Abstract

Recent advances in wastewater treatment processes have resulted in high removal efficiencies for various hazardous pollutants. Nevertheless, some technologies are more suitable for targeting specific contaminants than others. We comprehensively reviewed the recent advances in removing hazardous pollutants from industrial wastewater through membrane technologies, adsorption, Fenton-based processes, advanced oxidation processes (AOP), and hybrid systems such as electrically-enhanced membrane bioreactors (eMBRs), and integrated eMBR-adsorption system. Each technology’s key features are compared, and recent modifications to the conventional treatment approaches and limitations of advanced treatment systems are highlighted. The removal of emerging contaminants such as pharmaceuticals from wastewater is also discussed.

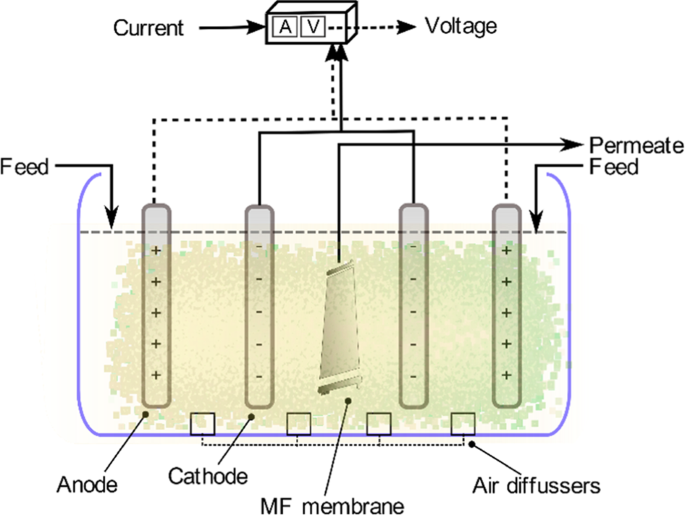

Similar content being viewed by others

Introduction

Industries are significant water consumers. On a global scale, they consume ~22% of the total water produced, whereas, in high-income counties, it can reach up to 60%. It is estimated that by 2050, manufacturing industries alone could increase their water usage by 400%1. Aqueous discard from the use of water in various industrial steps such as cooling tower, heating by the boiler, purification, etc. may contain numerous suspended or dissolved contaminants, and these effluents are referred to as industrial wastewater2. Industries such as chemical and petrochemical, paper and pulp, food processing, tannery, and other manufacturing industries constitute the primary sources of industrial wastewater3. These wastewaters usually have high organic strength (1-200 g/L), non-neutral pH, different temperatures, salinity, turbidity, and high heavy metal content4. Wastewater from leather manufacturing, food processing and preservation, textile processing, and petroleum refining may have high salt concentration5. Wastewater composition varies depending on the chemicals used in the upstream processes and the nature of treatment it has undergone; thus classifying industrial wastewater into specific categories is challenging2.

Ideally, industrial wastewater should undergo proper treatment and subsequent disposal into the environment or reuse for landscaping and housekeeping2. However, the regulatory control of industrial wastewater is region-specific, with many countries are having little or no effective legal frameworks supported by regulatory institutions6. According to UNESCO, 70% of industrial effluents in developing countries are dumped untreated7. However, as more countries are tightening their regulatory frameworks, industries are facing challenges in meeting the stringent water discharge and reuse requirements8.

Conventional treatments for removing heavy metals from wastewater include chemical precipitation, flotation, and ion exchange. However, these processes have several drawbacks, such as low removal efficiency, high energy consumption, and generation of toxic sludge, that limit their widespread application9. Recently, various alternative treatment methods have been investigated to improve the quality of the treated effluent. They include adsorption using low-cost materials, membrane separation, electro-technologies, and photocatalytic processes. Adsorption and membrane separation are widely used for treating wastewater contaminated with high heavy metals concentrations. Photocatalytic methods are effective in removing organic matter and recovering metals and hence are expected to be more prevalent in the future10. To the best of authors’ knowledge, no comprehensive and critical review in the literature discusses the latest innovations in the removal of hazardous pollutants from industrial wastewater. Therefore, this work is aimed at reviewing the recent advances in the removal of hazardous pollutants from industrial wastewaters. Membrane-based technologies, adsorption, Fenton-based process, advanced oxidation and photocatalytic processes, and hybrid systems are critically reviewed and discussed.

Membrane technologies

Microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO)

Membrane processes are increasingly being implemented for treating industrial and municipal wastewater because of their simplicity, modularity, and better energy efficiency11. Based on the pore size of the employed membrane, these processes can be broadly classified into microfiltration (MF), ultrafiltration (UF)8,12, nanofiltration (NF)8,13, and reverse osmosis (RO)13. MF, UF, and NF membranes are used for the removal of contaminants with a size range of 100–1000, 5–100, and 1–5 nm, respectively. There are several recent studies reporting treatment of industrial wastewater using membrane processes. For example, RO and NF were effective in removing Cu2+ and Cd2+ from synthetic wastewater14. RO achieved 98% and 99% removals for Cu2+ and Cd2+, respectively, whereas NF achieved ~90% for both Cu2+ and Cd2+. Another study reported 99.5% removal of Cu2+ and Ni2+ using RO15. Galambos et al. compared the chemical oxygen demand (COD) removal efficiency of RO and NF in treating the food industry wastewater; two samples of wastewater were used in this study with an initial COD of 9500 and 1160 ppm16. It was found that the permeate from RO has a COD of less than 125 mgO2 L−1 and hence can be discharged into natural waters. The study did not investigate the energy requirements associated with the treatment processes.

Polymer-supported ultrafiltration (PSU) has been investigated for treating synthetic wastewater containing heavy metals. Barakat and Schmidt added carboxyl methyl cellulose (CMC) as a water-soluble polymer for complexing the cationic forms of heavy metals such as Cu2+, Ni2+, and Cr3+ prior to filtration17. The results revealed that a high pH (≥7) enhanced the formation of CMC-heavy metal complexes, precipitation and size exclusive removal of metal hydroxides. In many cases, adjusting the solution pH is found to be an important step in heavy metal rejection as high pH can induce the precipitation of heavy metal hydroxides, which can then be filtered out through UF membranes. Juang and Shiau [20] investigated the removal of Cu2+ and Zn2+ from synthetic wastewater using chitosan-enhanced membrane filtration18. The presence of chitosan in the feed solution enhanced the metal removal by 6–10 times, which is attributed to the presence of the amino group in chitosan that served as a site for metal binding. Diethylaminoethyl cellulose19 and polyethyleneimine (PEI)20 are other examples of water-soluble metal-binding polymers used for heavy metal removal. Heavy metal removal can also be enhanced by the addition of minerals into the membrane reactor21. For example, the addition of 10 g L−1 vermiculite at pH=8 resulted in >99% removal of Pb2+, Ni2+, Cu2+ and Zn2+ 21. Consequently, the integrated process of sorption-UF with suitable pH adjustment (i.e. >7) can be applied as a pre-treatment stage to remove heavy metals from industrial wastewater, such as metal plating21,22.

Adsorbents can be used to increase the heavy metal removal efficiency in membrane processes. For instance, Malamis et al. (2010) used adsorbents such as bentonite, vermiculite, and zeolite (clinoptilolite) for removing Cu2+ from activated sludge permeate containing 317 mg L–1 Cu2+ 23. Adsorption using 10 and 20 g L–1 bentonite or vermiculite (pH: 5.5) followed by the ultrafiltration achieved a removal efficiency from 93.8–96.8 to 99.4% of Cu2+, respectively. The ultrafiltration alone was able to remove only 59.4–78.3% of Cu2+, indicating the superior performance of adsorbent-enhanced UF systems. The addition of zeolite and bentonite reduced the fouling, whereas vermiculite did not show any antifouling properties. As a follow-up study, Katsou et al. investigated the removal of Ni2+ via a combined adsorption and UF system24. In a batch UF unit with an initial Ni2+ concentration of 320 mg L–1 at a pH of 6, 65.3, and 80% removal efficiencies were obtained with 15 g L–1 each of bentonite and vermiculite respectively24. Membrane processes have also been used to treat saline industrial wastewaters containing high organic content. For instance, suspended solids (SS) and colloidal COD were reduced from seafood-processing wastewater by initial concentration via a UF system, followed by recycling of proteins to be used in fish meal production25. Turano et al. combined MF and centrifugation to remove up to 80% of the SS and 90% of the COD from olive oil mill effluent26.

It is worth noting that although RO is the most efficient in removing heavy metals from wastewater, it is not widely applied for this purpose when compared to other membrane processes such as MF, UF or NF, as it requires high energy for operation11. Also, the aerobic condition can promote the formation of metal oxides that can prematurely foul the RO membranes, necessitating frequent membrane replacements. However, if the wastewater also requires demineralization in addition to the removal of heavy metals, then RO might be a better technology to opt for.

Membrane bioreactors (MBRs)

Membrane bioreactors (MBRs) combine biological processes and membrane filtration to achieve better treated effluent quality by exploiting the dual benefits of membrane separation and activated sludge processes (ASPs). In the case of high strength industrial wastewater, operating parameters such as HRT, SRT, and MLSS should be optimized, and suitable pretreatment or neutralization should be provided to preserve the microbial community and prolong the membrane life2.

Metal sorption on activated sludge takes place as follows:

-

Cell wall and cell membrane contain various cations like Na+, Κ+, Mg2+, and Ca2+, and these ions will be exchanged with other dissolved metals in the MBR mixed liquor.

-

Interaction between metals and the sorption sites on cell surface induces complexation and/or microprecipitation.

The removal of metals in MBRs depends on a variety of parameters27,28 such as: (i) operating parameters like dissolved oxygen (DO) levels, mixed liquor SS (MLSS), and sludge retention time (SRT), (ii) physicochemical parameters such as metal type, species, and initial concentration, the type and concentration of ligands, the presence and concentration of competing cations, (iii) biochemical parameters such as the concentration and content of extracellular polymeric substances (EPS), ligands produced through bacterial activity, products from cell lysis, and bacterial species that favor metal uptake.

Aerobic MBR utilizes biological treatment with aerobic microorganisms that prosper in presence of oxygen. MBRs have been used for removing various pharmaceutical compounds with varying efficiencies. Although longer SRTs were usually associated with higher removal efficiencies, contradictory results were obtained for diclofenac and ethinylestradiol. It was concluded that antiepileptic compounds like carbamazepine were resistant to removal by MBR, whereas other compounds such as Bisphenol-A, the natural estrogens, ibuprofen, and bezafibrate were removed sufficiently. At a temperature of 10 °C, 80% removal of bisphenol-A was observed at SRT higher than 10 days. Also, the natural estrogens 17β-estradiol (E2), estrone (E1), and estriol (E3) were nearly removed completely. Similarly, the removal efficiency of more than 95% was observed for ibuprofen and bezafibrate29. GE Corp. has developed an effective MBR system named Zee-Weed MBR to treat wastewaters from the pharmaceuticals industry30. However, it should be noted that MBR processes, like any other biological process, is not specifically designed for removing pharmaceutical compounds. The level of biodegradation will thus depend on how recalcitrant these compounds are and whether they can be sorbed to activated sludge or remain in the liquid phase.

MBRs have been used for removing the oil, grease, and other organics from petrochemical-contaminated wastewater containing various compounds with typical 10,000–20,000 mg L–1 SS, 2000–4000 mg L–1 COD, and up to 1000 mg L–1 total Kjeldahl nitrogen (TKN)30. In another study, MBR reported 99.9% removal of fuel and lubricant oil at hydraulic retention time (HRT) of 13.3 h. It was observed that the quality of the treated effluent met industrial process water standards31. A study conducted on a full-scale MBR plant showed a 90% removal of COD and complete removal of grease, oil, and phenolics32, whereas, industrial site of Porto-Marghera has a huge petrochemical MBR plant, whose permeate is being discharged into Lagoon of Venice33.

Sometimes, industrial wastewater might contain compounds that are toxic to microorganisms, which necessitates pre-treatment before biological treatment3. Katsou et al. investigated a submerged MBR for treating heavy metals from a synthetic wastewater effluent21. The municipal wastewater was added with 3.9–14.7 mg L–1 Pb2+, 3.4–9.1 mg L–1 Cu2+, 3.2–12.1 mg L–1 Zn2+, and 4.3–14.7 mg L–1 Ni2+ and a hollow fiber membrane with a nominal pore size of 0.04 µm was employed. The MBR was operated at an HRT of 10.3 h and SRT of 15 days. A UF pre-treatment ensured the complete removal of total suspended solids (TSS). COD removal for the municipal wastewater was 95–97%, but it decreased to 83–91% upon the addition of heavy metals into the municipal wastewater. Comparing mixed liquor volatile suspended solids (MLVSS) before and after heavy metal addition showed that there was a 13% reduction in biomass due to the inhibition. Likewise, complete nitrification was observed in the case of municipal wastewater, but the addition of metals reduced it to 22–54%21.

When compared to traditional ASPs, MBR equipped with a UF membrane resulted in a 40–50% increase in the heavy metal removal efficiency34. Heavy metal removal mainly depends on the SRT, pH, and MLSS. High SRTs and MLSS, usually result in better heavy metal removal efficiency35. Metal ions are sorbed to the sludge particles attached to the UF membrane, which has resulted in the removal of Cu2+ (59.4–78.3%) and Ni2+ (23–50%) from industrial wastewater23. A submerged MBR with a hollow fiber membrane has also been found to significantly remove Cu2+ and Cr3+ from industrial wastewater36. Table 1 illustrates the literature data on MBR performance in industrial wastewater treatment for the removal of organics and nutrients from various industrial effluents.

There are several strategies for reducing the membrane fouling in MBRs. For instance, Deowan et al. coated a polyethersulfone (PES) UF membrane with an antifouling material and tested using synthetic textile dye wastewater13. The PBM MBR module showed around 10% higher dye removal when compared to commercial membranes and better fouling-resistance due to the antimicrobial properties of polymerizable cationic surfactant acryloyloxyundecyltriethylammonium bromide (AUTEAB).

Anaerobic membrane bioreactors (AnMBRs) are used to treat industrial wastewaters characterized by high organic matter. Anaerobic processes offer great sustainability benefits as they produce little sludge due to low biomass yield and consume less energy because of the absence of aeration. Moreover, anaerobic processes generate biogas that can be used as an alternative energy source3. Given the high organic loading of industrial wastewater, a comparably small amount of greenhouse gases is emitted to the atmosphere37. AnMBR system allows operation at high MLSS up to 15 g L–1 and can be run at long SRT of more than 20 days, and thus refractory and recalcitrant organics can be removed with high efficiency38. AnMBR can also retain specific microbial communities that can treat particular contaminants in wastewater39.

AnMBR has been employed for treating different types of wastewaters—from paper and pulp, food processing, winery, textile, pharmaceutical, oil, and petrochemical industries. For instance, the food processing industry produces wastewater that is non-toxic and readily biodegradable with high organic loading rate (OLR, 1000–85,000 mg COD L–1). AnMBR achieved a COD removal of >97% with OLRs higher than 12 kg COD m–3 d–1 4. It was reported that 15 full-scale AnMBR plants have been operating around the world for food industry treatment40.

Bioaugmentation involves supplementing the microbial community with particular microorganisms to improve biodegradation of recalcitrant molecules. The added microbes should be compatible and competitive with the existing microbial communities in the system to avoid any damaging effects. This method is more environment-friendly and affordable when compared to other extra physico-chemical processes. There are several studies on improving the degradation performance via bioaugmentation. For example, Saravanane and Sundararaman investigated the treatment of pharmaceutical wastewater with a high concentration of Cephalosporin derivative using an AnMBR with a submerged flat sheet membrane41. They found an enhanced removal efficiency upon bioaugmentation. In another study, Qu et al. bio-augmented an MBR with Sphingomonas xenophaga QYY strain for treating wastewater containing anthraquinone dyes intermediates to achieve an enhanced color and COD removals42. Thus, bioaugmentation or post-treatment may be needed with MBRs/AnMBRs to ensure the enhanced degradation of pollutants from industrial wastewaters.

Quorum sensing (QS) refers to the bacterial communication using chemical signals like N-acyl homoserine lactones (AHL), and subsequent regulation of gene expression in bacterial communities as a response to the population density43. Several studies showed a high correlation between AHL signals and biofilm growth44,45,46,47. When reaches a threshold level, QS activates the transcription of specific genes and induce the secretion of exocellular enzymes, extracellular polymeric substances (EPSs), soluble microbial products (SMP), antibiotics, virulence, and bioluminescence. Quorum quenching (QQ) refers to the interference with QS via inhibiting or degrading signals, and interfering or blocking signal receptors for mitigating biofouling in MBRs48,49. Thus the use of antimicrobial compounds can be minimized, and the risk of developing anti-microbial resistance can be avoided48. For instance, Kim et al. reduced the biofouling by exploiting the double-benefits of improved friction and QQ using porous alginate beads trapped with QQ bacteria50. The increased friction between loose beads and the static membranes helped to loosen the biofilm on the membranes, whereas QQ bacteria helped reduce the formation of EPS. Another study reported an improved antifouling by encapsulating QQ bacteria on a polymer membrane layer51.

In general, the use of MBRs is useful for treating industrial wastewater. However, further research is needed to optimize the process and overcome the limitations. For instance, membrane fouling due to the deposition and growth of microbes on membrane surface or pores causes a gradual increase in trans-membrane pressure (TMP) and a decline in water flux. This necessitates frequent cleaning and membrane replacements, leading to increased operation and maintenance costs52,53. Furthermore, the exact nature of the interactions between membrane surface and foulants cannot be easily identified. Also, most of the published research investigated the efficiency of the bench and pilot-scale systems. Limitations of pH, temperature, pressure, and some corrosive chemicals constrain the use of MBR, especially in large-scale operations2. Leakage of contaminants through the membranes, due to the gradual degradation of membranes poses another challenge. Although QQ is promising in ensuring the long-term operation of MBR with minimal fouling, further work should be conducted to evaluate MBR performance with QQ bacteria in treating industrial wastewater in the pilot and full-scale. The electricity consumption of MBRs is usually higher than most of treatment processes. Due to the high membrane aeration rates required to manage fouling and clogging, MBR energy consumption was three times higher even than that of conventional activated sludge (CAS) systems combined with advanced treatment techniques54. Recently, more efforts have been focusing on reducing the energy consumption associated with MBR. The electrical consumption was reported to be in the range 1.43 kWh m–3 to 4.23 kWh m–3 55, Energy consumption at 985 Japanese municipal WWTPs were analyzed and it was reported that CAS systems consumed between 0.3 kWh m–3 and 1.9 kWh m–3 56. A balanced comparison of MBR and CAS (or other) systems is only possible, however, when similar effluent quality is produced.

Adsorption and ion exchange

Adsorption refers to the transfer of gas or liquid molecules into a solid sorbent surface and holding them via physical and/or chemical intermolecular interactions10. Ion exchange refers to the transfer of ions between an electrolyte and a complex or between two electrolytes solutions. In many textbooks, ion exchange is grouped under adsorption, and henceforth in this article, the term adsorption also covers the ion exchange as well. Adsorbents can be natural (e.g., charcoal, clays, minerals such as bentonite and vermiculite, zeolites, and ores) or synthetic (produced from agricultural products and wastes, industrial or urban wastes, sewage sludge, metal oxides, and polymeric adsorbents)57,58,59. The adsorption has been effective in removing dyes, and organic pollutants and metals from various industrial wastewater effluents60. It is pivotal to determine the thermodynamic parameters such as standard free energy change (ΔG°), to predict the feasibility of the process. For instance, if ΔG°< 0, the process is both spontaneous and feasible and vice versa60. Recently, adsorption via activated carbon (AC), low-cost industrial products, and biosorption has been investigated and are discussed below.

Adsorption on activated carbon (AC)

Activated carbon (AC) for industrial wastewater treatment is usually applied in two forms – powdered (PAC) and granular (GAC). Adsorption unit can either be used before biological treatment for removing toxic compounds or be placed after the physio-chemical treatment steps for ensuring the complete removal of micropollutants. AC can be used to remove organics such as pesticides, phenols, pharmaceuticals, organic halogens, non-biodegradable compounds, dyes, and inorganics such as Hg2+, Pb2+, Cd2+, Cu2+, and Ni2+,61,62. AC is also an efficient media for microbial growth, and biologically activated carbon (BAC) has been developed for the inactivation of biological pollutants within a short period. Attaching biomass to AC can remove contaminants by both adsorption and biodegradation62. However, AC has some disadvantages, such as expensive thermal/chemical regeneration methods and the loss of a significant fraction of adsorbent during regeneration63. Moreover, the adsorption mechanism on AC depends on various factors such as dispersive, electrostatic and chemical interactions; intrinsic properties of the solute and adsorbent and hence the interaction between the pollutants and AC is difficult to predict64. Although AC has a high adsorption capacity, it can maintain it only until the adsorption sites become exhausted with pollutants. Other absorbents such as polymeric absorbents are also used when recycling of valuable chemicals is desired58,62.

The adsorption of phenols by commercial PAC showed that the removal efficiency increases up to an optimum dosage, beyond which the improvement was negligible65. It can be observed that the GAC is usually used for removing natural organic matter, synthetic organic compounds, and heavy metals61. Zhang et al. used GAC for removing algal odorants like dimethyl trisulfide and ß-cyclocitral66. Adsorption isotherms were investigated for the process and found that Freundlich isotherm was fitting the best. The ΔG° for adsorption of ß-cyclocitral and dimethyl trisulfide were –4.24 and –3.61 kJ mol−1 at 298 K, respectively66.

Cyanide, for instance, was found to be better removed by biologically activated GAC compared to virgin GAC. Also, biodegradable anthraquinone dyes were removed more efficiently because of the elevated substrate concentration at the granular surface found in BAC systems62. Table 2 shows a summary of the adsorptive removal of heavy metals from industrial wastewater by AC.

Not only AC is an effective method to remove heavy metals, it has also been used for the removal of other pollutants. AC was used to remove crystal violet dye and had a maximum adsorption capacity of 84.11 mg/g and a removal efficiency of 85–90%67.

Adsorption on natural materials

Adsorption on natural materials such as zeolites has been gaining more interest. Adsorption of metal ions on the zeolite active sites produce inner and outer-sphere complexes. The interposition of at least one water molecule between the bound ion and the functional group of the adsorbent results in the formation of outer-sphere complexes. In contrast, inner-sphere complexes will be formed when there is no interposition of water molecule(s). A coordinate bond will be formed between the heavy metals and the surface functional groups68,69. For example, Clinoptilolite, a type of zeolite, has shown high selectivity to Pb2+, Cd2+, Zn2+, and Cu2+ 10. Also, it was found that polymeric materials can be used to increase the efficiency of natural clay to remove heavy metals by modifying the natural clay into a composite named clay-polymer composite70. For example, clay-poly(methoxyethyl)acrylamide (PMEA) composite has been synthesized to study its capacity to adsorb Pb2+ ions. Bentonite, another type of clay has also exhibited high removal (>99%) of heavy metals removals like Cu2+, Co2+, Ni2+, Zn2+, and Pb2+ ions. The adsorption affinities of the metal species were as in the below order: Co2+>Cu2+>Ni2+ = Zn2+>Pb2+ 71. Another study also reported the complete (100%) removal of Pb2+ from aqueous solutions using 20 g L–1 of bentonite72.

Natural phosphates (NP) constitute another category of raw adsorbents73. NPs are abundant, cheap, and non-hazardous to the environment, and can be used for heavy metals removal. It was reported that NP has a monolayer adsorption capacity of 26 mg g–1 for Cd2+ at a pH of 5.074. Another study reported a room temperature adsorption capacity of 200 mg Pb2+/g of rock phosphate (low-grade) when the initial aqueous Pb2+ concentration was 50 mg L–1. Adsorption of Pb2+ on PO43- followed a pseudo-first-order rate and Langmuir isotherm75. Nano-hydroxyapatite (nHA) is a less-soluble, abundant and stable phosphate that has a high sorption capacity for heavy metals. It has been used in the adsorptive removal of Pb2+ and Cd2+ from polluted soils73. Applying nHA can reduce water-soluble Pb2+ by 72% and Cd2+ by 90%, bioaccessible Pb2+ by 12.5–27.5% and Cd2+ by 17.7–34.6%73. It was also reported that nHA had a maximum adsorption capacity of 2500 mg of Sn2+ g–1. The process was endothermic and followed Langmuir isotherm76.

NPs have also been used to remove emerging and persistent organic contaminants. The adsorption of a reactive dye, Reactive Yellow 84, by hydroxyapatite (HAP) has been found to follow Langmuir isotherm with a monolayer adsorption capacity of 50.3 mg g–1 at a pH of 5.0. Adsorption of this dye is endothermic (enthalpy of adsorption is 2.2 kJ mol–1) and has a low temperature dependency77. Nanocrystalline HAP has been used to remove nitrobenzene78. The authors achieved a 52.4% removal with an adsorbent dosage of 5 g L–1, whereas the removal was increased up to 95% when the dosage was 25 g L–1 78. However, the adsorption capacity of nitrobenzene on nanocrystalline HAP is relatively low compared to adsorption on AC (100–300 mg g–1). This was attributed to the smaller surface area of nanocrystalline HAP (42.3 m2 g−1) when compared to AC (1000 m2 g–1)78. The effectiveness of mesoporous silica-alumina (MSA) on the removal of hydrocarbons from industrial wastewater has been investigated79. The dehydroxylated silicon content is the main factor in the adsorption process. Water is adsorbed on the MSA surface by interacting with silanol groups; aromatic hydrocarbons such as benzene and toluene interact with electron-poor acid sites. However, the presence of areas rich in hydrophilic Al enclosed in an active silica matrix can create spots that can deter the efficient removal of hydrophobic hydrocarbons.

Adsorption on industrial by-products

Industrial by-products such as carbonaceous wastes, agricultural by-products, mineral-derived sources, etc. can be used as low-cost adsorbents for industrial wastewater treatment80. For instance, steelmaking slag comprised of hydroxides of iron and calcium is used as a low-cost adsorbent81,82,83,84. Fe(OH)3 and Fe(OH)2 present in the slag provide adsorption sites for ions such as As3+, and Cr3+ whereas Ca(OH)2 increases the solution pH and enhances the heavy metal precipitation83. The removal of Cd2+ by steel industry slag has also been investigated. The optimum adsorbent concentration was found to be 10 g L–1 for treating 100 mg L–1 of Cd2+ solution at pH 4.0, and the removal rate could reach up to 99.1%. The removal is attributed to the chemisorption, including chemical precipitation and coordination reactions84.

Other examples of low-cost industrial by-product adsorbents are fly ashes85,86,87,88,89, waste Fe, hydrous TiO2, and other waste products which can be fine-tuned chemically to enhance pollutant removal10. Fly ash can be chemically modified with NaOH and CH3(CH2)15N(Br)(CH3)3 for Cd2+ and Cu2+ removal89. The mechanisms of adsorption on industrial by-products differ from one material to another. Adsorption on hydrothermally modified fly ash, for instance, is based on electrostatic attraction. Other mechanisms depend on ion exchange and the structure of surfaces11. In general, using low-cost adsorbents (such as the ones obtained as by-products or from natural resources) has introduced an alternative for industrial wastewater treatment systems. The comparative advantages of low-cost adsorbents are their relatively low prices and abundance since they are natural materials or by-products from agricultural and industrial activities. Some of these adsorbents exhibit a high selectivity for specific contaminants. Required wastewater-pretreatment and fine-tuning the adsorbent materials are some limitations. Moreover, in some cases, the heavy metals in the slag may leach out and cause secondary contamination, and hence using those industrial by-products as adsorbents has to be done carefully83.

Biosorption

Biosorption involves concentrating pollutants, particularly heavy metals, by binding them with inactive microbial biomass mainly via adsorption and chelations10,90,91,92. Although this is attributed to the metabolism-independent binding of heavy metals to the cell walls, the actual mechanisms are yet to be understood10,90. Several mechanisms, such as chemisorption (ion exchange and chelation), complexation, and physical adsorption, are proposed90. For example, a study on the removal mechanism of Cu2+, Ni2+, Zn2+, Pb2+ and Cr3+ by Penicillium chrysogenum attributed ion exchange as the principal removal mechanism93. The uptake of Pb2+ by R. glutinis is also attributed to the transfer of ions and biomass released phosphate induced precipitation. Also, the uptake of Pb2+ by Aspergillus parasiticus cell wall takes place by ion exchange and complexation processes94. Cu2+ ions are also bioadsobed by Fucus serratus by ion exchange. When Ca2+ ions are released from the surface of the biomass, a bond between Cu2+ and functional groups forms94,95. Also, when Ni2+ is bioadsorbed by Lathyrus sativus, dative bonds will be formed between Ni2+ and nitrogen in the ammonia functional group of the biomass species96. Chelation and ion-exchange are proposed to be the two main mechanisms of chemisorption of Cu2+ by walnut and hazelnut shells96. Many other biomass sources such as peanut and hazelnut shells 10,97, green alga98, orange peel99, Rhizopus sp. biomass100, jackfruit10, maize cob or husk10, and their chemical modification or thermal conversion to AC have been used during biosorption10.

Weak Van der Waals forces between the heavy metal ions and adsorbent surfaces constitute the primary removal mechanism in physisorption. An example of physical adsorption is Cd2+ adsorption by olive cake, which achieved a 66% removal at 28 °C and pH of 6101. Another study on the removal of Zn2+, Pb2+, Fe2+, and Cu2+ using dried red seaweed Kappaphycus sp. also indicated the removal of metals vis physisorption102. Malamis et al. (2011) applied activated sludge coupled with UF to enhance the removal of Ni2+, Cu2+, Pb2+ and Ni2+ 103. The highest removal of Pb2+ was found at pH=4 and Zn2+, Ni2+, and Cu2+ at pH = 6. Table 3 illustrates data obtained from the literature of several biosorption cases.

Biosorption has been reported to remove pollutants other than heavy metals. For instance, modified lemon leaf was used to remove cationic dye, and was found to have an adsorption maximum capacity of 36.10 mg g–1 and yielded 70% removal efficiency104. Another example was the utilization of modified biogas residue to remove nitrate and phosphate. The maximum adsorption capacity was reported to be 64.12 mg g–1 and 34.40 mg g–1 for nitrate and phosphate, respectively105.

Several modified biopolymers have been developed for heavy metal removal applications, which include natural rubber, Lyocell fiber, and chitosan-based adsorbents11. Biopolymers are widely used in industries due to their availability, environmental safety, and ability to reduce heavy metals to parts per billion10. Such materials do have certain drawbacks, however. For example, the biopolymer chitson in its natural form has low specific selectivity for heavy metals and low adsorption capacity for complex polluted wastewater106. Nevertheless, good sorption capacity for transition metals has been demonstrated for chitosan with a high content of hydroxyl and amine groups, but little to no sorption capacity for alkaine or alkaine earth elements106.

Heavy metal removal by biopolymers can be enhanced by modifying its chemical and physical properties10,11,107. For instance, chemical and physical methods can be used on chitosan to improve its removal efficiency. Chitsoan can be modified physically by preparing the polymer in different forms. Other forms of chitosan include water-soluble and water-insoluble chitosan, such as flakes nanoparticles and beads11,106. Modified chitosan beads were suggested for the diffusion of various metal ions and specifically Cu2+ ions through spherical chitosan-tripolyphosphate (TPP) chelating resins, which are prepared using an in-liquid ionotropic crosslinking method108. Additionally, the study of Liu et al. [149] suggests that non-porous glass beads can be used to create hybrid materials by immobilizing chitosan on their surface109. Chemically modified chitosan is also beneficial for wide heavy metal sorption applications. The most highlighted modifications of chitosan are the grafting chitosan and the cross-linked chitosan11. Polysaccharide-based-materials have also been developed as modified biopolymer adsorbent, which is derived from chitin, chitosan, and starch for the removal of heavy metals from wastewater10.

Future research should aim at developing new and low-cost adsorption materials with high treatment efficiencies as for most adsorption processes, the cost of the adsorbent constitutes up to 70% of the total cost110. Also, most of the studies focus on determining the maximum adsorption capacity of an adsorbent, which assumes a fixed-bed adsorption system. This might not be the case in industry, and more studies should aim at investigating the maximum capacity in real-life processes. The performance of fixed-bed adsorbers is different when compared to agitated batch adsorbers for instance. Another very important aspect that is often not focused on is desorption and regeneration. Since the world is more concerned with sustainability and environment nowadays, more studies should focus on adsorbents regeneration and reuse.

Advanced oxidation processes (AOPs)

Advanced oxidation processes (AOPs) are chemical treatments involving the generation of hydroxyl radicals (OH•) that can efficiently oxidize recalcitrant pollutants111. OH• are characterized by their high standard oxidation potential (up to 2.80 V) and their high reaction rate in comparison to common oxidants like chlorine, oxygen, ozone, H2O2, or potassium permanganate. Hence, high rate constants can be achieved during the reaction of OH• with both inorganic and organic solutes112. AOPs, in general, employ the efficacies of different oxidants to degrade hazardous pollutants by converting them from their reduced forms to their final harmless oxidized forms. This conversion mineralizes and degrades the contaminants to harmless substances for overcoming the environmental impacts due to the disposal of the primary pollutants to the aquatic ecosystem. Although these systems use different oxidants, they all tend to share the same radical production113. These processes have a high potential to purify water from pollutants that are hard to be removed by biological methods114. AOPs include two main stages: The formation of strong OH•/oxidants and the interaction of these radicals with the targeted pollutants to convert them to carbon and water in the best-case scenario. When two OH• interact, H2O2 is formed, as shown in below equation:

The comparative advantages of AOPs are (i) high disinfection strength: Several AOPs are used because of their great disinfection properties115, and (ii) standalone destruction of organic contaminants. If methyl tert-butyl ether, for example, was removed by stripping, additional processes such as catalytic oxidation would be needed for effective treatment. However, AOPs destroy the organic contamination directly without the need for other chemical processes116.

However, the generation of undesirable oxidation by-products affect AOPs. If these oxidation by-products have slow reaction rates, there would be a delay in mineralization, leading to unwanted accumulation. Also, inorganic substances are formed during some AOPs, such as bromide conversion to bromate during ozonation. These inorganic compounds interfere with AOPs and inhibit the oxidation reactions. These compounds scavenge the OH•, which are meant to remove and destroy the concerned contaminants116. Therefore, there is need to address the issue of radical scavengers and the likelihood of producing unwanted intermediate derivatives from the oxidized forms of pollutants. pH influences the acid-base equilibrium involving OH• formation and the radical’s concentration.

Two critical parameters should be taken into considerations while designing and constructing an efficient AOP system. Firstly, the dosage of chemicals as it will increase the cost and may give the possibility of by-product formation. Secondly, reactor configuration and contact time, which is often determined when implementing a pilot study rather than a lab-scale, should also be considered116. The quality of industrial wastewater and other operating conditions also affect the efficiency of degradation of concerned pollutants. It is known that most of the organic substances would react instantly with the introduced radicals116. Turbidity also acts as an influencer to the system performance because the more turbid the industrial wastewater, the lower is the penetration of UV source to the water. Additionally, Fe2+ and Cu2+ or other heavy metals in wastewater may also cause the formation of Fe or Cu organic complexes thus results in fouling for the system116. The recently employed AOPs are the Fenton-based processes, electrokinetic treatment, and degradation with metal oxides.

Fenton-based processes

Fenton processes are catalytic processes that generate hydroxyl radicals (OH•) from H2O2 upon the addition of Fe2+ 112. OH• are produced from the oxidation of Fe2+ to Fe3+ as in below equation 111:

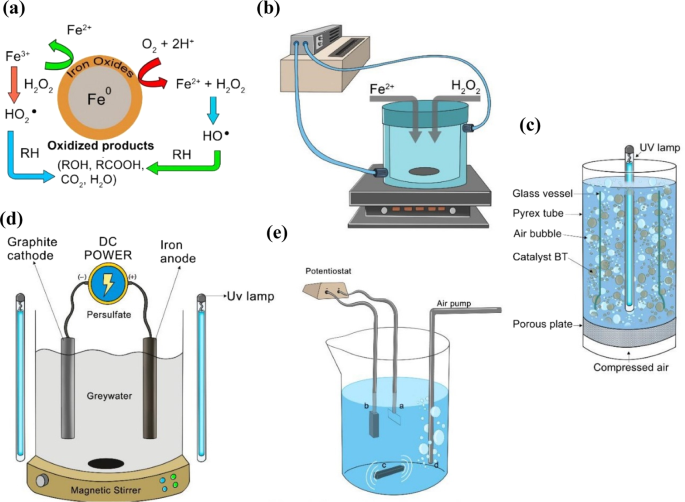

However, the Fenton process produces Fe sludge waste because Fe3+ precipitates as FeO(OH)112. Thus, the typical Fenton process can be improved by coupling it with electricity to have an electro-Fenton process, or with UV or solar light to have a photo-Fenton process, to reduce Fe3+ back to Fe2+ and reduce the amount of waste sludge111. The UV produces more OH• by photolysis and activates photo-decarboxylation of ferric carboxylates117. Table 4 summarizes the application of Fenton treatment for the removal of various types of contaminants. Recent advances in the Fenton-based processes such as Fenton, photo-Fenton, and electro-Fenton are elaborated in the next subsections.

FeSO4 is an adequate salt for ferrous generation, and it showed a TOC removal efficiency of 94% after 2 h118. FeSO4 can be generated by adding Fe catalyst to H2SO4. Fenton process via FeSO4 was shown to be very useful and efficient in terms of oxidation and degradation of TOC118. Organophosphorus pesticides removal from wastewater has been evaluated using the Fenton process under various reaction conditions at room pressure and temperature. The optimum condition was determined by several parameters such as pH, stirring time, and dosage of FeSO4 and H2O2. COD removal efficiencies for an actual triazophs wastewater treatment plant and a bench-scale experiments were 85.4% and 96.3%, respectively. Complete oxidation of phosphorus and nitrogen content was observed through which eutrophication is minimized119. The efficiency of treating wastewater obtained from a synthetic fiber factory that uses acrylic polymer has also been investigated. The more H2O2 was added, the more the effectiveness of degrading the unwanted pollutants. However, an increase in the COD content of the treated effluent was observed at a concentration above 500 mg L–1 of H2O2. Also, pH levels seemed to impact the removal efficiency of color and COD. The pH was carefully selected for the removal of color since a decrease in pH (<6) led to the destabilization and aggregation of particles120.

Apart from FeSO4, Fe3O4 has also been examined as a reagent that can be combined with H2O2 in a Fenton process for the degradation of phenols121,122. Many characteristics were taken into consideration, but the one that played a significant role was Fe2+ and Fe3+ ratio, which was determined by the chemical analysis. Fenton reaction started slow but accelerated eventually. Phenol degradation was achieved efficiently in Fe3O4 that has a higher structural content of Fe2+. The use of magnetite showed positive features such as safe levels of Fe2+ content in wastewater/water effluent, a magnetic behavior that separates the reagent easily from the treated feed, and easy absorption of UVA radiation, which enhanced the reaction.

Recently, Fenton pilot-scale experiment has been implemented to degrade synthesized C20H18NO4+ 123. The main parameters were optimized using response surface methodology technique. Acidic industrial wastewater sample was collected from a chemical factory, and subsequently, pH was adjusted prior to the oxidation process. Values given by the statistical method were highly efficient and relatively close to the obtained experimental results. The berberine removal efficiency was found to be 35.6% at a pH of 3.5.

The photo-Fenton process has improved the TOC removal efficiency when compared with the Fenton process due to the enhancement of TOC degradation rate by photons124. Photo-Fenton process at neutral pH with UV254 is a promising technique in which it degrades all pollutants in a limited time. For this process, Fe is not necessarily needed if the treated water contains at least 1.5 mg L–1 of Fe2+ or Fe3+ 125. This technique is appropriate for large-scale systems and can be used to replace the available conventional solutions such as ozonation. However, a relatively low amount of pollutant degradation would be observed when photo-Fenton is implemented using regular sunlight.

Photo-Fenton technology has also proved to be efficient for the removal of pesticides from the water with high salinities126. Additionally, photo-Fenton technology has also been reported as efficient for the removal of pesticides from the water with high salinities. Oxidation rates were much faster from the beginning when the water was more saline. For water with lower salinity, oxidation rates started to increase only after about 60 min of treatment. The effect of conductivity on the mineralization of organic content of saline water was mainly caused by interference by chloride. The photo-Fenton process has also been used for dye removal. Low levels of H2O2 in the process may result in the formation of more toxic products. In some cases, however, the pollutant may be degraded without the creation of any toxic by-products depending on the solubility of the contaminant in water. Therefore, the solubility of pollutant in water has a significant role in the photo-Fenton process. Photo-Fenton is also reported as useful for the full degradation of 4 colorants in wastewater streams from the food and cosmetics industries127.

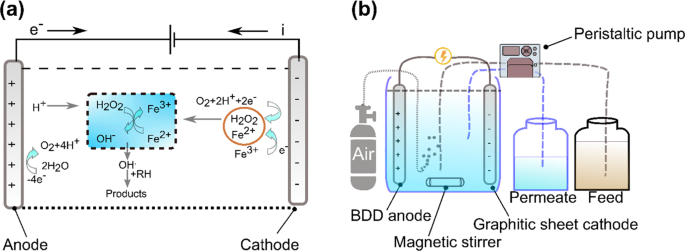

Electro-Fenton is an emerging process where H2O2 is electro-generated at the cathode made with carbon materials. This method is safe because H2O2 is produced in-situ, and the risk of handling H2O2 is reduced. It is also a faster process in degrading many pollutants because of the constant generation of Fe catalyst at the cathode128. A simple illustration of the electro-Fenton mechanism is shown in Fig. 1a. Removal of Alizarin Red has been successfully implemented recently using the electro-Fenton technique with a graphite-felt electrode where the cathode was fed with air to reproduce H2O2. Ferrous ions played the central role in the removal since the oxidant alone has a limited capability. Through this method, Alizarin Red was oxidized to a colorless acid and then to carbon dioxide129. 100% color removal has also been achieved through the electro-Fenton process130. By using the GAC electrode as the cathode and air in the electro-Fenton process, stability, and efficiency in removing methyl orange has been achieved130. It was, however, observed that the electro-generation of H2O2 was limited at longer times due to the oxidation to oxygen at the anode, but still, the limited value is much more significant when compared to methods without air bubbling approach. It was also mentioned that oxygen did not contribute to the reduction process since the rate of increase of H2O2 generation followed a linear relationship with the imposed current for the first hour130. The use of AC cathode was also studied previously in Taiwan by131, where the pollutant adsorption on the cathode was measured, and the highest COD removal reached around 75%.

Electro-Fenton process has also been applied for the degradation of surfactants by using graphite-felt cathode119. The critical parameter was to apply different electrolytes in the presence of Fe catalyst. The decay kinetics of the surfactant was unaffected by its initial dosage, highly dependent on the applied current, Fe catalyst concentration, and pH; and followed a pseudo-first-order reaction. Another recent application of the graphite cathode electro-Fenton process is the removal of antibiotic residue from industrial wastewater. A highly bioactive antibiotic (tetracycline) was mineralized to carbon dioxide through this method123. Meanwhile, the recent development and use of nano-enhanced carbon electrodes in the electro-Fenton process can ensure enhanced stability and pollutant degradation rate. Graphite cathodes have been compared with carbon nanotube (CNT) sponge in an electro-Fenton process114. The CNT sponge was used as the cathode of the electro-Fenton process under high electrical power. The CNT sponge showed enhanced stability and a good degradation rate that was estimated to be ten times higher than the one obtained by graphite cathode. Recently, the efficiency of carbon-felt electrode has also been compared with those of alternative non-carbon materials as anode132. The materials, such as boron-doped diamond (BDD), Ti with Pt coating, and Ti with TiO2 coating, were used as electrodes to remove carbamazepine from wastewater. The BDD anode showed the fastest oxidation and mineralization efficiency; and exhibited much better catalytic ability than the others125. Also, the BDD anode showed a better performance in mineralizing Atrazine into C3H3N3O3 as the ultimate end product. This study compared its results with the previous experiment conducted on C8H14ClN5 removal with classical Pt anode. Although the classical Pt anode was faster in decaying Atrazine, it was slower in mineralizing it. BDD anode has the potential to produce high amounts of OH•. These formed OH• are physically adsorbed to the anode surface, which enhanced pollutant uptake. The study concluded a full removal of the insecticide at an initial pH of 2. The efficiency of the BDD anode agreed with previous results132. A continuous electro-Fenton process with graphite sheet cathode and BDD anode is illustrated in Fig. 1b.

Furthermore, Tylosin antibiotic was degraded after 15 min of applying electro-Fenton, and it followed pseudo-first-order124. The degradation of Tylosin antibiotic showed a possibility to combine biological treatment with electro-Fenton because the biodegradability showed an improvement where the BOD5/COD ratio increased from zero to 0.6 after 6 h of electrolysis. After 6 h, the application of electro-Fenton alone gave more energy efficiency than the combination. It was suggested that the mineralization should be optimized by balancing the energy used in case both processes are operating together. In addition, electro-Fenton has been integrated with absorption in order to enhance the kinetics of color removal. The use of Fe-loaded AC as an absorbent, together with electro-Fenton has shown promising results in winery wastewater treatment133. Fe-loaded AC implementation alone exhibited 23% color removal after 24 h. However, almost total color removal was achieved at the same time when electro-Fenton was integrated with Fe-loaded AC absorption. The adsorbent was used as a catalyst to optimize the process kinetics so that higher degradation rates can be reached. The adsorbent also showed a better physical capability than Mn and Fe alginate beads. Several conventional electro-Fenton process studies emphasized that the process can ensure a total removal or high removal efficiency at a pH of 3128. However, a recent optimization study using Box-Behnken design and response surface methodology showed higher efficiency when the pH was increased up to 5128. It was illustrated that if the pH was below 5, then H2O2 cannot be decomposed to the oxidant radical by Fe2+. At pH below 5, hydrogen would gain one electron, and this would lead to a reduction in the rate of reaction between the Fe2+ and H2O2. Consequently, a reduction in the degradation of pollutants would be observed. The results obtained in several recent studies on Fenton-based processes in terms of the removal of highly hazardous pollutants are shown in Table 5. An overview illustration of various Fenton processes is presented in Fig. 2

Electrokinetic treatment

Electrokinetic treatments such as electrocoagulation (EC), electrochemical oxidation (EO), and electroflotation (EF), electroosmosis, and electrophoresis help in the degradation of various pollutants via electrochemical mechanisms. They are specifically beneficial for the treatment of industrial wastewater, such as textile wastewater. Some of the contaminants that have been removed successfully by electrokinetic treatments include decolorizing reactive dye solutions and phenolic compounds, and heavy metals134.

Electrocoagulation (EC) is an electrokinetic process that utilizes the electrical field to form aggregated particles. EC generates coagulates via the decomposition of electrodes. Ion generation occurs at the anode, while hydrogen gas is produced at the cathode, allowing electofloculation to take place since the hydrogen released helps in keeping the flocculated particles float135. Colloidal solids and particles, metals, and soluble inorganic pollutants are some of the materials that EC can remove from aqueous media by neutralizing their charges using the charged polymeric metal hydroxide species. Neutralizing suspended solids charges causes the contaminates to agglomerate and then separate from the aqueous phase.

EC has been widely used for treating industrial wastewaters with metallic content136. The efficiency of EC depends on the type of wastewater. For example, COD removal by EC in textile wastewater has been found to be from 40 to 70%, 96% for soluble oils, and 80% for paper waste137. One of the key factors to consider when using EC for the treatment of industrial wastewater is the electrode material. The effect of three different types of electrode materials, namely Al, stainless steel, and Fe on EC’s efficiency for the removal SO42- from a refinery’s wastewater has been reported138. The electrodes used in the study have the same area, contact time, and CD. It was observed that Al electrodes have the highest efficiency, in which, the sulfide reduction was 2.5 times higher than stainless steel and Fe electrodes. This is due to the reaction between Al(OH)3 and SO42- in the cell, causing sulfate salts to participate at the bottom of the cell. SO42- can also get trapped in porous precipitate and increase extraction efficiency. Additionally, the solubility of Al2(SO4)3 is less than that of ferrous sulfates (400 kg m−3 vs. 600 kg m−3). Therefore, the precipitation of Al2(SO4)3 can occur at a faster rate. The electrode with the lowest efficiency among the three materials is stainless steel, due to its resistance to corrosion138. However, a high concentration of calcium or magnesium ions can increase stainless steel effectivity drastically135. This demonstrates that the type of pollutant should be taken into consideration when choosing an electrode. Wang and Chou [209] reported that using Al as cathode and anode, because of its low hydrogen overvoltage, gives the highest turbidity removal and COD in the treatment of tanning wastewater. At the same time, Fe or steel can be more effective in treating the same wastewater, depending on the targeted pollutant139. Another study showed that Al electrodes yield better effluent quality for leather tanning industrial wastewater treatment in comparison with other electrodes140. Therefore, in general, Al pairs of electrodes might be more suitable for the removal of organic matter. In contrast, Fe electrodes might provide a higher removal of inorganic pollutants, such as Cr, Ca, and Zn141. For instance, Fe electrode is not effective for COD removal, since soluble and miscible organic compounds such as glucose, isopropyl alcohol, phenol, sucrose do not react with Fe2+ and Fe3+. Only a small amount of these organic compounds can be incidentally removed by sorption on the floc. COD value might increase when compounds (usually acids) react with Fe2+ to form soluble products, which remain in the solution. Additionally, COD can be partially removed when sodium oxalate, other similar salts, and certain acids are present in the wastewater. In addition to protons, EC generates Fe ions which hydrolyze to form Fe(OH)2 and Fe(OH)3. OH− ions are not attracted to sodium ions since Fe ions are more acidic, which causes a very low percentage of CH3COO− and similar ions are removed. Acids, such as C6H8O7, C7H6O3, C4H6O6 and C2H2O4 acids, react with Fe2+ and Fe3+ to form soluble and insoluble, respectively. COD can only be effectively removed if the present organic compounds can react with Fe ions to form insoluble compounds, as exhibited by hydroxoaluminum ions142. Therefore, when Al and Fe electrodes are compared, Al electrodes show higher COD removal efficiencies, especially at lower pH values. This is because Al has only one oxidation state, namely Al3+, which allows a complete reaction of the organic compound to form an insoluble compound142.

EC can also be used to treat oil-in-water emulsions143,144,145,146,147. The coagulants produced in-situ cause the break-up of the emulsion by reducing the surface charge of the droplets. This causes the coalescence of oil droplets, which is then followed by separation either by settling or by dissolved air-flotation. The primary removal mechanism is bridging flocculation or the attachment of absorbing macromolecules to several droplets simultaneously148,149. In bridging flocculation, electrically charged sites on the surface of the droplet are attracted to species with the opposite charge. Additionally, the adsorption properties of growing metal hydroxides can be utilized for the elimination of oil (Fe and Al hydroxides). It was found that the adsorptive layers of anions and cations of growing hydroxides, in addition to its nucleus, produce positively charged particles that have high adsorption of oil droplets148,149. Also, destabilization by non-absorbing polymers can happen by depletion flocculation148. It has been found that the instability of oil emulsions and the removal of COD can only be attained for values of pH in the range of 5–9.

The aqueous behavior of Al includes the production of polymeric hydroxoaluminum ions, monomeric hydroxoaluminum ions, and Al(OH)3 precipitates. Monomeric cationic hydroxoaluminum are the predominant species at low range of pH. When the pH is close to neutrality, aluminum hydroxides precipitates are the predominant species. The dissolution of the precipitates into monomeric anionic hydroxoaluminum occurs with an increase in pH150. The inability of the monomeric Al ionic species to destabilize oil emulsions can also be attributed to their steric constraints; monomeric Al ionic species have a smaller size in comparison to the size of the droplet; thus, enabling to act over oil droplets. On the other hand, the size of hydroxide precipitates, and polymeric ions can help more than one droplet in the attraction to the coagulant species151. When the electrical charge exceeds a certain threshold, de-emulsification occurs, which slightly decreases the removal efficiency. This is because the coagulant at an excess concentration reduces the efficiency, since it increases the concentration of Al(OH)3 particles, and thus decreases the chance of attracting more than one droplet on the same particle of coagulant.

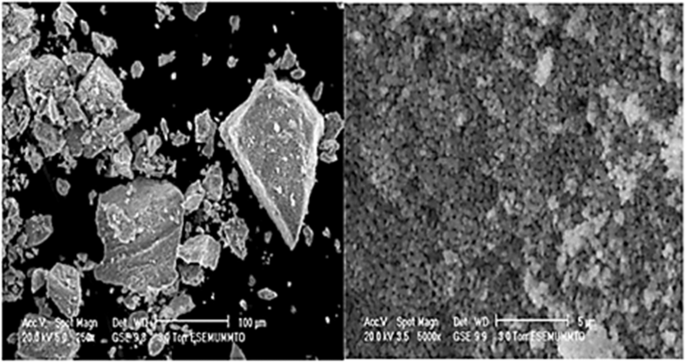

EC has been used to treat industrial wastewater rich in heavy metals such as Cr6+. Hexavalent Cr removal is achieved by reducing Cr6+ to Cr3+, which then later precipitates in the form of neutral hydroxide. It was found that a higher CD corresponds to faster removal of Cr. Additionally, unlike Fe electrodes, COD removal was not affected by the presence of Cr6+ by using Al electrodes152. 5 min was sufficient for the removal of 99% of Cr6+, but 10 min is required with using Al electrodes153. After 60 min of EC, flecks of aggregates were observed (Fig. 3). Cr6+ ions can react with Fe2+ to produce Cr3+ and Fe3+ 154. By using Fe electrodes, the residual Cr concentration is dependent on the residual Fe concentration, because the removal of Cr ions is carried out by co-precipitation of Cr ions and Fe ions. Hence, complete precipitation of Fe ions is preferred154.

Flecks showed by scanning electron microscope (SEM) after 60 min of EC153.

EC has also been used recently to treat industrial wastewater containing Mn, Cu, and Zn at concentrations of 5 mg L–1, 5 mg L–1, and 10 mg L–1, respectively, and at a pH of 6155. Cu and Zn were removed entirely, and more than 95% removal of Mn was achieved. Decreasing the initial pH resulted in a decrease in removal efficiency. Also, the higher applied current was associated with higher efficiency. The use of different initial concentrations did not affect the removal of heavy metals. Another study reported a 96% arsenic (As) reduction by EC when Fe electrodes were used156. Cu, Cr, Pb, and Zn removal from billet industry wastewater was also studied. Around 99% of these heavy metals were removed at pH 5, CD of 98 A m−2, and 30 min treatment time157.

EC has also been utilized to extract fluoride (F−) from treated industrial wastewater, particularly that generated from steel industry158. F− is additionally present in wastewater generated from semiconductor, electroplating, glass, and ceramic industries159,160. By using EC, F− concentration can be reduced to 0.5 mg L–1 from a concentration of 4.0–6.0 mg L−1 using optimum HRT of 5 min158. Although an increase in HRT is associated with increased removal efficiency, this increase in removal efficiency is negligible after 5 min. Another study reported that increasing the number of Al plates in a reactor from one to three, increased the F− removal from around 90% to 93% at a constant potential of 30 V153. However, increasing the number of plates to about 6 had a negative impact on the F− removal efficiency. This can be explained by Ohm’s law; the current and resistance are inversely proportional at a fixed voltage. It can also be observed that increasing the number of plates resulted in producing more coagulants, resulting in increased resistance, and reduced current. The CD determines the coagulant dosage and size of the bubble production, which affects the growth of flocs.

EC process has also been tested for the removal of organics from the textile industry wastewater. A study reported COD reduction from 1316 mg L–1 to 42.9 mg L–1 by using RuO2/IrO2/TaO2 and titanium electrodes161. In another study, COD and turbidity removal, the effect of electrode material, cell voltage, and other parameters were investigated in textile wastewater treatment using Al and Fe electrodes152. EC removes organic matters by two mechanisms. The first mechanism involves the removal of organic matters through indirect oxidation by utilizing chloride. The second mechanism is adsorptive/entrapment of organic matter, particularly colloids, and SS on metal hydroxide flocs162,163. Apart from the removal of organics, several studies have been conducted to investigate the extraction of color from textile wastewater. The extraction efficiency of color was found to be 95%-99% by EC using Fe and Al electrodes164. The decolorization kinetics followed the first-order law. The highest color extraction efficiency was attained at neutral and slightly acidic pH values164. Another study tested EC’s color removal efficiency for both synthetic and real wastewaters. It was found that the removal of color from synthetic wastewater was higher than that of real wastewater. This was due to the higher organic content in real wastewater, in addition to the complexity165. Table 6 summarizes the recent advances in industrial wastewater treatment by EC.

The specific energy consumption is directly proportional to the current and time166. It was predicted that US $1.86 is required for treating 1 m3 of dye by EC process167. The operating cost increases with the increase in operating time for iron and aluminum electrode, while the operating cost is double for aluminum electrode EC as compared to iron electrode EC for the same operating time168. The operating cost of EC process for the treatment of industrial wastewater is minimal as compared with other process like Fenton and chemical coagulation. Furthermore, the cost of adsorption process is less compared to that of EC, where the generation of huge quantity of sludge is the major problem169.

Electrochemical oxidation (EO) of pollutants in industrial wastewater can be achieved via two main mechanisms. The first is direct anodic oxidation, where oxygen or OH• in the oxide lattice MOx+1 is generated170. The other mechanism is by indirect electrooxidation process in which the oxidation process is carried out via a generated mediator, such as chlorine, hypochlorite, ozone, and H2O2171. Generally, the EO technique can remove a wide variety of pollutants, such as nitrogen species, microorganisms, and refractory organic matter, which are often found in industrial wastewater. Additionally, it is effective in treating non-biodegradable, toxic organic pollutants, nitrite, and nitrate, and some micro contaminants such as pharmaceuticals135. Advanced technologies that are based on chemical oxidation are usually used to treat biologically recalcitrant effluents172. Electrochemical reactions are additionally utilized for disinfection purposes by generating oxidizing species. High disinfection efficiency would be obtained from waters that contain chloride ions because the generation of oxidizing species would be achieved173.

EO is affected by cell design, pH, electrolyte composition, CD, temperature, and electrode materials. Electrodes should be stable and should display low activity toward oxygen evolution reaction and high activity towards organic oxidation174.

The most common electrochemical oxidant is chlorine, which is formed by the oxidation of chloride at the anode. The electrochemical oxidation of ammonia has also been reported, specifically that present in saline industrial wastewater175. An electrochemical cell consisting of circular BDD on a stainless-steel cathode and silicon anode was used. A high level of chloride ions in wastewater increased the ammonia elimination, and the TOC removal was reached up to 90%175. It was also found that the highest efficiency was associated with the lowest CD175. If the chloride content in wastewater is not high enough, salt must be added to increase the treatment efficiency135. The removal of dyes, solvents, and surfactants has also been achieved by EO111. BDD was used as an anode and stainless steel (AISI 304) as a cathode. A complete COD removal was achieved with very high current efficiency, depending on CD and the type of anions in the wastewater. The treatment of dyes is more efficient with using chlorine, while phosphates are better suited for the extraction of aliphatic compounds.

EO has also been utilized for the disinfection and treatment of latex wastewater. The initial concentration of COD and microorganism was 3820 mg L–1 and 180 CFU mL–1, respectively. COD was reduced to a level of 78 mg L–1, while the microorganism was completely removed. This was achieved through the hydrochlorites acid produced from electrolytic reactor that utilizes graphite as an anode and stainless steel as cathode. Equations (3–5) illustrates the electrochemical generation of chlorine/hydrochlorite in a solution that contains chloride ions176:

Nowadays, due to their high stability and efficiency, conductive-diamond anodes have been gaining more attention in the treatment of industrial wastewater containing organic pollutants177. This can be justified by the fact that the anodic activity depends on the value of the overpotential of oxygen evolution. High oxygen evolution overpotential is essential to avoid undesired side reactions that reduce the current efficiency of oxidizing organics135. IrO2, graphite, and Pt exhibit low values of overpotential of oxygen evolution in EO when compared to conductive-diamond anodes. This necessitates the application of a very low CD to remove pollutants effectively or the use of this anode when there is a high concentration of chlorides or metallic mediators. BDD film on titanium substrate also gives a high value of oxygen evolution overpotential. When this anode is used, oxidation can take place with a low amount of oxygen evolved when high values of current densities are present.

EO has been additionally used to remove tetrahydrofuran (THF) from rubber manufacturing wastewater178. THF is a cyclic ether used as a solvent and raw material for synthesizing polymers in the industry. The wastewater has an initial THF concentration of 688 ± 140 mg L–1. THF was treated by EO by using four anodic materials, namely, BDD, RuO2, PbO2, and Pt. The CD applied was 300–1200 A m–2. The experiment resulted in a fast THF removal when BDD anode was used using sodium sulfate as an electrolyte to prevent the formation of organochloride secondary products. Also, COD removal was higher than 98% and TOC elimination higher than 95%. However, the mineralization of organic pollutants was not achieved by using RuO2 as an anode and sodium chloride as an electrolyte. The reason why sodium chloride was chosen as an electrolyte was that DSA, such as RuO2 generates chlorine when NaCl is the electrolyte. The reduced efficiency of Ti/RuO2 in NaCl electrolyte showed that the free chlorine generated is not an active oxidant for THF removal and mineralization179.

EO has also been used to remove COD from vegetable tannery wastewater by using a graphite anode180. The initial COD value was 9600 mg L−1, and the final value obtained was 59 mg L−1 at a CD of 34 mA cm–2 and 120 min of electrolysis. In the case of chrome tanning wastewater, Cr3+ was oxidized to Cr6+ with a conversion of 96 ± 3% at a pH of 2.5–5.5. Cr6+ was then converted to Cr2(SO4)3 for reuse in tanning operation180. EO treatment of tannery wastewater has also been carried out by using Ti/Pt and Ti/Pt/Ir anodes181. It was found that COD removal was not enough to meet the discharge regulations. Hence, the EO process via these electrodes cannot be used alone in the treatment of tannery wastewater181. Moreover, EO has been utilized to extract organic pollutants from textile and finishing wastewater182. The wastewater produced from the textile industry is challenging since it has a high pH, high temperature, intense color, high COD, and low degradability. Usually, dyeing wastewater can be treated by biological oxidation and adsorption. The effect of EO on finishing wastewater and textile dye was investigated using a stainless-steel cathode and titanium or platinum anode. The organic pollutants present in the wastewater were oxidized to water and carbon dioxide when passing through the cell. This is because of the high oxidizing ability of the chemicals generated in the cell, which include hydroxyl, chlorine, oxygen, and other oxidants. In total, 2 mL of 36% hydrochloric acid was added, and electrolysis was allowed to take place for 18 min at a current of 0.89 A cm−2. The COD/BOD ratio decreased from 2.16 to 1.52, indicating that the biodegradability of wastewater was improved. Additionally, COD removal was found to be 86%, BOD removal was 71%, and ADMI color units were reduced completely182.

One comparative study that investigated energy consumption of EC and photocatalytic process for textile dye wastewater treatment has concluded that EC was more economically feasible as the energy consumption of EC process was less than 0.01 kWh m−3 per unit COD removed when compared to >100 kWh m−3 for the photocatalytic process183. Photocatalytic ozonation is considered to be one of the least energy-demanding amongst AOPs technologies. It was reported that the specific energy consumption of the photocatalytic ozonation system in the decomposition of oxalic acid and dichloroacetic acid was 0.007 kWh mM–1 and 0.024 kWh mM–1, respectively. These values were less than those of catalytic ozonation (0.017 kWh/mM and 0.050 kWh mM–1) and photocatalytic oxidation (0.063 kWh mM–1 and 0.350 kWh mM–1)184.

EF technique is an electrokinetic phenomenon that has been used for the treatment of various types of industrial wastewater treatment185,186,187,188. It involves the flotation by electrically generated bubbles to separate two liquid phases or solid from liquid phases. Colloidal or finely dispersed particles in wastewater are removed by the small bubbles of O2 and H2 lifting contaminants to clarify the solution. The best recoveries could be obtained in the particle size range of 20–50 µm. The advantages of EF include simplicity, efficiency, environmental compatibility, safety, selectivity, reduction in sludge generation, minimization of added chemicals, and relatively little space requirement due to its shorter residence time189. The efficiency of EF in treating wastewater rich in heavy metals was studied by preparing a solution of NiSO4.6H2O, CuSO4.5H2O, PbSO4, ZnSO4.7H2O, CdSO4.8H2O, and FeSO4.7H2O at an initial concentration of 100 mg L–1 for each salt, initial pH of 8, and conductivity of 2.7 mS cm−1 in the presence of sulfate189. EF showed an average heavy metal removal efficiency of 93%, and the kinetics was found to be fast (around 15 min) except for Ni. Another study investigated the feasibility of EC/EF process for heavy metals removal such as Pb, Ba, and Zn190. Up to 97% removal was achieved with stainless steel mesh electrodes. EC/EF has also been used to remove F− and CaF2 nanoparticles from semiconductor industry wastewater191. Suspended matter and F− were eliminated by the combined methods. Additionally, the high turbidity removal efficiency was achieved by EF technique. Stainless steel was the cathode, and DSA titanium coated with RuO2 (Ti/RuO2) was the anode of the EF cell. The turbidity and F− removals were 97% and 73%, respectively.

EF is the most effective method for the separation of low-density SS and oil185,187,188. Up to 99.71% oil removal from an initial concentration of 1050 mg L–1 emulsified oil has been achieved by using an EF cell with DSA anode composed of Ti/Ru0.34Ti0.66O2 and a stainless-steel cathode187. EF has also been used to treat wastewater from the dairy industry192, palm oil effluent using Pb dioxide-coated titanium anode193, mining wastewater194, and others. Moreover, EF can be a part of a hybrid process. One example of a hybrid EF process is composed of three stages: (i) adsorption by a bonding agent; (ii) wastewater filtration to separate the loaded bonding agent by two variants, i.e. crossflow MF for low-contaminated wastewater or a hybrid process combining flotation and submerged MF for highly contaminated wastewater; and (iii) bonding agent regeneration195.

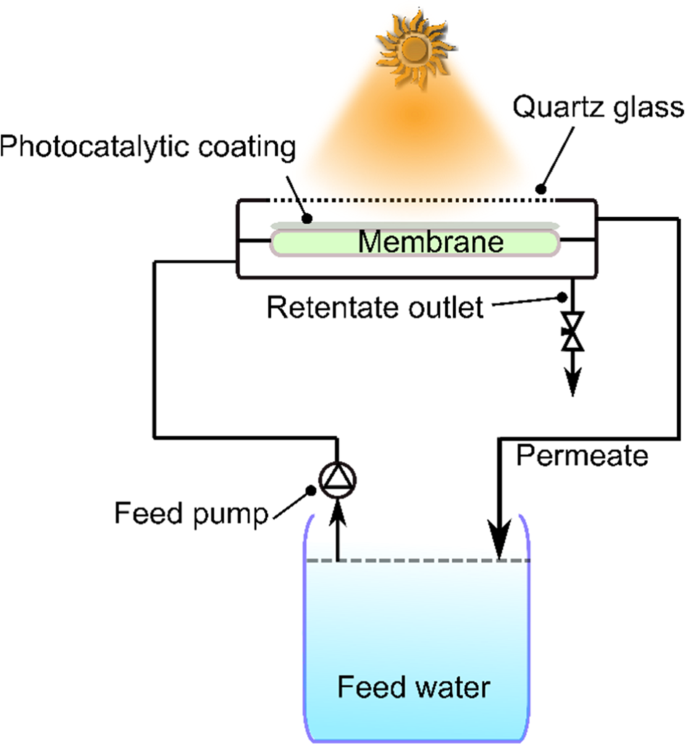

Photodegradation by nano-scale TiO2

Nano-TiO2 can be utilized to photocatalytically degrade the residual organic contaminants in treated effluents. Nano-TiO2 is useful for the degradation of endocrine disruptors, organic contaminants, micropollutants, and in water filtration membranes. Nano-TiO2 structure and performance would depend on the preparation method. However, certain limitations such as inefficiency under visible light illumination, post-recovery, incomplete removal of toxic byproducts (in some cases), and low mechanical strength still need to be addressed for enhanced performance. TiO2 post-treatment of secondary treated effluents from industrial wastewater treatment plants is a possible solution for the extraction of toxic organics. Nanocrystals of TiO2 possess a high surface-area-to-volume ratio, making them suitable for photocatalysis and adsorption196,197. This means that nano-TiO2 has a higher number of delocalized carriers on its surface, which ensures better-charged transport and efficient generation and separation of photo-generated electrons and holes. Photo-generated holes in TiO2 nanocrystals are powerful oxidants198. Nanocrystals exhibit these properties because of their low dimensionality and quantum size effects199. TiO2 is an n-type semiconductor with a relatively wide bandgap, and has three crystalline phases: rutile (tetragonal), brookite (orthorhombic), and anatase (tetragonal). TiO2 has become the most popular photocatalyst at the nanoscale, and a lot of energy can be saved with photocatalysis without secondary pollution through process control. The types of TiO2 nanostructures include: nanoparticles, nanotubes, nanorods, nanofibers, nanoflowers, and nanowires, in accordance with the preparation method and desired characteristics200. Nano-TiO2 can be prepared through sol-gel201, hydrothermal202, solvothermal203, anodic oxidation204, hard template205, and reverse microemulsion206 methods.

Nano-TiO2 prepared from a sol-gel method has been used for phenol degradation207. Phenols possess endocrine-disrupting properties. Zeng et al. synthesized the nano-TiO2 via the sol-gel process208. Titanium n-butoxide was dissolved in anhydrous ethanol to obtain the solution A. DI water, glacial CH3COOH, and C2H6O were mixed to obtain solution B. Solution A was mixed with solution B to get the sol. The sol was aged for 72 h and then dried at 100 °C and annealed. Regular sizes of anatase nano-TiO2 were obtained. The TiO2 was doped with B, Ni, and Ce for increased phenol degradation under visible light illumination. The best performance was attributed to BNiCeTiO2. In the work of Liu et al.209, porous TiO2 hollow aggregates were synthesized through the hydrothermal method for the photocatalytic degradation of Rhodamine B. NH4F and Ti(SO4)2 were dissolved in DI water, and then the mixture was added to a Teflon-lined autoclave. Hydrothermal synthesis was carried out at 160 °C for 6 h. It was observed that the obtained photocatalyst were more effective than the commercially available photocatalyst P25 for Rhodamine B degradation.

Nano-TiO2 has also been used for chloroform decomposition. In the work of Kang et al. (2001), C12H28O4Ti was dispersed in 1,4-butanediol under 300 °C for 50 min210. The anatase powder was efficient in chloroform degradation. In chloroform decomposition under the UV-light (254 nm, 24 W m–2) with O2 bubbling (500 mL min–1), more than 95% of the chloroform was removed. Nano-TiO2 has been employed for ethylene decomposition. In the work of Praserthdam et al., titanium n-butoxide was added to toluene211. The mixture was autoclaved at 300 °C for 2 h. Spherical shaped particles obtained promoted ethylene decomposition. A high amount of Ti3+ surface defect with Ti3+/OH was found in the TiO2 sample that was quenched in the air at 77K. The sample also exhibited the highest photocatalytic activity for ethylene decomposition. However, despite its versatility for photodegradation of trace pollutants in water, the use of nano-TiO2 still faces some limitations212. Currently, the exploitation of readily available visible light for photodegradation via nano-TiO2 is still inefficient for large-scale treatment, as most studies on large-scale TiO2 photocatalysis have focused on the use of UV light213. Secondly, there is a low adsorption capacity of nano-TiO2 for hydrophobic contaminants because TiO2 is hydrophilic214. Therefore, the efficiency of removing hydrophobic contaminants through nano-TiO2 structures is low. Thirdly, there is inadequate post-recovery of TiO2 particles after treatment in water. The process of regenerating the particles after dispersion in water might be tedious and costly. Fourthly, there might be the production of toxic byproducts after the degradation of the primary contaminants by nano-TiO2215. Although these byproducts might subsequently be removed by further photo-degradation, they remain in trace amounts in the final effluents in many cases. Lastly, many nano-TiO2 structures lack mechanical strength or stabilization for long-time utilization in production plants. These structures would become fractured or destabilized under continuous feed system after some time. In case of polymer membranes, there is a danger of destruction of the membrane structure by UV light or OH• and problems of high cost216.