Abstract

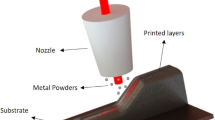

The main problems of the development of 3D printers for machine engineering are related to low rate of printing and low quality of fabricated items. The problems can be solved using a new principle of high-efficiency 3D printing for steel melt based on the compression of the melt jet by magnetic field of flowing current and an increase in the crystallization temperature. Under certain conditions, the heat liberation of current can be compensated for using alternative processes. Ranges of parameters at which the effect can be implemented are determined.

Similar content being viewed by others

Notes

Strictly speaking, the distribution of the current density over the cross section of the jet is determined from the condition for energy minimization. However, the corresponding estimation leads to a correction by a constant factor of about unity.

REFERENCES

I. V. Shishkovsky, I. A. Yadroitsev, and I. Yu. Smurov, Tech. Phys. Lett. 39, 1081 (2013).

M. M. Pant, Phys. Earth Planet. Inter. 17 (2), 14 (1978).

M. S. Tillack and N. B. Morley, Magnetohydrodynamics, 14th ed. (McGraw-Hill, New York, 1998).

F. M. White, Fluid Mechanics, 7th ed. (McGraw-Hill, New York, 2011).

E. R. Parker, Materials Data Book for Engineers and Scientists (McGraw-Hill, New York, 1967).

H. Schlosser, P. Vinet, and J. Ferrante, Phys. Rev. B 40, 5929 (1989).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Chikishev

Rights and permissions

About this article

Cite this article

Oshurko, V.B., Mandel’, A.M., Sharts, A.A. et al. Magnetohydrodynamic Model of a 3D Printer for Steel Melt. Tech. Phys. 63, 1730–1735 (2018). https://doi.org/10.1134/S1063784218120137

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784218120137