Abstract

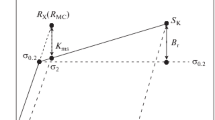

The relations between ultimate tensile strength σu and Brinell hardness HB are known for some groups of steels. These relations represented in the form of formulas, tables, or plots make it possible to quickly estimate σu from HB without fabricating specimens. Therefore, they are necessary during input control of blanks, treatment of steels by various methods, diagnostics of steel state after long-term service, or reductive heat treatment, and in other cases. There are very limited data on such relations for nonferrous metals and alloys; however, there are tables, which give the values of σu and HB for some alloys based on aluminum, copper, and titanium. When establishing more general and correct σu–HB relations for various structural materials (ferrous and nonferrous alloys), it is appropriate to relate σu to the maximum Brinell hardness, which enables one to obtain a general relation for ferrous and nonferrous alloys. To determine the maximum Brinell hardness, it is proposed to use depth-sensing indentation with recording the load F–indenter displacement α indentation diagram with its subsequent conversion to the unrecovered Brinell hardness HBt–relative indentation depth t/R diagram. The maximum hardness (HB)max can be easily determined from the maximum of the HBt–t/R diagram. This report presents the results of tests, in which σu and \({{(H{{B}_{t}})}^{{(\max )}}}\) have been determined for many steels, aluminum, magnesium, and titanium alloys, and a directly proportional relation between these mechanical characteristics is found.

Similar content being viewed by others

REFERENCES

M. P. Markovets, Determination of Mechanical Properties of Metals by Their Hardness (Mashinostroenie, Moscow, 1979).

W. D. Callister, Materials Science and Engineering: An Introduction John Weley and Sons, New York, NY, USA), pp. 139–140.

S. G. Sandomirskii, “Generalized correlation dependences between the ultimate strength of steels and their hardness,” Zavod. Lab. 83 (11), 52–57 (2017).

M. M. Matlin, A. I. Mozgunova, E. I. Kazankina, and V. A. Kazankin, Nondestructive Methods of Controlling the Strength Properties of Machine Elements (Innovatsionnoe Mashinostroenie, Moscow, 2019).

G. P. Zaitsev, “Brinell hardness as a function of parameters of material plasticity,” Zavod. Lab., No. 6, 704–717 (1949).

J. R. Cahoon, “An improved equation relating hardness to ultimate strength.” Metallurg. Trans. 3 (11), 3040 (1972).

M. P. Markovets, “Construction of true stress diagram using hardness and technological specimen,” Zh. Tekh. Fiz. 19 (3), 371–382 (1949).

V. V. Varnello, “Hardness and mechanical constants of metals,” Extended Abstract of Doctoral (Eng.) Dissertation, Institute of Materials Science Problems, Kiev, 1969.

G. O’Neil’, Hardness of Metals and Its Measurement (Metallurgiya, Moscow, 1940).

V. M. Matyunin, Indentation in the Diagnostics of Mechanical Properties of Materials (MEI, Moscow, 2015).

V. M. Matyunin, A. Yu. Marchenkov, N. Abusaif, P. V. Volkov, and D. A. Zhgut, “Regularities and properties of instrumented indentation diagrams obtained by ball-shaped indenter,” Zavod. Lab. 86 (5), 43–51 (2020).

V. M. Matyunin, V. G. Draganov, and A. Yu. Marchenkov, “Size effect in the indentation of materials at the micro- and nanoscale strained volumes,” in: Piezoelectrics and Nanomaterials. Fundamentals, Developments, and Applications (Nova Publishers, New York, 2015), pp. 133–168.

E. J. Pavlina and C. L. Van Tyne, “Correlation of yield strength and tensile strength with hardness for steels,” J. Mater. Eng. Perform. 17 (6), 888–892 (2008).

Funding

This work was carried out at National Research University MPEI and was supported by the Ministry of Science and Higher Education of the Russian Federation, state project no. FSWF-2020-0023.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Yu. Ryzhkov

Rights and permissions

About this article

Cite this article

Matyunin, V.M., Marchenkov, A.Y., Agafonov, R.Y. et al. Correlation between the Ultimate Tensile Strength and the Brinell Hardness of Ferrous and Nonferrous Structural Materials. Russ. Metall. 2021, 1719–1724 (2021). https://doi.org/10.1134/S0036029521130164

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521130164