Abstract

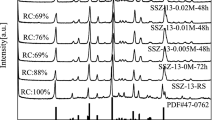

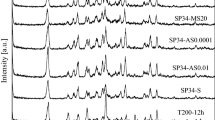

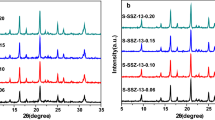

Two different seed crystals (K–CHA and nano-scaled SAPO-34) were used to promote the rapid interzeolite conversion of USY and fumed silica to pure SSZ-13 zeolite phase via a grinding route. The results show that both seeds can shorten the crystallization time of SSZ-13 zeolite to 24h, which is much shorter than the syntheses in the absence of seeds. The phase purity, morphology, textural parameters, elemental compositions and acid properties of two typical H–SSZ-13 samples with seeds were analyzed by XRD, SEM, N2 physisorption, EDS and NH3–TPD techniques in detail, and compared with the sample without seeds and a reference sample. The results indicate that the introduction of seeds can effectively modify the acid properties of H–SSZ-13, especially their medium strong acid sites. The methanol-to-olefins (MTO) reaction was employed as a probe to evaluate the catalytic stability of above four H–SSZ-13 catalysts. The results reveal that the catalytic lifetime of the two catalysts using seeds is much longer than that of the one without seeds and the reference sample H–SSZ-13–RS. It was speculated that the appropriate concentration of medium strong acid sites may play a pivotal role in prolonging their catalytic lifetime. Here our findings may throw light on the rational design of long-lifetime H-SSZ-13 catalysts in the MTO reaction.

Similar content being viewed by others

REFERENCES

Auerbach, S.M., Carrado, K.A., and Dutta, P. K., Handbook of Zeolite Science and Technology, CRC Press, 2003.

Cejka, J., van Bekkum, H., Corma, A., and Schüeth, F., Introduction to Zeolite Science and Practice; in Studies in Surface Science and Catalysis, 2007, vol. 168, Elsevier.

Xu, R., Pang, W., Yu, J., Huo, Q., and Chen, J., Chemistry of Zeolites and Related Porous Materials: Synthesis and Structure, John Wiley & Sons, 2009. ISBN: 978-0-470-82233-3

Corma, A., Chem .Rev., 1997, vol. 97, no. 6, pp. 2373–2420. https://doi.org/10.1021/cr960406n

Li, Y., Li, L., and Yu, J., Chem., 2017, vol. 3, no. 6, pp. 928–949. https://doi.org/10.1016/j.chempr.2017.10.009

Davis, M.E., Chem. Mater., 2014, vol. 26, no. 1, pp. 239–245. https://doi.org/10.1021/cm401914u

Kumar, M., Luo, H., Román-Leshkov, Y., and Rimer, J.D., J. Am. Chem. Soc., 2015, vol. 137, no. 40, pp. 13007–13017. https://doi.org/10.1021/jacs.5b07477

Dusselier, M.and Davis, M.E., Chem. Rev., 2018, vol. 118, no. 11, pp. 5265–5329. https://doi.org/10.1021/acs.chemrev.7b00738

Bleken, F., Bjorgen, M., Palumbo, L., Bordiga, S., Svelle, S., Lillerud, K.-P., and Olsbye, U., Top. Catal., 2009, vol. 52, no. 3, pp. 218–228. https://doi.org/10.1007/s11244-008-9158-0

Xu, S., Zheng, A., Wei, Y., Chen, J., Li, J., Chu, Y., Zhang, M., Wang, Q., Zhou, Y., Wang, J., Deng, F., and Liu, Z., Angew. Chem. Int. Ed., 2013, vol. 52, no. 44, pp. 11564–1568. https://doi.org/10.1002/anie.201303586

Prodinger, S., Derewinski, M.A., Wang, Y., Washton, N.M., Walter, E.D., Szanyi, J., Gao, F., Wang, Y., and Peden, C.H.F., Appl. Catal. B: Environ., 2017, vol. 201, pp. 461–469. https://doi.org/10.1016/j.apcatb.2016.08.053

Zones, S.I., Patent US 4 544 538, 1985.

Yu, H.-F., Zhang, G.-P., Han, L.-N., Chang, L.-P., Bao, W.-R., and Wang, J.-C., Acta Phys.-Chim. Sin., 2015, vol. 31, no. 11, pp. 2165–2173. https://doi.org/10.3866/pku.whxb201509184

Zones, S.I., J. Chem. Soc., Faraday Trans., 1991, vol. 87, no. 22, pp. 3709–3716. https://doi.org/10.1039/ft9918703709

Zones, S.I., J. Chem. Soc., Faraday Trans., 1990, vol. 86, no. 20, pp. 3467–3472. https://doi.org/10.1039/ft9908603467

Takata, T., Tsunoji, N., Takamitsu, Y., Sadakane, M., and Sano, T., Microporous Mesoporous Mater., 2016, vol. 225, pp. 524–533. https://doi.org/10.1016/j.micromeso.2016.01.045

Khan, N.A., Yoo, D.K., Bhadra, B.N., Jun, J.W., Kim, T.-W., Kim, C.-U., and Jhung, S.H., Chem. Eng. J., 2019, vol. 377, p. 119546. https://doi.org/10.1016/j.cej.2018.07.148

Ren, L., Wu, Q., Yang, C., Zhu, L., Li, C., Zhang, P., Zhang, H., Meng, X., and Xiao, F.-S., J. Am. Chem. Soc., 2012, vol. 134, no. 37, pp. 15173–15176. https://doi.org/10.1021/ja3044954

Jin, Y., Sun, Q., Qi, G., Yang, C., Xu, J., Chen, F., Meng, X., Deng, F., and Xiao, F.-S., Angew. Chem.-Int. Ed., 2013, vol. 52, no. 35, pp. 9172–9175. https://doi.org/10.1002/anie.201302672

Wu, Q., Liu, X., Zhu, L., Ding, L., Gao, P., Wang, X., Pan, S., Bian, C., Meng, X., Xu, J., Deng, F., Maurer, S., Müller, U., and Xiao, F.-S., J. Am. Chem. Soc., 2015, vol. 137, no. 3, pp. 1052–1055. https://doi.org/10.1021/ja5124013

Wu, Q., Meng, X., Gao, X., and Xiao, F.-S., Acc. Chem.Res., 2018, vol. 51, no. 6, pp. 1396–1403. https://doi.org/10.1021/acs.accounts.8b00057

Han, Z., Zhang, F., and Zhao, X., Microporous Mesoporous Mater., 2019, vol. 290, p. 109679. https://doi.org/10.1016/j.micromeso.2019.109679

Zhao, X., Zhao, J., Wen, J., Li, A., Li, G., and Wang, X., Microporous Mesoporous Mater., 2015, vol. 213, pp. 192–196. https://doi.org/10.1016/j.micromeso.2015.03.031

Wang, X., Wu, Q., Chen, C., Pan, S., Zhang, W., Meng, X., Maurer, S., Feyen, M., Mueller, U., and Xiao, F.-S., Chem. Commun., 2015, vol. 51, no. 95, pp. 16920–16923. https://doi.org/10.1039/c5cc05980a

Pashkova, V., Mlekodaj, K., Klein, P., Brabec, L., Zouzelka, R., Rathousky, J., Tokarova, V., and Dedecek, J., Chem. Eur. J., 2019, vol. 25, no. 52, pp. 12068–12073. https://doi.org/10.1002/chem.201902107

Miyagawa, S., Miyake, K., Hirota, Y., Nishiyama, N., Miyamoto, M., Oumi, Y., and Tanaka, S., Microporous Mesoporous Mater., 2019, vol. 278, pp. 219–224. https://doi.org/10.1016/j.micromeso.2018.11.037

Ye, Z., Zhang, H., Zhang, Y., and Tang, Y., Front. Chem. Sci. Eng., 2020, vol. 14, no. 2, pp. 143–158. https://doi.org/10.1007/s11705-019-1852-x

Iyoki, K., Itabashi, K., and Okubo, T., Microporous Mesoporous Mater., 2014, vol. 189, pp. 22–30. https://doi.org/10.1016/j.micromeso.2013.08.008

Zhang, D., Lu, H., Su, N., Li, G., Ji, D., and Zhao, X., J. Inorg. Mater., 2021, vol. 36, no. 1, pp. 101–106. https://doi.org/10.15541/jim20200059

Lu, H., Duan, W., and Zhao, X., React. Kinet. Mech. Cat., 2019, vol. 128, no. 2, pp. 1029–1042. https://doi.org/10.1007/s11144-019-01655-0

Xiong, X., Yuan, D., Wu, Q., Chen, F., Meng, X., Lv, R., Dai, D., Maurer, S., McGuire, R., Feyen, M., Mueller, U., Zhang, W., Yokoi, T., Bao, X., Gies, H., Marler, B., De Vos, D.E., Kolb, U., Moini, A., and Xiao, F.-S., J. Mater. Chem. A, 2017, vol. 5, no. 19, pp. 9076–9080. https://doi.org/10.1039/c7ta01749a

Razavian, M., Halladj, R., and Askari, S., Rev. Adv. Mater. Sci., 2011, vol. 29, no. 1, pp. 83–99.

Najafi, N., Askari, S., and Halladj, R., Powder Technol., 2014, vol. 254, pp. 324–330. https://doi.org/10.1016/j.powtec.2014.01.037

Nedyalkova, R., Montreuil, C., Lambert, C., and Olsson, L., Top. Catal., 2013, vol. 56, nos. 9–10, pp. 550–557. https://doi.org/10.1007/s11244-013-0015-4

Mintova, S., Verified Syntheses of Zeolitic Materials, Synthesis Commission of the International Zeolite Association, 2016.

Wang, Y., Chen, J., Lei, X., Ren, Y., and Wu, J., Adv. Powder Technol., 2018, vol. 29, no. 5, pp. 1112–1118. https://doi.org/10.1016/j.apt.2018.02.001

Sarker, M., Khan, N.A., Yoo, D.K., Bhadra, B.N., Jun, J.W., Kim, T.-W., Kim, C.-U., and Jhung, S.H., Chem. Eng. J., 2019, vol. 377, p. 120116. https://doi.org/10.1016/j.cej.2018.10.053

Tang, L., Haw, K.-G., Zhang, Y., Fang, Q., Qiu, S., and Valtchev, V., Microporous Mesoporous Mater., 2019, vol. 280, pp. 306–314. https://doi.org/10.1016/j.micromeso.2019.02.021

Bing, L., Tian, A., Wang, F., Yi, K., Sun, X.and Wang, G., Chem. Eur. J., 2018, vol. 24, no. 29, pp. 7428–7433. https://doi.org/10.1002/chem.201705784

Li, Y., Zhang, Y., Lan, A., Bian, H., Liu, R., Li, X., Han, P., and Dou, T., Microporous Mesoporous Mater., 2019, vol. 279, pp. 1–9. https://doi.org/10.1016/j.micromeso.2018.11.038

Li, Y., Wang, Y., Zhang, Y., Liu, R., Li, X., and Dou, T., China Pet. Process. Petrochem. Technol., 2017, vol. 19, no. 3, pp. 68–76.

Xu, Z., Li, J., Huang, Y., Ma, H., Qian, W., Zhang, H., and Ying, W., Catal. Sci. Technol., 2019, vol. 9, no. 11, pp. 2888–2897. https://doi.org/10.1039/c9cy00412b

Wu, L., Degirmenci, V., Magusin, P. C.M.M., Szyja, B.M., and Hensen, E.J.M., Chem. Commun., 2012, vol. 48, no. 76, pp. 9492–9494. https://doi.org/10.1039/c2cc33994c

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China (Grant no. 21666019, 22168022) and Youth Natural Science Foundation of Gansu Province (Grant no. 20JR10RA189).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare no conflict of interest requiring disclosure in this article.

Rights and permissions

About this article

Cite this article

Hao, Z., Niu, L., Long, X. et al. Seeds Promoted Interzeolite Transformation of USY and Fumed Silica to Long-Lifetime SSZ-13 Catalysts in Methanol-to-Olefins Reaction via a Grinding Route. Pet. Chem. 62, 962–971 (2022). https://doi.org/10.1134/S0965544122070246

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544122070246