Abstract

Biological approach synthesis and characterization of Iron Sulfide (FeS) thin films from banana peel extract for contamination remediation of environment studied. Iron chloride, Sodium thiosulfate and Ethylene-di-amine-tetra acetate (EDTA) were used as precursor solutions without further purification. The nanoparticle of banana peel was extracted and prepared with synthesized FeS thin films and analyzed by X ray-diffraction for structural examination, Scanning electron microscope (SEM) for surface morphological analysis, Ultra-violet-visible-spectrometer (UV–Vis) and photo-luminescence spectro-photo-meter (P-L) for optical characterizations. XRD peaks are shown with recognized to (110), (200), (310), and (301) crystalline planes. The occurrence of this deflection peak are recognised the FeS crystal segment of the tetragonal crystalline systems. SEM micrographs of the films prepared biological method show the distribution of grains, which cover the surface of the substrate completely and are uniform and films deposited purely have defects. The photo-luminescence, absorbance, and transmittance strength of banana peel extract FeS thin film is greater than pure FeS thin films in which wide-ranging and symmetries groups were perceived. In the present study, the comparison of pure FeS thin films and Nano synthesized banana peel extract with FeS thin films was studied. It is observed that Nano synthesized banana fibre absorbs higher than pure FeS thin films in solar cell application. Finally, green synthesis is an ecofriendly, easy and cheap promising method for the fabrication of thin films for solar cell applications.

Similar content being viewed by others

Introduction

Today, ecological challenges such as enlarged air as well as water pollution have prolonged because of populace growth and fast industrialized expansion woeldwide1,2. Semiconductors have become the furthermost significant part of investigations throughout the ancient few years, particularly in the areas of electricity and optoelectronic technology3. Thin-film technologies are concurrently one of the eldest paintings and one of the latest science associations with thin-film ages to the metallic days of ancient times. Though non-solid and the related matters of interfering insignias have been investigated for over three eras, Integrating thin solid film was perhaps first attained by electrolyses very recently. A composite is a material made up of two or more other materials which give properties, in combination, which is not available from any of the ingredients alone. Nature continues to be generous to mankind by providing all kinds of resources in abundance for his living and existence. In this era of technology, products depend on new varieties of materials that have special characteristics4,5. Metal composites, plastic and fibre-reinforced polymer composites are playing a vital role in the fields of nanotechnology. The performance of machine components depends mainly on the material that it is made of in the fields of automobile, railways, aerospace, structural applications, etc., and the strength to weight ratio of the material plays an important role6. Due to the improved physical characteristics, the importance of fibers strengthened polymers compounds are gradually substituting numerous of the conservative ingredients7. Above the previous era, polymers compounds covered with ordinary fiber have been getting consideration, both from the theoretical biosphere as well as from several manufacturing8. Currently, the applications of natural fibers, particularly in motorized manufacturing, have collective repetition. Effectively instigated examples comprise both green fiber thermosets as well as thermo-plastic composite for internal uses such as door boards, shapely parts, and orchestra and tract tables9.

Biological technology is the addition of natural technologies as well as engineering to accomplish the claim of creatures, cells, body’s thereof as well as molecules correspondents for yields as well as facilities10. Biotechnology is multipurpose and has been considered an important area that has significantly impacted numerous technologies depending on the solicitation of bio procedure in engineering, farming, food-processing, medical approach, eco-friendly protection, and resource upkeep11. This new groundswell of high-tech deviations has strong-minded affected enhancements in numerous segments (preparation of medicines, vitamins, minerals, interferon, yields of fermentation serve as nutrition or drink, energy from renewable basis and contaminations and hereditary engineering applied on plants, animals, humans) since it can give completely novel chances for maintainable preparation of surviving and novel yields and services12. Additionally, ecological fears help determine the use of biological technology not only for pollution control (decontamination of water, air, and soil) but to preclude pollution and reduce waste in the first place and for ecologically friendly production of chemicals bio-monitoring12. The preparation of polycrystalline Iron Sulfide thin films via the biological techniques using enzymes, micro-organisms, and bodies of florae, as well as their excerpts, has been recommended as cheap techniques13.

A Nanocomposite material has meaningfully broadened in the previous few years. This term now encompasses a huge diversity of schemes joining one to two as well as three dimensions material with Iron Sulfide constituents variegated at the Nano-meter scales. Natural fibres are universal throughout the world in plants such as flax, sisal, banana, hemp, banana, wood, grasses etc. From naturally available fibres, banana fibre is effortlessly obtainable in fabrics as well as fibres systems with fine mechanically and thermally characteristics14.

Cultured banana is resulting from two species of the genus Musa, explicitly from Musa-acuminate and Musa-balbisiana. Musa-acuminate originated from Malaysians, while Musa-balbisiana initiated from Indians. Banana in Africa is categorized into three types, comprising East African(mainly desserts) banana, African plantains bananas grown up largely in the centre as well as west African and the East Africans highlands bananas, applied in cooking and beer preparation15. The banana varieties that have been released by the Ethiopian Institute of Agricultural Research (EIAR) are kept in order as (Ducasse Hybrid, Dwarf Cavendish, Giant Cavendish, poyo, Matoke, Nijiru, Kitawira, Cardaba, Butuzua, Robusta, Grand Nain and Williams-1) having Potential Yield (q/ha)16 between 261 and 556. Because of availability in the large area, the researchers have done their study on the Williams-1 banana variety.

Banana fibre is biodegradable, cost-effective and lowers compactness fibre with extraordinary precise behaviours. So, banana grounded combination constituents could be applied in industrial, automobile, structural and aerospace applications. Banana fibre is hydrophilic in nature which causes poor wettability with hydrophobic organic matrix resins like polyester when preparing composites17. The hydrophobicity nature of banana fibre is reduced by chemical modifications like alkalization, lightening etc. These treatments not only decrease the water absorption capacity of the fibre but also increase the wettability of the fibre with resin and improve inter bond between fibre and matrix. The foremost features of banana fibre are celluloses, lignins, hemicelluloses and pectin18. The importance of banana cellulose fibre resulting from yearly renewables resource as a supporting part in polymer atmosphere composite delivers optimistic environmentally welfare with respect to eventual disposable and raw materials. The main advantage of banana cellulose fibers is: a Renewables environment, a wide variety of plasters obtainable throughout the world, Nonfood undeveloped grounded economies, Low-slung energy consumption, cheap, lowest density, Extraordinary precise asset and modulus, great comprehensive repetition of cellulosic based composite, the reprocessing by ignition of cellulose filled composites are easier in contrast with mineral filler systems. The possibility of using banana cellulose fibres as a reinforcing phase has received considerable interest in accumulation, the intrinsic Nanoscale properties of banana fibre cellulose material for developing advanced Nanomaterials and composites19.

This environmentally suitable technique for polycrystalline Iron Sulfide (FeS) preparation draws extra significance and is unusual to the biochemical and physical techniques15 because of the escaping of the importance of poisonous chemicals as well as maximum energy components in the preparation procedures. Bodies of plant extracts vigorously contribute to the biological decline procedure to change the metallic ions to metals and metallic oxides16. Green deposition FeS plays a vital role in contradiction of the degradation procedure of engineering dyes because of photocatalytic influence20.

Presently the earth is in fear of airborne and water contamination unconfined from non-renewable energy bases like Coal, natural gases, fossil fuel and gas released from the industry. The excess fluids released out of fabrics pour out to the streams and result in water contamination. This contaminated water is in a straight line drunken by the community and causes diseases such as cholera, amoeba and typhoids. Commonly it disturbs human’s protection fitness in the biosphere. Solar technology connects solar panels, and renewable and Sustainable energy sources21. This sustainable energy source starts from natural possessions that endlessly substitute. These contain the sunlight, oceans as well as the power of winds. These types of technologies are considered clean and do not contain carbons since it doesn’t emit greenhouse gas. The solar cell is an uncontaminated energy source; it hasn’t an environmental impact on nature like the energy originates from fossil coals. When fossil fuels are burned, it releases hazardous carbon poisonous radiations into the atmosphere10,22. To minimize these harmful wastes and contaminations from the environment, the preparation and manufacture of solar energy from compound semiconductors and thin films are the only elucidations. As presently, prevailing elemental semiconductors are very expensive and developing countries like Ethiopia cannot operate them. Widespread vacillating research has been enthusiastic about depositing several types of semiconductor thin films which are used in renewable sources of energy like solar cells23,24,25,25, due to their applications in the manufacture of photovoltaic ingredients optoelectronic devices, sensors and infrared indicators devices. Iron Sulfide (FeS) thin-film appeals attention of various scholars for they comprise cheap, existence in the large area as well as hold semiconducting materials26.In this concern, we have efficiently produced the FeS thin films from banana peel extract. The photocatalytic degradation of maximum concentrations of crystal violet has been studied for the first time in facet.

Materials and methods

All chemicals, iron chloride, Sodium thiosulfate and Ethylene-di-amine-tetr-acetate (EDTA), were bought from Sigma Aldrich and used without any distillation. Triple deionized water was served as solvents in all laboratory works. The peel of bananas was collected from the local area, Ethiopian country, Oromia region, and Gudaya Bila, as shown in Fig. 1. This peel of banana was polluting the area, and we collected it to make it dry in normal conditions and grind it to make it powder by using a pistol and mortar. The plant we have used in this report was cultivated in Gudaya Bila, Ethiopia. This study complies with relevant legislation and international, national, and institutional guidelines.

Characterization techniques

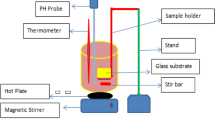

The structure, morphology and optical characteristics of Iron Sulfide (FeS) were investigated through X-ray diffraction (XRD), Scanning electron microscope(SEM) and UV–vis spectro-photo-meter (UV) and Photoluminescence(PL). Figure 2 displays the characterization techniques with utilities.

Furthermore, the average crystal size of the peel of the banana collected was calculated using the Scherer equation.

D = The crystallite size (D) of the grains can be evaluated using the Scherer’s formula10

where K = 0.94 is Scherer constant, \(\lambda \) is X-ray wavelength, \(\theta \) is Bragg diffraction angle, and \(\beta \) is the peak width of the diffraction line at the maximum intensity. Table 1 presents the variation of the measured FeS thin films.

Experimental details : green deposition of polycrystalline iron sulfide (FeS) using banana peel extraction

The peel of the banana was collected and dried in the normal condition for 3 weeks. Then by using a mortar with a pestle, grinded to get a powder form. In the chemical bath deposition techniques, a water bath beaker with 0.2 M of 250 ml solution was added to 70 mL of Iron Chloride(99.99% purity), 30 mL of Sodium thiosulfate (99.997% purity), and 0.1 M f 10 mL of EDTA (99.89% purity), was added as complexing agent. After appropriate involvement, this solution reaction was placed on a heater of temperature 180℃ with PH value was adjusted to two (PH = 2 acidic bath) adding a droplet of H2SO4 for the 20 min string time and Plastic substrate inserted vertically, then taken at 120 min as sample 1. Then 10 mg of banana peel extract powder was added to the newly prepared solution with the same step. Finally, the substrate was vertically immersed, and the total time of deposition was 120 min (2 h). After the accomplishment of synthesis time, the sample was taken out of the bath as sample 2 and kept in the oven for further characterization.

Result and discussion

Structural analysis of polycrystalline FeS thin films

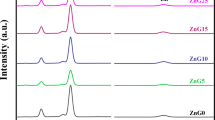

Structure characteristics of the organized banana collected were conducted XRD and given in Fig. 3. XRD of FeS prepared by 2.5 mL of 10 mg of banana leaf extract powder was added to the solution (Fig. 3) displays principal crests at 2\(\uptheta \) values 12.8°, 28.9°, 37.9°, 46.9°, 50.9°, 69.0°, and 69.9° which are recognized to (110), (200), (310), and (301) Crystal planes with codes COD (R2) = 0.89428054885579, correspondingly. The occurrence of this deflection peak is attributed to the FeS crystal segment of the tetragonal crystalline systems. This result shows in good agreement with nanoparticles published previously27.

From XRD patterns, numerous peaks were observed for banana peel extract of FeS thin films and no peak was gained from pure FeS thin films. This shows that the pure FeS thin films are an amorphous structure, and the tetragonal crystal structure was observed for the biosynthesis of FeS thin films from banana peel extract. The crystal size and parameters gained from XRD data are discussed in the table below.

Optical characterization of iron sulfide (FeS) thin films

The photoluminescence (PL) spectra of FeS thin films at 180 °C for 2 h prepared using banana peel extracts and pure FeS thin films are displayed in Fig. 4, and spectrums are gained from the U-V; Figs. 5 and 6 show the absorbance and transmittance of excitation wavelength λ = 300–700 nm. It obviously can be seen that the photo-luminescence strength of banana peel extracts FeS thin film is greater than pure FeS thin films in which wide-ranging and symmetries groups were perceived. This may be because the existence of impurity comes from substrates. The profound emanations in the visible range designate the existence of structural defects28. A feeble band's emissions in the U-V section are detected at 372–428 nm, conforming to the radiated re-combinations between the animated electron in the conductions band as well as the holes in the valence bands29,30,31,32. The optical characteristics allow banana peel extracts FeS thin films are useful for photovoltaic solar cells33. According to the findings of this research, it is also anticipated to carry out similar studies insight of regulating the shapes of the Nanoparticles and investigating other physical characteristics as reported beforehand on other Nanoscaled metal-sulfide Nanocomposites or oxide34.

Morphological characterization

Figure 7 displays the scanning-electron-microscopy (SEM) micrographs of the Iron sulfide films deposited using chemical or pure and banana peel extracts. Depending on Fig. 7a,b, the films prepared by chemical and biological methods confirm complete exposure of materials on superficial substrates. The Scanning electron microscope micrographs of the films prepared from the biological approach show distribution of grains, which covers the surface of the substrate completely and uniform (Fig. 7a). The result may be because of an inadequate quantity of iron source and banana peel extracts of Iron sulfide ions in the solution and has good agreement with reports35. The FeS thin film deposited through biological methods is uniformly covered on the substrate. Established on the scanning electron microscope micro-graph, the particle configurations are made on an agglomerate surface (average size is around 21 μ-m)36. Comparison between the thin films deposited at biological methods from peel extracts exposes that the amount of Iron Sulfide thin films peak enlarged, demonstrating the best crystal phases for the films prepared37. The thin films show slighter grain associated with the other thin films prepared from chemicals only or pure ones (Fig. 7b). The pin-holes are perceived on the superficial of the thin film. This result is finely matched with reports38,39,40,41.

Conclusion

Iron Sulfide (FeS) films were effectively deposited through chemical bath deposition techniques. X-Ray Diffraction examination shows the polycrystalline nature of the thin films with the tetragonal segment. Thin films organized through banana peel extract FeS was a higher number of peaks than pure FeS thin films. The superficial morphology of biosynthesized films was detected moderately even and fully deposited on the substrate than the pure FeS thin films. Experimental outcomes showed that the deposition using 0.2 M iron chloride and sodium thiosulphate was the best complaint about the preparation of Iron Sulfide thin films. The spectra are obtained using the UV excitation wavelength λ = 300–700 nm and PL. It is evidently seen that the photo-luminescence strength of banana peel extract FeS thin film is greater than pure FeS thin films in which broads and symmetries bands are witnessed. These profound emanations in the visible ranges show the presence of structural imperfections. Finally, the use of biosynthesis in the production of thin films as a photo absorber is promising for future energy sources which are clean, portable and simple operations.

Data availability

The data are included with in the article.

References

Gonçalves, R. A., Toledo, R. P., Joshi, N. & Berengue, O. M. Green synthesis and applications of ZnO and TiO2 nanostructures. Molecules 26(8), 2236 (2021).

Awan, S. et al. A preliminary study of influence of zinc oxide nanoparticles on growth parameters of Brassica oleracea var italic. J. Sau. Soc. Agric. Sci. 20(1), 18–24 (2021).

Raafat, M., El-Sayed, A. S. & El-Sayed, M. T. Biosynthesis and anti-mycotoxigenic activity of zingiber officinale roscoe-derived metal nanoparticles. Molecules 26(8), 2290 (2021).

Ahmad, S. et al. Green nanotechnology: A review on green synthesis of silver nanoparticles: An ecofriendly approach. Int. J. Nanomed. 14, 5087 (2019).

Abbasian, R. & Jafarizadeh-Malmiri, H. Green approach in gold, silver and selenium nanoparticles using coffee bean extract. Open Agric. 5(1), 761–767 (2020).

Painuli, S., Semwal, P., Bachheti, A., Bachheti, R. K. & Husen, A. Nanomaterials from non-wood forest products and their applications. In Nanomaterials for Agriculture and Forestry Applications 15–40 (2020).

Devasia, J., Muniswamy, B. & Mishra, M. K. Investigation of ZnO nanoparticles on in vitro cultures of coffee (Coffea Arabica L.). Int. J. NanoSci. Nano. 16(4), 271–277 (2020).

Rossi, L., Fedenia, L. N., Sharifan, H., Ma, X. & Lombardini, L. Effects of foliar application of zinc sulfate and zinc nanoparticles in coffee (Coffea arabica L.) plants. Plant Phys. Biochem. 135, 160–166 (2019).

García-López, J. I. et al. Foliar application of zinc oxide nanoparticles and zinc sulfate boosts the content of bioactive compounds in habanero peppers. Plants. 8(8), 254 (2019).

Mosquera-Sánchez, L. P. et al. Antifungal effect of zinc oxide nanoparticles (ZnO-NPs) on Colletotrichum sp., causal agent of anthracnose in coffee crops. Biocat. Agric. Biotech. 25, 101579 (2020).

Singh, R., Hano, C., Nath, G. & Sharma, B. Green biosynthesis of silver nanoparticles using leaf extract of Carissa carandas L. and their antioxidant and antimicrobial activity against human pathogenic bacteria. Biomolecules 11, 299 (2021).

Bacco, M., Barsocchi, P., Ferro, E., Gotta, A. & Ruggeri, M. The digitization of agriculture: A survey of research activities on smart farming. Array 3, 100009 (2019).

Ambisa, Z., Tesfa, B., Olani, T. & Abdeta, D. Review on the production and marketing of banana in Ethiopia. World J. Agric. Soil. Sci. 2, 1 (2019).

Irshad, S. et al. Biosynthesis of ZnO nanoparticles using Ocimum basilicum and determination of its antimicrobial activity. J. Anim. Plant Sci 301, 185–191 (2020).

Marimuthu, S. et al. Silver nanoparticles in dye effluent treatment: A review on synthesis, treatment methods, mechanisms, photocatalytic degradation, toxic effects and mitigation of toxicity. J. Photochem. Photobiol. B Biol. 205, 111823 (2020).

Vinayagam, R., Pai, S., Varadavenkatesan, T., Pugazhendhi, A. & Selvaraj, R. Characterization and photocatalytic activity of ZnO nanoflowers synthesized using Bridelia retusa leaf extract. Appl. NanoSci. 2021, 1–10 (2021).

Ngom, I. et al. On the use of moringa oleifera leaves extract for the biosynthesis of NiO and ZnO nanoparticles. MRS Adv. 5(21–22), 1145–1155 (2020).

Li, J. et al. Influence of α-and γ-Fe 2 O 3 nanoparticles on watermelon (Citrullus lanatus) physiology and fruit quality. Water Air Soil Pol. 231(4), 1–12 (2020).

Klomchit, A., Calderin, J. D., Jaidee, W., Watla-Iad, K. & Brooks, S. Napthoquinones from Neocosmospora sp.—Antibiotic activity against acidovorax citrulli, the causative agent of bacterial fruit blotch in watermelon and melon. J. Fungi. 7(5), 370 (2021).

Bhattacharjee, C., Dutta, S. & Saxena, V. K. A review on biosorptive removal of dyes and heavy metals from wastewater using watermelon rind as biosorbent. Environ. Adv. 2, 100007 (2020).

Dejen, K. D., Zereffa, E. A., Murthy, H. A. & Merga, A. Synthesis of ZnO and ZnO/PVA nano composite using aqueous Moringa oleifeira leaf extract template: Antibacterial and electrochemical activities. Rev. Adv. Mater. Sci. 59(1), 464–476 (2020).

Bakir, A., Hamimed, S., Landoulsi, A. & Chatti, A. Biogenic zinc oxide nano-structures differentiation under musical sounds (preprint). Res. Sqr (2021).

Nurman, S., Yulia, R., Irmayanti, I., Noor, E. & Candra Sunarti, T. Optimizing anti-inflammatory activities of arabica coffee ground (Coffea arabica L) nanoparticle gel. Jundishapur J. Nat. Pharm. Prod. 16(2), e102673 (2021).

Pavelkova, R., Matouskova, P., Hoova, J., Porizka, J. & Marova, I. Preparation and characterisation of organic UV filters based on combined PHB/liposomes with natural phenolic compounds. J. Biotech. X. 7, 100021 (2020).

Desalegn, T., Ravikumar, C. R. & Murthy, H. A. Eco-friendly synthesis of silver nanostructures using medicinal plant Vernonia amygdalina Del. leaf extract for multifunctional applications. Appl. Nanosci. 11(2), 535–551 (2021).

Song, C. et al. Metabolic profile and physiological response of cucumber foliar exposed to engineered MoS2 and TiO2 nanoparticles. NanoImpact 20, 100271 (2020).

Baghaienezhad, M., Boroghani, M. & Anabestani, R. Silver nanoparticles synthesis by coffee residues extract and their antibacterial activity. Nano. Res. J. 5(1), 29–34 (2020).

Garrido-Hernández, A. et al. Effect of europium on the blue–green emission of ZnS thin films by polyol and dip-coating technique. Mater. Sci. Semicond. Process. 121, 105403 (2021).

Naseema, K., Ribin, K., Navya, N. & Prasannan, P. Catalytic growth and photoluminescence properties of ZnS nanowires. Z. Naturfor. Teil A. 76(1), 65–73 (2021).

Onochie, U. P. et al. Analysis of optical band gap and urbach tail of zinc sulphide coated with aqueous and organic dye extracts prepared by chemical bath deposition technique. Opt. Mater. 114, 110970 (2021).

Vargas-Rueda, J.A., Alonso, A.R., Meléndez-Zamudio, M. & Meléndez-Lira, M. Chemical stability diagrams as a powerful tool to the synthesis of Cu2SnS3 thin films by chemical bath deposition. Mat. Chem. Phy. 124478 (2021).

Vall, C. S. et al. Effect of chromium percentage doping on the optical, structural, morphological and electrical properties of ZnS: Cr thin films. Phys. E Low Dimen. Syst. Nanostruct. 130, 114694 (2021).

Benyahia, K. et al. Microstructured ZnO-ZnS composite for earth-abundant photovoltaics: Elaboration, surface analysis and enhanced optical performances. Sol. Energy 218, 312–319 (2021).

Offor, P. O. et al. Effect of concentration of trisodium citrate complexing agent on spray-synthesized ZnS thin films. Mater. Today Proc. 36, 133–140 (2021).

Abdulrahman, A. F., Ahmed, S. M., Hamad, S. M. & Barzinjy, A. A. Effect of growth temperature on morphological, structural, and optical properties of ZnO nanorods using modified chemical bath deposition method. J. Electron. Mater. 50, 1–14 (2021).

Maria, K. H., Sultana, P. & Asfia, M. B. Chemical bath deposition of aluminum doped zinc sulfide thin films using non-toxic complexing agent: Effect of aluminum doping on optical and electrical properties. AIP Adv. 10(6), 065315 (2020).

Kim, J. et al. Role of hydrazine in the enhanced growth of zinc sulfide thin films using chemical bath deposition for Cu (In, Ga) Se2 solar cell application. Mater. Sci. Semicond. Process. 105, 104729 (2020).

Arandhara, G., Bora, J. & Saikia, P. K. Effect of pH on the crystallite size, elastic properties and morphology of nanostructured ZnS thin films prepared by chemical bath deposition technique. Mat. Chem. Phy. 241, 122277 (2020).

Trejo-Ramos, A. I., González-Chan, I. J. & Oliva, A. I. Physical properties of chemically deposited ZnS thin films: Role of the solubility curves and species distribution diagrams. Mater. Sci. Semicond. Process. 118, 105207 (2020).

Geremew, T. & Abza, T. Microstructural and optical characterization of heterostructures of ZnS/CdS and CdS/ZnS synthesized by chemical bath deposition method. Adv. Mater. Sci. Eng. 2020, 1–11 (2020).

Benamra, H. et al. Physical properties of Al-doped ZnS thin films prepared by ultrasonic spray technique. Surf. Interfaces 21, 100645 (2020).

Author information

Authors and Affiliations

Contributions

Conceptualization: A.S and K.R. Data curation: A.S, K.R. L.T.J and N.N. Analysis and validation: A.S, L.G, S.S., K.R and V.S. Formal analysis: A.S, L.G, S.S, V.S and K.R. Investigation: A.S, L.G and S.S.. Methodology: A.S, L.T.J, K.R.. and N.N . Project administration: A.S, K.R, L.T.J. and N.N. Resources: A.S, K.R., L.T.J and N.N. Software: A.S, K.R., L.G, S.S and N.N. Supervision: K.R. and L.T.J. Validation: A.S, S.S, L.G. and K.R. Visualization: A.S, K.R, L.T.J and N.N. Writing—original draft, A.S, K.R., and N.N. Data visualization, editing and rewriting, A.S, K.R. and V.S.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saka, A., Jule, L.T., Soressa, S. et al. Biological approach synthesis and characterization of iron sulfide (FeS) thin films from banana peel extract for contamination of environmental remediation. Sci Rep 12, 10486 (2022). https://doi.org/10.1038/s41598-022-14828-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-14828-0

This article is cited by

-

Recent progress in organic waste recycling materials for solar cell applications

Environmental Science and Pollution Research (2023)

-

Growth, yield, and yield variables of onion (Allium Cepa L.) varieties as influenced by plantspacing at DambiDollo, Western Ethiopia

Scientific Reports (2022)

-

Biosynthesis of TiO2 nanoparticles by Caricaceae (Papaya) shell extracts for antifungal application

Scientific Reports (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.