Abstract—

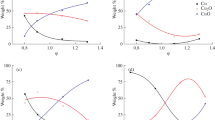

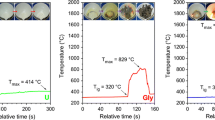

A Cu2 – nSe phase has been prepared by self-propagating high-temperature synthesis in the combustion regime using mixtures of Cu and Se powders. We have carried out thermodynamic analysis of the formation of Cu2 – nSe from its constituent elements and calculated the adiabatic combustion temperature, which is 912 K for a mixture with the composition 2Cu + Se. Using X-ray diffraction data, we have determined the composition of the combustion product and the unit-cell parameters of the α- and β-phases of Cu2 – nSe in its homogeneity range. The phase composition of the material and the stoichiometry of Cu2 – nSe have been shown to depend on the composition of the starting mixture. Synthesis from 2Cu + Se and 1.85Cu + Se mixtures leads to predominant formation of the monoclinic phase α-Cu2 – nSe, whereas combustion of a 1.7Cu + Se mixture, having a considerable deviation from stoichiometry, yields the cubic phase β-Cu2 – nSe. The effect of isothermal annealing at 673 K on the phase composition of the material is examined.

Similar content being viewed by others

REFERENCES

Tan, G., Zhao, L.D., and Kanatzidis, M.G., Rationally designing high-performance bulk thermoelectric materials, Chem. Rev., 2016, vol. 116, no. 2, pp. 12123–12149. https://doi.org/10.1021/acs.chemrev.6b00255

Yang, L., Chen, Z.G., Dargusch, M.S., and Zou, J., High performance thermoelectric materials: progress and their applications, Adv. Eng. Mater., 2017, vol. 8, no. 6, paper 1701797. https://doi.org/10.1002/aenm.201701797

Chen, R., Lee, J., Lee, W., and Li, D., Thermoelectrics of nanowires, Chem. Rev., 2019, vol. 119, no. 15, pp. 9260–9302. https://doi.org/10.1021/acs.chemrev.8b00627

Snyder, G.J. and Snyder, A.H., Figure of merit ZT of a thermoelectric device defined from materials properties, Energy Environ. Sci., 2017, vol. 10, no. 11, pp. 2280–2283. https://doi.org/10.1039/c7ee02007d

Zebarjadi, M., Esfarjani, K., Dresselhaus, M.S., Ren, Z.F., and Chen, G., Perspectives on thermoelectrics: from fundamentals to device applications, Energy Environ. Sci., 2012, vol. 5, no. 1, pp. 5147–5162. https://doi.org/10.1039/c1ee02497c

Zhao, L.D., Lo, S.H., Zhang, Y., Sun, H., Tan, G., Uher, C., Wolverton, C., Dravid, V.P., and Kanatzidis, M.G., Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals, Nature, 2014, vol. 508, no. 7496, pp. 373–377. https://doi.org/10.1038/nature13184

Gahtori, B., Bathula, S., Tyagi, K., Jayasimhadri, M., Srivastava, A.K., Singh, S., Budhani, R.C., and Dhar, A., Giant enhancement in thermoelectric performance of copper selenide by incorporation of different nanoscale dimensional defect features, Nano Energy, 2015, vol. 13, pp. 36–46. https://doi.org/10.1016/j.nanoen.2015.02.008

Yang, L., Chen, Z.G., Han, G., Hong, M., Zou, Y., and Zou, J., High-performance thermoelectric Cu2Se nanoplates through nanostructure engineering, Nano Energy, 2015, vol. 16, pp. 367–374.https://doi.org/10.1016/j.nanoen.2015.07.012

Zhang, Q., Cao, F., Liu, W., Lukas, K., Yu, B., Chen, S., Opeil, S., Broido, D., Chen, G., and Ren, Z., Heavy doping and band engineering by potassium to improve the thermoelectric figure of merit in p-type PbTe, PbSe, and PbTe1 – ySey , J. Am. Chem. Soc., 2012, vol. 134, no. 24, pp. 10031–10038. https://doi.org/10.1021/ja301245b

Yang, L., Chen, Z.G., Han, G., Hong, M., Huang, L., and Zou, J., Te-doped Cu2Se nanoplates with a high average thermoelectric figure of merit, J. Mater. Chem. A, 2016, vol. 4, no. 23, pp. 9213–9219. https://doi.org/10.1039/c6ta02998a

Yu, B., Liu, W., Chen, S., Wang, H., Wang, H., Chen, G., and Ren, Z., Thermoelectric properties of copper selenide with ordered selenium layer and disordered copper layer, Nano Energy, 2012, vol. 1, no. 3, pp. 472–478. https://doi.org/10.1016/j.nanoen.2012.02.010

Wang, H., Gibbs, Z.M., Takagiwa, Y., and Snyder, G.J., Tuning bands of PbSe for better thermoelectric efficiency, Energy Environ. Sci., 2014, vol. 7, no. 2, pp. 804–811. https://doi.org/10.1039/c3ee43438a

Tyagi, K., Gahtori, B., Bathula, S., Jayasimhadri, M., Singh, N.K., Sharma, S., Haranatha, D., Srivastavaa, A.K., and Dhar, A., Enhanced thermoelectric performance of spark plasma sintered copper-deficient nanostructured copper selenide, J. Phys. Chem. Solids, 2015, vol. 81, pp. 100–105. https://doi.org/10.1016/j.jpcs.2015.01.018

Alleno, E., Benyahia, M., Vaney, J.B., Provost, K., Paul-Boncour, V., Monnier, J., Dauscher, A., and Lenoir, B., High thermoelectric figure of merit in well optimized YbyCo4Sb12, J. Mater. Chem. C, 2020, vol. 8, no. 47, pp. 17034–17044. https://doi.org/10.1039/d0tc03455j

Zheng, L., Zhang, X., Liu, H., Li, S., Zhou, Z., Lu, Q., Zhang, J., and Zhang, F., Optimized nanostructure and thermoelectric performances of Mg2(Si0.4Sn0.6)Sbx solid solutions by in situ nanophase generation, J. Alloys Compd., 2016, vol. 671, pp. 452–457. https://doi.org/10.1016/j.jallcom.2016.02.057

Kim, S.I., Lee, K.H., Mun, H.A., Kim, H.S., Hwang, S.W., Roh, J.W., Yang, D.J., Shin, W.H., Li, X.S., Lee, Y.H., Snyder, G.J., and Kim, S.W., Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics, Science, 2015, vol. 348, no. 6230, pp. 109–114. https://doi.org/10.1126/science.aaa4166

Ivanova, L.D., Petrova, L.I., Granatkina, Yu.V., Leont’ev, V.G., Ivanov, A.S., Varlamov, S.A., Prilepo, Yu.P., Sychev, A.M., Chuiko, A.G., and Bashkov, I.V., Thermoelectric and mechanical properties of the Bi0.5Sb1.5Te3 solid solution prepared by melt spinning, Inorg. Mater., 2013, vol. 49, no. 2, pp. 120–126. https://doi.org/10.1134/S0020168513020106

Bulat, L.P., Drabkin, I.A., Karatayev, V.V., Osvenskii, V.B., Parkhomenko, Y.N., Pshenay-Severin, D.A., and Sorokin, A.I., The influence of anisotropy and nanoparticle size distribution on the lattice thermal conductivity and the thermoelectric figure of merit of nanostructured (Bi,Sb)2Te3, J. Electron. Mater., 2014, vol. 43, no. 6, pp. 2121–2126. https://doi.org/10.1007/s11664-014-2988-6

Asfandiyar Cai, B., Zhao, L.D., and Li, J.F., High thermoelectric figure of merit ZT > 1 in SnS polycrystals, J. Materiomics, 2019, vol. 6, no. 1, pp. 77–85. https://doi.org/10.1016/j.jmat.2019.12.003

Wang, S., Xie, W., Li, H., and Tang, X., Enhanced performances of melt spun Bi2(Te,Se)3 for n-type thermoelectric legs, Intermetallics, 2011, vol. 19, no. 7, pp. 1024–1031. https://doi.org/10.1016/j.intermet.2011.03.006

Mukherjee, S., Ghosh, S., and Chattopadhyay, K., Ultralow thermal conductivity and high thermoelectric figure of merit in Cu2Te–Ag2Te composites, J. Alloys Compd., 2020, vol. 848, paper 156540. https://doi.org/10.1016/j.jallcom.2020.156540

Ivanova, L.D., Petrova, L.I., Granatkina, Yu.V., Kichik, S.A., Marakushev, I.S., and Mel’nikov, A.A., Melt-spun materials based on an n-type Bi2Te2.7Se0.3 solid solution, Inorg. Mater., 2015, vol. 51, no. 7, pp. 741–745. https://doi.org/10.1134/S0020168515070067

Chen, J., Liu, T., Bao, D., Zhang, B., Han, G., Liu, C., Tang, J., Zhou, D., Yang, L., and Chen, Z.G., Nanostructured monoclinic Cu2Se as near-room-temperature thermoelectric materials, Nanoscale, 2020, vol. 12, no. 39, pp. 20536–20542. https://doi.org/10.1039/d0nr05829g

Mao, J., Wang, Y., Kim, H.S., Liu, Z., Saparamadu, U., Tian, F., Dahal, K., Sun, J., Chen, S., Liu, W., and Ren, Z., High thermoelectric power factor in Cu–Ni alloy originate from potential barrier scattering of twin boundaries, Nano Energy, 2015, vol. 17, pp. 279–289. https://doi.org/10.1016/j.nanoen.2015.09.003

Patidar, D. and Saxena, N.S., Characterization of single phase copper selenide nanoparticles and their growth mechanism, J. Cryst. Growth, 2012, vol. 343, no. 1, pp. 68–72. https://doi.org/10.1016/j.jcrysgro.2012.01.026

Rong, F., Bai, Y., Chen, T., and Zheng, W., Chemical synthesis of Cu2Se nanoparticles at room temperature, Mater. Res. Bull., 2012, vol. 47, no. 1, pp. 92–95. https://doi.org/10.1016/j.materresbull.2011.09.026

Hsiang, H.I., Hsu, W.H., Lu, L.H., Chang, Y.L., and Yen, F.S., Cuprous selenide nano-crystal synthesis and characterization, Mater. Res. Bull., 2013, vol. 48, no. 2, pp. 715–720. https://doi.org/10.1016/j.materresbull.2012.11.020

Tyagi, K., Gahtori, B., Bathula, S., Jayasimhadri, M., Sharma, S., Singh, N.K., Haranath, D., Srivastava, A.K., and Dhar, A., Crystal structure and mechanical properties of spark plasma sintered Cu2Se: an efficient photovoltaic and thermoelectric material, Solid State Commun., 2015, vol. 207, pp. 21–25. https://doi.org/10.1016/j.ssc.2015.02.004

Xue, L., Zhang, Z., Shen, W., Ma, H., Zhang, Y., Fang, C., and Jia, X., Thermoelectric performance of Cu2Se bulk materials by high-temperature and high-pressure synthesis, J. Materiomics, 2018, vol. 5, no. 1, pp. 102–110. https://doi.org/10.1016/j.jmat.2018.12.002

Liu, H., Shi, X., Xu, F., Zhang, L., Zhang, W., Chen, L., Li, Q., Uher, C., Day, T., and Snyder, G.J., Copper ion liquid-like thermoelectrics, Nat. Mater., 2012, vol. 11, no. 5, pp. 422–425. https://doi.org/10.1038/nmat3273

Vinod, T.P., Jin, X., and Kim, J., Hexagonal nanoplatelets of CuSe synthesized through facile solution phase reaction, Mater. Res. Bull., 2011, vol. 46, no. 3, pp. 340–344. https://doi.org/10.1016/j.materresbull.2010.12.017

Filippo, E., Manno, D., and Serra, A., Synthesis and growth mechanism of dendritic Cu2 – xSe microstructures, J. Alloys Compd., 2012, vol. 538, pp. 8–10. https://doi.org/10.1016/j.jallcom.2012.05.111

Danilkin, S.A., Avdeev, M., Sale, M., and Sakuma, T., Neutron scattering study of ionic diffusion in Cu–Se superionic compounds, Solid State Ionics, 2012, vol. 225, pp. 190–193. https://doi.org/10.1016/j.ssi.2012.02.046

Liu, H., Shi, X., Xu, F., Zhang, L., Zhang, W., Chen, L., Li, Q., Uher, C., Day, T., and Snyder, G.J., Copper ion liquid-like thermoelectrics, Nat. Mater., 2012, vol. 11, no. 5, pp. 422–425. https://doi.org/10.1038/nmat3273

Ivanov, A.A., Akchurin, R.K., Osvenskii, V.B., Tarasova, I.V., Bublik, V.T., Shchetinin, I.V., Tabachkova, N.Y., and Pshenay-Severin, D.A., Temperature dependence of the lattice parameters of Cu2 – xSe (0.03 ≤ x ≤ 0.23) powders fabricated by mechanochemical synthesis, Solid State Phys., 2018, vol. 60, no. 11, pp. 2255–2259. https://doi.org/10.21883/FTT.2018.11.46673.131

Rogachev, A.S., Mechanical activation of heterogeneous exothermic reactions in powder mixtures, Russ. Chem. Rev., 2019, vol. 88, no. 9, pp. 875–900. https://doi.org/10.1070/RCR4884

Hu, C., Li, F., Qu, D., Wang, Q., Xie, R., Zhang, H., and Zhou, Y., Developments in hot pressing (HP) and hot isostatic pressing (HIP) of ceramic matrix composites, Adv. Chem. Matrix Compos., 2014, pp. 164–189.https://doi.org/10.1533/9780857098825.1.164

Cavaliere, P., Sadeghi, B., and Shabani, A., Spark plasma sintering: process fundamentals, in Spark Plasma Sintering of Materials, 2019, pp. 3–20. https://doi.org/10.1007/978-3-030-05327-7_1

Siegrist, T., Crystallographica – a software toolkit for crystallography, J. Appl. Crystallogr., 1997, vol. 30, pp. 418–419. http://www.crystallographica.co.uk.

International Centre for Diffraction Data. http://www.icdd.com.

Firsova, V.A., Pyatygina, N.G., and Ivanova, T.I., The Rietveld–Rietveld method, Certificate of Registration of the Computer Program no. 2010613016, 2010.

Crystallography Open Database. http://www.crystallography.net/cod

Jain, A., Ong, S.P., Hautier, G., et al., The Materials Project: a materials genome approach to accelerating materials innovation, APL Mater., 2013, vol. 1, no. 1, paper 011002. https://materialsproject.org/.https://doi.org/10.1063/1.4812323.

Novikov, N.P., Borovinskaya, I.P., and Merzhanov, A.G., Thermodynamic analysis of reactions of self-propagating high-temperature synthesis, in Combustion Processes in Chemical Technology and Metallurgy, Chernogolovka, 1975, pp. 174–188.

Thermodynamic Properties of Compounds, CuS to ErF 3 . Landolt–Börnstein, Group IV, Physical Chemistry 19A3, Pure Substances, part 3: Compounds from CoCl 3 _g to Ge 3 N 4 . https://materials.springer.com/lb/docs/ sm_lbs_978-3-540-46702-1_10

Pashinkin, A.S., Mikhailova, M.S., and Fedorov, V.A., Heat capacity of Cu2Se at temperatures above 298 K, Inorg. Mater., 2015, vol. 51, no. 11, pp. 1090–1091. https://doi.org/10.1134/S0020168515110084

Kubaschewski, P. and Nolting, H., Specific heat and thermal disorder of copper chalcogenides. Part I: Cu2Se and Cu2Te with an approximate stoichiometric composition, Ber. Bunseuges. Phys. Chem., 1973, vol. 77, no. 1, pp. 70–74. https://doi.org/10.1002/bbpc.19730770203

Villars, P., Cu–Se binary phase diagram 33-38 at.% Se, Pauling File, in: Inorganic Solid Phases, Springer Materials (online database), Heidelberg: Springer. https://materials.springer.com/isp/phase-diagram/ docs/c_0905191

Heyding, R. and MacLarsen-Murray, A., The crystal structures of Cu1.8Se, Cu3Se2, α- and γ-CuSe, CuSe2, and CuSe2II, Can. J. Chem., 1976, vol. 54, pp. 841–848. https://doi.org/10.1139/v76-122

Machado, K.D., Lima, J.C., Grandi, T.A., Campos, C.E.M., Maurmann, C.E., Gasperini, A.A.M., Souza, S.M., and Pimenta, A.F., Structural study of Cu2 − xSe alloys produced by mechanical alloying, Acta Crystallogr., Sect. B: Struct. Sci, 2004, vol. 60, no. 3, pp. 282–286. https://doi.org/10.1107/S0108768104007475

Danilkin, S.A., Skomorokhov, A.N., Hoser, A., Fuess, H., Rajevac, V., and Bickulova, N.N., Crystal structure and lattice dynamics of superionic copper selenide Cu2 – δSe, J. Alloys Compd., 2003, vol. 361, nos. 1–2, pp. 57–61. https://doi.org/10.1016/S0925-8388(03)00439-0

Skomorokhov, A.N., Trots, D.M., Knapp, M., Bickulova, N.N., and Fuess, H., Structural behaviour of β-Cu2 − δSe (δ = 0, 0.15, 0.25) in dependence on temperature studied by synchrotron powder diffraction, J. Alloys Compd., 2006, vol. 421, nos. 1–2, pp. 64–71. https://doi.org/10.1016/j.jallcom.2005.10.079

ACKNOWLEDGMENTS

In this study, we used equipment at the Distributed Shared Research Facilities Center, Merzhanov Institute of Structural Macrokinetics and Materials Science, Russian Academy of Sciences.

Funding

This work was supported by the Russian Federation Ministry of Science and Higher Education through the state research target for the Merzhanov Institute of Structural Macrokinetics and Materials Science, Russian Academy of Sciences, theme no. 44.1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Kovalev, D.Y., Nigmatullina, G.R. & Bikkulova, N.N. Synthesis of Cu2 – nSe via Autowave Combustion of an Elemental Powder Mixture. Inorg Mater 57, 1124–1134 (2021). https://doi.org/10.1134/S0020168521110078

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521110078