Abstract

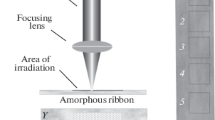

The morphological features of changes in the surface layers of melt-quenched ribbons of an Fe53.3Ni26.5B20.2 amorphous alloy are studied as functions of the nanopulsed laser treatment intensity. The behavior of the mechanical properties of the alloy (hardness, elastic modulus, elastic recovery parameter of indentation under indenter) is investigated by depth-sensing indentation along the radius of a circular laser irradiation zone at various numbers of pulses. Effective laser irradiation parameters, which promote an increase in the mechanical properties of the surface layer of the amorphous Fe53.3Ni26.5B20.2 alloy, are found.

Similar content being viewed by others

REFERENCES

A. Inoue, “Stabilization of metallic supercooled liquid and bulk amorphous alloys,” Acta Materialia 48, 279–306 (2000).

A. M. Glezer, I. E. Permyakova, V. V. Gromov, and V. V. Kovalenko, Mechanical Behavior of Amorphous Alloys (SibGIU, Novokuznetsk, 2006).

F. E. Luborsky, Amorphous Metallic Alloys (Butterworth, London, 1983).

I. Permyakova and A. Glezer, “Mechanical behavior of Fe- and Co-based amorphous alloys after thermal action,” Metals 12 (2), 297 (2022).

I. E. Permyakova, “Effect of laser radiation on the structure and properties of amorphous alloys: a review,” Bull. Russ. Acad. Sci.: Phys. 82, 1086–1095 (2018).

H. Huang, M. Jiang, and J. Yan, “Softening of Zr-based metallic glass induced by nanosecond pulsed laser irradiation,” J. Alloys Compd. 754, 215–221 (2018).

Y. Qian, M. Jiang, Z. Zhang, H. Huang, J. Hong, and J. Yan, “Microstructures and mechanical properties of Zr-based metallic glass ablated by nanosecond pulsed laser in various gas atmospheres,” J. Alloys Compd. 901, 163717 (2022).

N. N. Sitnikov, A. V. Shelyakov, I. A. Khabibullina, and K. A. Borodako, “Two-way shape memory effect in rapidly quenched highly doped alloys of TiNi–TiCu system upon laser treatment,” Bull. Russ. Acad. Sci.: Phys. 82 (9), 1136–1142 (2018).

K. A. Borodako, A. V. Shelyakov, N. N. Sitnikov, A. V. Irzhak, N. Y. Tabachkova, A. A. Ivanov, and V. V. Koledov, “Application of laser radiation for creation of metamaterial based on rapidly quenched shape memory TiNiCu alloy,” J. Phys.: Conf. Ser. 1461 (1), 012018 (2020).

S. Moradi, S. Kamal, P. Englezos, and S. G. Hatzi-kiriakos “Femtosecond laser irradiation of metallic surfaces: effects of laser parameters on superhydrophobicity,” Nanotechnology 24 (41), 415302 (2013).

A. H. A. Lutey, L. Gemini, L. Romoli, G. Lazzini, F. Fuso, M. Faucon, and R. Kling, “Towards laser-textured antibacterial surfaces,” Sci. Reports 8 (1), 10112 (2018).

Z. Ou, M. Huang, and F. Zhao, “The fluence threshold of femtosecond laser blackening of metals: the effect of laser-induced ripples,” Optics Laser Technol. 79, 79–87 (2016).

J. Yao, C. Zhang, H. Liu, Q. Dai, L. Wu, S. Lan, A. V. Gopal, V. A. Trofimov, and T. M. Lysak, “Selective appearance of several laser-induced periodic surface structure patterns on a metal surface using structural colors produced by femtosecond laser pulses,” Appl. Surf. Sci. 258 (19), 7625–7632 (2012).

R. Drevinskas, M. Beresna, J. Zhang, A. G. Kazanskii, and P. G. Kazansky, “Ultrafast laser-induced metasurfaces for geometric phase manipulation,” Adv. Opt. Mater. 5 (1), 1600575 (2017).

A. Makino, T. Kubota, C.T. Chang, M. Makabe, and A. Inoue, “FeSiBP bulk metallic glasses with high magnetization and excellent magnetic softness,” J. Magn. Magn. Mater. 320, 2499–2503 (2008).

T. Chang, T. Kubota, A. Makino, and A. Inoue, “Synthesis of ferromagnetic Fe-based bulk glassy alloys in the Fe–Si–B–P–C system,” J. Alloys Compd. 473, 368–372 (2009).

H. R. Lashgari, D. Chu, S. Xie, H. Sun, M. Ferry, and S. Li, “Composition dependence of the microstructure and soft magnetic properties of Fe-based amorphous/nanocrystalline alloys: a review study,” J. Non-Cryst. Solids 391 (19), 61–82 (2014).

A. Useinov, V. Reshetov, I. Maslenikov, and K. Kravchuk, “ISO is simple!” Nanoindustr., No. 7, 52–60 (2015).

W. C. Oliver and G. M. Pharr, “An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments,” J. Mater. Res. 7 (6), 1564–1583 (1992).

ISO 14577–1. Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters. Part 1: Test Method (ISO Central Secretariat, Geneva, 2002).

W. D. Liu, L. M. Ye, and K. X. Liu, “Micro-nano scale ripples on metallic glass induced by laser pulse,” J. Appl. Phys. 109, 043109 (2011).

I. E. Permyakova, “Modeling thermal fields in amorphous alloys during treatment with a pulsed excimer laser,” Bull. Russ. Acad. Sci.: Phys. 84, 839–843 (2020).

S. A. Firstov, V. F. Gorban’, E. P. Pechkovskii, and N. A. Mameka, “Relation between the strength characteristics of materials and automatic indentation indicators,” Materialoved. 11, 26–31 (2007).

B. R. Lawn and V. R. Howes, “Elastic recovery at hardness indentations,” J. Mater. Sci. 16, 2745–2752 (1981).

S. Veprek, “The search for novel superhard material,” J. Vac. Sci. Technol., A 17 (5), 2401–2420 (1999).

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 20-08-00341 “a.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Permyakova, I.E., Ivanov, A.A. & Chernogorova, O.P. Mechanical Properties of a Laser-Modified Amorphous Fe–Ni–B Alloy. Russ. Metall. 2022, 1264–1269 (2022). https://doi.org/10.1134/S003602952210038X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S003602952210038X