Abstract

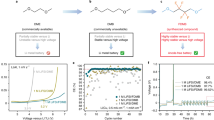

Electrolyte engineering improved cycling of Li metal batteries and anode-free cells at low current densities; however, high-rate capability and tuning of ionic conduction in electrolytes are desirable yet less-studied. Here, we design and synthesize a family of fluorinated-1,2-diethoxyethanes as electrolyte solvents. The position and amount of F atoms functionalized on 1,2-diethoxyethane were found to greatly affect electrolyte performance. Partially fluorinated, locally polar –CHF2 is identified as the optimal group rather than fully fluorinated –CF3 in common designs. Paired with 1.2 M lithium bis(fluorosulfonyl)imide, these developed single-salt-single-solvent electrolytes simultaneously enable high conductivity, low and stable overpotential, >99.5% Li||Cu half-cell efficiency (up to 99.9%, ±0.1% fluctuation) and fast activation (Li efficiency >99.3% within two cycles). Combined with high-voltage stability, these electrolytes achieve roughly 270 cycles in 50-μm-thin Li||high-loading-NMC811 full batteries and >140 cycles in fast-cycling Cu||microparticle-LiFePO4 industrial pouch cells under realistic testing conditions. The correlation of Li+–solvent coordination, solvation environments and battery performance is investigated to understand structure–property relationships.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data are included in the paper and its Supplementary Information. Source data are provided with this paper.

Code availability

The Python script and rationale for analysing the Li+ solvation structures are available at https://github.com/xianshine/LiSolvationStructure.

References

Liu, J. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 4, 180–186 (2019).

Cao, Y., Li, M., Lu, J., Liu, J. & Amine, K. Bridging the academic and industrial metrics for next-generation practical batteries. Nat. Nanotechnol. 14, 200–207 (2019).

Tikekar, M. D., Choudhury, S., Tu, Z. & Archer, L. A. Design principles for electrolytes and interfaces for stable lithium-metal batteries. Nat. Energy 1, 16114 (2016).

Cheng, X.-B. et al. A review of solid electrolyte interphases on lithium metal anode. Adv. Sci. 3, 1500213 (2016).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Flamme, B. et al. Guidelines to design organic electrolytes for lithium-ion batteries: environmental impact, physicochemical and electrochemical properties. Green Chem. 19, 1828–1849 (2017).

Aspern, N., Röschenthaler, G.-V., Winter, M. & Cekic-Laskovic, I. Fluorine and lithium: Ideal partners for high-performance rechargeable battery electrolytes. Angew. Chemie Int. Ed. 58, 15978–16000 (2019).

Jie, Y., Ren, X., Cao, R., Cai, W. & Jiao, S. Advanced liquid electrolytes for rechargeable li metal batteries. Adv. Funct. Mater. 30, 1910777 (2020).

Fan, X. & Wang, C. High-voltage liquid electrolytes for Li batteries: progress and perspectives. Chem. Soc. Rev. 50, 10486–10566 (2021).

Hobold, G. M. et al. Moving beyond 99.9% Coulombic efficiency for lithium anodes in liquid electrolytes. Nat. Energy 6, 951–960 (2021).

Yamada, Y., Wang, J., Ko, S., Watanabe, E. & Yamada, A. Advances and issues in developing salt-concentrated battery electrolytes. Nat. Energy 4, 269–280 (2019).

Cao, X., Jia, H., Xu, W. & Zhang, J.-G. Review—localized high-concentration electrolytes for lithium batteries. J. Electrochem. Soc. 168, 010522 (2021).

Ren, X. et al. Enabling high-voltage lithium-metal batteries under practical conditions. Joule 3, 1662–1676 (2019).

Chen, J. et al. Electrolyte design for Li metal-free Li batteries. Mater. Today 39, 118–126 (2020).

Holoubek, J. et al. An all-fluorinated ester electrolyte for stable high-voltage li metal batteries capable of ultra-low-temperature operation. ACS Energy Lett. 5, 1438–1447 (2020).

Wang, H. et al. Dual-solvent li-ion solvation enables high-performance Li-metal batteries. Adv. Mater. 33, 2008619 (2021).

Zhang, H. et al. Electrolyte additives for lithium metal anodes and rechargeable lithium metal batteries: progress and perspectives. Angew. Chemie Int. Ed. 57, 15002–15027 (2018).

Yang, Y. et al. Liquefied gas electrolytes for wide-temperature lithium metal batteries. Energy Environ. Sci. 13, 2209–2219 (2020).

Weber, R. et al. Long cycle life and dendrite-free lithium morphology in anode-free lithium pouch cells enabled by a dual-salt liquid electrolyte. Nat. Energy 4, 683–689 (2019).

Louli, A. J. et al. Diagnosing and correcting anode-free cell failure via electrolyte and morphological analysis. Nat. Energy 5, 693–702 (2020).

Yu, Z. et al. Molecular design for electrolyte solvents enabling energy-dense and long-cycling lithium metal batteries. Nat. Energy 5, 526–533 (2020).

Amanchukwu, C. V. et al. A new class of ionically conducting fluorinated ether electrolytes with high electrochemical stability. J. Am. Chem. Soc. 142, 7393–7403 (2020).

Xue, W. et al. Ultra-high-voltage Ni-rich layered cathodes in practical Li metal batteries enabled by a sulfonamide-based electrolyte. Nat. Energy 6, 495–505 (2021).

Holoubek, J. et al. Tailoring electrolyte solvation for Li metal batteries cycled at ultra-low temperature. Nat. Energy 6, 303–313 (2021).

Ma, P., Mirmira, P. & Amanchukwu, C. V. Effect of building block connectivity and ion solvation on electrochemical stability and ionic conductivity in novel fluoroether electrolytes. ACS Cent. Sci. 7, 1232–1244 (2021).

Xiao, J. et al. Understanding and applying coulombic efficiency in lithium metal batteries. Nat. Energy 5, 561–568 (2020).

Chen, Y. et al. Steric effect tuned ion solvation enabling stable cycling of high-voltage lithium metal battery. J. Am. Chem. Soc. 143, 18703–18713 (2021).

Pham, T. D. & Lee, K. Simultaneous stabilization of the solid/cathode electrolyte interface in lithium metal batteries by a new weakly solvating electrolyte. Small 17, 2100133 (2021).

Xu, R. et al. Designing and demystifying the lithium metal interface toward highly reversible batteries. Adv. Mater. 33, 2105962 (2021).

Chen, X. & Zhang, Q. Atomic insights into the fundamental interactions in lithium battery electrolytes. Acc. Chem. Res. 53, 1992–2002 (2020).

Kim, S. C. et al. Potentiometric measurement to probe solvation energy and its correlation to lithium battery cyclability. J. Am. Chem. Soc. 143, 10301–10308 (2021).

Su, C.-C. et al. Principle in developing novel fluorinated sulfone electrolyte for high voltage lithium-ion batteries. Energy Environ. Sci. 14, 3029–3034 (2021).

Wang, H. et al. Efficient lithium metal cycling over a wide range of pressures from an anion-derived solid-electrolyte interphase framework. ACS Energy Lett. 6, 816–825 (2021).

Liu, X. et al. Enhanced Li+ transport in ionic liquid-based electrolytes aided by fluorinated ethers for highly efficient lithium metal batteries with improved rate capability. Small Methods 9, 2100168 (2021).

Halat, D. M. et al. Modifying Li+ and anion diffusivities in polyacetal electrolytes: a pulsed-field-gradient nmr study of ion self-diffusion. Chem. Mater. 33, 4915–4926 (2021).

Ando, H. et al. Mixture of monoglyme-based solvent and lithium bis(trifluoromethanesulfonyl)amide as electrolyte for lithium ion battery using silicon electrode. Mater. Chem. Phys. 225, 105–110 (2019).

Sasaki, Y., Shimazaki, G., Nanbu, N., Takehara, M. & Ue, M. Physical and electrolytic properties of partially fluorinated organic solvents and its application to secondary lithium batteries: Partially fluorinated dialkoxyethanes. ECS Trans. 16, 23–31 (2019).

Yue, Z., Dunya, H., Aryal, S., Segre, C. U. & Mandal, B. Synthesis and electrochemical properties of partially fluorinated ether solvents for lithium–sulfur battery electrolytes. J. Power Sources 401, 271–277 (2018).

Zhang, Y. & Viswanathan, V. Design rules for selecting fluorinated linear organic solvents for li metal batteries. J. Phys. Chem. Lett. 12, 5821–5828 (2021).

Yu, Z. et al. A dynamic, electrolyte-blocking, and single-ion-conductive network for stable lithium-metal anodes. Joule 3, 2761–2776 (2019).

Jia, M. et al. Fluorinated bifunctional solid polymer electrolyte synthesized under visible light for stable lithium deposition and dendrite-free all-solid-state batteries. Adv. Funct. Mater. 31, 2101736 (2021).

Zou, Y. et al. Interfacial model deciphering high-voltage electrolytes for high energy density, high safety, and fast-charging lithium-ion batteries. Adv. Mater. 33, 2102964 (2021).

Aurbach, D., Gofer, Y. & Langzam, J. The correlation between surface chemistry, surface morphology, and cycling efficiency of lithium electrodes in a few polar aprotic systems. J. Electrochem. Soc. 136, 3198–3205 (1989).

Adams, B. D., Zheng, J., Ren, X., Xu, W. & Zhang, J.-G. Accurate determination of coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater. 8, 1702097 (2018).

Niu, C. et al. Balancing interfacial reactions to achieve long cycle life in high-energy lithium metal batteries. Nat. Energy 6, 723–732 (2021).

Sripad, S., Bills, A. & Viswanathan, V. The iron age of automotive batteries: techno-economic assessment of batteries with lithium metal anodes paired with iron phosphate cathodes. Preprint at ECSarXiv https://doi.org/10.1149/osf.io/fx4p9 (2021).

Eftekhari, A. LiFePO4/C nanocomposites for lithium-ion batteries. J. Power Sources 343, 395–411 (2017).

Nanda, S., Gupta, A. & Manthiram, A. Anode-free full cells: a pathway to high-energy density lithium-metal batteries. Adv. Energy Mater. 11, 2000804 (2021).

Park, S. H., Jun, D., Lee, G. H., Lee, S. G. & Lee, Y. J. Toward high-performance anodeless batteries based on controlled lithium metal deposition: a review. J. Mater. Chem. A 9, 14656–14681 (2021).

Qian, J. et al. Anode-free rechargeable lithium metal batteries. Adv. Funct. Mater. 26, 7094–7102 (2016).

Guo, R. & Gallant, B. M. Li2O solid electrolyte interphase: probing transport properties at the chemical potential of lithium. Chem. Mater. 32, 5525–5533 (2020).

May, R., Fritzsching, K. J., Livitz, D., Denny, S. R. & Marbella, L. E. Rapid interfacial exchange of li ions dictates high coulombic efficiency in li metal anodes. ACS Energy Lett. 6, 1162–1169 (2021).

Huang, W., Wang, H., Boyle, D. T., Li, Y. & Cui, Y. Resolving nanoscopic and mesoscopic heterogeneity of fluorinated species in battery solid-electrolyte interphases by cryogenic electron microscopy. ACS Energy Lett. 5, 1128–1135 (2020).

Abraham, M. J. et al. GROMACS: High performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 1–2, 19–25 (2015).

Jorgensen, W. L., Maxwell, D. S. & Tirado-Rives, J. Development and testing of the OPLS all-atom force field on conformational energetics and properties of organic liquids. J. Am. Chem. Soc. 118, 11225–11236 (1996).

Dodda, L. S., Cabeza de Vaca, I., Tirado-Rives, J. & Jorgensen, W. L. LigParGen web server: an automatic OPLS-AA parameter generator for organic ligands. Nucleic Acids Res. 45, W331–W336 (2017).

Sambasivarao, S. V. & Acevedo, O. Development of OPLS-AA force field parameters for 68 unique ionic liquids. J. Chem. Theory Comput. 5, 1038–1050 (2009).

Self, J., Fong, K. D. & Persson, K. A. Transport in superconcentrated LiPF6 and LiBF4/propylene carbonate electrolytes. ACS Energy Lett. 4, 2843–2849 (2019).

Humphrey, W., Dalke, A. & Schulten, K. VMD: visual molecular dynamics. J. Mol. Graph. 14, 33–38 (1996).

Michaud-Agrawal, N., Denning, E. J., Woolf, T. B. & Beckstein, O. MDAnalysis: a toolkit for the analysis of molecular dynamics simulations. J. Comput. Chem. 32, 2319–2327 (2011).

Sinnaeve, D. The Stejskal-Tanner equation generalized for any gradient shape-an overview of most pulse sequences measuring free diffusion. Concepts Magn. Reson. Part A 40A, 39–65 (2012).

Ammann, C., Meier, P. & Merbach, A. A simple multinuclear NMR thermometer. J. Magn. Reson. 46, 319–321 (1982).

Spees, W. M., Song, S.-K., Garbow, J. R., Neil, J. J. & Ackerman, J. J. H. Use of ethylene glycol to evaluate gradient performance in gradient-intensive diffusion MR sequences. Magn. Reson. Med. 68, 319–324 (2012).

Acknowledgements

This work is supported by the US Department of Energy, under the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies, the Battery Materials Research Program and Battery500 Consortium. Part of this work was performed at the Stanford Nano Shared Facilities, supported by the National Science Foundation under award no. ECCS-2026822. Z.Y. thanks B. Siegl at Arkema for providing LiFSI. Z.Y. also thanks J. Yang at Stanford University for measuring mass spectrometry and X. Chen at Tsinghua University for discussing the definition of Li+ solvates. Z.Z. acknowledges support from Stanford Interdisciplinary Graduate Fellowship. S.T.O. acknowledges support from the Knight Hennessy Scholarship for graduate studies at Stanford University. G.A.K. gratefully acknowledges support from the National Science Foundation Graduate Research Fellowship under grant no. 1650114.

Author information

Authors and Affiliations

Contributions

Z.Y., Y.Cui and Z.B. conceived the idea. J.Q., Y.Cui and Z.B. directed the project. Z.Y. designed the logical flow and experiments. Z.Y. performed syntheses, material characterizations, DFT calculations, electrochemical measurements and battery tests. P.E.R., X.K. and J.Q. conducted molecular dynamics simulations and rationales. Z.Z. performed cryo-TEM and cryo-TEM EDS experiments. Z.H. took SEM images and collected viscosity data. H.C. performed DOSY–NMR experiments. S.T.O. collected XPS data. Y.Chen collected 7Li- and 19F-NMR and contributed to key discussion. S.C.K. measured solvation free energies. X.X. carried out ion milling and took part of SEM images. H.W. helped with electrochemical measurements and battery testing. Y.Z. and G.A.K. helped with syntheses. M.S.K. helped with discussion. All authors discussed and analysed the data. Z.Y., S.F.B., J.Q., Y.Cui and Z.B. cowrote and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

Z.B., Y.Cui. and Z.Y. declare that this work has been filed as US Provisional Patent Application No. 63/283,828. The remaining authors declare no competing interests.

Peer review information

Nature Energy thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables 1–5, Figs. 1–66 and Refs. 1–31.

Source data

Source Data Fig. 2

Source data of the plots.

Source Data Fig. 4

Source data of the plots.

Source Data Fig. 5

Source data of the plots.

Source Data Fig. 8

Source data of the plots.

Rights and permissions

About this article

Cite this article

Yu, Z., Rudnicki, P.E., Zhang, Z. et al. Rational solvent molecule tuning for high-performance lithium metal battery electrolytes. Nat Energy 7, 94–106 (2022). https://doi.org/10.1038/s41560-021-00962-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-021-00962-y

This article is cited by

-

High lithium oxide prevalence in the lithium solid–electrolyte interphase for high Coulombic efficiency

Nature Energy (2024)

-

Safe electrolyte for long-cycling alkali-ion batteries

Nature Sustainability (2024)

-

Hybridizing carbonate and ether at molecular scales for high-energy and high-safety lithium metal batteries

Nature Communications (2024)

-

Single-phase local-high-concentration solid polymer electrolytes for lithium-metal batteries

Nature Energy (2024)

-

External-pressure–electrochemistry coupling in solid-state lithium metal batteries

Nature Reviews Materials (2024)