Abstract

An original method has been suggested for producing polycrystalline  samples with undoped faces. Generation characteristics of a

samples with undoped faces. Generation characteristics of a  laser are studied under pulse-periodic pumping by a

laser are studied under pulse-periodic pumping by a  : YLF-laser. The efficiency of converting the pump radiation into laser generation at a wavelength of

: YLF-laser. The efficiency of converting the pump radiation into laser generation at a wavelength of  is 20%.

is 20%.  samples exhibit high resistance to surface breakdown.

samples exhibit high resistance to surface breakdown.

Export citation and abstract BibTeX RIS

Among numerous materials used as active media for femtosecond and tunable mid-IR lasers, most promising are zinc chalcogenides doped with ions of transition metals [1, 2]. In recent years, research activity has been concentrated on enhancing the efficiency and output power of laser radiation needed for constructing compact sources of tunable coherent radiation in the range of  [3 – 5]. As shown in [6] the distribution profile of the dopant determines the profile of absorbed energy, which, in turn, substantially affects the efficiency and absolute values of parameters of laser generation. At high pump power densities there is a high probability of laser breakdown on surfaces of a doped optical element due to a high concentration of the dopant. This problem can be solved by providing a minimal (or zero) concentration of the dopant material on the surface, through which laser radiation is coupled in/out, and a maximal concentration in the sample bulk.

[3 – 5]. As shown in [6] the distribution profile of the dopant determines the profile of absorbed energy, which, in turn, substantially affects the efficiency and absolute values of parameters of laser generation. At high pump power densities there is a high probability of laser breakdown on surfaces of a doped optical element due to a high concentration of the dopant. This problem can be solved by providing a minimal (or zero) concentration of the dopant material on the surface, through which laser radiation is coupled in/out, and a maximal concentration in the sample bulk.

In the present work we report results of investigations of generation characteristics of polycrystalline  : ZnSe samples obtained by the original method which provides zero concentration of the doping material on the surface of the sample and a maximal concentration inside it.

: ZnSe samples obtained by the original method which provides zero concentration of the doping material on the surface of the sample and a maximal concentration inside it.

Polycrystalline ZnSe samples with the size of  and high optical quality obtained preliminarily by the CVD-method were polished by diamond powder with the grain size of

and high optical quality obtained preliminarily by the CVD-method were polished by diamond powder with the grain size of  , washed in an ultrasonic bath and placed into a reactor conventionally used for synthesising ZnSe. The CVD-reactor comprised the unit for feeding chromium precursor vapours, equipped with a system of independent heating, and a high-precision unit for controlling evaporator temperature. The chromium precursor vapour was introduced into the reactor by a flow of a gas carrier (argon). Chemical deposition of a metal chromium film on the surface of polished ZnSe substrates was performed by reducing chromium trichloride in zinc vapours.

, washed in an ultrasonic bath and placed into a reactor conventionally used for synthesising ZnSe. The CVD-reactor comprised the unit for feeding chromium precursor vapours, equipped with a system of independent heating, and a high-precision unit for controlling evaporator temperature. The chromium precursor vapour was introduced into the reactor by a flow of a gas carrier (argon). Chemical deposition of a metal chromium film on the surface of polished ZnSe substrates was performed by reducing chromium trichloride in zinc vapours.

As soon as the chromium film of desired thickness was deposited on the ZnSe surface, the flux of the precursor stopped and hydrogen selenide diluted by argon passed to the reaction zone for depositing ZnSe. Synthesis of zinc selenide was performed by the method thoroughly described in [7]. The layers of ZnSe were grown for  (depending on the required deposition thickness). In the result of experiment, three-layer ZnSe – Cr – ZnSe structures with a thickness up to

(depending on the required deposition thickness). In the result of experiment, three-layer ZnSe – Cr – ZnSe structures with a thickness up to  were obtained. The samples grown were extracted from the CVD-reactor and polished to obtain a required geometrical shape. Then, the samples were annealed in evacuated quartz ampoules at a temperature of

were obtained. The samples grown were extracted from the CVD-reactor and polished to obtain a required geometrical shape. Then, the samples were annealed in evacuated quartz ampoules at a temperature of  in argon atmosphere at a pressure of approximately

in argon atmosphere at a pressure of approximately  for

for  . The process of obtaining the required chromium concentration profile was made noticeably faster under barothermic treatment of synthesised structures. For this purpose, the annealing was performed in a gas-static box at a pressure of

. The process of obtaining the required chromium concentration profile was made noticeably faster under barothermic treatment of synthesised structures. For this purpose, the annealing was performed in a gas-static box at a pressure of  and temperature of

and temperature of  for

for  .

.

The concentration of chromium in samples determined by the method of IR Fourier spectroscopy was about  and depended on experimental conditions. The distribution of chromium in samples was found by the optical method using radiation of a Tm : YLF laser at a wavelength of

and depended on experimental conditions. The distribution of chromium in samples was found by the optical method using radiation of a Tm : YLF laser at a wavelength of  [8]. The concentration profile of a

[8]. The concentration profile of a  sample is presented in Fig. 1. One can see that the maximal chromium concentration is observed in the sample bulk, whereas near surfaces it is below a detection limit.

sample is presented in Fig. 1. One can see that the maximal chromium concentration is observed in the sample bulk, whereas near surfaces it is below a detection limit.

Figure 1. Normalised profile of chromium distribution over thickness of the ZnSe sample with a total thickness of  .

.

Download figure:

Standard imageThe laser element cut from the  crystal had no antireflection coatings. Plates of

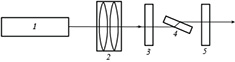

crystal had no antireflection coatings. Plates of  were placed at the Brewster angle to the optical axis of the cavity (Fig. 2) and pressed to a copper heatsink through indium gasket without active cooling. The crystal was excited at a wavelength

were placed at the Brewster angle to the optical axis of the cavity (Fig. 2) and pressed to a copper heatsink through indium gasket without active cooling. The crystal was excited at a wavelength  by radiation of a repetitively pulsed diode-pumped Tm : YLF-laser. The duration of Tm : YLF-laser pulses was

by radiation of a repetitively pulsed diode-pumped Tm : YLF-laser. The duration of Tm : YLF-laser pulses was  (depending on the power) at a pulse repetition rate

(depending on the power) at a pulse repetition rate  . Radiation of the pump laser ( 1 ) was focused by the lens system ( 2 ) through a dichroic mirror ( 3 ) inside the

. Radiation of the pump laser ( 1 ) was focused by the lens system ( 2 ) through a dichroic mirror ( 3 ) inside the  sample ( 4 ) into a spot of diameter

sample ( 4 ) into a spot of diameter  . The cavity of length

. The cavity of length  was formed by the dichroic mirror ( 3 ) and a flat-concave outcoupling mirror ( 5 ) (the reflection coefficient was

was formed by the dichroic mirror ( 3 ) and a flat-concave outcoupling mirror ( 5 ) (the reflection coefficient was  in the range

in the range  ) with the radius of curvature

) with the radius of curvature  . The laser radiation power was measured with a calibrated power meter Gentec with the spectral sensitivity range of

. The laser radiation power was measured with a calibrated power meter Gentec with the spectral sensitivity range of  . Time parameters of generation were measured with a photodetector based on a MCT-structure with the response time of

. Time parameters of generation were measured with a photodetector based on a MCT-structure with the response time of  . Output radiation was spectrally analysed by a Solar M833 diffraction monochromator with the resolution of

. Output radiation was spectrally analysed by a Solar M833 diffraction monochromator with the resolution of  .

.

Figure 2. Schematic diagram of the  laser : ( 1 ) Tm : YLF laser; ( 2 ) lens system; ( 3 ) dichroic mirror; ( 4 ) active element made of

laser : ( 1 ) Tm : YLF laser; ( 2 ) lens system; ( 3 ) dichroic mirror; ( 4 ) active element made of  ; ( 5 ) outcoupling mirror.

; ( 5 ) outcoupling mirror.

Download figure:

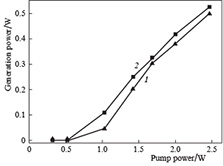

Standard imageGeneration characteristics of polycrystalline  samples with a minimal chromium concentration on the surface obtained by the method described above were compared to those of polycrystalline samples with a maximal concentration of chromium on the surface obtained by the conventional method [9]. The effective chromium concentrations in the samples were close and equal to

samples with a minimal chromium concentration on the surface obtained by the method described above were compared to those of polycrystalline samples with a maximal concentration of chromium on the surface obtained by the conventional method [9]. The effective chromium concentrations in the samples were close and equal to  . The active elements had no antireflection coatings. At the pump radiation power of

. The active elements had no antireflection coatings. At the pump radiation power of  , close values of the average generation power

, close values of the average generation power  were obtained (Fig. 3). The greater threshold power of samples with undoped faces is, probably, related to nonoptimal doping conditions and, hence, to higher losses due to scattering. The maximal power and efficiency of laser generation were limited by the pump power and high pulse repetition rate.

were obtained (Fig. 3). The greater threshold power of samples with undoped faces is, probably, related to nonoptimal doping conditions and, hence, to higher losses due to scattering. The maximal power and efficiency of laser generation were limited by the pump power and high pulse repetition rate.

Figure 3. Output power of the  laser vs. pump power in the case of an active elements with ( 1 ) 'minimal' and ( 2 ) 'maximal' surface chromium concentrations.

laser vs. pump power in the case of an active elements with ( 1 ) 'minimal' and ( 2 ) 'maximal' surface chromium concentrations.

Download figure:

Standard imageGeneration spectra of both samples did not substantially differ, at a higher pump power they shifted to a longer-wavelength range approaching the maximum of the active medium gain at  at the generation linewidth of

at the generation linewidth of  .

.

Estimates of the power density corresponding to surface breakdown in undoped ZnSe samples and in the samples with maximal and minimal surface concentrations of chromium made for the case of tight focusing of the pump radiation at a wavelength of  (at a pulse duration of

(at a pulse duration of  ) show a noticeable difference between the samples of undoped ZnSe and samples with a maximal surface chromium concentration (

) show a noticeable difference between the samples of undoped ZnSe and samples with a maximal surface chromium concentration ( and

and  , respectively). Nevertheless, the power density for the samples with a minimal chromium concentration on the surface actually did not differ from that for undoped ZnSe samples.

, respectively). Nevertheless, the power density for the samples with a minimal chromium concentration on the surface actually did not differ from that for undoped ZnSe samples.

Further optimisation of the method of producing  structures may, seemingly, substantially enhance the laser resistance of optical elements and efficiency of generation especially in the range of high radiation powers.

structures may, seemingly, substantially enhance the laser resistance of optical elements and efficiency of generation especially in the range of high radiation powers.

Thus, we have fabricated polycrystalline  samples with a maximal chromium concentration in the sample bulk and zero concentration on the surfaces through which the laser radiation is coupled in/out. Comparison of the efficiencies of generation in the

samples with a maximal chromium concentration in the sample bulk and zero concentration on the surfaces through which the laser radiation is coupled in/out. Comparison of the efficiencies of generation in the  samples with undoped faces and in samples produced by the conventional method shows close results. An enhanced resistance of the obtained

samples with undoped faces and in samples produced by the conventional method shows close results. An enhanced resistance of the obtained  samples to surface laser breakdown has been demonstrated.

samples to surface laser breakdown has been demonstrated.

Acknowledgements.

The work was supported by the grant of the Ministry of Education and Science of the Russian Federation and Lobachevsky State University of Nizhny Novgorod (Agreement of the 27 August 2013, No. 02.V.49. 21.0003).