Abstract

Biominerals serve as critical structures of living systems and play important roles in biochemical processes. Understanding their crystallization mechanisms is therefore central to many areas of biology, biogeoscience, and biochemistry. Some biominerals, such as bone and dentin, are hierarchical nanocomposite structures constructed by sequential addition of individual oriented nanocrystals. The driving forces that enable this oriented assembly are still poorly understood, with advances in understanding limited in part by the availability of techniques that can precisely measure the delicate interactions between nanocrystals as a function of their separation distance and mutual orientation. Here, we provide a comprehensive protocol for (i) fabricating oriented single-nanocrystal atomic force microscopy (AFM) probes using focused ion beam (FIB) milling and (ii) performing oriented nanocrystal interaction force measurements using dynamic force spectroscopy (DFS)-based AFM and environmental transmission electron microscopy (ETEM)–AFM techniques. We illustrate how to fabricate oriented nanocrystal force probes using commercial bulk crystals or nano/microcrystals of calcite, zinc oxide, and rutile. The typical protocol for fabricating one AFM crystal probe takes 2–3 h. In addition, we illustrate how to quantify the direction-specific interaction forces for a given pair of interacting oriented nanocrystal faces. The methods are fully transferrable to other minerals of interest, such as the apatites constituting bone minerals. This allows researchers across many fields to measure and understand particle-based crystallization processes.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Gadd, G. M. Metals, minerals and microbes: geomicrobiology and bioremediation. Microbiology 156, 609–643 (2010).

Anbu, P., Kang, C. H., Shin, Y. J. & So, J. S. Formations of calcium carbonate minerals by bacteria and its multiple applications. + 5, 250 (2016).

DeVol, R. T. et al. Nanoscale transforming mineral phases in fresh nacre. J. Am. Chem. Soc. 137, 13325–13333 (2015).

Wright, C. G. et al. A calcareous concretion in the posterior semicircular duct of a human labyrinth. Am. J. Otolaryngol. 3, 196–201 (1982).

Jiang, W. et al. Chiral acidic amino acids induce chiral hierarchical structure in calcium carbonate. Nat. Commun. 8, 15066 (2017).

Henriksen, K., Stipp, S. L. S., Young, J. R. & Marsh, M. E. Biological control on calcite crystallization: AFM investigation of coccolith polysaccharide function. Am. Mineral. 89, 1709–1716 (2004).

De Yoreo, J. J. et al. Crystal growth. Crystallization by particle attachment in synthetic, biogenic, and geologic environments. Science 349, aaa6760 (2015).

Weiner, S. & Dove, P. M. An overview of biomineralization processes and the problem of the vital effect. Rev. Mineral. Geochem. 54, 1–29 (2003).

Pokroy, B. et al. Narrowly distributed crystal orientation in biomineral vaterite. Chem. Mater. 27, 6516–6523 (2015).

Banfield, J. F., Welch, S. A., Zhang, H., Ebert, T. T. & Penn, R. L. Aggregation-based crystal growth and microstructure development in natural iron oxyhydroxide biomineralization products. Science 289, 751–754 (2000).

Zhang, H. & Banfield, J. F. Interatomic Coulombic interactions as the driving force for oriented attachment. CrystEngComm 16, 1568–1578 (2014).

Ruths, M. & Israelachvili, J. N. in Nanotribology and Nanomechanics 417–515 (Springer, Berlin, 2008).

Hopkins, J. C., Podgornik, R., Ching, W.-Y., French, R. H. & Parsegian, V. A. Disentangling the effects of shape and dielectric response in van der Waals interactions between anisotropic bodies. J. Phys. Chem. C 119, 19083–19094 (2015).

Sushko, M. L. & Rosso, K. M. Origin of facet selectivity and alignment in anatase TiO2 nanoparticles in electrolyte solutions: implications for oriented attachment in metal oxides. Nanoscale 8, 19714–19725 (2016).

Zhang, X. & Weeks, B. L. Tip induced crystallization lithography. J. Am. Chem. Soc. 136, 1253–1255 (2014).

Ma, X. et al. Tuning crystallization pathways through sequence engineering of biomimetic polymers. Nat. Mater. 16, 767–774 (2017).

Lupulescu, A. I. & Rimer, J. D. In situ imaging of silicalite-1 surface growth reveals the mechanism of crystallization. Science 344, 729–732 (2014).

Jin, H. et al. Highly stable and self-repairing membrane-mimetic 2D nanomaterials assembled from lipid-like peptoids. Nat. Commun. 7, 12252 (2016).

O’Shea, S. J. & Welland, M. E. Atomic force microscopy at solid−liquid interfaces. Langmuir 14, 4186–4197 (1998).

Zhang, X. & Weeks, B. L. Effects on the surface structure of organic energetic materials using spin coating. Thin Solid Films 550, 135–139 (2013).

Dorobantu, L. S., Goss, G. G. & Burrell, R. E. Atomic force microscopy: a nanoscopic view of microbial cell surfaces. Micron 43, 1312–1322 (2012).

Dufrene, Y. F. Atomic force microscopy, a powerful tool in microbiology. J. Bacteriol. 184, 5205–5213 (2002).

Coles, J. M. et al. In situ friction measurement on murine cartilage by atomic force microscopy. J. Biomech. 41, 541–548 (2008).

Koren, E., Lörtscher, E., Rawlings, C., Knoll, A. W. & Duerig, U. Adhesion and friction in mesoscopic graphite contacts. Science 348, 679–683 (2015).

Friddle, R. W., Aleksandr, N. & De Yoreo, J. J. Interpreting the widespread nonlinear force spectra of intermolecular bonds. Proc. Natl. Acad. Sci. USA 109, 13573–13578 (2012).

Newcomb, C. J., Qafoku, N. P., Grate, J. W., Bailey, V. L. & De Yoreo, J. J. Developing a molecular picture of soil organic matter-mineral interactions by quantifying organo-mineral binding. Nat. Commun. 8, 396 (2017).

Aman, Z. M. et al. Adhesion force between cyclopentane hydrate and mineral surfaces. Langmuir 29, 15551–15557 (2013).

Dufrene, Y. F. Towards nanomicrobiology using atomic force microscopy. Nat. Rev. Microbiol. 6, 674–680 (2008).

Ong, Y.-L., Razatos, A., Georgiou, G. & Sharma, M. M. Adhesion forces between E. coli bacteria and biomaterial surfaces. Langmuir 15, 2719–2725 (1999).

Newton, R. et al. Combining confocal and atomic force microscopy to quantify single-virus binding to mammalian cell surfaces. Nat. Protoc. 12, 2275 (2017).

Larson, I., Drummond, C. J., Chan, D. Y. & Grieser, F. Direct force measurements between titanium dioxide surfaces. J. Am. Chem. Soc. 115, 11885–11890 (1993).

Finot, E., Lesniewska, E., Mutin, J.-C. & Goudonnet, J.-P. Investigations of surface forces between gypsum microcrystals in air using atomic force microscopy. Langmuir 16, 4237–4244 (2000).

Zhang, X. et al. Direction-specific van der Waals attraction between rutile TiO2 nanocrystals. Science 365, 434–437 (2017).

Zhang, X. et al. Direction-specific interaction forces underlying zinc oxide crystal growth by oriented attachment. Nat. Commun. 8, 835 (2017).

Penn, R. L. & Banfield, J. F. Imperfect oriented attachment: dislocation generation in defect-free nanocrystals. Science 281, 969–971 (1998).

Penn, R. L. & Soltis, J. A. Characterizing crystal growth by oriented aggregation. CrystEngComm 16, 1409–1418 (2014).

Xue, X., Penn, R. L., Leite, E. R., Huang, F. & Lin, Z. Crystal growth by oriented attachment: kinetic models and control factors. CrystEngComm 16, 1419–1429 (2014).

Zhang, J., Ji, G., Huang, X., Xu, W. & Sun, F. An improved cryo-FIB method for fabrication of frozen hydrated lamella. J. Struct. Biol. 194, 218–223 (2016).

He, J. et al. Cryo-FIB specimen preparation for use in a cartridge-type cryo-TEM. J. Struct. Biol. 199, 114–119 (2017).

Marchetto, D. et al. AFM investigation of tribological properties of nano-patterned silicon surface. Wear 265, 577–582 (2008).

Jiang, S. W. et al. Structural characteristics of SrTiO3 thin films processed by rapid thermal annealing. J. Cryst. Growth 274, 500–505 (2005).

Thompson, K. et al. In situ site-specific specimen preparation for atom probe tomography. Ultramicroscopy 107, 131–139 (2007).

Heinz, W. F. & Hoh, J. H. Spatially resolved force spectroscopy of biological surfaces using the atomic force microscope. Trends Biotechnol. 17, 143–150 (1999).

Butt, H.-J., Cappella, B. & Kappl, M. Force measurements with the atomic force microscope: technique, interpretation and applications. Surf. Sci. Rep. 59, 1–152 (2005).

Xu, S. et al. Optimizing and improving the growth quality of ZnO nanowire arrays guided by statistical design of experiments. ACS Nano 3, 1803–1812 (2009).

Acknowledgements

This protocol is based upon work supported by the U.S. Department of Energy (DOE), Office of Science, Office of Basic Energy Sciences, Chemical Sciences, Geosciences, and Biosciences Division through its Geosciences Program at Pacific Northwest National Laboratory (PNNL). The Materials Synthesis and Simulation across Scales Initiative, a Laboratory Directed Research and Development Program at PNNL, supported the development of tip fabrication methods. We acknowledge fruitful discussions with J. Tao on the dynamic force measurements and calcite crystal growth. The work was performed using the Environmental and Molecular Sciences Laboratory (EMSL), a national scientific user facility at PNNL sponsored by the DOE’s Office of Biological and Environmental Research. PNNL is a multi-program national laboratory operated by Battelle Memorial Institute under contract no. DE-AC05-76RL01830 for the DOE.

Author information

Authors and Affiliations

Contributions

X.Z., J.J.D.Y., and K.M.R. conceived and designed the experiments. X.Z. and J.L. developed the crystal AFM tip fabrication method and fabricated all tips. Y.H., X.Z., C.W., and S.X.M. conducted the ETEM–AFM experiments and force data analysis. X.Z. conducted the AFM experiments and force data analysis. M.E.B. conducted the XRD analyses. L.K. developed the gas delivery system in the environmental TEM. X.Z., Y.H., and K.M.R. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

Key references using this protocol

1. Zhang, X. et al. Science 356, 434–437 (2017): https://doi.org/10.1126/science.aah6902

2. Zhang, X. et al. Nat. Commun. 8, 835 (2017): https://doi.org/10.1038/s41467-017-00844-6

Integrated supplementary information

Supplementary Figure 1

AFM topographic images of the SrTO3 substrate used for polishing the nanocrystal AFM tips.

Supplementary Figure 2 Nanocrystal-nanocrystal interaction force measurements.

(a) Representative force curves for ZnO (0001)-ZnO (000) nanocrystal interaction in 0.2 mM Zn(NO3)2 solution. Point 1 to 2 presents the approach process until jump-to-contact (point 2 to 3); followed by a chosen amount of increasing applied force up the contact ramp from point 3 to 4; after a chosen dwell time to stabilize the interaction, tip retraction is performed (point 4 to 5) until jump-from-contact (point 5 to 6). (b) Data fitting using the multiple bond model developed by Friddle et al.25 for the different retraction rates at each azimuthal orientation between ZnO (0001)-ZnO (000) nanocrystals to obtain the equilibrium rupture forces from 0° to 60°. Error bars in b and c represent the standard error (n=25). Adapted with permission from Zhang et al.34 (original material licensed under a Creative Commons Attribution License 4.0).

Supplementary Figure 3 The original AFM tip-cutting strategy.

Schematics illustrating (a) an original AFM tip, (b) a FIB cut AFM tip without tilt angle correction, and (c) with tilt angle correction; (d) and (e) SEM images of the AFM tip glued on a stage with 11° tilt for adjusting the AFM tip surface to the horizontal plane during tip fabrication. Adapted with permission from Zhang et al.34 (original material licensed under a Creative Commons Attribution License 4.0).

Supplementary Figure 4 Procedure for fabricating oriented nanoscale ZnO (0001) AFM tips using ZnO nanowire on substrate.

(a) Binding a ZnO NW onto the Omniprobe (scale bar 5 µm) (Step 4-5 of Box 1); (b) FIB milled hole in pre-milled AFM tip (scale bar 5 µm) (Step 7-8 of Box 1); (c) ZnO NW secured by Pt on the AFM tip (scale bar 5 µm) (Step 9-14 of Box 1); (d) The ZnO (0001) AFM tip after FIB sharpening (scale bar 0.5 µm) (Step 15-19 of Box 1); (e) The ZnO (0001) AFM tip after high-speed polishing using AFM (scale bar 0.5 µm) (Step 20 of Box 1). Adapted with permission from Zhang et al.34 (original material licensed under a Creative Commons Attribution License 4.0).

Supplementary Figure 5 Procedure for fabricating an oriented face-specific rutile (001) AFM tip with an atomically flat surface.

(a) FIB cut a small piece of rutile (001) crystal with Ag and Pt protective layers followed by lift-off using the Omniprobe (Step 5 of Box 2); (b) Make a groove in the original AFM tip (Step 3 of Box 2); (c) Transfer the rutile (001) microcrystal from Omniprobe to the AFM tip and then stabilize it using Pt glue (Step 6 of Box 2); (d) FIB milling (30 KV) the rutile (001) microcrystal to a cylindrical shape (Step 7 of Box 2); (e) Further FIB milling (30 KV) the rutile (001) microcrystal to a needle-like shape and then remove the Pt protective layer using a lower milling voltage (2 KV) (Step 8-9 of Box 2); (f) Remove the Ag protective layer after FIB milling using the 0.5 M iron nitrate etching solution (Step 11 of Box 2). Adapted with permission from ref. 33, American Association for the Advancement of Science.

Supplementary Figure 6

The AFM tip holder was made using the Hastelloy C-276 material.

Supplementary Figure 7 Procedure for fabricating an oriented face-specific calcite (104) AFM tip.

(a) Calcite (104) crystal on silicon substrate (Step 1 of Box 4); (b) FIB cut a calcite microslab (Step 4-5 of Box 4); (c) lift-out the calcite microslab (Step 4-5 of Box 4) (d) transfer the calcite microslab on the AFM tip (Step 6 of Box 4); (e) cut a small size calcite crystal in the AFM tip (Step 6 of Box 4); (f) FIB milling the calcite crystal to the target size (Step 7-8 of Box 4).

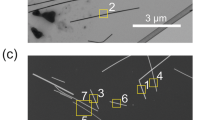

Supplementary Figure 8 Procedure for fabricating an oriented face-specific rutile (001) nanocrystal needle with an atomically flat surface.

(a) original gold needle; (b) FIB cut the needle with a flat surface ~ 4 µm in diameter (Step 3 of Box 3); (c) Transfer the rutile (001) microcrystal from Omniprobe to the gold needle and then stabilize it using Pt glue (Step 4-5 of Box 3); (d) FIB milling (30 KV, 93 pA) the rutile (001) microcrystal to a cylindrical shape with a diameter ~1.0 µm and a height ~1.0 µm (Step 5 of Box 3); (e) Further FIB milling (30 KV, 28 pA) the rutile (001) microcrystal to a cylindrical shape and then remove the Pt protective layer using a lower milling voltage (2 KV) (Step 6 of Box 3); (f) Remove the Ag protective layer after FIB milling using the 0.5 M iron nitrate etching solution (Step 8-9 of Box 3). f adapted with permission from ref. 33, American Association for the Advancement of Science.

Supplementary information

Supplementary Text and Figures

Supplementary Figures 1–8, Supplementary Methods

Supplementary Video 1

Jump-to-contact process. Real-time movie to showing the jump-to-contact happen when the rutile (001) substrate on the gold needle is driven close to the rutile (001) nanocrystal on the AFM tip. The azimuthal angle is 26.83° and the water vapor pressure is 10-1 mbar. Adapted with permission from ref. 33, American Association for the Advancement of Science

Supplementary Video 2

Jump-from-contact process in water vapors. Real-time movie showing the rutile (001) AFM tip remains attractively bound in contact with the substrate during retraction until the elastic force of the AFM cantilever exceeds the attractive force and the deflection returns to its starting value, as noted by the red line, at long-range. The azimuthal angle is 1.63° and the water pressure is 10-3 mbar

Rights and permissions

About this article

Cite this article

Zhang, X., He, Y., Liu, J. et al. Accessing crystal–crystal interaction forces with oriented nanocrystal atomic force microscopy probes. Nat Protoc 13, 2005–2030 (2018). https://doi.org/10.1038/s41596-018-0027-4

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41596-018-0027-4

This article is cited by

-

Connecting energetics to dynamics in particle growth by oriented attachment using real-time observations

Nature Communications (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.