Abstract

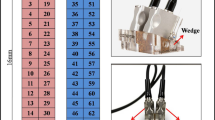

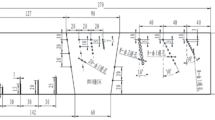

The T-shaped weld structure of LNG tank nickel-based alloy is complex and the grain of the weld is coarse and anisotropy. The conventional ultrasonic detection technique cannot effectively detect its internal defects. In this paper, the acoustic model of T-shaped weld was built based on CIVA software, the ultrasonic wave propagation characteristics and defect response in 9% Ni alloy specimen was simulated. Then, the 9% Ni alloy specimen with artificial flaws was designed, and the phased array imaging based on total focusing method was studied using double-sided array. The quantification and localization of artificial defects were successfully detected. Finally, the research results were applied to the engineering project, and the lack of penetration flaw in the T-shaped weld of one large LNG storage tank were successfully detected, which effectively ensuring the safe use of the storage tank.

Similar content being viewed by others

REFERENCES

Zhao Zhong Ling, Cui Jian Ying, Li Ming, and Xu He, Ultrasonic testing of huge 9%Ni steel sphere welds, J. North. Jiao Tong Univ., 1997, no. 4, pp. 100–104.

Kolokolnikov, S., Dubov, A., Medvedev, A., et al., Comprehensive inspection of refrigerated ammonia storage tank welded joints by the metal magnetic memory technique and conventional NDT methods, Weld. World, 2020, vol. 64, no. 10, pp. 1659–1670.

Marie-Aude Ploix, Philippe Guy, Bertrand Chassignole, et al., Measurement of ultrasonic scattering attenuation in austenitic stainless steel welds: Realistic input data for NDT numerical modeling, Ultrasonics, 2014, vol. 54, no. 7, pp. 1729–1736.

Kim, G.H., Park, C.K., Jin, S.W., et al., Qualification of phased array ultrasonic examination on T-joint weld of austenitic stainless steel for ITER vacuum vessel, Fusion Eng. Des., 2016, vol. 109, pp. 1099–1103.

Rui Wang, Zhihong Liu, Jiefeng Wu, et al., Design of DMA probe for the ultrasonic testing of CFETR vacuum vessel weld, Fusion Eng. Des., 2019, vol. 146, pp. 987–990.

Nakahata, K., Tokumasu, S., and Sakai, A., Ultrasonic imaging using signal post-processing for a flexible array transducer, NDT & E Int., 2016, vol. 82, pp. 13–25.

Hunter, A.J., Drinkwater, B.W., and Wilcox, P.D., Autofocusing ultrasonic imagery for non-destructive testing and evaluation of specimens with complicated geometries, NDT & E Int., 2010, vol. 43, no. 2, pp. 78–85.

Wang Zheng, Research of phase array testing in weld seam of thick wall nickel-base dissimilar steel, Boiler Manuf., 2018, vol. 5, pp. 35–39.

Wang Xu., Application of PAUT Technology in 9Ni steel process piping weld, Nondestr. Test., 2020, vol. 44, no. 1, pp. 41–42.

Zeyu Zhuang, Jie Zhang, Guoxuan Lian, Zhang, Guoxuan Lian, and Drinkwater, B.W., Comparison of time domain and frequency-wavenumber domain ultrasonic array imaging algorithms for nondestructive evaluation, Sensors, 2020, vol. 20, no. 17, p. 4951.

Xinyu Zhao, Zemin Ma, and Jiaying Zhang, Simplifed matrix focusing imaging algorithm for ultrasonic nondestructive testing, Preprint of Chin. J. Mech. Eng., 2022.

Po-Yen Tseng, Young-Fo Chang, et al., Study of total focusing method for ultrasonic nondestructive testing, J. Test. Eval., 2013, vol. 41, no. 4, pp. 557–563.

Camacho, J., Atehortua, D., Cruza, J.F., et al., Ultrasonic crack evaluation by phase coherence processing and TFM and its application to online monitoring in fatigue tests, NDT & E Int., 2018, vol. 93, pp. 164–174.

Guo Wei Can, Qian Sheng Jie, and Ling Zhang Wei, Research on phased array ultrasonic technique for testing tube to tube-sheet sheet welds of heat exchanger. Proceedings of the ASME 2016 pres-welds of heat exchanger, Proc. ASME Pressure Vessels Piping Conf. (Vancouver, 2016), pp. 1–5.

Roman Fernandez and Fabrice Foucher Extende, New applications of the NDT simulation platform CIVA, Singapore Int. NDT Conf. Exhib., Singapore, 2013, pp. 19–20.

Funding

The work was supported by the NQI Project of Zhejiang Provincial Bureau of Quality and Technical Supervision (no. 20180119), EYAS project of Zhejiang Provincial Bureau of Quality and Technical Supervision (CY2022225), and Major project of Zhejiang Provincial Bureau of Quality and Technical Supervision (no. 20170143).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Dong, H.H., Jie, Q.S., Xiang, S.Z. et al. T-Shaped Fillet Weld Testing of 9% Ni Alloy Steel Based on Total Focusing Phased Array Technique. Russ J Nondestruct Test 58, 444–454 (2022). https://doi.org/10.1134/S1061830922060043

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830922060043