Abstract

Polyrotaxane networks (PRNs) were synthesized by exploiting a Pd-templated bis-macrocycle as a topological cross-linker during radical polymerization of a vinyl monomer. The bis-macrocycle (9) was prepared by combining two macrocycles with a linear linker. Radical polymerization of 4-vinylpyridine in the presence of 9 and a catalytic amount of 2,2′-azobisisobutyronitrile (AIBN) yielded a gelled polymer. The addition of 4-tert-butylstyrene as a vinyl co-monomer to the polymerization system afforded a sufficiently stable gel as the PRN, clearly indicating that 4-tert-butylstyrene was successfully introduced as end-capping moieties of the trunk polymer. The swelling properties of the PRN were evaluated using several solvents. The topological structure and swelling properties of the PRNs were confirmed by a control experiment using a bis-acyclic pincer-type Pd complex (13) as a cross-linker.

Similar content being viewed by others

Introduction

Among networked polymers, polyrotaxane networks (PRNs) that have rotaxane structures on the cross-link points are the most interesting class of cross-linked polymers. The generation of unique properties in a network polymer having rotaxane-like cross-links was predicted by de Gennes;1 one such property leads to easy polymer chain sliding. Ito and coworkers synthesized a hydrogel possessing rotaxane structures at the cross-link points2 using Harada's cyclodextrin-based polyrotaxane,3 and this hydrogel has recently been made practicable (Nissan, Kanagawa, Japan) and NTT docomo (Tokyo, Japan) used a PRN as a coating paint of automobile or mobile phone, which is termed as ‘SCRATCH SHIELD’. The coating paint shows self-healing properties to scrapes depending on the high elasticity of PRN.).4, 5 However, we reported crown ether-based PRNs that exploit strategic rotaxanation as the cross-linking reaction.6, 7, 8, 9, 10, 11, 12, 13 Although the use of a crown ether as a wheel component allows more precise structures of PRNs than the use of cyclodextrin, the crown ether-based PRN requires the somewhat troublesome synthesis of sec-ammonium axle. To find a simple and widely applicable approach to PRNs, especially toward PRNs containing vinyl polymers, we planned the development of a topological cross-linker that includes a bis-macrocycle moiety to enable efficient penetration of the propagation end of radical polymerization into macrocyclic cavities. We became intrigued in exploiting a Pd(II)-templated bis-macrocycle based on the metal-templated method that is often used for rotaxane architectures (Scheme 1)14, 15, 16 because of the following three merits: (1) the coordination bond of the Pd complex with the ligand-containing polymer axle should be the most stable among many intermolecular interactions, such as hydrophobic interactions, hydrogen bonding and electrostatic interactions, which probably maintain the interlocked structure even under polymerization conditions; (2) the Pd complex method should be applicable to macrocycles (as the wheel component) that have a cavity size larger than the size of vinyl polymers,14, 15, 16 yielding unprecedented PRNs; and (3) the movable distance of the macrocycle along the polymer axle should be easily controlled by manipulating the introduction ratio of a bulky group as the stopper group into the polymer axle. The manipulation of the distance of the macrocycle along the polymer axle can render an ideal scaffold to reveal an inherent sliding effect of the PRN. This paper discloses the synthesis of a Pd-templated bis-macrocycle, its application as a topological cross-linker for vinyl polymers and the evaluation of the properties of the resulting PRNs.

Experimental procedure

Materials

The compounds 1, 2, 4 and 7 were prepared according to the literature.17, 18, 19, 20 Other materials are available commercially and were used without further purification.

Measurements

1H and 13C nuclear magnetic resonance (NMR) spectra were recorded on a Jeol AL-400 spectrometer (JEOL, Tokyo, Japan) using CDCl3, CD3CN and dimethyl sulfoxide (DMSO)-d6 as solvents, and measurements were calibrated using residual non-deuterated solvent or tetramethylsilane as the internal standard (see Supplementary Material). Molecular weights and distributions were estimated by size-exclusion chromatography on a Jasco Gulliver system (JASCO, Tokyo, Japan) equipped with two consecutive linear polystyrene gel columns (Tosoh TSK-gel GMHXL and G5000HXL) at 30 °C (column flow rate of 0.85 ml min−1) according to polystyrene standards using N,N-dimethylformamide (DMF) as the eluent. Glass transition temperatures (Tg) were measured using a Shimadzu DSC-60 instrument (Shimadzu, Kyoto, Japan) under nitrogen (heating rate of 10 °C min−1, nitrogen flow rate of 50 ml min−1). Thermogravimetric analyses were performed using a Shimadzu TGA-50 instrument under nitrogen (heating rate of 10 °C min−1, nitrogen flow rate of 50 ml min−1). Fourier transform infrared spectra were recorded on a Jasco FT/IR-460 Plus spectrophotometer (see Supplementary Material). Melting points were measured using a Stuart Scientific SMP3 (Bibby Scientific, Stone, UK). Matrix-assisted laser desorption/ionization-time of flight mass spectrometry spectra were measured with a Shimazdu AXIMA-CFR mass spectrometer using a dithranol matrix. The fast atom bombardment high resolution mass (FAB-HRMS) spectra were requested and obtained from the National University Corporation Tokyo Institute of Technology Center for Advanced Materials Analysis.

Synthesis of 3

To a mixture of 117 (5.83 g, 22.4 mmol) and 4-hydroxybenzylamine (218) (6.06 g, 49.3 mmol) in tetrahydrofuran (THF) (100 ml), Et3N (17.2 ml, 123 mmol) was added dropwise at room temperature and stirred for 16 h. The mixture was cooled to 0 °C and neutralized by adding 1 M aqueous HCl. The products were extracted with EtOAc (x3). The combined organic layer was washed with sat. aqueous NaCl, dried over MgSO4, filtrated and concentrated in vacuo. MeOH was added to the resulting yellow solids and refluxed to yield white solids that were then collected by filtration to give the amide 3 (6.54 g, 15.1 mmol, 67.4%) as white solids: mp 232.8–233.4 °C; 1H NMR (400 MHz, DMSO-d6, 293 K) δ 9.77 (t, J=6.0 Hz, 2H), 9.30 (s, 2H), 7.71 (s, 2H), 7.12 (d, J=8.4 Hz, 4H), 6.71 (d, J=8.4 Hz, 4H), 6.06 (ddt, J=17.2, 10.8, 5.2 Hz, 1H), 5.42 (dd, J=17.2, 1.2 Hz, 1H), 5.31 (dd, J=10.8, 1.2 Hz, 1H), 4.83 (d, J=5.2 Hz, 2H), 4.46 (d, J=6.0 Hz, 4H) p.p.m.; 13C NMR (100 MHz, DMSO-d6, 298 K) δ 166.8, 163.0, 156.3, 150.9, 132.4, 129.4, 128.3, 118.2, 115.1, 110.6, 68.8, 41.7 p.p.m.; IR (KBr) υ 3328, 2929, 2812, 2697, 2599, 2478, 2284, 1873, 1752, 1667, 1599, 1542, 1449, 1344, 1227, 1171, 997, 822, 726, 691, 419 cm–1; FAB-HR-MS (matrix: NBA) calculated for C24H23N3NaO5+ [M+Na+]: 456.1535, found: 456.1529.

Synthesis of 5

To a solution of 3 (131 mg, 0.300 mmol) and ditosylate (419) (166 mg, 0.330 mmol) in DMF (6.0 ml), Cs2CO3 (977 mg, 3.00 mmol) was added at room temperature and stirred for 1 h. The mixture was warmed to 50 °C and stirred for 3 days. The mixture was cooled to 0 °C and quenched by adding H2O. The products were extracted with CHCl3 (x3). The combined organic layer was washed with sat. aqueous NaCl, dried over MgSO4, filtrated and concentrated in vacuo. The crude product was purified by column chromatography on silica gel (MeOH:CH2Cl2=1:20) to give the corresponding macrocycle 5 (84.3 mg, 0.142 mmol, 47.2%) as white solids: mp 170.0–170.7 °C; 1H NMR (400 MHz, CDCl3, 298 K) δ 7.85 (s, 2H), 7.79 (t, J=5.6 Hz, 2H), 7.15 (d, J=8.4 Hz, 4H), 6.81 (d, J=8.4 Hz, 4H), 6.03 (ddt, J=17.2, 10.4, 5.2 Hz, 1H), 5.45 (dd, J=17.2, 1.2 Hz, 1H), 5.34 (dd, J=10.4, 1.2 Hz, 1H), 4.72 (d, J=5.2 Hz, 2H), 4.55 (d, J=5.6 Hz, 4H), 4.10–4.04 (m, 4H), 3.90–3.84 (m, 4H), 3.72–3.63 (m, 8H) p.p.m.; 13C NMR (100 MHz, CDCl3, 298 K) δ 167.1, 163.4, 157.6, 150.3, 131.7, 130.2, 128.5, 118.8, 114.0, 111.4, 70.6, 70.5, 69.5, 69.3, 67.2, 42.6 p.p.m.; IR (KBr) υ 3300, 2925, 1658, 1615, 1598, 1573, 1515, 1441, 1339, 1230, 1170, 1130, 1104, 1148, 997, 932, 879, 826, 691, 591, 408 cm–1; FAB-HR-MS (matrix: NBA) calculated for C32H37N3NaO8 [M+Na+]: 614.2478, found: 614.2499.

Synthesis of 6

To a suspension of 10% Pd/C (0.22 g) in H2O (4.4 ml), MeOH (0.1 ml) and DMF (44 ml), 5 (1.9 g, 3.2 mmol) and p-toluenesulfonic acid (0.22 g, 1.2 mmol) were added at room temperature. The mixture was refluxed for 17 h. The mixture was cooled to room temperature and filtered through a Celite pad (Wako, Osaka, Japan). The cake was repeatedly washed with CHCl3. The filtrate was concentrated in vacuo to ∼10 ml and washed with sat. aqueous NaCl. The products were extracted with CH2Cl2. The combined organic layer was dried over MgSO4, filtrated and concentrated in vacuo. The crude product was purified by column chromatography on silica gel (MeOH:CH2Cl2=1:20) to give the corresponding macrocycle 6 (1.2 g, 2.1 mmol, 64%) as white solids: mp 274.2–274.9 °C; 1H NMR (400 MHz, DMSO-d6, 298 K) δ 9.67 (t, J=6.0 Hz, 2H), 7.56 (s, 2H), 7.20 (d, J=8.4 Hz, 4H), 6.87 (d, J=8.4 Hz, 4H), 4.53 (d, J=6.0 Hz, 4H), 4.04–4.02 (m, 4H), 3.72–3.70 (m, 4H), 3.54–3.33 (m, 8H) p.p.m.; 13C NMR (100 MHz, DMSO-d6, 298 K) δ 166.7, 163.1, 157.4, 150.8, 131.2, 128.1, 114.2, 111.5, 69.9 (2C), 68.9, 67.2, 41.0 p.p.m.; IR (KBr) υ 3368, 3081, 2925, 2885, 1676, 1659, 1612, 1540, 1515, 1444, 1347, 1300, 1251, 1184, 1125, 1112, 1066, 996, 953, 891, 812, 794, 668 cm–1; FAB-HR-MS (matrix: NBA) calculated for C29H33N3NaO8 [M+Na+]: 574.2165, found: 574.2166.

Synthesis of bis-macrocycle (8)

A mixture of 6 (450 mg, 0.81 mmol), Cs2CO3 (470 mg, 1.4 mmol) and 1,8-octane ditosylate (720) (163 mg, 0.36 mmol) in DMF (3.6 ml) was refluxed for 18 h. The solvent was concentrated in vacuo. The crude product was diluted with CHCl3 and washed with H2O. The aqueous layer was extracted with CHCl3. The combined organic layer was dried over MgSO4, filtrated and concentrated in vacuo. The crude product was purified by column chromatography on silica gel (MeOH:CH2Cl2=1:20) to give 8 (530 mg, 0.44 mmol, 54%) as white solids: mp 223.7–224.6 °C. 1H NMR (400 MHz, CDCl3, 298 K) δ 7.92 (t, J=5.6 Hz, 4H), 7.83 (s, 4H), 7.09 (d, J=8.5 Hz, 8H), 6.75 (d, J=8.5 Hz, 8H), 4.52 (d, J=5.6 Hz, 8H), 4.13 (t, J=6.4 Hz, 4H), 4.08–4.06 (m, 8H), 3.88–3.86 (m, 8H), 3.69–3.65 (m, 16H), 1.86–1.23 (m, 12H) p.p.m.; 13C NMR (100 MHz, CDCl3, 298 K) δ 168.0, 163.2, 158.2, 150.6, 130.0, 128.8, 114.7, 111.3, 70.8, 70.6, 69.6, 68.9, 67.6, 42.9, 29.0, 28.7, 25.7 p.p.m.; IR (KBr) υ 3567, 3349, 2920, 2870, 1670, 1252, 1178, 1132, 1063, 1035, 996, 803 cm–1; FAB-HR-MS (matrix: NBA) calculated for C66H80N6NaO16 [M+Na+]: 1235.5529, found: 1235.5495.

Synthesis of 9

To a solution of 8 (81 mg, 0.067 mmol) in CH3CN (2.0 ml), Pd(OAc)2 (30 mg, 0.13 mmol) was added at room temperature and stirred for 6 h to give a yellow precipitate. The precipitate was collected by filtration and washed with CH3CN repeatedly to give 9 (95 mg, 0.063 mmol, 95%) as yellow solids: No mp (>300 °C, decomp.); 1H NMR (400 MHz, CDCl3–CD3CN (10:1), 298 K) δ 7.17 (s, 4H), 7.10 (d, J=7.6 Hz, 8H), 6.72 (d, J=7.6 Hz, 8H), 4.43 (s, 8H), 4.11 (t, J=5.9 Hz, 4H), 4.03–3.95 (m, 8H), 3.80–3.72 (m, 8H), 3.66–3.56 (m, 16H), 1.79–1.34 (m, 12H) p.p.m.; 13C NMR (100 MHz, CDCl3, 298 K) δ 170.1, 169.2, 156.8, 154.3, 133.5, 127.7, 113.5, 110.6, 70.3, 70.1, 69.6, 69.4, 67.1, 48.4, 28.7, 28.2, 25.3 p.p.m.; IR (KBr) υ 3449, 2863, 1608, 1559, 1447, 1411, 1383, 1340, 1319, 1288, 1245, 1174, 1134, 1099, 1060, 1019, 923, 817, 778, 749, 662, 614, 509 cm–1.

Synthesis of 10

A suspension mixture of 3 (0.20 g, 0.46 mmol), K2CO3 (0.32 g, 2.3 mmol) and MeI (0.28 ml, 4.6 mmol) in DMF (5.0 ml) was stirred at 40 °C for 18 h under an argon atmosphere. The mixture was cooled to room temperature and concentrated in vacuo. The crude materials were diluted with CH2Cl2 and washed with water. The products were extracted with CH2Cl2 (x3). The combined organic layer was washed with sat. aqueous NaCl, dried over MgSO4, filtrated and concentrated in vacuo to give 10 as a yellow oil (0.19 g, 0.41 mmol, 88%). 1H NMR (400 MHz, CDCl3, 298 K): δ 8.26 (t, J=6.2 Hz, 2H), 7.83 (s, 2H), 7.16 (d, J=8.4 Hz, 4H), 6.76 (d, J=8.4 Hz, 4H), 6.00 (ddt, J=17.4, 10.6, 5.1 Hz, 4H), 5.41 (dd, J=17.4, 0.4, 1H), 5.33 (dd, J=10.6, 0.4 Hz, 1H), 4.64 (d, J=5.1 Hz, 2H), 4.50 (d, J=6.2 Hz, 4H), 3.84 (s, 6H) p.p.m.; 13C NMR (100 MHz, CDCl3, 298 K) 171.0, 167.7, 162.5, 154.5, 135.2, 134.0, 132.7, 122.7, 117.5, 115.2, 73.0, 58.9, 46.6 p.p.m.; IR (KBr) υ 3303, 3079, 3033, 3003, 2962, 2930, 2835, 2550, 2488, 2058, 1885, 1733, 1678, 1653, 1609, 1600, 1531, 1512, 1458, 1437, 1339, 1300, 1260, 1174, 1106, 1032, 1000, 931, 878, 800, 750, 692, 591, 518 cm–1; FAB-HR-MS (matrix: NBA) calculated for C26H27N3NaO5 [M+Na+]: 484.1848, found: 484.1851.

Synthesis of 11

To a suspension of 10% Pd/C (40 mg) in a mixed solvent of H2O (0.1 ml), MeOH (0.1 ml) and DMF (0.9 ml), 10 (0.30 g, 0.65 mmol) and p-toluenesulfonic acid (40 mg, 0.21 mmol) were added at room temperature. The mixture was refluxed for 17 h. The mixture was cooled to room temperature and filtered through a Celite pad. The cake was washed with CHCl3 repeatedly. The filtrate was concentrated in vacuo to ∼10 ml and washed with sat. aqueous NaCl. The aqueous layer was extracted with CH2Cl2. The combined organic layer was dried over MgSO4, filtrated and concentrated in vacuo. The crude product was purified by column chromatography on silica gel (MeOH:CH2Cl2=1:20) to give 11 (0.13 g, 0.31 mmol, 64%) as yellow solids: mp 188.8–189.5 °C; 1H NMR (400 MHz, CDCl3, 298 K) δ 10.70 (brd, 1H), 8.63 (t, J=5.5 Hz, 2H), 7.75 (s, 2H), 7.10 (d, J=8.5 Hz, 4H), 6.69 (d, J=8.5 Hz, 4H), 4.40 (d, J=5.5 Hz, 4H), 3.68 (s, 6H) p.p.m.; 13C NMR (100 MHz, CDCl3, 298 K) δ 167.0, 164.1, 158.8, 149.9, 129.6, 129.0, 113.8, 112.8, 55.1, 43.0 p.p.m.; IR (KBr) υ 3296, 2960, 2931, 2835, 2692, 2592, 2481, 2059, 1653, 1610, 1537, 1512, 1461, 1437, 1345, 1302, 1247, 1174, 1109, 1032, 997, 943, 888, 818, 802, 749, 693, 592, 545, 517 cm–1; FAB-HR-MS (matrix: NBA) calculated for C23H24N3O5 [M+H+]: 422.1716, found: 422.1723.

Synthesis of 12

A mixture of 11 (70 mg, 0.17 mmol), Cs2CO3 (98 mg, 0.30 mmol) and 1,8-dibromooctane (20 mg, 0.076 mmol) in DMF (0.8 ml) was refluxed for 23 h. The mixture was cooled to room temperature and concentrated in vacuo. The crude product was diluted with CHCl3 and washed with H2O. The aqueous layer was extracted with CHCl3. The combined organic layer was dried over MgSO4, filtrated and concentrated in vacuo. The crude product was purified by column chromatography on silica gel (MeOH:CH2Cl2=1:20) to give 12 (42 mg, 0.044 mmol, 58%) as white solids: mp 175.5–176.4 °C; 1H NMR (400 MHz, CDCl3, 298 K) δ 8.40 (s, 4H), 7.77 (s, 4H), 7.11 (d, J=8.4 Hz, 8H), 6.71 (d, J=8.4 Hz, 8H), 4.46 (d, J=5.6 Hz, 8H), 3.99 (t, J=6.0 Hz, 4H), 3.69 (s, 12H), 1.81–1.69 (m, 4H), 1.43–1.26 (m, 8H) p.p.m.; 13C NMR (100 MHz, CDCl3, 298 K) δ 167.7, 163.6, 158.7, 150.5, 130.1, 128.9, 113.8, 111.3, 68.7, 55.1, 42.8, 28.8, 28.5, 25.4 p.p.m.; IR (KBr) υ 3480, 3308, 2999, 2932, 2854, 2835, 1653, 1601, 1534, 1512, 1458, 1441, 1340, 1302, 1247, 1174, 1129, 1110, 1033, 996, 882, 819, 752, 692, 595, 517 cm–1; FAB-HR-MS (matrix: NBA) calculated for C54H61N6O10 [M+H+]: 953.4449, found: 953.4479.

Synthesis of 13

To a solution of 12 (31 mg, 0.032 mmol) in a mixed solvent of CH3CN (1.0 ml) and CHCl3 (1.0 ml), Pd(OAc)2 (14 mg, 0.064 mmol) was added at room temperature and stirred for 2 h to give a yellow precipitate. The precipitate was collected by filtration and washed with CH3CN repeatedly to give 13 (35 mg, 0.028 mmol, 88%) as yellow solids: No mp was observed (>300 °C, decomp.); 1H NMR (400 MHz, CDCl3–CD3CN (10:1), 298 K) δ 7.21 (s, 4H), 7.20 (d, J=5.4 Hz, 8H), 6.79 (d, J=5.4 Hz, 8H), 4.41 (s, 4H), 4.11 (t, J=5.2 Hz, 4H), 3.75 (s, 12H), 1.86–1.75 (m, 4H), 1.47–1.29 (m, 8H) p.p.m.; 13C NMR (100 MHz, CDCl3, 298 K) δ 170.2, 157.8, 154.1, 133.3, 128.1, 116.3, 113.2, 110.5, 69.5, 54.9, 49.1, 28.7, 28.2, 25.3 p.p.m.; IR (KBr) υ 3400, 2925, 2852, 2836, 2359, 2339, 1607, 1545, 1509, 1437, 1413, 1381, 1336, 1322, 1288, 1245, 1173, 1098, 1031, 820 cm–1.

Typical procedure for the preparation of a PRN: synthesis of PRN (16)

A solution of bicyclic 9 (7.5 mg, 5.0 mmol) and 4-vinylpyridine (530 mg, 5.0 mmol) in DMF (1.4 ml) was stirred for 2 h at room temperature. After 4-tert-butylstyrene (800 mg, 5.0 mmol) was added, the solution was degassed using the frozen thaw technique repeatedly. AIBN (8.2 mg, 10 μmol) was added to the mixture, and the mixture was warmed to 60 °C and stirred for 16 h to give a gel. The obtained gel was swollen in CHCl3 (10 ml) overnight to remove impurities and dried under vacuum to give the corresponding PRN 16 (1.1 g, 82%) as a reddish gel: No Tg was observed (in the range from 30 to 150 °C); Td5 227 °C; IR (KBr) υ 3434, 3065, 3025, 2958, 2926, 2867, 2713, 2359, 2339, 1933, 1905, 1684, 1597, 1559, 1508, 1457, 1415, 1395, 1362, 1269, 1219, 1201, 1110, 1069, 1016, 993, 903, 824, 799, 755, 711, 668, 576 cm–1.

PRN 17: Tg 143.8 °C; Td10 354.2 °C; IR (KBr) υ 3675, 3185, 3063, 3050, 3022, 2957, 2867, 1932, 1905, 1787, 1679, 1597, 1558, 1510, 1474, 1448, 1415, 1362, 1322, 1269, 1219, 1202, 1111, 1090, 1069, 1016, 993, 920, 823, 754, 710, 658, 578 cm–1.

Typical procedure for the preparation of gel 20

A solution of bis(pincer-type Pd complex) 13 (6.2 mg, 5.0 mmol) and 4-vinylpyridine (530 mg, 5.0 mmol) in DMF (1.4 ml) was stirred for 2 h at room temperature. To the solution was added 4-tert-butylstyrene (800 mg, 5.0 mmol), and the solution was degassed using the frozen thaw technique repeatedly. AIBN (8.2 mg, 10 μmol) was added to the mixture, and the mixture was warmed to 60 °C and stirred for 16 h to give a red gel 20. When the obtained gel was treated with DMF (5.0 ml) at room temperature, the gel immediately changed to give the corresponding sol containing poly(4-vinylpyridine-co-4-tert-butylstyrene) and 13.

Results and Discussion

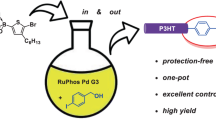

Syntheses of Pd-templated bis-macrocyclic 9 and bis(pincer-type Pd complex) 13

Scheme 2 features the synthesis of the Pd-templated bis-macrocycle as the topological cross-linker of vinyl polymers. Treatment of 117 with 218 in the presence of Et3N afforded amide 3 in 67% yield. Macrocyclization of 3 and 4 under high dilution conditions gave the corresponding macrocycle 5 in 47% yield. Deprotection of the allyl ether moiety21 of 5 and subsequent ether formation with 1,8-octane-ditosylate 720 gave a bis-cyclic compound 8. Successive treatment of 8 with Pd(OAc)2 in CH3CN afforded the Pd-templated bis-macrocycle 9 in 95% yield. The structure of 9 was determined by 1H NMR, 13C NMR and infrared spectra.

To clarify the significance of the rotaxane cross-link, we prepared an acyclic bis(pincer-type Pd complex) 13 having a structure similar to 9, except for the acyclic structure, in the same manner as the synthesis of 9. Bis-Pd complex 13 was prepared in good yield according to Scheme 3, as determined by 1H NMR, 13C NMR and IR spectra.

1H NMR spectral change of 9 before and after the addition of 4-vinylpyridine to 9

As we had previously found that the combination of a Pd-templated wheel component with a pyridine-containing axle component enables an efficient formation of rotaxane,14, 16 we focused on the use of 4-vinylpyridine as a vinyl monomer. Thus, before PRN synthesis, we examined the coordination behavior of 4-vinylpyridine to the Pd of 9 using 1H NMR measurements.

Figure 1 shows the 1H NMR spectral change of 9 before and after addition of 4-vinylpyridine. In spectrum c, the slightly downfield-shifted signal originating from the terminal olefin afforded the direct evidence for the formation of Pd-complex 14. Moreover, the aromatic signals assigned to Hb and Hc of 9 in spectrum a were upfield-shifted, probably due to the shielding effect of 4-vinylpyridine placed between the two 1,4-phenylene moieties of the macrocycle. In addition, the characteristic signal disappearance of Ha and He could be explained by the coalescence based on the slow molecular motion of the macrocycle in accordance with reports in the literature.9 These results strongly indicate the formation of inclusion complex 14, which strongly suggests the role of 9 as the topological cross-linker for poly(4-vinylpyridine).

Syntheses of PRNs

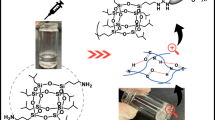

The synthesis of the PRN was investigated using the topological cross-linker 9 through the ligand exchange reaction of centered Pd during the radical polymerization of 4-vinylpyridine. Surprisingly, the radical polymerization of 4-vinylpyridine in the presence of small amounts of 9 (0.5 mol%) and AIBN (1.0 mol%) in DMF at 60 °C afforded a gelled product in a quantitative yield (Scheme 4 and Table 1, entry 1). The swollen product was assumed to be an organogel derived from poly(4-vinylpyridine) cross-linked by 9 and can be regarded as a pseudo-PRN. However, dilution of the gel with a large amount of DMF led to the prompt dissociation to poly(4-vinylpyridine) and 9. This is consistent with the characteristic property of a conventional cross-linked polymer by metal–ligand interactions, strongly indicating that the gel includes only topological cross-linking points without any covalent ones.

For preparation of a stable PRN, we next undertook the addition of 4-tert-butylstyrene as a vinyl co-monomer because it is bulky enough to prevent the dissociation of the polyrotaxane components (Scheme 5). Treatment of a 1:1 mixture of 4-vinylpyridine and 4-tert-butylstyrene with AIBN (1.0 mol%) in the presence of 9 (0.5 mol%) in DMF at 60 °C for 16 h afforded a gelled product that was named PRN 16 (Scheme 5 and Table 1, entry 2). The obtained gel kept its shape even under high dilution conditions in DMF, indicating that 4-tert-butylbenzene moieties in the trunk polymer of the gel clearly behave as stopper moieties that prevent the dethreading of the polymer axle from the macrocyclic parts of 9. In a similar manner, the radical polymerization of a 1:1 mixture of 4-vinylpyridine and 4-tert-butylstyrene in the presence of twice the amount of 9 (1.0 mol%) was performed to obtain the highly cross-linked PRN 17 with the rationale that it would provide a sufficiently stable gel. In fact, the solvent-insoluble gel was obtained in a quantitative yield (entry 3).

However, it turned out that the addition of 9 to poly(4-vinylpyridine) obtained by the radical polymerization of 4-vinylpyridine resulted in the formation of an organogel 18 (entry 4). The result strongly indicates that the gel product formation during polymerization of 4-vinylpyridine in the presence of 9 comes from the thermodynamically controlled formation of the coordination bond between Pd-templated macrocycles and pyridine moieties on the polymer axles rather than from the accidental penetration of the propagation end into the macrocyclic cavity of 9. In addition, as a control experiment, we examined a radical polymerization reaction without the topological cross-linker 9 under the same conditions (entry 5). As a result, the reaction gave the corresponding linear polymer 19 (Mw 34 000, Mw/Mn 1.4, estimated by size-exclusion chromatography based on polystyrene standards), supporting the role of 9 as a cross-linker.

To clarify the role of the rotaxane cross-links or the significance of the topological cross-linker 9, the polymerization in the presence of bis(pincer-type Pd complex) 13 was investigated (Scheme 6). In a manner similar to that for entry 2 in Table 1, a 1:1 mixture of 4-vinylpyridine and 4-tert-butylstyrene was heated with AIBN (1.0 mol%) at 60 °C for 16 h in the presence of 13 (0.5 mol%) in DMF. A gel 20 obtained in a quantitative yield was treated with a large amount of DMF and immediately changed to a sol containing the trunk polymer (poly(4-vinylpyridine-co-4-tert-butylstyrene)) and 13. The result surely reveals the importance of the macrocyclic structure of the cross-linker for the formation of stable gelled products.

Swelling behaviors of PRNs

Table 2 summarizes the percentage swelling ratios of PRNs 16 and 17, which has a more tightly cross-linked structure than 16. PRN 16 was swollen to 5400% in CHCl3 and to 140% in H2O, and this result is consistent with the essential affinity of the trunk polymer toward solvents. All percentage swelling ratios of 16 in various solvents were bigger than those of 17, which was in good agreement with the number and movable length of the topological cross-linking points.

Conclusions

This article has described the usefulness of the topological cross-linker consisting of Pd-templated bis-macrocycle 9, which is widely applicable to cross-linking vinyl polymers. Radical polymerization of 4-vinylpyridine in the presence of 9 afforded the corresponding PRN, in which the addition of 4-tert-butylstyrene as a vinyl co-monomer gave sufficiently stable gels upon exposure to various solvents. Thus, the present protocol provides a new procedure for preparation of network polymers through the penetration of the propagation end into macrocyclic cavities during radical polymerization. Moreover, this protocol would also render a new manner for introduction of topological characteristics into a desired vinyl polymer. The application to various vinyl polymers and the evaluation of the physical properties of the resulting PRNs would be important future work.

Schematic representation of new synthetic protocol for a polyrotaxane network using a bis-macrocycle. A full color version of this figure is available at Polymer Journal online.

Synthesis of bis-macrocycle 9.

Synthesis of Bis (Pincer-type Pd complex) 13.

Formation and dissociation of a pseudo-polyrotaxane network prepared during the radical polymerization of 4-vinylpyridine in the presence of 9. A full color version of this figure is available at Polymer Journal online.

Polyrotaxane network including end-capping moieties. A full color version of this figure is available at Polymer Journal online.

Formation and dissociation of the Pd-complex Gel 20 using the Bis (Pincer-type Pd complex) 13. A full color version of this figure is available at Polymer Journal online.

References

de Gennes, P. G. Sliding gels. Physica A 271, 231–237 (1999).

Okumura, Y. & Ito, K. The polyrotaxane gel: a topological gel by figure-of-eight cross-links. Adv. Mater. 13, 485–487 (2001).

Harada, A., Li, J. & Kamachi, M. The molecular necklace: a rotaxane containing many threaded α-cyclodextrins. Nature 356, 325–327 (1992).

Watanabe, J., Ooya, T., Park, K. D., Kim, Y. H. & Yui, N. Preparation of characterization of poly(ethylene glycol) hydrogels cross-linked by hydrolyzable polyrotaxane. J. Biomater. Sci. Polym. Ed. 11, 1333–1346 (2000).

Kihara, N., Hinoue, K. & Takata, T. Solid-state end-capping of pseudopolyrotaxane possessing hydroxy-terminated axle to polyrotaxane and its application to the synthesis of a functionalized polyrotaxane capable of yielding a polyrotaxane network. Macromolecules 38, 223–226 (2005).

Oku, T., Furusho, Y. & Takata, T. A concept for recyclable cross-linked polymers: topologically networked polyrotaxane capable of undergoing reversible assembly and disassembly. Angew. Chem. Int. Ed. 43, 966–969 (2004).

Furusho, Y., Hasegawa, T., Tsuboi, A., Kihara, N. & Takata, T. ‘Unlock-lock’ approach to [2] and [3]Rotaxanes: entering of a ring through disulfide linkage that is unlocked by thiol ‘key’. Chem. Lett. 29, 18–19 (2000).

Furusho, Y., Oku, T., Hasegawa, T., Tsuboi, A., Kihara, N. & Takata, T. Dynamic covalent approach to [2]- and [3]Rotaxanes by utilizing a reversible thiol–disulfide interchange reaction. Chem. Eur. J. 9, 2895–2903 (2003).

Bilig, T., Oku, T., Furusho, Y., Koyama, Y., Asai, S. & Takata, T. Polyrotaxane networks formed via rotaxanation utilizing dynamic covalent chemistry of disulfide. Macromolecules 41, 8496–8503 (2008).

Yoshii, T., Kohsaka, Y., Moriyama, T., Suzuki, T., Koyama, Y. & Takata, T. An efficient synthetic entry to rotaxanes utilizing reversible cleavage of aromatic disulphide bonds. Supramol. Chem. 23, 65–68 (2011).

Takata, T. Polyrotaxane and polyrotaxane network: supramolecular architectures based on the concept of dynamic covalent bond chemistry. Polym. J. 38, 1–20 (2006).

Takata, T. & Otsuka, H. Novel synthetic protocol for supramolecules and polymers by molecular construction and integration based on dynamic covalent chemistry. Yuki Gosei Kagaku Kyoukaishi 64, 194–207 (2006).

Kohsaka, Y., Nakazono, K., Koyama, Y. & Takata, T. Size-complementary rotaxane cross-link: effect on stabilization and degradation of supramolecular network. Angew. Chem. Int. Ed. 50, 4872–4875 (2011).

Furusho, Y., Matsuyama, T., Takata, T., Moriuchi, T. & Hirao, T. Synthesis of novel interlocked systems utilizing a palladium complex with 2,6-pyridinedicarboxamide- based tridentate macrocyclic ligand. Tetrahedron Lett. 45, 9593–9597 (2004).

Fuller, A.- M., Leigh, D. A., Lusby, P. J., Oswald, I. D. H., Parsons, S. & Walker, D. B. A 3D interlocked structure from a 2D template: structural requirements for the assembly of a square-planar metal-coordinated [2]Rotaxane. Angew. Chem. Int. Ed. 43, 3914–3918 (2004).

Miyagawa, N., Watanabe, M., Matsuyama, T., Koyama, Y., Moriuchi, T., Hirao, T., Furusho, Y. & Takata, T. Successive catalytic reactions specific to Pd-based rotaxane complexes as a result of wheel translation along the axle. Chem. Commun. 46, 1920–1922 (2010).

Seitz, M., Milius, W. & Alt, H. G. Iron(II) coordination compounds with ω-alkenyl substituted bis(imino)pyridine ligands: self-immobilizing catalysts for the polymerization of ethylene. J. Mol. Cat. A: Chem. 261, 246–253 (2007).

Sinning, C., Watzer, B., Coste, O., Nüsing, R. M., Ott, I., Ligresti, A., Marzo, V. D. & Imming, P. New analgesics synthetically derived from the paracetamol metabolite N-(4-hydroxyphenyl)-(5Z,8Z,11Z,14Z)-icosatetra-5,8,11,14-enamide. J. Med. Chem. 51, 7800–7805 (2008).

Mohler, D. L. & Shen, G. The synthesis of tethered ligand dimers for PPARγ-RXR protein heterodimers. Org. Biomol. Chem. 4, 2082–2087 (2006).

Nguyen, T. B., Castanet, A.- S., Nguyen, T.- H., Nguyene, K. P. P., Bardeau, J.- F., Gibaud, A. & Mortier, J. Synthesis of model long-chain ω-alkenyltrichlorosilanes and triethoxysilanes for the formation of self-assembled monolayers. Tetrahedron 62, 647–651 (2006).

Boss, R. & Scheffold, R. Cleavage of allyl ethers with Pd/C. Angew. Chem., Int. Ed. Engl. 15, 558–559 (1976).

Acknowledgements

This study was supported by KAKENHI on Innovative Areas (no. 22106511) from the Ministry of Education, Culture, Sports, Science and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Ogawa, M., Kawasaki, A., Koyama, Y. et al. Synthesis and properties of a polyrotaxane network prepared from a Pd-templated bis-macrocycle as a topological cross-linker. Polym J 43, 909–915 (2011). https://doi.org/10.1038/pj.2011.84

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.84

Keywords

This article is cited by

-

Topology-transformable polymers: linear–branched polymer structural transformation via the mechanical linking of polymer chains

Polymer Journal (2018)

-

Synthesis of rotaxane cross-linked polymers derived from vinyl monomers using a metal-containing supramolecular cross-linker

Polymer Journal (2015)

-

Synthesis of topologically crosslinked polymers with rotaxane-crosslinking points

Polymer Journal (2014)