Abstract

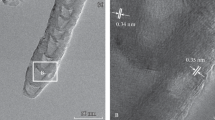

Energy parameters (dose D and the work of surface formation) have been determined for the formation of a defective structure as a result of mechanical activation of graphite. Graphite activation has been shown to be a two-stage process: at low doses (D ≤ 20 kJ/g), the disruption and shift of graphite particles are the main processes, which are accompanied by a reduction in particle size, formation of meso- and micropores, and a rise in the BET specific surface area to 450–550 m2/g predominantly due to the development of a slitlike mesoporosity. At the same time, the crystalline structure of graphite is transformed into a turbostrate one with a concomitant increase in the lattice parameter and a decrease in the sizes of coherentscattering regions. The shape of diffraction lines can be described under the assumption that several fractions with greatly different degrees of defectiveness coexist in graphite. At higher doses, turbostrate graphite is transformed into X-ray amorphous carbon with a concomitant decrease in the specific surface area and meso- and microporosity. The defects resulting from the mechanical activation cannot be completely annealed at 2800°C. The main parameter of mechanical activation is the dose of supplied energy D = J g t (J g is the specific power consumption, and t is the duration of the activation). The curves describing accumulation of different defects can be represented in the form of a unified dependence on the dose for the J g and, accordingly, t values varied by more than an order of magnitude (J g = 1.7–22 W/g).

Similar content being viewed by others

References

Heinike, G., Tribochemistry, Berlin: Akademie, 1984.

Salver-Disma, F., Lenain, C., Beaudoin, B., Aymard, L., and Tarascon, J.-M., Solid State Ionics, 1997, vol. 98, p. 145.

Simon, P. and Gogotsi, Y., Nat. Mater., 2008, vol. 7, p. 845.

Huang, Z.G., Guo, Z.P., Calka, A., Wexler, D., and Liu, H.K., J. Alloys Compd., 2007, vol. 427, p. 94.

Nedorezova, P.M., Tsvetkova, V.I., Kolbanev, I.V., and D’yachkovskii, F.S., Vysokomol. Soedin., Ser. A, 1989, vol. 31, p. 2657.

Rodriguez-Reinozo, F., Carbon, 1998, vol. 36, p. 159.

Streletskii, A.N., Kolbanev, I.V., Borunova, A.B., Leonov, A.V., and Butyagin, P.Yu., Colloid J., 2004, vol. 66, p. 729.

Portnoi, V.K., Leonov, A.V., Streletskii, A.N., and Logachev, A.V., Inorg. Mater., 2013, vol. 49, p. 266.

Timoshchuk, E.V., Samoilov, V.M., Timoshchuk, E.I., and Smirnov, V.K., Solid Fuel Chem., 2011, vol. 45, p. 57.

Fetisova, O.Yu., Cand. Sci. (Chem.) Dissertation, Krasnoyarsk: Inst. of Chemistry and Chemical Technology, Sib. Branch, RAS, 2012.

Lobarev, A.V., Sister, V.G., Vishnevskaya, I.A., Ivannikova, E.M., and Kolbanev, I.V., Patent RF 23315779.

Li, J.L., Peng, Q.S., Bai, G.Z., and Jiang, W., Carbon, 2005, vol. 43, p. 2830.

Kostecki, M., Olszyna, A.R., and Sokolowska, A., Mater. Sci.-Poland, 2013, vol. 31, p. 165.

Liu, L., Xiong, Z., Hu, D., Wu, G., and Chen, P., Chem. Commun., 2013, vol. 49, p. 7890.

Chen, Y., Gerald, J.F., Chadderton, L.T., and Chaffron, L., Appl. Phys. Lett., 1999, vol. 74, p. 2782.

Chen, X.H., Yang, H.S., Wu, G.T., Wang, M., Deng, F.M., Zhang, X.B., Peng, J.C., and Li, W.Z., J. Cryst. Growth, 2000, vol. 218, p. 57.

Hermann, H., Schubert, Th., Gruner, W., and Mattern, N., Nanostruct. Mater., 1997, vol. 8, p. 215.

Salver-Disma, F., Taraskon, J.-M., Clinard, C., and Rouzaud, J.-N., Carbon, 1999, vol. 37, p. 1941.

Welham, N.J., Berbenni, V., and Chapman, P.G., J. Alloys Compd., 2003, vol. 349, p. 255.

Touzik, A., Hentsche, M., Wenzel, R., and Hermann, H., J. Alloys Compd., 2006, vol. 421, p. 141.

Milev, A., Wilson, M., Kannangara, G.S.K., and Tran, N., Mater. Chem. Phys., 2008, vol. 111, p. 346.

Butyagin, P.Yu., Kuznetsov, A.R., and Pavlychev, I.K., Prib. Tekh. Eksp., 1986, no. 6, p. 201.

Butyagin, P.Yu. and Pavlichev, I.K., React. Solid, 1986, vol. 1, p. 361.

Streletskii, A.N., Proc.2nd Int. Conf. on Mechanical Alloying, Vancouver, 1993, p. 51.

Borunova, A.B., Zhernovenkova, Yu.V., Streletskii, A.N., and Portnoi, V.K., in Obrabotka dispersnykh materialov i sred (Treatment of Disperse Materials and Media), Odessa: NPO “VOTUM”, 1999, no. 9, p. 158.

Barrett, E.P., Joyner, L.G., and Hallenda, P.H., J. Am. Chem. Soc., 1951, vol. 73, p. 273.

Shelekhov, E.V., Abstracts of Papers, Nats. konf. po primeneniyu rentgenovskogo, sinkhrotronnogo izluchenii, neitronov i elektronov dlya issledovaniya materialov (Natl. Conf. on Using X-ray, Synchrotron Radiations, Neutrons and Electrons for Materials Investigation), Dubna: OIYaI, 1997, vol. 3, p. 316.

Gregg, S. and Sing, K., Adsorption, Surface Area and Porosity, New York: Academic, 1982.

Tanaka, T., Nasu, S., Nakagawa, K., Ishihara, K.N., and Shingu, P.H., Mater. Sci. Forum, 1992, vol. 88, p. 269.

Tsybulya, S.V. and Cherepanova, S.I., Vvedenie v strukturnyi analiz nanokristallov. Uchebnoe posobie (Introduction to Structural Analysis of Nanocrystals: A Manual), Novosibirsk: Novosibirsk. Gos. Univ., 2008.

Samoilov, V.M. and Streletskii, A.N., Khim. Tverd. Topl., 2004, no. 2, p. 53.

Ostrovskii, V.S., Virgil’ev, Yu.S., Kostikov, V.I., and Shipkov, N.N., Iskusstvennyi grafit (Artificial Graphite), Moscow: Metallurgiya, 1986.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.B. Borunova, A.N. Streletskii, D.G. Permenov, A.V. Leonov, 2015, published in Kolloidnyi Zhurnal, 2015, Vol. 77, No. 2, pp. 134–143.

Rights and permissions

About this article

Cite this article

Borunova, A.B., Streletskii, A.N., Permenov, D.G. et al. The effect of the mechanical activation dose on the defective structure of artificial graphite. Colloid J 77, 125–134 (2015). https://doi.org/10.1134/S1061933X15020039

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061933X15020039