Abstract

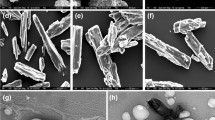

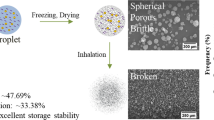

The aim of the present investigation was to prepare and evaluate the influence of adding fines on the in vitro performance of liposomal amikacin dry powder inhaler (AMK LDPI) formulations. Liposomes composed of hydrogenated soyaphosphatidylcholine, cholesterol and saturated soyaphosphatidylglycerol (AMK 1), or stearylamine (AMK 2) were prepared by a reverse phase evaporation technique, extruded to reduce size and separated from unentrapped drug. Purified liposomal dispersion was subjected to lyophilization using optimized cryoprotectant to achieve maximum percentage drug retentio (PDR). Lactose carrier in varying mass ratios with or without addition of fines in different mixing sequences was used to formulate AMK LDPI formulations. AMK LDPI formulations were characterized for angle of repose, compressibility index, dispersibility index, scanning electron microscopy, and fine perticle fraction (FPF). PDR was found to be 97.6%±2.2% for AMK1 and 98.5%±1.9% for AMK2 using sucrose as optimized cryoprotectant in lipid:sucrose ratio of 1∶4. Lactose carrier containing 10% fines (wt/wt) was found to be the optimum blend at 1∶5 mass ratio of liposome:lactose. The addition of fines and the order of mixing of fines were found to influence the FPF with significantly different device fractions. FPF of AMK LDPI formulations using Rotahaler as the delivery device at 30, 60, and 90 L/min were found to be 21.85%±2.2% and 24.6%±2.4%, 25.9% ±1.8% and 29.2%±2.1%, and 29.5%±2.6% and 34.2%±2.0% for AMK1 and AMK2, respectively. From the studies performed in this investigation, it was observed that liposomal charge, addition of fines and order of mixing fines, has a significant effect (P<.05) on in vitro deposition of drug from LDPI formulation.

Similar content being viewed by others

References

Kumana CR, Yuen KY. Parenteral aminoglycoside therapy, selection, administration and monitoring.Drugs. 1994;47:902–913.

Molitoris BA. Cell biology of aminoglycoside nephrotoxicity: newer aspects.Curr Opin Nephrol Hypertens. 1997;6:384–388.

Senior J. Fate and behavior of liposomes in vivo.Crit Rev Ther Drug Carrier Syst. 1987;3:123–193.

Patel HM. Serum opsonins and liposomes: their interaction and opsonophagocytosis.Crit Rev Ther Drug Carrier Syst. 1992;15:57–88.

Ganderton D. The generation of respirable cloud from coarse powder aggregates.J Biopharm Sci. 1992;3:101–105.

French DL, Edwards DA, Niven RW. The influence of formulation on emission, deaggregation and deposition of dry powders for inhalation.J Aerosol Sci. 1996;27:769–783.

Steckel H, Muller BW. In vitro evaluation of dry powder inhalers II: Influence of carrier particle size and concentration on in vitro deposition.Int J Pharm. 1997;154:31–37.

Staniforth JN. Improvement in dry powder inhaler performance: surface passivation effects. In:Proceedings of Drug Delivery to the Lungs VII. The Aerosol Society, London, UK; 1996:86–89.

Zeng XM, Tee SK, Martin GP, Marriott C. Effect of mixing procedure and particle size distribution of carrier particles on the deposition of salbutamol sulphate from dry powder inhaler formulations. In:Proceedings of Drug Delivery to the Lungs VII. The Aerosol Society, London, UK; 1996:40–43.

Lucas P, Anderson K, Staniforth JN. Protein deposition from dry powder inhalers: fine particle multiplets as performance modifiers.Pharm Res. 1998;15:562–569.

Kim JC, Kim JD. Preparation by spray drying of amphotericin B-phospholipid composite particles and their anticellular activity.Drug Deliv. 2001;8:143–147.

Farr SJ, Kellaway IW, Carman-Meakin B. Assessing the potential of aerosol generated liposomes from pressurized pack formulations.J Control Release. 1987;5:119–127.

McCallion ONM, Taylor KMG, Bridges PA, Thomas M, Taylor AJ. Jet nebulizers for pulmonary drug delivery.Int J Pharm. 1996;130:1–11.

Davidson IG, Langner EJ, Plowman SV, Blair JA. Release mechanism of insulin encapsulated in trehalose ester derivative microparticles delivered via inhalation.Int J Pharm. 2003;254:211–222.

Alcock R, Blair JA, O'Mahony DJ, Raoof A, Quirk AV. Modifying the release of leuprolide from spray dried OED microparticles.J Control Release. 2002;82:429–440.

Fiegel J, Fu J, Hanes J. Poly(ether-anhydride) dry powder aerosols for sustained drug delivery in the lungs.J Control Release. 2004;96:411–423.

Surendrakumar K, Martyn GP, Hodgers EC, Jansen M, Blair JA. Sustained release of insulin from sodium hyaluronate based dry powder formulations after pulmonary delivery to beagle dogs.J Control Release. 2003;91:385–394.

Sethuraman VV, Hickey AJ. Powder properties and their influence on dry powder inhaler delivery of an antitubercular drug.AAPS PharmSciTech. 2002;3:E28.

Fu J, Fiegel J, Krauland E, Hanes J. New polymeric carriers for controlled drug delivery following inhalation or injection.Biomaterials. 2002;23:4425–4433.

Joshi M, Misra A. Dry powder inhalation of liposomal Ketotifen fumarate: formulation and characterization.Int J Pharm. 2001;223:15–27.

Joshi MR, Misra A. Liposomal budesonide for dry powder inhaler: preparation and stabilization.AAPS PharmSciTech. 2001;2:E25.

Cortesi R, Esposito E, Gambarin S, Telloli P, Menegatti E, Nastruzzi C. Preparation of liposomes by reverse-phase evaporation using alternative organic solvent.J Microencapsul. 1999;16:251–256.

Rizk M, Younis F. Spectrophotometric assay of certain aminoglycoside antibiotics using chloranil.Anal Lett. 1984;17:1803–1809.

Carr RL. Evaluating flow properties of solids.Chem Eng. 1965;72:163–168.

British Pharmacopoeia Commission. Pressurized inhalations: deposition of the emitted dose. In:British Pharmacopoeia, Vol 2. London, UK: Her Majesty's Stationary Office; 1993:A194-A196.

Hino T, Serigano T, Yamamoto H, Takeuchi H, Niwa T, Kawashima Y. Particle design of wogon extract dry powder for inhalation aerosols with granulation method.Int J Pharm. 1998;168:59–68.

Betageri GV, Jenkins SA, Parsons DL.Liposome Drug Delivery Systems. Lancaster, PA: Technomic Publishing Company, 1993:16–17.

Staniforth JN. Preformulation aspects of dry powder aerosols. In: Byron PR, Dalby RN, Farr SJ, eds.Respiratory Drug Delivery V. Buffalo Grove, IL: Interpharm Press; 1996: 65–73.

Gonda I. Physico-chemical principles in aerosol-delivery. In: Crommelin DJA, Midha KK, eds.Topics in Pharmaceutical Sciences. Stuttgart, Germany: Medipharm Scientific Publishers: 1992: 95–115.

Hickey AJ.Inhalation Aerosols—Physical and Biological Basis for Theerapy. New York, NY: Marcel Dekker Inc; 1996:441–473.

Hamaker HC. London-van der Waals forces attraction between spherical particles.Physica (Utrecht). 1937;4:1058–1072.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shah, S.P., Misra, A. Liposomal amikacin dry powder inhaler: Effect of fines on in vitro performance. AAPS PharmSciTech 5, 65 (2004). https://doi.org/10.1208/pt050465

Received:

Accepted:

DOI: https://doi.org/10.1208/pt050465