Abstract

This report describes the development of a chromatographic method for the simultaneous quantification of a polymer, hydroxypropyl methylcellulose (HPMC), and a surfactant, dodecyl β-D-maltoside (DM), that are commonly used in the physical stabilization of pharmaceutical formulations such as nanosuspensions and solid dispersions. These excipients are often challenging to quantify due to the lack of chromophores. A reverse phase size exclusion chromatography (SEC) with evaporative light scattering detector (ELSD) technique was utilized to develop an accurate and robust assay for the simultaneous quantification of HPMC and DM in a nanosuspension formulation. The statistical design of experiments was used to determine the influence of critical ELSD variables including temperature, pressure, and gain on accuracy, precision, and sensitivity of the assay. A robust design space was identified where it was determined that an increase in the temperature of the drift tube and gain of the instrument increased the accuracy and precision of the assay and a decrease in the nebulizer pressure value increased the sensitivity of the assay. In the optimized design space, response data showed that the assay could quantify HPMC and DM simultaneously with good accuracy, precision, and reproducibility. Overall, SEC-ELSD proved to be a powerful technique for the simultaneous quantification of HPMC and DM. This technique can be used to quantify the amount of HPMC and DM in nanosuspensions, which is critical to understanding their effects on the physical stability of nanosuspensions.

Similar content being viewed by others

INTRODUCTION

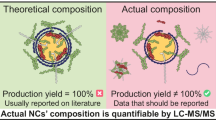

Polymers such as hydroxypropyl methylcellulose (HPMC), polyvinyl pyrrolidone (PVP), and hydroxypropyl cellulose (HPC) and surfactants such as dodecyl β-D-maltoside (DM), sodium dodecyl sulfate (SDS), and polyethylene glycol (PEG) are frequently used in nanosuspension formulations intended for oral or parenteral drug administration as means to enhance the physical stability of nanosuspensions (1–5). It is well known that a significant number of new chemical entities exhibit poor water solubility, resulting in poor oral absorption and the need for bioavailability enhancement (6–8). Nanosuspensions are one of several possible routes for bioavailability enhancement of such poorly soluble drug substances (2). Physical stabilization of nanosuspensions is challenging, often requiring an optimum combination of surfactants and polymer excipients thus allowing for a synergy in the types of interactions between these stabilizers and the drug molecule as a means to enhance the physical stability of nanosuspensions (2,9). For better selection of the polymers and surfactants, it is essential to quantify these stabilizers as a first step toward developing a mechanistic understanding of the interactions between the stabilizers themselves and with drug molecules. A significant gap in the literature continues to exist in this area due to the lack of suitable analytical methods to simultaneously and accurately quantify levels of polymers and surfactants in nanosuspensions. The objective of this study was to develop a robust method to simultaneously quantify a model polymer, HPMC, and a model surfactant, DM.

As a pharmaceutical excipient, HPMC is employed in a wide range of solid and liquid formulations (10). HPMC is a mixed alkyl hydroxyalkyl cellulose ether that is derivatized with hydroxypropyl and methoxyl groups. The chromatographic quantification of HPMC, with acceptable baseline separation from other excipients, is challenging due to a wide molecular weight distribution and the lack of strong chromophores. There are only a few reports describing quantitative assays for HPMC that are suitable for pharmaceutical products (11–13). Delker et al. (11) employed refractive index detection of HPMC in polyethylene glycol; however, this method was not as sensitive and limited to the milligram/milliliter concentration range of HPMC. While employing evaporative light scattering detector (ELSD), Whelan et al. (12) reported a chromatographic retention time of 1.7 min that was close to the solvent peak for HPMC in the presence of ibuprofen. Rashan and Chen (13) used a Polymer X RP-1 column along with a gradient elution method that is typically not used along with ELSD detectors for the analysis of different grades of HPMC. In both methods, the elution of the HPMC was close to the solvent peak, lacked sensitivity, and could not simultaneously quantify HPMC with other surfactants.

DM is an alkyl polyglucosides manufactured from sugars that are typically derivatives of glucose and fatty alcohols (14–16). These surfactants have garnered considerable amount of interest as a result of their low surface tension, ionic strength tolerance, and environmental compatibility (17–21). DM was used as a model surfactant to represent other nonionic surfactants in this study. The methods reported for the detection of DM include measuring the total organic carbon (TOC) and calorimetry, both of which are not very fast, accurate, or sensitive (1).

For the simultaneous detection of HPMC and DM in nanosuspension, we have selected ELSD as a detection method since both excipients are nonvolatile and lack UV chromophores (22,23). ELSD is much more sensitive over other techniques such as refractive index, and ELSD-based HPLC analytical methods can be easily transferred to liquid chromatographic mass spectroscopy (LCMS), as both methods employ compatible solvents (24). Besides the higher sensitivity (almost equivalent to that of liquid chromatography (LC) method) and solvent compatibility, the ELSD method has some additional advantages over other universal techniques (i.e., refractive index (RI) and LCMS) such as low cost and ease of operation. While this method has several benefits, there are also some limitations such as low selectivity, requirement for volatile mobile phase, nonlinear response, and also being destructive to the sample (25). This detection method has been applied effectively for at least the last two decades to quantify a wide spectrum of natural and synthetic compounds including pharmaceuticals (i.e., drug molecules and excipients including polymers, sugars, lipids, and surfactants) (4,24,26–29), natural products and biologics (30,31). foods, and beverages (32,33). Additionally, size exclusion chromatography (SEC) has been used to resolve polymers based on differences in molecular size where separation occurs as a result of pore size of the packing material (11). To the best of our knowledge, there are no methods published outlining an SEC-ELSD assay for the simultaneous detection of DM and HPMC. We report here a full factorial design to optimize the impact of critical SEC and ELSD instrument variables on a HPMC/DM assay with respect to precision, accuracy, and sensitivity. We have also determined the interactions of instrument variables in producing the optimal response. The assay reported here was evaluated for accuracy and precision in the simultaneous quantification of DM and HPMC as per the Guidance for Industry, ICH-Q2A (34). This method would be used in our future studies to understand the mechanism of nanosuspension stabilization by DM and HPMC.

MATERIALS AND METHODS

Chemicals and Solvents

Dodecyl β-D-maltoside (>98%) was obtained from Sigma-Aldrich (St. Louis, MO). Hydroxypropyl methylcellulose (Benecel® K-4M) was obtained from Ashland Aqualon Functional Ingredients, Ashland Inc. (Wilmington, DE). The chemical structures for DM and HPMC are shown in Fig. 1. Acetonitrile (HPLC grade) was purchased from Fischer (Fair Lawn, NJ). HPLC grade water (18.2 MΩ cm) was obtained from a Milli-Q water purification system (Millipore, Billerica, MA). All other reagents were of pharmaceutical grade and used as received.

Equipment and Software

All studies in this work were carried out on the HPLC system that consisted of a Waters 2695 Separations Module (Waters, Milford, MA) coupled with a Sedex 85 low-temperature evaporative light scattering detector (SEDERE, France). The signal was acquired and processed with Millennium software (Waters, Milford, MA). Nitrogen gas (ultrapure >99%) was obtained from Scott Gross Company Inc. (Lexington, KY). Stat-Ease® software was used for the design and analysis of experiments and was obtained from Stat-Ease, Inc. (Minneapolis, MN).

Column Selection and Chromatographic Conditions

A Waters Ultrahydrogel® 120 size exclusion column (5 μm, 300 mm × 7.8 mm) with a pore size of 120 Å (Waters Corporation, Milford, MA) was used to separate DM and HPMC. The mobile phase consisted of acetonitrile: Milli-Q water (30/70, v/v) and a flow rate of 1 mL/min under isocratic conditions. The column was allowed to equilibrate for 2 h under the above conditions prior to the first injection. The injection volume was fixed at 100 μL. Additionally, the column was conditioned by a minimum of four consecutive injections of the standard mixtures. When used in ELSD, solvent gradients can be quite problematic as the response factor may no longer remain constant. As the organic content of the mobile phase increases, the transport efficiency of the nebulizer may increase leading to changes in size and number of droplets carrying the analyte to the detector (35). Nonlinearity of the standard curve is often the result. Several combinations of isocratic mobile phase along with buffers were tested. The use of buffers in the mobile phase led to significant peak broadening, tailing, and carryover. The retention times of the surfactant and polymer peaks were within 2% and the area under the curves were within 20%. The column temperature was maintained at 25°C. The resolution (R s) between the HPMC and DM peaks in mixed systems was calculated using Eq. 1.

where RTa and RTb are the retention times and W a and W b are the widths at baseline of HPMC and DM peaks, respectively.

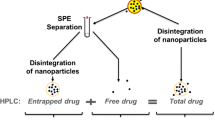

Sample Preparation

Standard solutions were prepared by dissolving known weights of HPMC and DM in mobile phase. All solutions of DM and HPMC and mixtures containing both were prepared using stock solutions. The samples containing mixtures of DM, HPMC, and nanoparticles were first dissolved in the mobile phase and then centrifuged at 5000 rpm for 1 h to sediment any undissolved nanoparticles. The supernatant obtained from this was used for analysis. The working range for the concentration of DM and HPMC standards was 10–325 μg/mL. Standards and samples were prepared on the day of use.

Detector Variables

Since the ELSD works on the principle of detecting nonvolatile particles that scatter light, it is imperative to fully control the variables that are critical for the formation of these particles, most notably the optimal carrier gas pressure, drift tube temperature, and amplifier gain (25,26). A two-level full factorial design was chosen to generate response surfaces in order to choose the optimal carrier gas pressure, drift tube temperature, and amplifier gain (Table I). In lieu of a center point in the factorial design, a validation run was conducted within the identified optimized design space upon completion of the design of experiment (DoE). Preliminary screening experiments showed that amplifier gain values outside 10–12 resulted in very low signal/noise. Similarly, drift tube temperatures outside of 40–50°C and carrier gas pressures outside of 3–3.2 bar resulted in poor reproducibility. These preliminary results defined the relatively narrow design space to be optimized.

Standard Curves

The signal intensity of an ELSD detector has been related to the concentration of the analyte according to Eq. 2.

The parameters α and β are directly influenced by factors such as the size of the particles, nature and volatility of the analyte, nebulizer gas flow rate, mobile phase flow rate, and temperature of the drift tube. Some authors have employed a linear model similar to Beer’s law; however, the concentration range in such cases is typically quite narrow (28,36,37). Logarithmic models have been successfully employed to fit ELSD response data over a much wider range of analyte concentration (27,38,39). A logarithmic transformation of Eq. 2 is described by Eq. 3:

where α is the slope and logβ is the y-intercept, respectively. Chromatographic area under the peak data was collected for both DM and HPMC in the concentration range of 10–325 μg/mL. The chromatographic data was fit to Eq. 3 separately for each solute and the slope value of each plot determined. A second series of solutions, with both solutes present simultaneously, was also subjected to chromatographic analysis. A calibration curve was constructed for each solute in the mixed samples and the slopes of each were determined. It should be noted that this process was carried out under each set of conditions listed in Table I.

Design of Experiments

Several experiments were carried out to assess the characteristics of the assay for mixed solute samples, including precision, accuracy, sensitivity, and percent deviation of the slope and intercept of the calibration curves of DM and HPMC. For each DoE condition listed in Table I, the slopes obtained from fitting Eq. 3 for each single-component DM and HPMC solutions were compared to those of the same solutes in the mixed system. The results are expressed as percent deviation of each slope from the mixed samples relative to the single-component standards. Accuracy of the assay was determined by comparing the peak areas of DM and HPMC in mixed solutions, each present at 100 μg/mL, with those areas obtained from the same solutes in single-component standards. Accuracy is expressed as percent recovery of each solute from the mixed samples relative to the single-component standards. Precision was determined by replicate analysis of four independent injections of the 300-μg/mL standard and run under the factorial ELSD conditions listed in Table I. Precision of response used in the analysis of variance (ANOVA) is expressed as percent relative standard deviation (RSD). The sensitivity response calculation was conducted with the 50-μg/mL standards. Sensitivity of the instrument was determined as the slope of the calibration curves obtained from the three lowest concentrations of DM and HPMC.

After the initial selection of a full model containing all the main effects along with all orders of interaction terms, ANOVA was performed for each response. Diagnostic tools such as normal or half-normal plots of residuals, Box-Cox plots, p value comparisons, and stepwise regression routines were employed to fit response data to obtain a simpler and more adequate model that had a minimum number of needed effects and interactions. ANOVA results and regression coefficients of the ELSD variables were subsequently determined for each response with the simple model as described above.

RESULTS AND DISCUSSION

Chromatograms

The SEC column with a pore size of 120 Å provided optimal resolution of DM and HPMC. Along with the SEC column, the mobile phase and flow rate were adjusted so as to obtain the sharpest peak for the HPMC molecular weight grade used in this work.

After a series of preliminary chromatographic experiments to optimize resolution, a suitable isocratic mobile phase, flow rate, and injection volume were identified. In the chromatograms of a mixture of HPMC-DM as well as chromatograms of individual solutes (Fig. 2), HPMC eluted at 4.9 min (Table II) in single and mixed standard solutions, whereas DM eluted at 15.9 min in the mixed standards and at 15.7 min in the single standards. The RSD values for the mean retention times of HPMC and DM were 0.35% and 0.37%, respectively (n = 16). In all mixtures, R s values greater than 1.5 were observed. As specified in the FDA-CDER guidelines (21) and by Chen, Hsu and Chien (22). an R s value greater than 1.5 is recommended to assure good peak resolution for quantification purposes.

As is typical of pharmaceutical grade polymer, HPMC K-4M exhibits a wide range of molecular weights. The manufacturer reports a weight-average molecular weight range from 20,000 to 115,000 and a number-average molecular weight of 86,000, and it has been reported to show broad or multiple peaks by SEC (13). In initial method development, three peaks were obtained (data not shown) for the rather broad molecular weight distribution of the HPMC K-4M grade used; however, in order to make this assay more robust, chromatographic manipulations described earlier were conducted in order to obtain a sharper peak with a small shoulder. Despite this diversity of molecular weights, a relatively symmetric chromatogram was observed (Fig. 2b, c). The small shoulder in the HPMC peak observed in the chromatogram is likely indicative of a low molecular weight HPMC fraction resolved by the column. As a point of reference, the calculated elution volume of this system is less than 3 mL.

Impact of Instrument Variables on Critical Responses

Precision, accuracy, sensitivity, and percent deviation of slope from the calibration curves (Fig. 3) of DM and HPMC were employed to evaluate the impact of ELSD instrument variables outlined in Table I. The summary of the process variables and the results of responses in the design space are summarized in Table III. The responses and their statistical analysis with each instrument variable are discussed in greater detail below.

One-factor assay response values of % deviation of slope and sensitivity as a function of ELSD instrument variables were also determined. From the analysis, temperature and amplifier gain were found to be statistically significant (P < 0.05) for % deviation of slope response for DM. Only instrument gain was found to be statistically significant (P < 0.05) for % deviation of slope response for HPMC, and the accuracy results showed that the variables of temperature and instrument gain were significant (P < 0.05) while pressure was not statistically significant. Drift tube temperature of the ELSD detector in an ideal scenario should completely volatilize the mobile phase without any loss of analyte by thermal degradation; hence, the temperature would need to be optimized such that there is a minimization of the baseline noise that may occur at low temperatures while also balancing the lack of sensitivity and accuracy that could occur at higher temperatures (25). The variable of nebulizer pressure was found to be statistically significant (P < 0.05) toward the sensitivity of the assay. Nebulizer pressure is reported to be critical in the effluent atomization from the chromatographic column by allowing the formation of uniform sized droplets with a narrow size distribution which can directly influence the assay sensitivity and repeatability. It has also been seen in certain studies that an increase in droplet size contributed to an enhancement of the ELSD response and is in agreement with the present study (25). In ANOVA, the F value associated with the selected simple model was determined for each response and expressed as percent (%). The F value is the ratio of the model sum of squares and residual sum of squares that shows the relative contribution of the model variance to the residual variance. A large value for this ratio would indicate that more of the variance can be explained by the model selected, whereas a smaller value would suggest that the variance is more a result of signal noise. The F value with an optimized model thus selected can explain the actual variance and can distinguish this from a mere signal to noise interference.

From the response plots and ANOVA results, it was determined that drift tube temperature (F value 50.01%) and amplifier gain (F value 61.85%) of the ELSD instrument were the most important interacting parameters that positively influenced the accuracy of the assay (Fig. 4). This result indicates that the accuracy of the assay would increase with an increase in the drift tube temperature and amplifier gain. On the other hand, it was observed that the nebulizer pressure (F value 13.34%) impacted the accuracy of the assay negatively. Thus, a decrease in the nebulizer pressure would be favored to increase the accuracy of the assay. In the case of the % deviation of slope (DM), the significant factors were instrument gain (F value 13.85%) with a small contribution from drift tube temperature (F value 8.18%), and in the case of % deviation of slope (HPMC), the significant factor was determined to be drift tube temperature (F value 9.17%), and both factors had a positive impact on the % deviation of slope (HPMC and DM). Hence, from these analyses, % deviation values were found to decrease with an increase in the drift tube temperature and instrument gain. Furthermore, significant factors for sensitivity of the assay were determined to be pressure (F value 13.43%) and instrument gain (F value 3.65%). The impact of factors on % deviation of slope and sensitivity although significant (P < 0.05) was small compared to the influence of the factors on the accuracy of assay. In all these analyses, however, interactions were seen between the factors; hence to predict the desired response and the selection of the appropriate design space, the putative interactions must be considered.

Interactions Between the Factors

An interaction between factors may be defined as the failure of one variable to produce identical response at different levels of another variable. The ANOVA results demonstrated that the interaction between the drift tube temperature and instrument gain (termed AC) had a significant (P < 0.05) impact on the accuracy of the assay (Table IV). Although data in Table IV show an interaction between the drift tube temperature and nebulizer pressure (termed AB) that influenced accuracy response, this effect was not statistically significant. Furthermore, while a decrease in the accuracy data was seen with an increase in drift tube temperature at amplifier gain value of 10, a slight increase in the accuracy data was seen at gain value of 12. Therefore, we can conclude that the highest level of drift tube temperature and an intermediate level of the amplifier gain would provide the optimal response with respect to the accuracy of the assay. Interaction AB (between drift tube temperature and nebulizer pressure) had a small influence on the precision of the assay. The simple model selected sufficiently described the impact of the drift tube temperature, nebulizer gas pressure, and instrument gain and interactions of these factors on the accuracy, precision, peak area responses, and sensitivity of the assay.

Identification of Design Space

Desirability was defined as the optimal conditions of the ELSD instrument when % deviation of slope, precision, and accuracy were not greater than 0.05, 5, and 110, respectively. Desirability values range from 0 to 1, with 1 as the most desirable. From the 3D graphical plots of response surface for desirability obtained from the Stat-Ease® software (Figs. 4 and 5), it can be determined that drift tube temperature and amplifier gain of the ELSD instrument were the most important parameters that significantly and positively (positive coefficient) influenced the accuracy of the assay. Figure 5 shows that a desirability index of 0.93 was obtained at a high level of the three factors of temperature, instrument gain, and pressure, whereas at a lower gain value of 10, a desirability of only 0.6 could be achieved (Fig. 4). However, for maximum sensitivity of the assay at low concentrations of the analyte, a lower level of nebulizer pressure was suggested by the ANOVA analysis and hence was considered in the criteria for the overlay plot. Although this negative effect was of lower magnitude, it was observed to contribute to overall desirability of the assay in the overlay plot (Fig. 6). Therefore, we can conclude that all the three factors were statistically significant (P < 0.05) in order to obtain the optimal desired response. The optimal responses were obtained at the highest levels of drift tube temperature and instrument gain and an intermediate level of nebulizer pressure.

Method Validation of Assay for Mixed Samples of DM and HPMC

The optimized variables obtained from the multifactorial analysis described earlier were employed in the validation of the assay for mixed standards of DM and HPMC. In the method validation process, linearity, precision, accuracy, selectivity, sensitivity, and robustness of the assay were tested (40).

Linearity

As mentioned in selection of the response model, peak area responses are not typically linearly correlated to the sample concentrations; hence, a logarithmic model (log-log model) as described by Eq. 3 was employed (38). Within the optimized design space, the relationship between response peak area and analyte concentration was accurately fit by the log-log model with correlation coefficients of 0.991 and 0.996 for DM and HPMC in the mixed standards, respectively (Table IV). In contrast, when a linear model was applied, lower values for the correlation coefficients of 0.955 and 0.966 for DM and HPMC, respectively, were obtained along with large negative y-intercepts (results not shown).

Calibration curves for DM and HPMC demonstrated good linearity over the range of 1–32.5 μg in independent and mixed standards (Fig. 2). Table IV summarizes the results of the fitting of the response model selected to the peak area data for the independent and mixed standards. A standard error of 0.007 and 0.004 for the intercept and 0.014 and 0.015 for the slope between the independent and mixed standards was determined for DM and HPMC, respectively.

Sensitivity and Limits of Detection and Quantification

The limit of detection (LOD) is defined as the lowest concentration of the analyte that can be reliably detected. The FDA guidance(Guidance for Industry, ICH-Q2A) document specifies that LOD = 3.3 σ / S, where σ is the standard deviation of the response and S is the sensitivity defined as the slope of the calibration curve (25–28). The limit of quantification (LOQ) is similarly defined as the lowest concentration of the analyte that can be quantified with acceptable accuracy and precision. Based on the FDA guidance document, LOQ was calculated by 10 σ / S. For these calculations, the sensitivity was based on the slope of calibration curve for the three lowest concentrations. The sensitivity, LOD, and LOQ values obtained in the optimized design are listed in Table V.

Precision and Accuracy

Precision and accuracy were determined for samples of DM and HPMC within the optimized design space as described in section “Identification of Design Space.” For DM and HPMC at low concentration (50 μg/mL), the precision was determined to be 1.4% RSD and 3.8% RSD, respectively, and at the higher concentration (300 μg/mL), was determined to be 1.2% RSD and 4.7% RSD, respectively. In the samples (mixed standards), precision was also found to be similar with the obtained values of 1.8% RSD and 4.9% RSD for DM and HPMC, respectively.

Accuracy for the DM and HPMC samples was determined in the optimized design space. The recoveries in the calibration curve (1–32.5 μg; amount injected) ranged from 95% to 104% for DM and between 98% and 103% for HPMC analyzed within the optimized design space. Additionally, the %RSD (n = 4) of the accuracy obtained in the optimized design space were 3% and 2% for DM and HPMC, respectively. Accuracy was significantly decreased (9–21% RSD) when samples were run in ELSD conditions outside the design space. The data shows that within the optimized design space the developed assay for the mixed standards of DM and HPMC is robust and reproducible.

CONCLUSIONS

A fast, robust, and accurate assay was developed for the simultaneous quantification of polymer (HPMC) and surfactant (DM) in pure standards and mixed standards present in nanosuspension formulations. The design of experiments was used successfully to understand the influence of critical parameters of ELSD on the responses of the assay. A design space was also identified by using a full factorial DoE. It was found that an increase in temperature of the drift tube and the instrument gain increased the accuracy of the assay, while a decrease in the nebulizer pressure improved the sensitivity of the assay. An increase in the drift tube temperature and instrument gain decreased the % deviation of slopes for both DM and HPMC responses. On the other hand, the nebulizer gas showed no influence on the accuracy and peak area response of the assay. The assay was proven to be robust with respect to all three critical parameters within the optimized design space. The optimization of the assay using the factorial design of experiments led to the prediction of 93% desirability at the extreme levels of the two factors (drift tube temperature and instrument gain) and an intermediate level of the third factor (nebulizer pressure). Overall, the graphical mapping of the critical factors within the optimized design space helped to identify the best conditions to develop an assay that is both repeatable and robust. This method was used to quantify these pharmaceutical excipients (HPMC and DM) in nanosuspension formulations. The sensitivity and accuracy of this method is critical toward developing a mechanistic understanding for the physical stabilization process of nanosuspensions.

References

Zhang L, Somasundaran P, Maltesh C. Adsorption of n-dodecyl-beta-D-maltoside on solids. J Colloid Interface Sci. 1997;191(1):202–8.

Rabinow BE. Nanosuspensions in drug delivery. Nat Rev Drug Discov. 2004;3(9):785–96.

Verma S, Kumar S, Gokhale R, Burgess DJ. Physical stability of nanosuspensions: investigation of the role of stabilizers on Ostwald ripening. Int J Pharm. 2011;406(1–2):145–52.

Mishra B, Sahoo J, Dixit PK. Formulation and process optimization of naproxen nanosuspensions stabilized by hydroxy propyl methyl cellulose. Carbohydr Polym. 2015;127:300–8.

Bi Y, Liu J, Wang J, Hao J, Li F, Wang T, et al. Particle size control and the interactions between drug and stabilizers in an amorphous nanosuspension system. J Drug Deliv Sci Technol. 2015;29:167–72.

Lipinski CA. Drug-like properties and the causes of poor solubility and poor permeability. J Pharmacol Toxicol Methods. 2000;44(1):235–49.

Lipinski CA, Lombardo F, Dominy BW, Feeney PJ. Experimental and computational approaches to estimate solubility and permeability in drug discovery and development settings. Adv Drug Deliv Rev. 2001;46(1–3):3–26.

O’Driscoll CM, Griffin BT. Biopharmaceutical challenges associated with drugs with low aqueous solubility—the potential impact of lipid-based formulations. Adv Drug Deliv Rev. 2008;60(6):617–24.

Goddard ED. Polymer/surfactant interaction: interfacial aspects. J Colloid Interface Sci. 2002;256(1):228–35.

Niazi S, editor. Handbook of pharmaceutical manufacturing formulations. 2nd ed. New York: Informa Healthcare; 2004.

Delker G, Chen C, Miller RB. Size-exclusion chromatographic determination of hydroxypropyl methyl cellulose and polyethylene-glycol-400 in an ophthalmic solution. Chromatographia. 1995;41(5–6):263–6.

Whelan MR, Ford JL, Powell MW. Simultaneous determination of ibuprofen and hydroxypropylmethylcellulose (HPMC) using HPLC and evaporative light scattering detection. J Pharm Biomed Anal. 2002;30(4):1355–9.

Rashan J, Chen R. Developing a versatile gradient elution LC/ELSD method for analyzing cellulose derivatives in pharmaceutical formulations. J Pharm Biomed Anal. 2007;44(1):23–8.

Balzer D. Cloud point phenomena in the phase-behaviour of alkyl polyglucosides in water. Langmuir. 1993;9(12):3375–84.

Aoudia M, Zana R. Aggregation behavior of sugar surfactants in aqueous solutions: effects of temperature and the addition of nonionic polymers. J Colloid Interface Sci. 1998;206(1):158–67.

Zhang R, Zhang L, Somasundaran P. Study of mixtures of n-dodecyl-β-D-maltoside with anionic, cationic, and nonionic surfactant in aqueous solutions using surface tension and fluorescence techniques. J Colloid Interface Sci. 2004;278(2):453–60.

Carion-Taravella B, Chopineau J, Ollivon M, Lesieur S. Phase behavior of mixed aqueous dispersions of DPPC and dodecyl glycosides: aggregation states implicated in the micelle-to-vesicle transition. Langmuir. 1998;14(14):3767–77.

Bucci S, Fagotti C, Degiorgio V, Piazza R. Small-angle neutron-scattering study of ionic nonionic mixed micelles. Langmuir. 1991;7(5):824–6.

Boyd BJ, Krodkiewska I, Drummond CJ, Grieser F. Chiral glucose-derived surfactants: the effect of stereochemistry on thermotropic and lyotropic phase behavior. Langmuir. 2002;18(3):597–601.

Bergstrom M, Eriksson JC. A theoretical analysis of synergistic effects in mixed surfactant systems. Langmuir. 2000;16(18):7173–81.

Bashford MT, Woolley EM. Enthalpies of dilution of aqueous decyltrimethylammonium, dodecyltrimethylammonium, tetradecyltrimethylammonium and hexaadecyltrimethylammonium at 10 degrees C, 25 degrees C and 55 degrees C. J Phys Chem. 1985;89(14):3173–9.

Chen Y-P, Hsu M-C, Chien CS. Analysis of forensic samples using precolumn derivatization with (+)-1-(9-fluorenyl) ethyl chloroformate and liquid chromatography with fluorimetric detection. J Chromatogr A. 1994;672(1):135–40.

Descalzo A, Insani E, Pensel N. Light-scattering detection of phospholipids resolved by HPLC. Lipids. 2003;38(9):999–1003.

Nair LM, Konkel J, Thomas M, Koberda M. Comparison of electrospray ionization mass spectrometry and evaporative light scattering detections for the determination of Poloxamer 188 in itraconazole injectable formulation. J Pharm Biomed Anal. 2006;41(3):725–30.

Megoulas NC, Koupparis MA. Twenty years of evaporative light scattering detection. Crit Rev Anal Chem. 2005;35(4):301–16.

Megoulas NC, Koupparis MA. Development and validation of a novel LC/ELSD method for the quantitation of gentamicin sulfate components in pharmaceuticals. J Pharm Biomed Anal. 2004;36(1):73–9.

Megoulas NC, Koupparis MA. Development and validation of a novel HPLC/ELSD method for the direct determination of tobramycin in pharmaceuticals, plasma, and urine. Anal Bioanal Chem. 2005;382(2):290–6.

Miwa H, Yamamoto M, Asano T. High-performance liquid chromatographic analysis of fatty acid compositions of platelet phospholipids as their 2-nitrophenylhydrazides. J Chromatogr B Biomed Sci Appl. 1991;568(1):25–34.

Mengesha A, Bummer P. Simple chromatographic method for simultaneous analyses of phosphatidylcholine, lysophosphatidylcholine, and free fatty acids. AAPS PharmSciTech. 2010;11(3):1084–91.

Peterson JA, Lorenz LJ, Risley DS, Sandmann BJ. Amino acid analysis of peptides using HPLC with evaporative light scattering detection. J Liq Chromatogr Relat Technol. 1999;22(7):1009–25.

Schaneberg BT, Molyneux RJ, Khan IA. Evaporative light scattering detection of pyrrolizidine alkaloids. Phytochem Anal. 2004;15(1):36–9.

Sugawara T, Miyazawa T. Separation and determination of glycolipids from edible plant sources by high-performance liquid chromatography and evaporative light-scattering detection. Lipids. 1999;34(11):1231–7.

Zhou Q, Zhang L, Fu XQ, Chen GQ. Quantitation of yeast ceramides using high-performance liquid chromatography-evaporative light-scattering detection. J Chromatogr B Analyt Technol Biomed Life Sci. 2002;780(1):161–9.

Guidance for industry: Q2B validation of analytical procedures: methodology. In: (CDER) FDA CDER, editor. 1996.

Mathews BT, Higginson PD, Lyons R, Mitchell JC, Sach NW, Snowden MJ, et al. Improving quantitative measurements for the evaporative light scattering detector. Chromatographia. 2004;60(11–12):625–33.

Kang D, Lee S, Row K. Separation of phospholipids from soybean by NP-HPLC with ELSD. Korean J Chem Eng. 2002;19(5):818–20.

Keary CM. Characterization of METHOCEL cellulose ethers by aqueous SEC with multiple detectors. Carbohydr Polym. 2001;45(3):293–303.

Spacil Z, Folbrova J, Megoulas N, Solich P, Koupparis M. Simultaneous liquid chromatographic determination of metals and organic compounds in pharmaceutical and food-supplement formulations using evaporative light scattering detection. Anal Chim Acta. 2007;583(2):239–45.

Galanakis EG, Megoulas NC, Solich P, Koupparis MA. Development and validation of a novel LC non-derivatization method for the determination of amikacin in pharmaceuticals based on evaporative light scattering detection. J Pharm Biomed Anal. 2006;40(5):1114–20.

CDER, editor. Guidance for industry: ICH-Q2A: text on validation of analytical procedures, Center for Drug Evaluation and Research (CDER), March edition, 1995.

Acknowledgments

The authors would like to thank Dr. Eric Munson, Patrick DeLuca Endowed Professor at the University of Kentucky for the critical review for this paper as well as for the many useful discussions and suggestions. This paper is dedicated to the memory of Dr. Paul M. Bummer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patel, S.G., Bummer, P.M. Development of a Robust Method for Simultaneous Quantification of Polymer (HPMC) and Surfactant (Dodecyl β-D-Maltoside) in Nanosuspensions. AAPS PharmSciTech 17, 1182–1191 (2016). https://doi.org/10.1208/s12249-015-0451-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-015-0451-5