Abstract

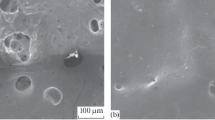

In this paper, we study the regularities of surface-relief formation, the elemental and phase composition distribution over depth, and an increase in the surface microhardness of steel 45 depending on the parameters of electroexplosive boron-copper plating and subsequent electron-beam processing. The structure of the region of electroexplosive alloying with a thickness of up to 25 μm in depth is shown to include a coating, and surface, intermediate, and boundary layers. At an increase in the absorbed power density and the boron powder weight, the surface roughness of the electroexplosive boron-copper plating region increases while the microhardness increases up to 1400 HV. Subsequent processing by a pulsed electron beam leads to unification of the coating with the surface layer, an increase in the depth of the hardening region to 80 μm and a decrease in the surface roughness and microhardness to 800 HV. Improvement in the physical and mechanical properties of the alloying region is due to the formation of submicrocrystalline and nanocrystalline quenching structures containing hardening phases.

Similar content being viewed by others

REFERENCES

O. A. Tsvirkun, E. A. Budovskikh, A. Ya. Bagautdinov, Yu. F. Ivanov, and V. E. Gromov, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 6, 40 (2007).

A. S. Zubchenko, M. M. Koloskov, Yu. V. Kashirskii, et al., Brands of Steels and Alloys (Mashinostroenie, Moscow, 2003) [in Russian].

M. V. Pridantsev, L. I. Davydova, and I. A. Tamarina, Structural Steels: A Reference Book (Metallurgiya, Moscow, 1980) [in Russian].

A. G. Grigor’yants, I. N. Shiganov, and A. I. Misyurov, Technological Processes of Laser Processing (Mosk. Gos. Tekh. Univ. im. N.E. Baumana, Moscow, 2006) [in Russain].

M. G. Krukovich, B. A. Prusakov, and I. G. Sizov, Plasticity of Borated Layers (Fizmatlit, Moscow, 2010) [in Russian].

M. V. Marusin, V. G. Shchukin, and V. V. Marusin, Fiz. Khim. Obrab. Mater., No. 5, 67 (2010).

M. V. Marusin, V. G. Shchukin, V. N. Filimonenko, and V. V. Marusin, Fiz. Khim. Obrab. Mater., No. 4, 54 (2003).

E. S. Astapova, A. S. Borilko, T. V. Glabets, Vestn. Amur. Gos. Univ., Ser.: Estestv. Ekon. Nauki, No. 59, 37 (2012).

E. E. Fel’dshtein, M. A. Kardapolova, R. Gaida, B. Khorodyski, and O. V. Kaval’chuk, Trenie Iznos 34, 175 (2013).

A. G. Grigor’yants, N. A. Smirnova, Tekhnol. Mashinostr., No. 11, 52 (2011).

Yu. F. Ivanov, Yu. A. Kolubaeva, S. V. Konovalov, N. N. Koval’, and V. E. Gromov, Met. Sci. Heat Treat. 50, 569 (2008).

I. N. Burnyshev, O. M. Valiakhmetova, and C. A. Mutagarova, Vestn. Izhevsl. Gos. Tekh. Univ., No. 4, 124 (2007).

Yu. A. Balandin, Met. Sci. Heat Treat. 47, 103 (2005).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by A. Ivanov

Rights and permissions

About this article

Cite this article

Vashchuk, E.S., Budovskikh, E.A., Aksenova, K.V. et al. Structure and Surface Properties of Steel 45 after Electroexplosive Boron-Copper Plating and Electron-Beam Processing. J. Surf. Investig. 16, 285–289 (2022). https://doi.org/10.1134/S1027451022010190

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451022010190