Abstract

The effects of rice husk flour (RHF), rice husk biochar (RHB), and rice husk-sludge cake biochar (RH-SCB, expresses sludge cake biochar deriving from a sludge that has been previously conditioned with rice husk) used as physical conditioners on sludge dewaterability were compared. The effects of characteristics of physical conditioners on sludge compressibility and zeta potential were analyzed. The optimal rice husk-based powder was RH-SCB, which presented the highest net sludge solid yield (YN, expresses the dry mass flow by filtration) at 20.39 kg/(m2 h) for 70% dry sludge (DS). Characterization analysis indicates that the hardness and surface Fe content of powders which could influence the compressibility coefficient of sludge cake and sludge zeta potential were the major factors influencing sludge dewaterability. The comparison of feasibility and economic analysis showed that adding RH-SCB improves the quality of the sludge filtrate and reduces the pollution potential of conditioned sludge (the ratio of secondary and primary (RSP) of Cu, Zn, Cd reduces from 43.05, 144.00, 7.25 to 7.89, 14.63, 4.27, respectively), and the costs of using RH-SCB were the lowest (at 88.4% lower than that of the raw sludge). Therefore, it is feasible to use RH-SCB to improve sludge dewaterability.

Similar content being viewed by others

Introduction

Most municipal wastewater treatment plants (WWTPs) use activated sludge to treat wastewater1. Due to the increasing amount of wastewater and current efficiency of wastewater treatments, the amount of sewage sludge (moisture content higher than 90%) produced worldwide has also increased. This sludge must be treated and disposed appropriately because it can contain several pollutants that were removed from the wastewater2,3. In this context, it is still a challenge to efficiently treat domestic and industrial wastewaters.

Sludge normally contains a significant proportion of water1, which hinders the use of disposal methods such as composting and incineration. Thus, sludge conditioning and dewatering are essential for its treatment4,5. Currently, a common technique for dewatering of sewage sludge is mechanical dewatering. However, this method can be costly due to the low filtration rate of sludge and the use of high mechanical pressure6. Therefore, sludge dewatering must be effectively improved. Chemical flocculants such as cationic polyacrylamide (CPAM) and ferric chloride (FeCl3) are commonly used in WWTPs to separate water from sludge and improve the efficiency of sludge dewatering by charge neutralization and adsorption bridge7,8. However, the final steps of sludge dewatering are difficult to perform due to the formation of a compact sludge cake9,10.

To solve this problem, physical conditioners are used in sludge dewatering as they can improve the structure permeability of sludge cakes11. The use of waste biomass-based materials has been investigated for this purpose12. The waste biomass-based materials include raw waste biomass-based materials flour (such as rice husk flour, bamboo flour13, and wood sawdust14, etc.), biomass-based biochar (such as rice husk biochar15), and sludge cake biochar conditioned by biomass-based materials (the sludge cake biochar derived from pyrolysis of dewatered sludge which was conditioned with different biomass-based materials such as rice husk, bamboo, and wood, etc.). All of these materials lead to low compressibility of the sludge cake during dewatering under high pressure. A permeable skeleton structure is formed in the sludge cakes, thus increasing the removal of water and, consequently, the sludge dewaterability. However, it is not clear what kind of waste biomass-based material is better for sludge dewatering, raw flour, biochar, or sludge cake biochar conditioned by biomass-based materials. It was reported that the dewaterability of sludge conditioned with sawdust and cationic polyacrylamide (CPAM) was superior to the dewaterability of sludge conditioned with CPAM alone14. And Wang et al. also found that the SRF and CST of sludge conditioned with bamboo flour and rice husk flour was lower than those of sludge conditioned without these skeleton builders13. The above studies showed that biomass-based materials could further increase sludge dewaterability. But few studies have compared the effects of different waste biomass-based materials on sludge dewaterability. Moreover, the feasibility of adding different waste biomass-based materials including the effects of different waste biomass-based materials on the pollution potential of heavy metals in the sludge, and pH and SCOD of sludge filtrate which can significantly influence sludge disposal, and the disposal costs have not been compared.

In our previous experiment, rice husk-based powders, such as rice husk flour, rice husk biochar, and sludge cake biochar conditioned by rice husk flour, are used as physical conditioners to improve sludge dewaterability6,16. In this study, the effects of different rice husk-based physical conditioners on sludge dewaterability were compared. Characteristics such as microstructure, surface element content, component analysis, surface zeta potential, and specific surface area of rice husk-based powders were analyzed to clarify the mechanisms of improving dewaterability. The transference and translation of heavy metals and their pollution levels in the sludge, in addition to the pH and SCOD of sludge filtrate and the disposal costs, were compared. The results provide a theoretical basis for choosing proper physical conditioners.

Materials and method

Materials

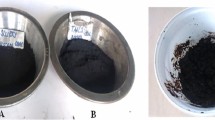

Physical conditioners

Following our preliminary study17, rice husk flour (RHF, 109–150 μm) was produced from rice husk upon grounding and sieved by 100-mesh and 140-mesh screen. Rice husk biochar (RHB, 80–250 μm) was prepared at 500 °C for 2 h in an electric tube furnace (SK2-2-13, China) under nitrogen protection, sieved by 60-mesh and 180-mesh screen. After the sludge conditioned with FeCl3 (115.07 g/kg DS) and rice husk flour (0.7 kg/kg DS), the conditioned sludge was dried and then put into an electric tube furnace under the protection of nitrogen prepared at 400 °C for 2 h. Finally, the sludge cake biochar deriving from a sludge that has been previously conditioned with rice husk (0.7 kg/kg DS) and FeCl3 (115.07 g/kg DS) (Rice husk-sludge cake biochar, RH-SCB, 80–250 μm) was obtained. For that, a FeCl3 solution (5 g/L), which is commonly used as an inorganic conditioner, was used.

Raw sewage sludge

For the experiments, the sample of raw sewage sludge from a local municipal WWTP of Chongqing, China, was used. Before the treatment, the samples were stored in sealed plastic buckets at 4 °C in a laboratory refrigerator to reduce the activity of microorganisms18. Before each experiment, the sludge was heated for 30 min at 20 °C in a thermostatic water bath to ensure compliance with the actual sludge treatment in the sewage treatment plant16. The main characteristics of raw sewage sludge are shown in Table 1. The YN used to evaluate the sludge filterability in this work, represents the mass of sludge solids filtered per unit area and unit time, which can be calculated according to Ning et al.19.

Sludge conditioning and dewatering

Rice husk-based powders and FeCl3 (115.07 g/kg DS) were added in sequence into the sewage sludge. After a mixing apparatus (JJ-6, China) was used to stir the mixture, 100 ml of the sample was poured into a Buchner funnel (8 cm), and then filtered at a filter pressure of 0.03 MPa. The net sludge solids yield (YN) was used as the main evaluating index of sludge dewaterability. Specific resistance to filtration (SRF) and moisture content of filtered sludge cake were used as secondary indexes. Additionally, the compressibility coefficient of sludge cakes conditioned with different rice husk-based powders was measured. The final value for each experiment was the average result of two to three repeated tests.

Transference and translation of heavy metals and their concentration in the sludge

In our previous studies, the main heavy metals observed in sludge were Cu, Zn, and Cd. Therefore, their contents in the raw and conditioned sludge filtrate were measured. Moreover, the content and five fractions (namely exchangeable, carbonate-bound, Fe–Mn oxide-bound, organic matter-bound, and residual) of heavy metals in the raw and conditioned sludge cake were tested to analyze the transference and translation of heavy metals. The content of heavy metals was measured by an inductively coupled plasma optical emission spectrometer (ICP-OES) (Optima 7000, USA), and the five fractions of heavy metals were measured by a sequential extraction procedure according to Fu Chuan20. The pollution level of heavy metals in sludge cakes was reflected with the ratio of secondary and primary phases (RSP) calculated by Li21. The calculation formula of RSP is shown in Text S1.

Characteristics of physical conditioners

The surface zeta potential of the physical conditioners was tested by using a Zetasizer Nano analyzer (ZEN3600, England). An environmental scanning electron microscope (ESEM; Quanta 200, America) was used to test the microstructures of the rice husk-based powders. Specific surface areas and component analysis were investigated by a specific surface area analyzer (ChemiSorb 2720, America) and X-ray diffractometer (XRD) (D5000, Germany), respectively. Surface element contents were analyzed by energy-dispersive spectrometry (EDS) (EDAX genesis XM-2, America).

Analytical methods

Sludge SRF was measured by the Buchner funnel method22, moisture content of sludge cake was tested by a gravimetric method, and YN was calculated by SRF, according to Ning et al.19. These methods were combined to evaluate the sludge filterability and dewaterability23. The compressibility coefficient of sludge cakes conditioned with different rice husk-based powders was calculated by sludge SRF under different filtration pressures24. The pH of the sludge filtrates was tested by an acidimeter (PHS-3C, China). The filtrate SCOD was measured according to the potassium dichromate method after filtering through a 0.45 μm membrane25.

Results and discussion

Effects of different rice husk-based powders on sludge dewaterability

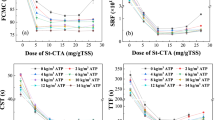

Figure 1 shows the effects of different rice husk-based powders used as physical conditioners on sludge dewaterability. The sludge YN increased with increasing powder dosage, while the sludge SRF and moisture content of sludge cakes decreased. The YN upon the use of rice husk-sludge cake biochar (RH-SCB) was higher than those upon the use of rice husk flour or biochar. Moreover, the SRF and moisture content were the lowest for the sludge cake conditioned with RH-SCB. The highest YN of 20.39 kg/(m2 h) was achieved when the dosage of RH-SCB was 70% dry sludge (DS) (0.7 kg RH-SCB/kg DS). These results indicate that, among the studied materials, RH-SCB is the optimal one for use as a physical conditioner to enhance sludge dewaterability. The reason may be that the surface iron content of RH-SCB is high, and the surface charge of the RH-SCB is positive, causing the RH-SCB to embed in flocs by charge neutralization with sludge particles before adding FeCl3 and work better as a skeleton builder during sludge dewatering17.

Effects of different rice husk-based powders on sludge cake compressibility

Reducing sludge cake compressibility is the main function of physical conditioners in sludge conditioning and dewatering4. Figure 2 shows the compressibility of sludge cake conditioned with different rice husk-based powders. All the compressibility coefficients were lower than those of raw sludge cake and sludge cake with FeCl3 alone. When the RH-SCB was used, the sludge cake compressibility (s = 0.79) was the lowest, which means that the obtained sludge cake was the most permeable and its sludge dewaterability was the best out of the different options tested17. These results indicated that RH-SCB plays a better support role during sludge dewatering which might be caused by the high content of surface iron of RH-SCB. Therefore, the RH-SCB, deriving from a sludge that has been previously conditioned with FeCl3 (115.07 g/kg DS) and rice husk flour (0.7 kg/kg DS), was the best option for use as a sludge physical conditioner in this study. The obtained results are consistent with those shown in Fig. 1.

Effects of different rice husk-based powders on sludge zeta potential

The zeta potential of the sludge with different rice husk-based powders are shown in Table S1. Only the surface charge of the RH-SCB was positive among all three rice husk-based powders. When only the RH-SCB was used, the zeta potential of the sludge was closer to 0 mV, which implies that the sludge colloids attracted each other and formed an unstable system that caused good settling and dewatering performance4. Both surface charge of RHF and RHB are negative, and they could not flocculate with sludge particles before adding FeCl3 and might be on the outside of sludge flocs with adding FeCl3. The flocs with adding RHF or RHB were still compact during sludge dewatering. But RH-SCB could flocculate with negatively-charged sludge particles and embedded in flocs before adding FeCl3. The flocs with adding RH-SCB were permeable and more moisture of sludge could be removed. These results prove the inference in Fig. 1, and they indicate that the surface zeta potential significantly impacts sludge conditioning and dewatering.

Characterization analysis

Characteristics such as microstructures, specific surface areas, surface Fe content, and component analysis of the different rice husk-based powders were tested to analyze the mechanism of improving dewaterability. The microstructures (Fig. S1) indicate that the RH-SCB contained rice husk-based biochar and sludge-based biochar17. The surface of the RHB was more porous and wrinkled than those of RHF and sludge-based biochar. The specific surface area (Table S2) was higher for RH-SCB (25.012 m2/g) compared to RHF (2.473 m2/g), but lower compared to RHB (56.032 m2/g). Therefore, the specific surface area of rice husk-based powders was not the major influencing factor for sludge conditioning and dewatering.

The component analysis (Fig. S2) shows that RH-SCB contains large amounts of silica, which may have caused the strongest hardness and greatest support of RH-SCB (RH-SCB could not be crushed under high pressure during sludge dewatering), consequently leading to the lowest compressibility coefficient of sludge cake (consistent with the results of Fig. 2). In addition, according to the Fe contents (Table S3), the highest content of iron species was observed on the surface of RH-SCB. Fig. S2 also indicates that the RH-SCB contains iron compounds such as NaFeS2•2H2O, KFe2P2, and Fe3(PO4)2·8H2O, which are not present in rice husk flour and biochar. These iron species derive from the existent FeCl3 and are formed in the preparation of the RH-SCB. These iron species on the surface of the RH-SCB lead to a positive charge, thereby resulting in optimal surface zeta potential and dewaterability of the sludge that was conditioned with FeCl3 (115.07 g/kg) and RH-SCB (70% DS)26. To sum up, the RH-SCB was hard, so they could not be crushed under high pressure during sludge dewatering and play a better support role in sludge cake; the surface charge of the RH-SCB was positive, so they could embed in flocs before adding FeCl3 and improve the flocs permeability, resulting in more moisture of sludge being removed. These results indicate that the hardness and content of the surface Fe element of rice husk-based powders can influence the sludge cake compressibility and sludge zeta potential. Therefore, they are the major influencing factors for sludge conditioning and dewatering.

Comparison of feasibility and economic analysis

Transference and translation of heavy metals in sludge

The heavy metal content in the raw and conditioned sludge filtrates and the content of five fractions of heavy metals in the raw and conditioned sludge cake were tested to analyze the transference and translation of heavy metals in the sludge. Figure 3 shows the heavy metals contents of sludge filtrates and cakes. As shown in Table S4, the heavy metal content of all sludge filtrates met the Chinese discharge standards, except for Zn in the raw sludge filtrate. All sludge cakes met the Chinese standards for grade B sludge agricultural products. The content of heavy metals in the sludge filtrate and cakes conditioned by RHF, RH-SCB, and RHB were lower than those in raw sludge filtrate, except for Zn after conditioning by RH-SCB. The heavy metals contents of the sludge filtrate and cake conditioned by RHB were the lowest, likely because the RHB has a strong adsorption capacity at the maximum specific surface area (Table S2). The heavy metals contents of sludge cake conditioned by RH-SCB were the highest, likely because the RH-SCB was prepared from a part of sludge, which contains a high content of heavy metals (Table S5). Also, the dry sludge cake of unit mass of the sludge conditioned by rice husk flour and rice husk biochar contained a certain amount of dry sludge and skeleton particles. It can be seen from Table S5 that rice husk flour and rice husk biochar contain relatively low heavy metal content. But in RH-SCB, the content of the three heavy metals is much higher than RHF and RHB (according to Table S5). So the content of three heavy metals in the sludge cake after the combined conditioning of RH-SCB and FeCl3 is higher. Table S6 shows the total mass of heavy metals of sludge filtrates and cakes. And the results in Table S6 indicate that the total mass of heavy metals in sludge has not changed.

Heavy metals contents of sludge filtrate and sludge cakes (FeCl3 dosage of 115.07 g/kg DS, RHF dosage of 70% DS, RH-SCB dosage of 70% DS, and RHB dosage of 60% DS). a-raw sludge, b-sludge conditioned by FeCl3 alone, c-sludge conditioned by RHF, d-sludge conditioned by RH-SCB, e-sludge conditioned by RHB.

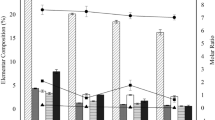

Figure 4 shows the five fractions of heavy metals in the sludge cakes. Table S7 shows the respective RSP values, which indicate the risks posed by heavy metals in different sludge cakes. All RSP values of sludge cakes conditioned by rice husk-based powders were lower than that of raw sludge cake (Cu (43.05), Zn (144.00), Cd (7.25)) and sludge cake conditioned by FeCl3 alone (Cu (48.07), Zn (173.88), Cd (8.01)), and the RSP of sludge cakes conditioned by RHB were the lowest (Cu (4.45), Zn (13.18), Cd (3.39)). Although the heavy metal contents of sludge cakes conditioned by RH-SCB were high, the RSP values (Cu (7.89), Zn (14.63), Cd (4.27)) were still lower, which indicates that the heavy metals in the sludge cake conditioned by RH-SCB presented a lower pollution potential than those in the raw sludge cake and sludge cake conditioned by FeCl3 alone.

Five fractions of heavy metals in sludge cakes (FeCl3 dosage of 115.07 g/kg DS, RHF dosage of 70% DS, RH-SCB dosage of 70% DS, and RHB dosage of 60% DS). a-raw sludge, b-sludge conditioned by FeCl3 alone, c-sludge conditioned by RHF, d-sludge conditioned by RH-SCB, e-sludge conditioned by RHB, F1—exchangeable, F2—carbonate-bound, F3—Fe–Mn oxide-bound, F4—organic matter-bound, F5—residual.

SCOD and pH of sludge filtrate

As shown in Fig. S3, the addition of RHF, RHB, and RH-SCB elevated the pH of the filtrate compared with FeCl3 conditioning, thereby reducing the corrosion of the filtrate on the elevated dewatering equipment. The SCOD of the sludge filtrate conditioned by RH-SCB was significantly lower than that of the other samples, thereby reducing the cost of filtrate reprocessing. This result indicates that sludge dewatering conditioned by RH-SCB does not deteriorate the water quality of the filtrate and is feasible from an economic perspective.

Economic analysis

An economic analysis of the raw sludge dewatering and sludge conditioning by FeCl3 alone, RHF (70% DS), RHB (60% DS), and RH-SCB (70% DS) was performed, and it considered materials, reagents, and final disposal costs. The energy requirement for the pyrolysis of rice husk biomass was determined as 0.3 MJ/kg dry rice husk27, dried sludge 0.15 MJ/kg DS28, and the energy consumed for the preparation of RHB and dried sludge cake was calculated following Gil-Lalaguna28. The selling price of RH-SCB is assumed to be 0.04 USD/kg29. The CaO is used to stabilize the dewatered sludge, except for the dewatered sludge conditioned by RH-SCB, and the dosage is assumed to be 25% of the wet sludge30. The prices and other economic parameters are shown in Table S8. According to the calculations, the disposal costs of raw sludge and sludge conditioned by FeCl3 alone, RHF, RHB, and RH-SCB were 7.07, 0.94, 1.29, 1.59, and 0.82 USD/kg DS, respectively. Therefore, RH-SCB conditioning was the most economical disposal method, as it represented an 88.4% cost reduction compared with the disposal of raw sludge.

Conclusions

From all analyzed options, the RH-SCB (rice husk-sludge cake biochar), deriving from a sludge that has been previously conditioned with FeCl3 (115.07 g/kg DS) and rice husk flour (0.7 kg/kg DS), was the best option for use as a physical conditioner to condition and dewater sludge in this work. The YN (20.39 kg/(m2 h)) was the highest for 115.07 g/kg of FeCl3 and 70% DS RH-SCB. The sludge cake compressibility (s = 0.79) was the lowest and the zeta potential of the sludge was the closest to 0 mV when RH-SCB was used. The characterization analysis indicated that the surface zeta potential, hardness, and surface Fe content of rice husk-based powders were the major factors influencing sludge conditioning and dewatering. In addition, sludge conditioning with RH-SCB improved the water quality of the sludge filtrate and reduced the risk of heavy metals in the sludge cake and the costs of treatment and disposal. However, this economic analysis was based on the expansion of experimental data, and it does not represent the result of an actual application. As a whole, the RH-SCB used as a latent physical conditioner to improving dewaterability is economical and feasible.

References

Sanin, F. D., Clarkson, W. W. & Vesilind, P. A. Sludge Engineering: The Treatment and Disposal of Wastewater Sludges (DEStech Publications Inc, Lancaster, 2011).

Yang, G., Zhang, G. M. & Wang, H. C. Current state of sludge production, management, treatment and disposal in China. Water Res. 78, 60–73. https://doi.org/10.1016/j.watres.2015.04.002 (2015).

Verlicchi, P. & Zambello, E. Pharmaceuticals and personal care products in untreated and treated sewage sludge: Occurrence and environmental risk in the case of application on soil: a critical review. Sci. Total Environ. 538, 750–767. https://doi.org/10.1016/j.scitotenv.2015.08.108 (2015).

Wu, B. R., Dai, X. H. & Chai, X. L. Critical review on dewatering of sewage sludge: Influential mechanism, conditioning technologies and implications to sludge re-utilizations. Water Res. 180, 18. https://doi.org/10.1016/j.watres.2020.115912 (2020).

Wei, H., Gao, B., Ren, J., Li, A. & Yang, H. Coagulation/flocculation in dewatering of sludge: a review. Water. Res. 143, 608–631. https://doi.org/10.1016/j.watres.2018.07.029 (2018).

Thapa, K. B., Qi, Y., Clayton, S. A. & Hoadley, A. F. A. Lignite aided dewatering of digested sewage sludge. Water Res. 43, 623–634. https://doi.org/10.1016/j.watres.2008.11.005 (2009).

Zhao, Y. X., Gao, B. Y., Shon, H. K., Cao, B. C. & Kim, J. H. Coagulation characteristics of titanium (Ti) salt coagulant compared with aluminum (Al) and iron (Fe) salts. J. Hazard. Mater. 185, 1536–1542. https://doi.org/10.1016/j.jhazmat.2010.10.084 (2011).

Feng, L. et al. Using ultrasonic (US)-initiated template copolymerization for preparation of an enhanced cationic polyacrylamide (CPAM) and its application in sludge dewatering. Ultrason. Sonochem. 44, 53–63. https://doi.org/10.1016/j.ultsonch.2018.02.017 (2018).

Liang, J. L. et al. A highly efficient conditioning process to improve sludge dewaterability by combining calcium hypochlorite oxidation, ferric coagulant re-flocculation, and walnut shell skeleton construction. Chem. Eng. J. 361, 1462–1478. https://doi.org/10.1016/j.cej.2018.10.143 (2019).

Qi, Y., Thapa, K. B. & Hoadley, A. F. A. Benefit of lignite as a filter aid for dewatering of digested sewage sludge demonstrated in pilot scale trials. Chem. Eng. J. 166, 504–510. https://doi.org/10.1016/j.cej.2010.11.003 (2011).

Liu, H. et al. A comprehensive insight into the combined effects of Fenton’s reagent and skeleton builders on sludge deep dewatering performance. J. Hazard. Mater. 258, 144–150. https://doi.org/10.1016/j.jhazmat.2013.04.036 (2013).

Chen, X., Kong, F., Fu, Y., Si, C. & Fatehi, P. Improvements on activated sludge settling and flocculation using biomass-based fly ash as activator. Sci. Rep. 9, 14590. https://doi.org/10.1038/s41598-019-50879-6 (2019).

Wang, S., Yang, Y. K., Chen, X. G., Lv, J. Z. & Li, J. Effects of bamboo powder and rice husk powder conditioners on sludge dewatering and filtrate quality. Int. Biodeterior. Biodegrad. 124, 288–296. https://doi.org/10.1016/j.ibiod.2017.05.013 (2017).

Luo, H. J., Ning, X. A., Liang, X. J., Feng, Y. F. & Liu, J. Y. Effects of sawdust-CPAM on textile dyeing sludge dewaterability and filter cake properties. Bioresour. Technol. 139, 330–336. https://doi.org/10.1016/j.biortech.2013.04.035 (2013).

Zhang, X. C. et al. The porous structure effects of skeleton builders in sustainable sludge dewatering process. J. Environ. Manag. 230, 14–20. https://doi.org/10.1016/j.jenvman.2018.09.049 (2019).

Wu, Y. et al. Combined sludge conditioning of micro-disintegration, floc reconstruction and skeleton building (KMnO4/FeCl3/Biochar) for enhancement of waste activated sludge dewaterability. J. Taiwan Inst. Chem. Eng. 74, 121–128. https://doi.org/10.1016/j.jtice.2017.02.004 (2017).

Wu, Y. et al. Enhancing sewage sludge dewaterability by a skeleton builder: biochar produced from sludge cake conditioned with rice husk flour and FeCl3. ACS Sustain. Chem. Eng. 4, 5711–5717. https://doi.org/10.1021/acssuschemeng.6b01654 (2016).

Yu, W. B. et al. Roles of iron species and pH optimization on sewage sludge conditioning with Fenton’s reagent and lime. Water Res. 95, 124–133. https://doi.org/10.1016/j.watres.2016.03.016 (2016).

Ning, X. A., Luo, H. J., Liang, X. J., Lin, M. Q. & Liang, X. Effects of tannery sludge incineration slag pretreatment on sludge dewaterability. Chem. Eng. J. 221, 1–7. https://doi.org/10.1016/j.cej.2013.01.106 (2013).

Fu, C. et al. Influence of sediment characteristics on heavy metal fraction distribution in the water-level fluctuation zone of the three gorges reservoir area, China. Water Air Soil Pollut. https://doi.org/10.1007/s11270-020-04525-x (2020).

Li, R. et al. Reconstructing the historical pollution levels and ecological risks over the past sixty years in sediments of the Beijiang River, South China. Sci. Total Environ. 649, 448–460. https://doi.org/10.1016/j.scitotenv.2018.08.283 (2019).

Skinner, S. J. et al. Quantification of wastewater sludge dewatering. Water Res. 82, 2–13. https://doi.org/10.1016/j.watres.2015.04.045 (2015).

Rebhun, M., Zall, J. & Galil, N. I. Net sludge solids yield as an expression of filterability for conditioner optimization. J. Water Pollut. Control Fed. 61, 52–54 (1989).

Qi, Y., Thapa, K. B. & Hoadley, A. F. A. Application of filtration aids for improving sludge dewatering properties: a review. Chem. Eng. J. 171, 373–384. https://doi.org/10.1016/j.cej.2011.04.060 (2011).

Dhanjai, Sinha, A., Zhao, H., Chen, J. & Mugo, S. M. in Encyclopedia of Analytical Science (Third Edition) (eds Paul Worsfold, Colin Poole, Alan Townshend, & Manuel Miró) 258–270 (Academic Press, 2019).

Chen, Q. & Wang, Y. L. Influence of single- and dual-flocculant conditioning on the geometric morphology and internal structure of activated sludge. Powder Technol. 270, 1–9. https://doi.org/10.1016/j.powtec.2014.10.002 (2015).

Manganaro, J. et al. Conversion of residual biomass into liquid transportation fuel: an energy analysis. Energy Fuels 25, 2711–2720. https://doi.org/10.1021/ef200327e (2011).

Gil-Lalaguna, N., Sanchez, J. L., Murillo, M. B., Atienza-Martinez, M. & Gea, G. Energetic assessment of air-steam gasification of sewage sludge and of the integration of sewage sludge pyrolysis and air-steam gasification of char. Energy 76, 652–662. https://doi.org/10.1016/j.energy.2014.08.061 (2014).

Shahbeig, H. & Nosrati, M. Pyrolysis of municipal sewage sludge for bioenergy production: thermo-kinetic studies, evolved gas analysis, and techno-socio-economic assessment. Renew. Sust. Energ. Rev. 119, 13. https://doi.org/10.1016/j.rser.2019.109567 (2020).

Valderrama, C., Granados, R. & Cortina, J. L. Stabilisation of dewatered domestic sewage sludge by lime addition as raw material for the cement industry: understanding process and reactor performance. Chem. Eng. J. 232, 458–467. https://doi.org/10.1016/j.cej.2013.07.104 (2013).

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant Numbers 31670467, 51808089), Science and Technology Research Program of Chongqing Municipal Education Commission (Grant Number KJZDK201801202), Bayu Scholar of Chongqing and Synergy Innovation Center of Chongqing Three Gorges University, and College Student Innovation and Entrepreneurship Training Program (Grant Numbers 2018047, 201910643003, and 201910643031).

Author information

Authors and Affiliations

Contributions

M. W. and Y. W. wrote the manuscript. Y. Z., Z. L., J. W., and Y. Q. conducted experiments. B. Y. analyzed the results and P. D. prepared the figures and tables. C. F. and P. Z. revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, M., Wu, Y., Yang, B. et al. Comparative study of the effect of rice husk-based powders used as physical conditioners on sludge dewatering. Sci Rep 10, 17230 (2020). https://doi.org/10.1038/s41598-020-74178-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-74178-7

This article is cited by

-

Sludge deep dewatering enhanced by zero-valent iron/peroxymonosulfate/walnut shell powder

Korean Journal of Chemical Engineering (2023)

-

Application of coffee ground-based skeleton builder with FeCl3 for conditions of pre-dewatered sludge toward further deep dewatering

Environmental Science and Pollution Research (2023)

-

New biopolymer from biomass for conditioning and dehydration of sewage sludge: application on the sludge of Bouira WWTP

Environmental Science and Pollution Research (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.