Abstract

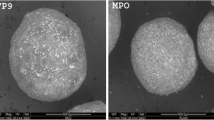

Purpose. The aim of this study was to improve the formation of spherical pectin pellets by investigating the effect of additive concentration in the granulation liquid on the shape and size of the products as well as by identifying an optimal additive concentration.Methods. High-methoxylated, low-methoxylated, and amidated low-methoxylated pectin types were evaluated in combination with different concentrations of methanol, ethanol, citric acid, lactic acid, and calcium chloride. Pellets were prepared in a power-consumption-controlled twin-screw extruder, then spheronized and dried. The moisture content of the extrudate was determined, and the final products were characterized by image analysis and sieving analysis. A cloud point test was employed for the identification of an optimal additive concentration.Results. The concentration of additive in the granulation liquid affected the moisture content of the extrudate and the shape, size, and mechanical stability of the pectin pellets. Improvements in the pellet characteristics are dependent on the pectin type employed. The 2 low-methoxylated pectins were more sensitive to concentration changes than was the high-methoxylated type. Above a certain threshold concentration, the quality of the pellets are improved. This additive concentration differs according to type of pectin and type of additive.Conclusion. It was demonstrated that there is a concentration-dependent interaction between pectin and substances added to the granulation liquid that can be utilized to improve the formation of spherical pectin pellets.

Similar content being viewed by others

References

Tho I, Kleinebudde P, Sande SA. Extrusion/spheronization of pectin-based formulations. I. Screening of important factors. tAAPS PharmSciTech. 2001;2(4) Article 26. Available from: http://www.aapspharmscitech.com

Ghebre Sellassie I. Pharmaceutical Pelletization Technology. New York: Marcel Dekker, 1989.

Kleinebudde P, Lindner H. Experiments with an instrumented twin-screw extruder using a single-step granulation extrusion process. Int J Pharm. 1993;94:49–58.

Baert L, Remon JP. Influence of amount of granulation liquid on the drug-release rate from pellets made by extrusion spheronization. Int J Pharm. 1993;95:135–141.

Vervaet C, Baert L, Remon JP. Extrusion-spheronization: a literature review. Int J Pharm. 1995;116:131–146.

Kleinebudde P. Use of a power-consumption-controlled extruder in the development of pellet formulations. J Pharm Sci. 1995;84:1259–1264.

Voragen AGJ, Pilnik W. Pectins. In: Stephen AM, ed. Food Polysaccharides and Their Applications. New York: Marcel Dekker, 1995:287–339.

Kjoniksen AL, Nystrom B, Lindman B. Dynamic viscoelasticity of gelling and nongelling aqueous mixtures of ethyl(hydroxyethyl)cellulose and an ionic surfactant. Macromol. 1998;31:1852–1858.

Millili GP, Schwartz JB. The strength of microcrystalline cellulose pellets: the effect of granulating with water ethanol mixtures. Drug Dev Ind Pharm. 1990;16:1411–1426.

Schroder M, Kleinebudde P. Structure of desintegrating pellets with regard to fractal geometry. Pharm Res. 1995;12:1694–1700.

Grant GT, Morris ER, Rees DA, Smith PJC, Thom D. Biological interactions between polysaccharides and divalent cations: the egg-box model. FEBS Letter. 1973;32:195–198.

Nystrom B, Kjoniksen AL, Iversen C. Characterization of association phenomena in aqueous systems of chitosan of different hydrophobicity. Adv Colloid Interface Sci. 1999;79:81–103.

Hileman GA, Upadrashta SM, Neau SH. Drug solubility effects on predicting optimum conditions for extrusion and spheronization of pellets. Pharm Dev Technol. 1997;2:43–52.

Author information

Authors and Affiliations

Additional information

Published: December 3, 2001

Rights and permissions

About this article

Cite this article

Tho, I., Kleinebudde, P. & Sande, S.A. Extrusion/spheronization of pectin-based formulations. II. Effect of additive concentration in the granulation liquid. AAPS PharmSciTech 2, 27 (2001). https://doi.org/10.1208/pt020427

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/pt020427