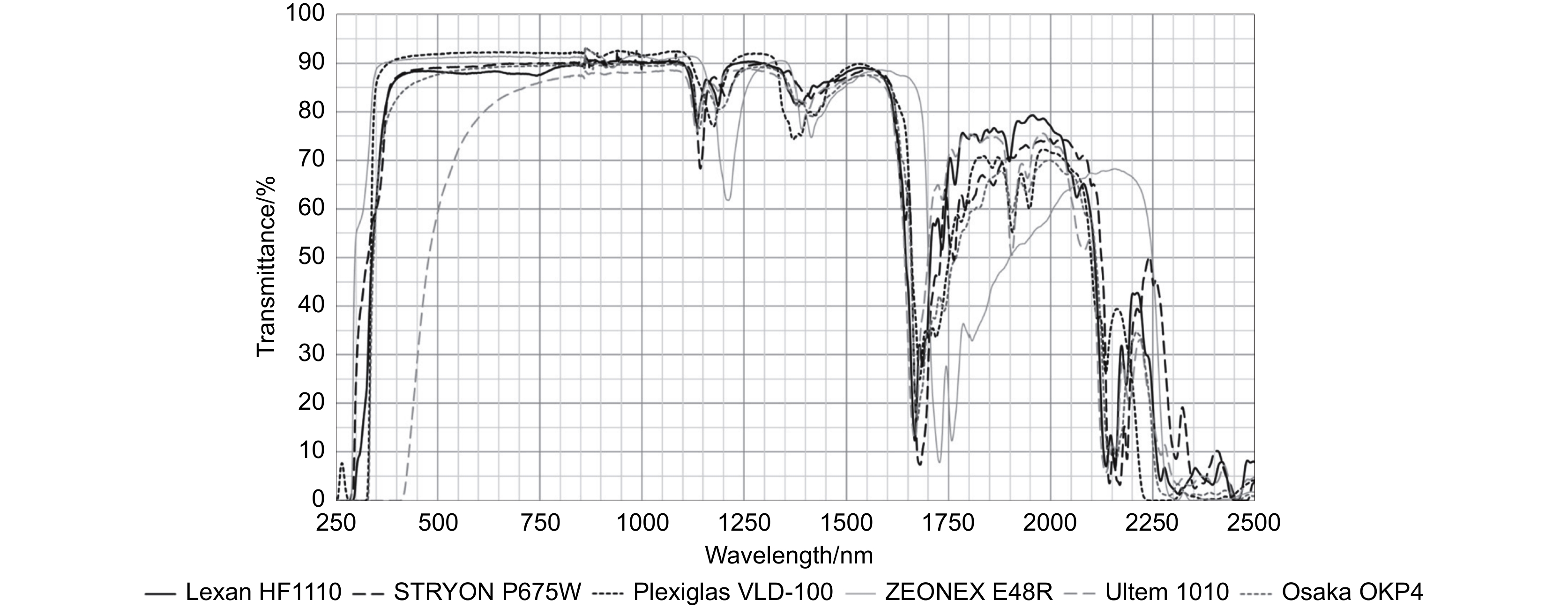

[59] Doushkina V, Fleming E. Optical and mechanical design advantages using polymer optics[J]. Proc SPIE, 2009, 7424: 74240Q. doi: 10.1117/12.832319

[60] Anderson L E, Kleine T S, Zhang Y Y, et al. Chalcogenide hybrid inorganic/organic polymers: ultrahigh refractive index polymers for infrared imaging[J]. ACS Macro Lett, 2017, 6(5): 500−504. doi: 10.1021/acsmacrolett.7b00225

[61] Griebel J J, Namnabat S, Kim E T, et al. New infrared transmitting material via inverse vulcanization of elemental sulfur to prepare high refractive index polymers[J]. Adv Mater, 2014, 26(19): 3014−3018. doi: 10.1002/adma.201305607

[62] Palmer A L. Practical design considerations for polymer optical systems[J]. Proc SPIE, 1982, 0306: 18−23. doi: 10.1117/12.932712

[63] Voznesenskaya A, Ekimenkova A. Modeling of hybrid polymer optical systems[J]. Proc SPIE, 2018, 10690: 1069014. doi: 10.1117/12.2312706

[64] Behrmann G P, Bowen J P, Mait J N. Thermal properties of diffractive optical elements and design of hybrid athermalized lenses[J]. Proc SPIE, 1993, 10271: 102710C. doi: 10.1117/12.170185

[65] 辛企明. 光学塑料非球面制造技术[M]. 北京: 国防工业出版社, 2005.

Xin Q M. Manufacturing Technology of Plastic Aspheric Lens[M]. Beijing: National Defense Industry Press, 2005.

[66] Chen S M, Li B H, Zhang Y J, et al. Effects of the injection compression process parameters on residual stress of plastic lenses[J]. Appl Opt, 2020, 59(30): 9626−9632. doi: 10.1364/AO.404024

[67] Li Z J, Fang F Z, Gong H, et al. Review of diamond-cutting ferrous metals[J]. Int J Adv Manuf Technol, 2013, 68(5): 1717−1731. doi: 10.1007/s00170-013-4970-5

[68] Lan X R, Li C, Yang C, et al. Optimization of injection molding process parameters and axial surface compensation for producing an aspheric plastic lens with large diameter and center thickness[J]. Appl Opt, 2019, 58(4): 927−934. doi: 10.1364/AO.58.000927

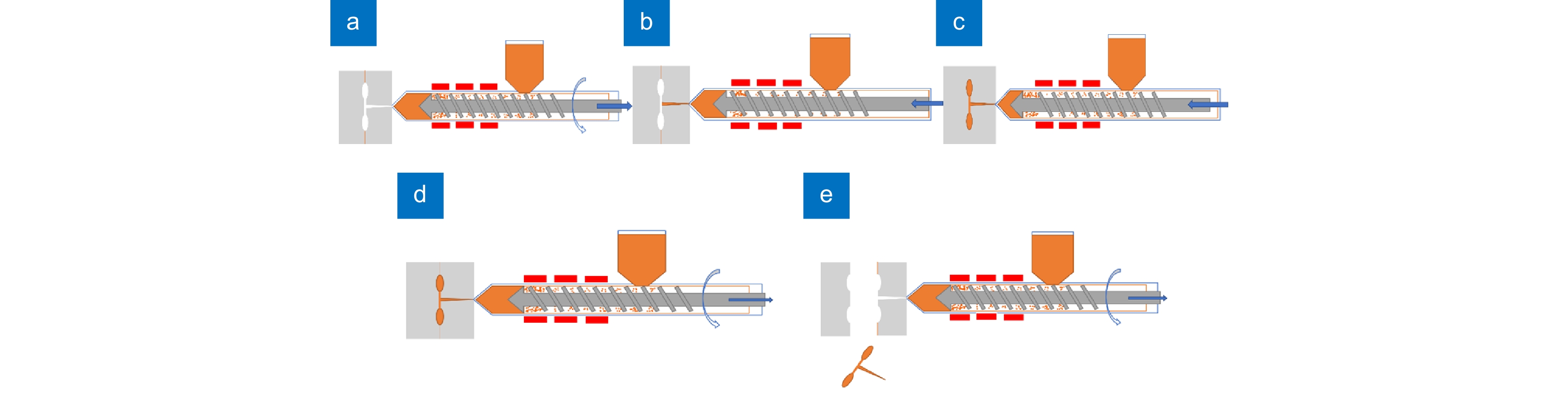

[69] 郑辉. 超声波辅助微注塑方法及工艺研究[D]. 天津: 天津大学, 2012: 5‒20.

Zheng H. Methodology and technology for[D]. Tianjin: Tianjin University, 2012: 5‒20.

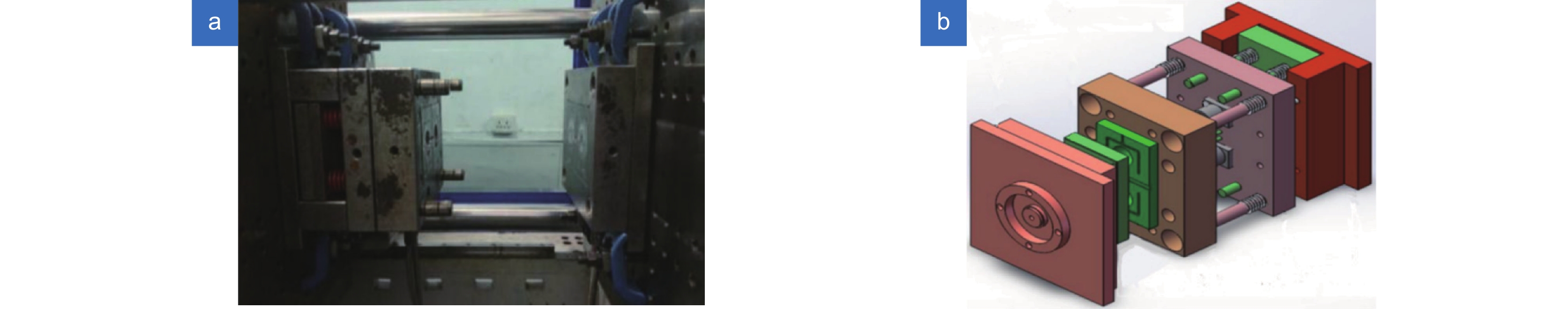

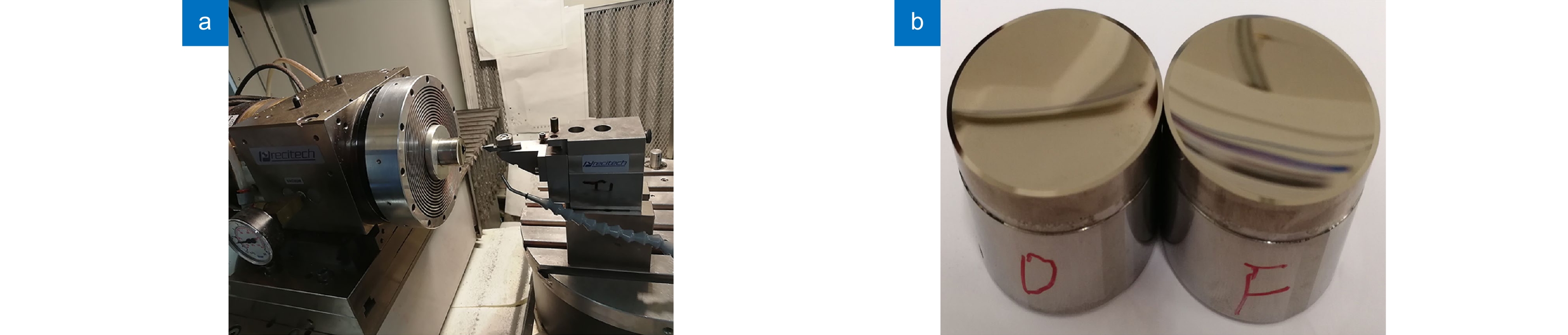

[70] 兰喜瑞. 成像光学塑料透镜的精密注塑成型技术研究[D]. 长春: 长春理工大学, 2019: 26‒40.

Lan X R. Studies on precision injection molding technology of imaging optical plastic lens[D]. Changchun: Changchun University of Science and Technology, 2019: 26‒40.

[71] 刘兴国. 衍射光学元件的精密注塑成型工艺研究[D]. 长春: 长春理工大学, 2020: 26‒50. https://doi.org/10.26977/d.cnki.gccgc.2020.000695.

Liu X G. Studies on precision injection molding process of diffractive optical elements[D]. Changchun: Changchun University of Science and Technology, 2020: 26‒50.

[72] Hsu M Y, Cheng Y C, Chang S T, et al. Residue stress analysis of molding aspherical plastic lens[J]. Proc SPIE, 2015, 9573: 95730P. doi: 10.1117/12.2185267

[73] 邓嘉乐. 塑胶成形镜片的双折射/内应力分布仿真[D]. 西安: 西安工业大学, 2021: 40‒50. https://doi.org/10.27391/d.cnki.gxagu.2021.000636.

Deng J L. Simulation of briefringence/internal stress distribution of plastic molded lenses[D]. Xi’an: Xi’an Technological University, 2021: 40‒50. https://doi.org/10.27391/d.cnki.gxagu.2021.000636.

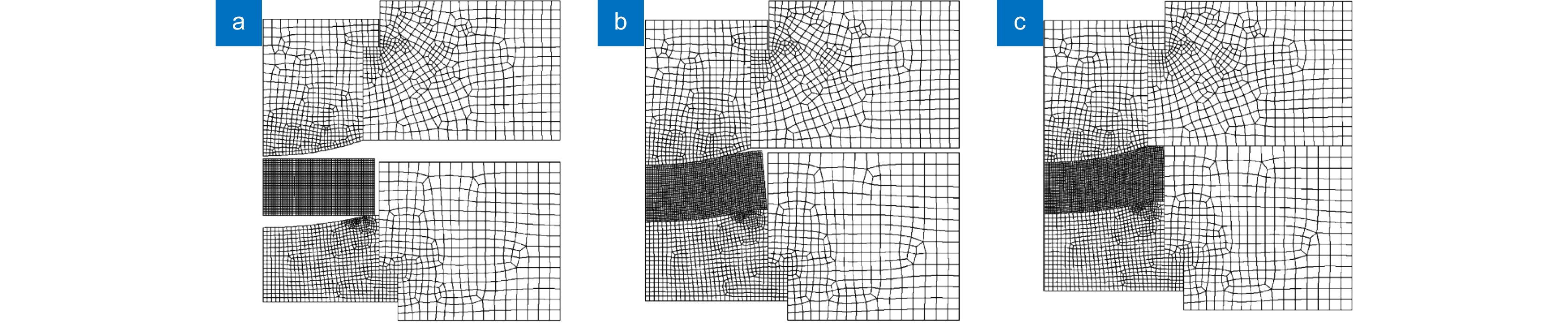

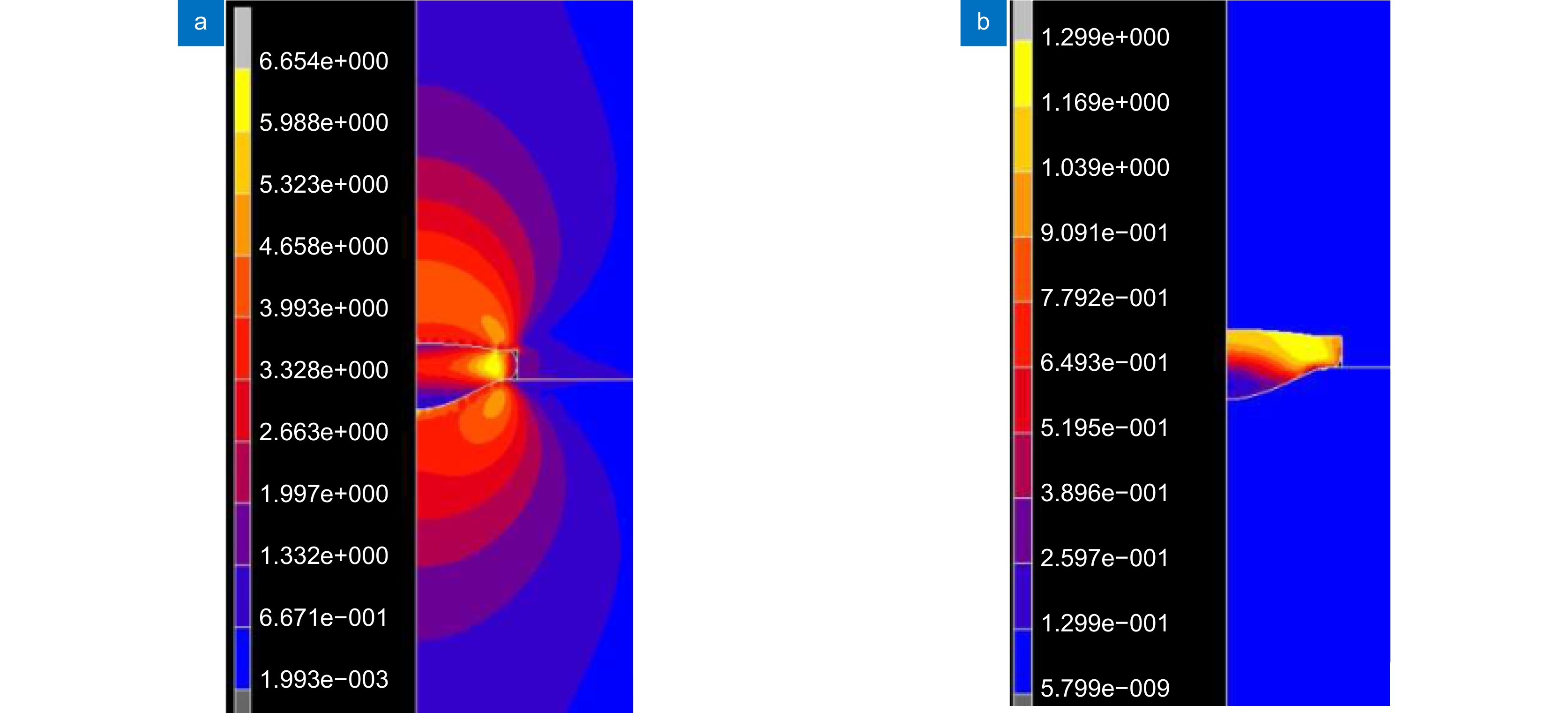

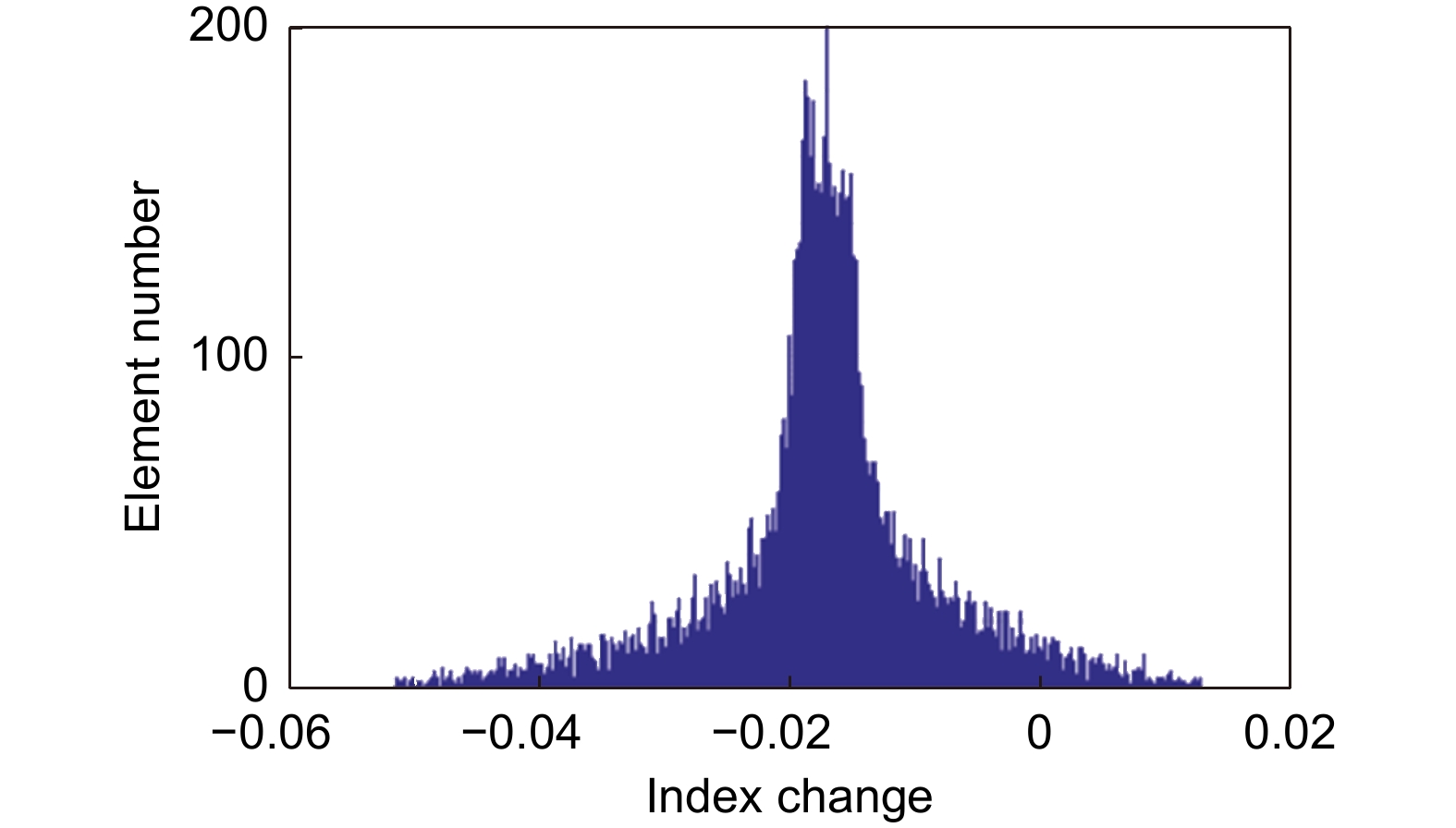

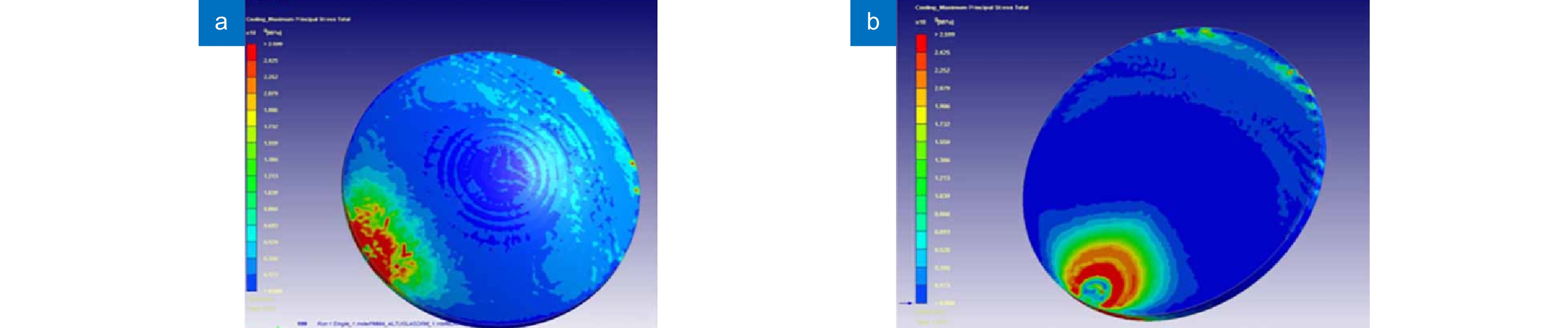

[74] Weng C, Lee W B, To S, et al. Numerical simulation of residual stress and birefringence in the precision injection molding of plastic microlens arrays[J]. Int Commun Heat Mass Transfer, 2009, 36(3): 213−219. doi: 10.1016/j.icheatmasstransfer.2008.11.002

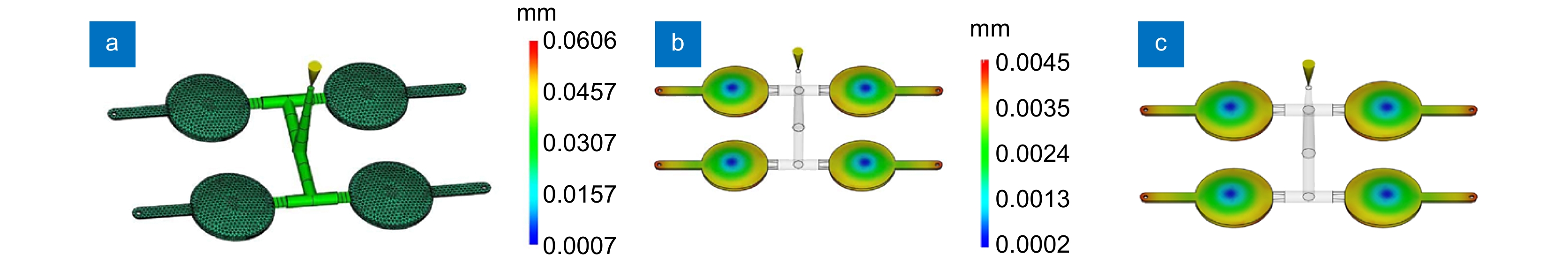

[75] Lin C M, Chen Y W. Grey optimization of injection molding processing of plastic optical lens based on joint consideration of aberration and birefringence effects[J]. Microsyst Technol, 2019, 25(2): 621−631. doi: 10.1007/s00542-018-4001-4

[76] Lin C M, Tan C M, Wang C K. Gate design optimization in the injection molding of the optical lens[J]. Optoelectron Adv Mater-Rapid Commun, 2013, 7(7): 580−584.

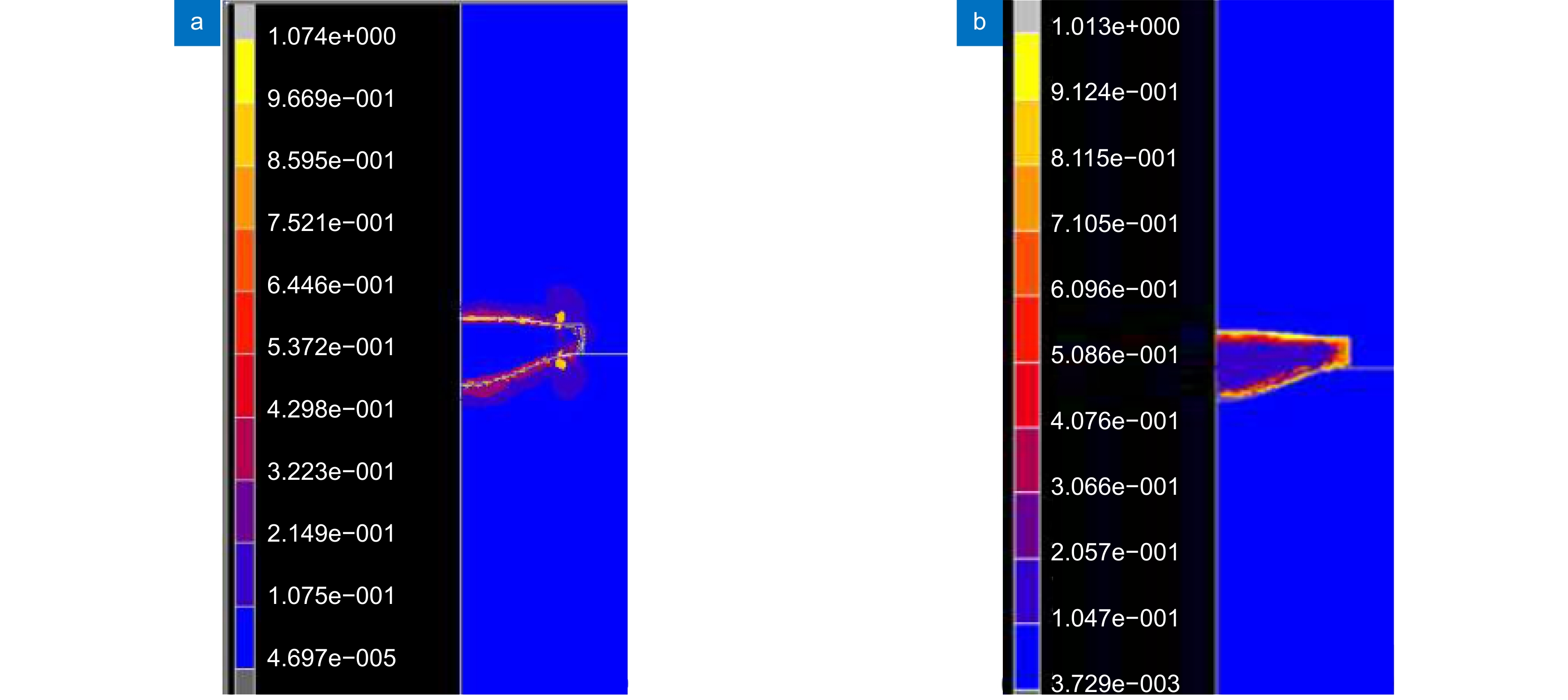

[77] Tsai K M. Runner design to improve quality of plastic optical lens[J]. Int J Adv Manuf Technol, 2013, 66(1): 523−536. doi: 10.1007/s00170-012-4346-2

[78] Tsai K M, Lin Y W. Quality improvement of optical lenses using innovative runner design[J]. Int J Manuf Res, 2013, 8(4): 337−356. doi: 10.1504/IJMR.2013.057746

[79] Dick L, Risse S, Tünnermann A. Injection molded high precision freeform optics for high volume applications[J]. Adv Opt Technol, 2012, 1: 39−50. doi: 10.1515/aot-2011-0009

[80] Lu X H, Khim L S. A statistical experimental study of the injection molding of optical lenses[J]. J Mater Process Technol, 2001, 113(1-3): 189−195. doi: 10.1016/S0924-0136(01)00606-9

[81] Shieh J Y, Wang L K, Ke S Y. A feasible injection molding technique for the manufacturing of large diameter aspheric plastic lenses[J]. Opt Rev, 2010, 17(4): 399−403. doi: 10.1007/s10043-010-0074-8

[82] Bensingh R J, Boopathy S R, Jebaraj C. Minimization of variation in volumetric shrinkage and deflection on injection molding of Bi-aspheric lens using numerical simulation[J]. J Mech Sci Technol, 2016, 30(11): 5143−5152. doi: 10.1007/s12206-016-1032-6

[83] Yin X H, Yang C, Li X P, et al. 3D thickness distributions of plano lenses as a means of cavity pressure characterization in microinjection molding[J]. Opt Express, 2018, 26(9): 11250−11264. doi: 10.1364/OE.26.011250

[84] Wen J L, Wen P F. The simulation and optimization of aspheric plastic lens injection molding[J]. J Wuhan Univ Technol-Mater Sci Ed, 2005, 20(2): 86−89. doi: 10.1007/BF02838498

[85] Tsai K M, Hsieh C Y, Lo W C. A study of the effects of process parameters for injection molding on surface quality of optical lenses[J]. J Mater Process Technol, 2009, 209(7): 3469−3477. doi: 10.1016/j.jmatprotec.2008.08.006

[86] Bensingh R J, Machavaram R, Boopathy S R, et al. Injection molding process optimization of a bi-aspheric lens using hybrid artificial neural networks (ANNs) and particle swarm optimization (PSO)[J]. Measurement, 2019, 134: 359−374. doi: 10.1016/j.measurement.2018.10.066

[87] Tsai K M, Luo H J. An inverse model for injection molding of optical lens using artificial neural network coupled with genetic algorithm[J]. J Intell Manuf, 2017, 28(2): 473−487. doi: 10.1007/s10845-014-0999-z

[88] Fang F Z, Zhang N, Zhang X D. Precision injection molding of freeform optics[J]. Adv Opt Technol, 2016, 5(4): 303−324. doi: 10.1515/aot-2016-0033

[89] Loaldi D, Calaon M, Quagliotti D, et al. Tolerance verification of precision injection moulded Fresnel lenses[J]. Proc CIRP, 2018, 75: 137−142. doi: 10.1016/j.procir.2018.05.004

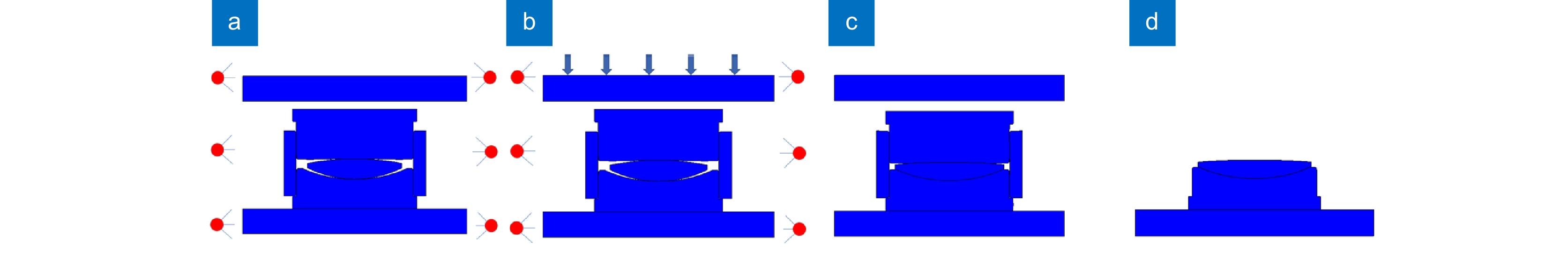

[90] Loaldi D, Quagliotti D, Calaon M, et al. Manufacturing signatures of injection molding and injection compression molding for micro-structured polymer fresnel lens production[J]. Micromachines, 2018, 9(12): 653. doi: 10.3390/mi9120653

[91] Wu C H, Chen W S. Injection molding and injection compression molding of three-beam grating of DVD pickup lens[J]. Sens Actuators A Phys, 2006, 125(2): 367−375. doi: 10.1016/j.sna.2005.07.025

[92] Chen Y C, Nian S C, Huang M S. Optical design of the Fresnel lens for LED-driven flashlight[J]. Appl Opt, 2016, 55(4): 712−721. doi: 10.1364/AO.55.000712

[93] Michaeli W, Wielpuetz M. Optimisation of the optical part quality of polymer glasses in the injection compression moulding process[J]. Macromol Mater Eng, 2000, 284–285(1): 8−13. doi: 10.1002/1439-2054(20001201)284:1<8::AID-MAME8>3.0.CO;2-1

[94] Michaeli W, Heßner S, Klaiber F, et al. Geometrical accuracy and optical performance of injection moulded and injection-compression moulded plastic parts[J]. CIRP Anna, 2007, 56(1): 545−548. doi: 10.1016/j.cirp.2007.05.130

[95] Sortino M, Totis G, Kuljanic E. Comparison of injection molding technologies for the production of micro-optical devices[J]. Proc Eng, 2014, 69: 1296−1305. doi: 10.1016/j.proeng.2014.03.122

[96] Roeder M, Drexler M, Rothermel T, et al. Injection compression molded microlens arrays for hyperspectral imaging[J]. Micromachines, 2018, 9(7): 355. doi: 10.3390/mi9070355

[97] Chen S C, Chen Y C, Peng H S. Simulation of injection-compression-molding process. II. Influence of process characteristics on part shrinkage[J]. J Appl Polym Sci, 2000, 75(13): 1640−1654. doi: 10.1002/(SICI)1097-4628(20000328)75:13<1640::AID-APP10>3.0.CO;2-L

[98] Young W B. Effect of process parameters on injection compression molding of pickup lens[J]. Appl Math Modell, 2005, 29(10): 955−971. doi: 10.1016/j.apm.2005.02.004

[99] Weng C, Lee W B, To S. Birefringence techniques for the characterization of residual stresses in injection-moulded micro-lens arrays[J]. Polym Test, 2009, 28(7): 709−714. doi: 10.1016/j.polymertesting.2009.06.007

[100] Su L J, Chen Y, Yi A Y, et al. Refractive index variation in compression molding of precision glass optical components[J]. Appl Opt, 2008, 47(10): 1662−1667. doi: 10.1364/AO.47.001662

[101] Zhang L, Zhou W C, Yi A Y. Investigation of thermoforming mechanism and optical properties’ change of chalcogenide glass in precision glass molding[J]. Appl Opt, 2018, 57(22): 6358−6368. doi: 10.1364/AO.57.006358

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: