Abstract

The effect of scandium on the superplasticity characteristics of Al–0.5Mg–Sc conductor aluminum alloys with a submicrocrystalline (SMC) structure is investigated. Large elongation to failure (~1060%) is achieved in the SMC alloys with 0.4 and 0.5% Sc at a deformation temperature of 500°C and a strain rate of 1 × 10–1 s–1. Intense pore formation is shown to occur during the superplasticity of the Al–0.5Mg–Sc SMC alloys. The kinetics of deformation-stimulated grain growth in the Al–0.5Mg–Sc SMC alloys is found to be determined by the mobility of junction disclinations and orientation-misfit dislocations.

Similar content being viewed by others

Notes

From here on, the element contents are given in wt %.

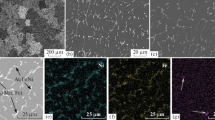

The microstructure of the as-cast and SMC Al–0.5% Mg–Sc alloys was described in detail in [10].

The fact that HV0.5 does not depend on the annealing temperature and the grain size for the Al–0.5% Mg SMC alloy is mainly caused by the small indentation size, which is comparable with the grain size during intense grain growth.

REFERENCES

V. I. Elagin, Alloying of Deformable Aluminum alloys with Transition Metals (Metallurgiya, Moscow, 1975).

V. V. Zakharov, “Effect of scandium on the structure and properties of aluminum alloys,” Metal Science and Heat Treatment 45 (7–8), 246–253 (2003).

V. I. Elagin, V. V. Zakharov, and T. D. Rostova, “Some features of the decomposition of the solid solution of scandium in aluminum,” Metal Science and Heat Treatment 25 (7), 546–549 (1983).

V. N. Chuvildeev, A. V. Nokhrin, I. M. Makarov, et al., “Solid solution decomposition mechanisms in cast and microcrystalline Al–Sc alloys: I. Experimental studies,” Russian metallurgy (Metally), No. 5, 415–427 (2012).

S. V. Dobatkin, V. V. Zakharov, A. Yu. Vinogradov, et al., “Nanocrystalline strucutre formation in Al–Mg–Sc alloys during severe plastic deformation,” Russian Metallurgy (Metally), No. 6, 533–540 (2006).

N. F. Yunusova, R. K. Islamgaliev, and R. Z. Valiev, “High-strain-rate superplasticity in aluminum 1420 and 1421 alloys subjected to equal-channel angular pressing,” Russian Metallurgy (Metally), No. 2, 123–128 (2004).

V. N. Perevezentsev, V. N. Chuvil’deev, V. I. Kopylov, A. N. Sysoev, and T. G. Langdon, “High-strain-rate superplasticity of Al–Mg–Sc–Zr alloys,” Russian Metallurgy (Metally), No. 1, 28–35 (2004).

T. Fujita, Z. Horita, and T. G. Langdon, “Characteristics of diffusion in Al–Mg alloys with ultrafine grain sizes,” Phil. Mag. A 82, 2249–2262 (2002).

I. I. Novikov and V. K. Portnoi, Superplasticity of Ultrafine Grain Alloys (Metallurgiya, Moscow, 1981).

V. N. Chuvil’deev, Ya. S. Shadrina, A. V. Nokhrin, V. I. Kopylov, A. A. Bobrov, M. Yu. Gryaznov, S. V. Shotin, N. Yu. Tabachkova, A. V. Piskunov, M. K. Chegurov, and N. V. Melekhin, “Thermal stability of the structure and mechanical properties of submicrocrystalline Al–0.5%Mg–Sc aluminum alloys,” Russ. Metall. (Metally), No. 1, 7–24 (2021).

I. I. Novikov, V. K. Portnoy, A. O. Titov, and D. Yu. Belov, “Dynamic recrystallization at superplastic deformation of duraluminum with initial recrystallized structure,” Scr. Mater. 42 (9), 899–904 (2000).

V. N. Chuvil’deev, A. V. Nokhrin, M. M. Myshlyaev, V. I. Kopylov, et al., “Effect of recovery and recrystallization on the Hall-Petch relation parameters in submicrocrystalline metals: I. Experimental studies,” Russ. Metall. (Metally), No. 1, 71–89 (2018).

V. N. Chuvil’deev, A. V. Nokhrin, M. M. Myshlyaev, V. I. Kopylov, et al., “Effect of recovery and recrystallization on the Hall-Petch relation parameters in submicrocrystalline metals: II. Model for calculating the Hall-Petch relation parameters,” Russ. Metall. (Metally), No. 5, 487–499 (2018).

V. N. Chuvil’deev, A. V. Nokhrin, M. M. Myshlyaev, V. I. Kopylov, et al., “Effect of recovery and recrystallization on the Hall–Petch relation parameters in submicrocrystalline metals: III. Model for the effect of recovery and recrystallization on the Hall-Petch relation parameters,” Russ. Metall. (Metally), No. 9, 867–879 (2018).

V. N. Perevezentsev, V. V. Rybin, and V. N. Chuvil’deev, “The theory of structural superplasticity. I. The physical character of the superplasticity phenomenon,” Acta Met. Mater. 40 (5), 887–894 (1992).

V. N. Perevezentsev, V. V. Rybin, and V. N. Chuvil’deev, “The theory of structural superplasticity. III. Boundary migration and grain growth,” Acta Met. Mater. 40 (5), 907–914 (1992).

V. N. Chuvil’deev, Nonequilibrium Grain Boundaries in Metals. Theory and Applications (Fizmatlit, Moscow, 2004).

V. N. Perevezentsev, O. E. Pirozhnikova, and V. N. Chuvil’deev, “Grain growth during superplastic deformation microduplex alloys,” Physics of Metals and Metallography 71 (4), 29–36 (1991).

S. S. Gorelik, Recrystallization of Metals and Alloys (Metallurgiya, Moscow, 1967).

V. M. Segal, I. J. Beyerlein, C. N. Tome, V. N. Chuvil’deev, and V. I. Kopylov, Fundamentals and Engineering of Severe Plastic Deformation (Nova Sci. Publ., New York, 2010).

V. N. Perevezentsev, V. V. Rybin, and V. N. Chuvil’deev, “The theory of structural superplasticity. IV. Cavitation during superplastic deformation,” Acta Met. Mater. 40 (5), 915–923 (1992).

V. N. Perevezentsev, V. V. Rybin, and V. N. Chuvil’deev, “Pore nucleation at the precipitate–matrix interface under superplastic deformation,” Poverkhnost’, No. 11, 130–139 (1986).

ACKNOWLEDGMENTS

We thank V.V. Zakharov (AO All-Russia Institute of Light Alloys) for his recommendations on the choice of aluminum alloy casting conditions.

Funding

This work was supported by the Russian Science Foundation, project no. 18-13-00306.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Chuvil’deev, V.N., Gryaznov, M.Y., Shotin, S.V. et al. Superplasticity of High-Strength Submicrocrystalline Al–0.5Mg–Sc Aluminum Alloys. Russ. Metall. 2021, 1102–1115 (2021). https://doi.org/10.1134/S0036029521090068

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521090068