Abstract

In this paper, we report for the first time the use of onion (Allium cepa) in the biosynthesis of silver nanoparticles (AgNPs) under microwave irradiation. Influence of various reaction parameters such as microwave irradiation power and microwave irradiation time was analyzed. The synthesized nanomaterial was characterized by UV-visible absorption spectroscopy and Fourier transform infrared spectrum analysis. X-ray diffraction (XRD) and transmission electron microscopy (TEM) confirm the formation and the crystalline nature of the synthesized nanomaterial. Further, these nanoparticles were found to exhibit high antibacterial activity against two different strains of bacteria Escherichia coli (Gram negative) and Staphylococcus aureus (Gram positive).

Similar content being viewed by others

Background

Most of the used chemical and physical methods for the production of nanoparticles are expensive and avoid the use of toxic solvents in the synthesis protocol which may pose environmental risk [1–5]. Therefore, the development of clean, biocompatible, non-toxic and eco-friendly methods for nanoparticle synthesis deserves merit. The use of biological organisms such as microorganisms [6, 7] and plant extracts [8, 9] have been suggested as possible eco-friendly alternatives to chemical and physical methods. Plant extracts may provide a better alternative to silver nanoparticle production since most microorganisms that have been reportedly used for the synthesis of silver nanoparticles are pathogenic to either plants and/or human [10, 11]. Moreover, plant extracts could be advantageous over microorganism synthesis because there is no need to elaborated process of culturing and maintaining the cell, and they are of low cost, fast, efficient and generally lead to the formation of crystalline nanoparticles with a variety of shapes and sizes.

Microwave heating method is especially important as its use provides increased reaction kinetics, rapid initial heating and, hence, enhanced reaction rates culminating in clean reaction products with rapid consumption of starting materials and higher yields [12]. Recently, microwave heating has been explored as a promising technique for nanoparticle synthesis. In the present study, we first report the reduction of silver ions using aqueous onion (Allium cepa) extract under microwave irradiation for facile and fast phytosynthesis of silver nanoparticles (AgNPs). To the best of our knowledge, no reports pertaining to a microwave method of using onion (A. cepa) extract are yet available. The antibacterial property of phytosynthesized silver nanoparticles was also investigated.

Results and discussion

Localized surface plasmon resonance

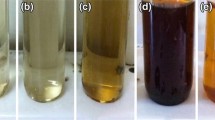

The formation of silver nanoparticles was initially confirmed using UV-visible spectroscopy technique which has been frequently used to characterize the synthesized metallic nanoparticles due to surface plasmon resonance phenomenon. Figure 1 shows the UV-visible (UV-vis) absorption spectra recorded for onion extract before (curve A) and after (curve B) the reaction with 10-1 M AgNO3 solution in a microwave oven at 100% power of 300 W and frequency of 2,450 MHz for 30 s. Only colloidal suspensions after reduction (curve B) show strong resonance at 450 nm, and the onion extract solution does not. It might arise from the excitation of longitudinal plasmon vibrations in silver NPs in the solution. The digital photograph in the inset of Figure 1 shows the change in the colour of the onion extract from pale yellow to brown. The characteristic brown colour of silver solutions provided a convenient spectroscopic signature to indicate the formation of silver nanoparticles in the reaction mixture. Apart from this, other peaks have been observed in the UV range corresponding to 250 and 350 nm which may be attributed to the presence of proteins in the solution released by the onion extract [13]. In order to better clarify the influence of microwave powers on the formation of AgNPs, we performed experiments at different power levels. From the UV-vis curves of AgNPs synthesized with different microwave power levels (Figure 2), we observe that at lower power levels (100 and 150 W) no distinct surface plasmon resonance peak is observed, suggesting that at lower microwave power the temperature rising rate was so low that the formation of silver nanoparticles could not occur at a short time. Thirty seconds was not sufficient for reducing AgNO3 to AgNPs. As the power levels increases, surface plasmon peak begins to evolve, and at 500 W, a well-defined and broad peak is observed. Furthermore, it should be noted that there was an increase in intensity of the adsorption peaks until 500 W as a function of microwave power levels without any shift in the peak wavelength indicating the increase of the obtained AgNP concentrations. Supported by those reports, it is possible to affirm that at constant irradiation time (30 s) synthesis at 500 W of power allows to obtain a greater particle concentration than at 225 W. Also, when microwave power was 150 W, time was not sufficient to form AgNPs. This may be because at high microwave power level, the temperature rising rate is extremely high and the time of the maximum temperature rising rate is very short. Thus, at high microwave power levels, the microwave energy absorption of the solution becomes greater, and the reaction time becomes shorter, promoting a greater amount of nuclei, which in turn gives a greater concentration of particles in the dispersion. These results revealed that the adjustment of microwave power had no obvious effect on the peak location of surface plasmon resonance (SPR) absorption band of AgNPs, but it could affect the required reaction time for preparing the AgNPs. The experiment was completed at 300 W under two different microwave irradiation times (30 and 60 s) for examining the dependence of AgNP formation on the applied irradiation time at the initial stage of reaction. It was evidently found that the intensities of SPR absorption peaks increased with the increasing reaction time, indicating the enhancement of concentration of the synthesized AgNPs (Figure 3). Additionally, it was also observed that there was a blue shift in the characteristic surface plasmon resonance band of AgNPs from 445 to 427 nm with increase in time from 30 to 60 s. This clearly indicates the reduction in the particles size as the applied irradiation time increases [14].

Identification of functional groups

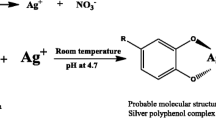

Fourier transform infrared spectroscopy (FTIR) measurements were carried out to identify the possible biomolecules responsible for reduction, capping and efficient stabilization of the Ag nanoparticles. The representative FTIR spectra of the onion extract untreated with silver nitrate (control) and silver nanoparticles were shown in Figure 4. The bands between the wavenumbers of 1,800 to 750 cm-1 (fingerprint regions) of the spectrum for the control reflected the biochemical compositions, especially the moieties of carbohydrate, lipid, protein and polyphenols in A. cepa extract.

An IR band assignment is based on the literature using [15–18]. The distinctive peak at the wavenumber of 1,648 cm-1 is attributed to the amide I vibration and to the presence of H2O (H-O-H bending). The band at 1,406 cm-1 is due to CH3 asymmetric deformation. The minor band at 1,253 cm-1 is from amide III (random coil) for protein. The wavenumber region between 1,200 and 950 cm-1 contains functional groups mainly from carbohydrate. For example, the 'shoulder’ peak at 1,105 cm-1 and the band at a wavenumber of 1,055 cm-1 are from the C-OH stretching band of oligosaccharide residue. The bands at both 925 and 869 cm-1 are assigned to the left-handed helix DNA (Z form). The band at 813 cm-1 is caused by ring CH deformation which could also reflect structural information about polyphenols. For the higher wavenumbers (lower frequencies), the peak at 3,402 cm-1 is due to N-H stretching of proteins and O-H stretching of carbohydrates and water, while the peak at 2,933 cm-1 is due to CH2 antisymmetric stretch of methyl groups mainly from lipids. By comparing FTIR spectra of both silver nanoparticles and plant extract, it was found that many peaks obtained by the plant extract have been repeated in the FTIR spectrum of AgNPs with changes in the position as well as in the intensity of absorption bonds. After the synthesis of AgNPs, the absorption peaks at 3,402 and 1,055 cm-1 corresponding to NH, OH and C-O observed in plant extract get narrower and shifted to higher frequency regions, while those at 2,933 and 1,648 cm-1 corresponding to CH3 and CO decrease in intensity and shifted to low-frequency regions. These structural changes indicated that the reduction and the stabilization of silver nanoparticles proceed via these groups. The bands obtained at 3,400 cm-1 and between 1,700 and 1,400 cm-1 in the AgNPs spectra corresponding to the amide groups which are the most important band protein infrared spectrum confirm that the phytoconstituents of the plant (mostly protein) interact with the silver nanoparticles. The most useful IR band for the direct measurement of structure of protein is the band found at 1,648 cm-1 which is related to the maximum absorbance of the amide I of protein [19]. After the reaction, this peak became sharp and decreased in intensity and shifted to 1,641 cm-1. Similarly, there is decreased band intensity at 1,253 cm-1 due to amide III band. This indicated that the structure of the proteins is affected as a consequence of binding with the silver nanoparticles. This evidences suggested that the silver nanoparticles synthesized from the onion extract are surrounded by some proteins through either free amine groups or cystein residues [20], and therefore, stabilization of AgNPs by coating of protein is possible (Figure 5).

Nanoparticle morphology and size distribution

Transmission electron microscopy (TEM) as a powerful tool has been extensively used to investigate the morphologies and size distribution of the synthesized AgNPs. Figure 5 showed a typical TEM image of AgNPs synthesized by microwave irradiation for 30 s at 300 W. The micrograph show individual silver particles as well as a number of aggregates. The morphology of the AgNPs is variable, with majority of them spherical. Under careful observation, we can see that the nanoparticles are not in direct contact even within the aggregates. They are surrounded by a thin layer of organic material, suggesting that biomolecules, such as proteins in onion extract, capped the silver nanoparticles which appear to be characteristic of AgNPs prepared by plant extracts [21, 22]. Figure 6 shows the particle size distribution of the prepared nanoparticles taken from a large number of particles. It can be seen that the particles range in size from 17 to 57 nm with mean size of 38.7 nm.

Crystal structure analysis

The X-ray diffraction (XRD) has proven to be a valuable research tool to prove the formation of silver NPs, determining the crystal structure of the prepared AgNPs and to calculate the crystalline particle size. Figure 7 displayed the diffraction peaks of pure onion extract not reacted with silver nitrate (control) (pattern A) and silver nanoparticle synthesized by microwave irradiation for 30 s at 300 W (pattern B). No diffraction peaks are shown in the pattern of the control thin film of onion extract. After the reaction, the diffraction peaks at 2θ = 38.2°, 44.4°, 64.6° and 77.5° assigned to the (111), (200), (220) and (311) planes of face-centred cubic crystal structure (fcc), respectively, similar to that of the Joint Commitee on Powder Diffraction Standards (JCPDS no. 01-087-0597) were obtained. A few additional and yet unassigned peaks (*) were also noticed in the vicinity of the characteristic peaks of silver. These peaks indicated that some crystalline compounds other than silver were also present in the final system. These products probably originated from the raw material used. These unidentified crystalline peaks are also apparent in many works [23–25]. Therefore, the formation of silver nanocrystals was confirmed by the above XRD results. The peak corresponding to the (111) planes was in the predominant orientation. This indicates that the prepared AgNPs may be enriched in (111) facets, and thus, the (111) plane seems to be preferentially oriented parallel to the surface of the supporting substrate [26]. The average particle size has been estimated using the well-known Scherrer formula, D = kλ/β cosθ, where D is the particle diameter, k is a constant equals 1, λ is the wavelength of X-ray source (0.1541 nm), β is the full width at half maximum (FWHM) and θ is the diffraction angle which corresponds to the lattice plane (111). The calculated particle size was 43.37 nm. The particle size obtained from XRD agreed well with that obtained from TEM.

Antimicrobial activity

The antibacterial activity of the extract and AgNPs was examined against both Gram-negative and Gram-positive bacteria by disc diffusion test. The radial diameter of the inhibition zone of E. coli and S. aureus by AgNPs are 20 and 16 mm, respectively (Figure 8). The discs filled with onion extract alone did not show any zone of inhibition suggesting that at the concentration used for synthesis of AgNPs onion extract showed no antibacterial activity, but silver AgNPs synthesized from the extract exhibited good antibacterial activity. The silver nanoparticles show efficient antibacterial property due to their extremely large surface area, which provides better contact with microorganisms. The nanoparticles release silver ions in the bacterial cells, which enhance their bacterial activity [27]. By comparative evaluation of the effects of AgNPs on both the test organisms, it was found that the Gram-negative bacterium E. coli showed maximum zone of inhibition (20 mm) which may be due to the cell wall of Gram-positive bacteria composed of a thick peptidoglycan layer, which consists of linear polysaccharide chains cross-linked by short peptides thus forming more rigid structure leading to difficult penetration of the silver nanoparticle compared to the Gram-negative bacteria where the cell wall possesses thinner peptidoglycan layer [28].

Conclusion

In the present work, we have developed a fast, eco-friendly and convenient method for the synthesis of silver nanoparticles using onion (A. cepa) extract in a microwave oven under different situations. No chemical reagent or surfactant template was required in this method, which consequently enable the bioprocess with the advantage of being environmental friendly. The developed nanoparticles were characterized by UV-vis, TEM, XRD and FTIR measurements and showed good antibacterial activity. This rapid synthesis technique can be a promising method for the preparation of other metal nanoparticles and can be valuable in environmental, biotechnological, pharmaceutical and medical applications.

Methods

Preparation of plant extract

Fresh yellow onion (A. cepa) was purchased from a traditional market in Casablanca, Morocco. The outer two to three layers of the scale were removed manually to eliminate senescent, damaged or contaminated tissue. The remaining portions of the bulbs (50 g) was cut into small pieces and pureed in a blender/food. The aqueous extract was prepared by boiling the puree with 100-ml deionized water for 10 min before finally decanting and filtering it. The filtrate was cooled to room temperature and used as reducing agent and stabilizer.

Phytosynthesis of silver nanoparticles

Silver nanoparticles were synthesized by a microwave heating system (MARS-5, CEM Corporation, Matthews, NC, USA). In a typical experimental procedure, 5 ml of fresh aqueous solution of onion extract was added to 50 ml of 0.1 M AgNO3 solution under stirring. The mixed solution was conveyed into a HP-500 PFTE reactor (Palo Alto, CA, USA) and placed in a microwave oven. After microwave irradiation treatment, the resulting colloidal silver solutions were naturally cooled to room temperature. In the reduction process, some experimental parameters such as microwave power and irradiation time were adjusted to investigate their effect on the formation of AgNPs.

Characterization

The bioreduction of silver ion in the solution was monitored using Perkin Elmer Lambda 2 double beam UV-visible spectrometer (Waltham, MA, USA) against distilled water as blank. After that, the solution mixture was centrifuged at 5,500 rpm for 15 min and subsequently redispersed in distilled water to get rid of any uncoordinated biological molecules. This process of centrifugation was repeated thrice to ensure better separation of the silver nanoparticles. The purified dried powders were then used for further characterization. The FTIR spectral measurements were carried out on Bruker Tensor 27 spectrophotometer (Ettlingen, Germany) in KBr pellets, and the XRD analysis was obtained using Bruker D8 Advance powder X-ray diffractometer. The size of nanoparticles was confirmed using TEM images obtained with a Phillips Tecnai G2 transmission electron microscope (Amsterdam, The Netherlands).

Antimicrobial activity

The silver nanoparticles synthesized using onion extract was tested for antimicrobial activity by agar disc diffusion method against pathogenic bacteria Escherichia coli (Gram negative), and Staphylococcus aureus (Gram positive). The pure cultures of bacteria were sub-cultured on nutrient agar medium. Each strain was swabbed uniformly onto the individual plates using sterile cotton swabs. Filter paper discs (Whatman no. 3, 6-mm diameter) were sterilized by autoclaving. Fifty microlitres of nanoparticle solution was loaded onto each paper discs and allowed to air dry. The dry discs were placed on the previously inoculated agar. After incubation at 37°C for 24 h, the different levels of zone of inhibition of bacteria were measured.

Abbreviations

- FTIR:

-

Fourier transform infrared spectroscopy

- TEM:

-

Transmission electron microscopy

- XRD:

-

X-ray diffraction

- NPs:

-

Nanoparticles

- SPR:

-

Surface plasmon resonance

- UV-vis:

-

UV-visible.

References

Parikh RY, Singh S, Prasad BLV, Patole S, Sastry M, Shouche YS: Extracellular synthesis of crystalline silver nanoparticles and molecular evidence of silver resistance from Morganella sp: towards understanding biochemical synthesis mechanism. Chem. BioChem. 2008, 9: 1415–1422.

Nadagouda MN, Hoag G, Collins J, Varma RS: Green synthesis of Au nanostructures at room temperature using biodegradable plant surfactants. Cryst. Growth Des. 2009, 9: 4979–4983. 10.1021/cg9007685

Mukherjee P, Roy M, Mandal BP, Dey GK, Mukherjee PK, Khatak J, Thyagi AK, Kale SP: Green synthesis of highly stabilized nanocrystalline silver particles by a non-pathogenic and agriculturally important fungus T. asperellum . Nanotechnology 2008, 19: 075103. doi:10.1088/0957–4484/19/7/075103 doi:10.1088/0957-4484/19/7/075103 10.1088/0957-4484/19/7/075103

Tripathy A, Raichur AM, Chandrasekaran N, Prathna TC, Mukherjee A: Process variables in biomimetic synthesis of silver nanoparticles by aqueous extract of Azadirachta indica (Neem) leaves. J. Nanopart. Res 2010, 12: 237–246. 10.1007/s11051-009-9602-5

Lee KJ, Jun BH, Choi J, Lee Y, Joung J, Oh YO: Environmentally friendly synthesis of organic-soluble silver nanoparticles for printed electronics. Nanotechnology 2007, 18: 335601. doi: 10.1088/0957–4484/18/33/335601 doi: 10.1088/0957-4484/18/33/335601 10.1088/0957-4484/18/33/335601

Otari SV, Patil RM, Nadaf NH, Ghosh SJ, Pawar SH: Green biosynthesis of silver nanoparticles from an actinobacteria Rhodococcus sp. Mater. Lett. 2012, 72: 92–94.

Zaki S, El Kady MF, Abd-El-Haleem D: Biosynthesis and structural characterization of silver nanoparticles from bacterial isolates. Mater. Res. Bull. 2011, 46: 1571–1576. 10.1016/j.materresbull.2011.06.025

Philip D: Green synthesis of gold and silver nanoparticles using Hibiscus rosa sinensis . Phys. E. 2010, 42: 1417–1424. 10.1016/j.physe.2009.11.081

Kumar P, Singh P, Kumari K, Mozumdar S, Chandra RA: Green approach for the synthesis of gold nanotriangles using aqueous leaf extract of Callistemon viminalis . Mater. Lett. 2011, 65: 595–597. 10.1016/j.matlet.2010.11.025

Silver S: Bacterial silver resistance: molecular biology and uses and misuses of silver compounds. FEMS Microbiol. Rev. 2003, 27: 341–353. 10.1016/S0168-6445(03)00047-0

Ahmed A, Mukherjee P, Senapati S, Mandal D, Khan MI, Kumar R, Satyr M: Extracellular biosynthesis of silver nanoparticles using the fungus Fusarium oxysporum . Colloids. Surface. B. 2003, 28: 313–318. 10.1016/S0927-7765(02)00174-1

Nadagouda MN, Speth T, Varma RS: Microwave-assisted green synthesis of silver nanostructures. Acc. Chem. Res. 2011, 44: 469–478. 10.1021/ar1001457

Rastogi L, Arunachalam J: Sunlight based irradiation strategy for rapid green synthesis of highly stable silver nanoparticles using aqueous garlic ( Allium sativum ) extract and their antibacterial potential. Mater. Chem. Phys. 2011, 129: 558–563. 10.1016/j.matchemphys.2011.04.068

Arshi N, Ahmed F, Kumar S, Anwar MS, Lu J, Koo BH, Lee CG: Microwave assisted synthesis of gold nanoparticles and their antibacterial activity against Escherichia coli ( E. coli ). Curr. Appl. Phys. 2011, 11: S360-S363. 10.1016/j.cap.2010.11.102

Lu X, Wang J, Al-Qadiri HM, Ross CF, Powers JR, Tang J, Rasco BA: Determination of total phenolic content and antioxidant capacity of onion ( Allium cepa ) and shallot ( Allium oschaninii ) using infrared spectroscopy. Food Chem. 2011, 129: 637–644. 10.1016/j.foodchem.2011.04.105

Chiriboga L, Xie P, Vigorita V, Zarou D, Diem M: Infrared spectroscopy of human tissue. II. A comparative study of spectra of biopsies of cervical squamous epithelium and of exfoliated cervical cells. Biospectroscopy 1998, 4: 54–59.

Schulz H, Baranska M: Identification and quantification of valuable plant substances by IR and Raman spectroscopy. Vib. Spectrosc. 2007, 43: 13–25. 10.1016/j.vibspec.2006.06.001

Gorinstein S, Park YS, Heo BG, Namiesnik J, Leontowicz H, Leontowicz M, Ham KS, Cho JY, Kang SG: A comparative study of phenolic compounds and antioxidant and antiproliferative activities in frequently consumed raw vegetables. Eur. Food Res. Technol. 2009, 228: 903–911. 10.1007/s00217-008-1003-y

Dong A, Huang P, Caughey B, Caughey WS: Infrared analysis of ligand-and oxidation-induced conformational changes in hemoglobins and myoglobins. Arch. Biochem. Biophys. 1995, 316: 893–898. 10.1006/abbi.1995.1120

Gole A, Dash C, Ramakrishnaan V, Sainkar SR, Mandal AB, Rao M, Sastry M: Pepsin-gold colloid conjugates: preparation, characterization, and enzymatic activity. Langmuir 2001, 17: 1674–1679. 10.1021/la001164w

Zayed MF, Eisa WH, Shabaka AA: Malva parviflora extract assisted green synthesis of silver nanoparticles. Spectrochim. Acta. Part. A. 2012, 98: 423–428.

Ghoreishi SM, Behpour M, Khayatkashani M: Green synthesis of silver and gold nanoparticles using Rosa damascena and its primary application in electrochemistry. Phys. E. 2011, 44: 97–104. 10.1016/j.physe.2011.07.008

Arockiya Aarthi Rajathi F, Partthiblan C, Ganesh Kumar V, Anantharaman P: Biosynthesis of antibacterial gold nanoparticles using brown alga, Stoechospermum marginatum (kützing). Spectrochim. Acta. Part. A. 2012, 99: 166–173.

Kumar R, Roopan SM, Prabhakarn A, Khanna VG, Chakroborty S: Agricultural waste Annona squamosa peel extract: biosynthesis of silver nanoparticles. Spectrochim. Acta. Part. A. 2012, 90: 173–176.

Philip D, Unni C: Extracellular biosynthesis of gold and silver nanoparticles using Krishna tulsi ( Ocimum sanctum ) leaf. Phys. E. 2011, 43: 1318–1322. 10.1016/j.physe.2010.10.006

Germain V, Li J, Ingert D, Wang ZL, Pileni MP: Stacking faults in formation of silver nanodisks. J. Phys. Chem. B 2003, 107: 8717–8720. 10.1021/jp0303826

Morones JR, Elechiguerra JL, Camacho A, Ramirez JT: The bactericidal effect of silver nanoparticles. Nanotechnology 2005, 16: 2346–2353. 10.1088/0957-4484/16/10/059

Rai M, Yadav A, Gade A: Silver nanoparticles as a new generation of antimicrobials. Biotechnol. Adv. 2009, 27: 76–83. 10.1016/j.biotechadv.2008.09.002

Acknowledgements

The authors gratefully acknowledge the financial support from the Islamic Azad University. They are also thankful to the Centre for Analysis and Research of the University Hassan II Mohammedia-Casablanca Morocco and to the Unit of Support for Technical and Scientific Research of the National Centre of Scientific and Technical Research (UATRS, CNRST-Morocco) for UV-vis, XRD, FTIR and TEM measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

YA designed the related subject, managed all of the processes, conceived this study and drafted the manuscript. AE, HA and JM carried out the experiments and organized the data. AEB and KB coordinated the project and discussed the results. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Abboud, Y., Eddahbi, A., El Bouari, A. et al. Microwave-assisted approach for rapid and green phytosynthesis of silver nanoparticles using aqueous onion (Allium cepa) extract and their antibacterial activity. J Nanostruct Chem 3, 84 (2013). https://doi.org/10.1186/2193-8865-3-84

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2193-8865-3-84