Abstract

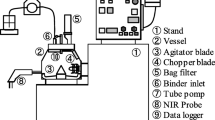

The aim of this study was to evaluate an instrumentation system for a bench scale fluid bed granulator to determine the parameters expressing the changing conditions during the spraying phase of a fluid bed process. The study focused mainly on four in-line measurements (dependent variables): fluidization parameter (calculated by inlet air flow rate and rotor speed), pressure difference over the upper filters, pressure difference over the granules (lower filter), and temperature of the fluidizing mass. In-line particle size measured by the spatial filtering technique was an essential predictor variable. Other physical process measurements of the automated granulation system, 25 direct and 12 derived parameters, were also utilized for multivariate modeling. The correlation and partial least squares analyses revealed significant relationships between various process parameters highlighting the particle size, moisture, and fluidization effect. Fluidization parameter and pressure difference over upper filters were found to correlate with in-line particle size and therefore could be used as estimates of particle size during granulation. The pressure difference over the granules and the temperature of the fluidizing mass expressed the moisture conditions of wet granulation. The instrumentation system evaluated here is an invaluable aid to gaining more control for fluid bed processing to obtain repeatable granules for further processing.

Similar content being viewed by others

References

M. E. Aulton, and M. Banks. Fluidised bed granulation—factors influencing the quality of the product. Int. J. Pharm. Technol. Prod. Manuf. 2:24–29 (1981).

M. Summers, and M. Aulton. Granulation. In M. Aulton (ed.), Pharmaceutics, The science of dosage form design, Churchill Livingstone, Spain, 2002, pp. 364–378.

O. Wørts. Wet granulation—fluidized bed and high shear techniques compared. Pharm. Technol. Eur. 10:27–30 (1998).

S. M. Iveson, J. D. Litster, K. Hapgood, and B. J. Ennis. Nucleation, growth and breakage phenomena in agitated wet granulation processes: a review. Powder Technol. 117:3–39 (2001).

T. Niskanen, J. Yliruusi, M. Niskanen, and O. Kontro. Granulation of potassium chloride in instrumented fluidized bed granulator—Part I: effect of flow rate. Acta Pharm. Fennica. 99:13–22 (1990).

P. Merkku, A.-S. Lindqvist, K. Leiviskä, and J. Yliruusi. Influence of granulation and compression process variables on flow rate of granules and on tablet properties, with special reference to weight variation. Int. J. Pharm. 102:117–125 (1993).

J. Rantanen, M. Känsäkoski, J. Suhonen, J. Tenhunen, S. Lehtonen, T. Rajalahti, J. P. Mannermaa, and J. Yliruusi. Next generation fluidized bed granulator automation. AAPS PharmSciTech. 1(2):26–36 (2000).

J. Rantanen, A. Jørgensen, E. Räsänen, P. Luukkonen, S. Airaksinen, J. Raiman, K. Hänninen, O. Antikainen, and J. Yliruusi. Process analysis of fluidized bed granulation. AAPS PharmSciTech. 2(4):13–20 (2001).

J. Rantanen, S. J. Laine, O. K. Antikainen, J.-P. Mannermaa, O. E. Simula, and J. Yliruusi. Visualization of fluid-bed granulation with self-organizing maps. J. Pharm. Biomed. Anal. 24:343–352 (2001).

T. Närvänen, K. Seppälä, O. Antikainen, and J. Yliruusi. A new rapid on-line imaging method to determine particle size distribution of granules. AAPS PharmSciTech 9(1):282–287 (2008).

T. Närvänen, T. Lipsanen, O. Antikainen, H. Räikkönen, J. Heinämäki, and J. Yliruusi. Gaining fluid bed process understanding by in-line particle size analysis. J. Pharm. Sci. (2008) doi:10.1002/jps.21486.

B. Scott, and A. Wilcock. Process analytical technology in the pharmaceutical industry: a toolkit for continuous improvement. PDA J. Pharm. Sci. Technol. 60:17–53 (2006).

D. M. Parikh. Airflow in batch fluid-bed processing. Pharm. Technol. 15:100–110 (1991).

D. Geldart. Types of gas fluidization. Powder Technol. 7:285–292 (1973).

D. Kunii, and O. Levenspiel. Fluidization Engineering, 2nd ed., Butterworth-Heinemann, Newton, 1991.

J. Z. H. Gao, D. B. Gray, R. Motheram, and M. A. Hussain. Importance of inlet air velocity in fluid bed drying of a granulation prepared in a high shear granulator. AAPS PharmSciTech. 1(4):1–3 (2000).

E. Räsänen, O. Antikainen, and J. Yliruusi. A new method to predict flowability using a microscale fluid bed. AAPS PharmSciTech. 4:418–424 (2003).

E. Räsänen, J. Rantanen, J.-P. Mannermaa, and J. Yliruusi. The characterization of fluidization behavior using a novel multichamber microscale fluid bed. J. Pharm. Sci. 93:780–791 (2004).

T. Lipsanen, O. Antikainen, H. Räikkönen, S. Airaksinen, and J. Yliruusi. Novel description of a design space for fluidised bed granulation. Int. J. Pharm. 345:101–107 (2007).

T. Närvänen, T. Lipsanen, O. Antikainen, H. Räikkönen, and J. Yliruusi. Controlling granule size by granulation liquid feed pulsing. Int. J. Pharm. 357:132–138 (2008).

N. Laitinen, O. Antikainen, J. Rantanen, and J. Yliruusi. New perspectives for visual characterization of pharmaceutical solids. J. Pharm. Sci. 93:165–176 (2004).

S. Wold, E. Johansson, and M. Cocchi. PLS. In H. Kubinyi (ed.), 3D-QSAR in Drug Design, Theory, Methods, and Applications, ESCOM Science, Ledien, 1993, pp. 523–550.

Food and Drug Administration FDA. Guidance for Industry; PAT—a framework for innovative pharmaceutical development, manufacturing and quality assurance (2004).

International Conference on Harmonisation. ICH harmonised tripartite guideline; Pharmaceutical Development Q8 (2005).

International Conference on Harmonisation. ICH harmonised tripartite guideline; Quality Risk Management Q9 (2005).

F. C. Harbert. Technical paper. Automatic control of dryers. Metron Tech. 4:1–5 (1972).

T. Lipsanen, O. Antikainen, H. Räikkönen, S. Airaksinen, and J. Yliruusi. Effect of fluidisation activity on end-point detection of a fluid bed drying process. Int. J. Pharm. 357:37–43 (2008).

Acknowledgements

This work was financially supported by the Finnish Funding Agency for Technology and Innovation TEKES and the Academy of Finland. Ritva Haikala and Henri Salokangas from Orion Pharma are acknowledged for contributing to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lipsanen, T., Närvänen, T., Räikkönen, H. et al. Particle Size, Moisture, and Fluidization Variations Described by Indirect In-line Physical Measurements of Fluid Bed Granulation. AAPS PharmSciTech 9, 1070–1077 (2008). https://doi.org/10.1208/s12249-008-9147-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-008-9147-4