Abstract

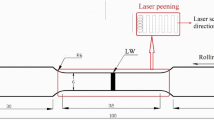

High Power Diode Lasers (HPDL) are becoming more and more attractive for industrial materials processing because of their high efficiency, low running costs, small sizes and low weight. Surface melting experiments have been carried out on 316L steel with a 1 kW HPDL, with application to modify its pitting corrosion resistance in NaCl 0.05 M. Surface modifications have been investigated with optical microscopy for the microstructure, microprobe analysis for the chemical content and X Ray Diffraction for phase transformations and residual stresses. Heat conduction characteristics, analysed with a 2D Finite element code, have driven to a 28% calculated absorption of the laser light generating nearly 400 μm melted depth. A refinement and homogenization of structure together with δ-ferrite transformation and the dissolution of inclusions was found in the melted thickness, driving to enhanced pitting resistance (nearly + 0.2 V on the pitting potential values, and factor 2 decrease of the passive current density). This pitting resistance, investigated at different depths below the surface, was found to be little affected by the δ ferrite content (6% estimated value), and the fineness of the microstructure, but depreciated by the surface state without post-polishing. Therefore, it is believed that localized corrosion improvements can be mainly attributed to the dissolution of Al-base and Mn-base detrimental inclusions, despite the generation of up to 6% δ ferrite susceptible to drive to enhanced galvanic couplings with γ phase.

Similar content being viewed by others

References

R. KE and R. ALKIRE, J. Electrochem. Soc. 122(12) (1995) 4056.

J. STEWARD and D. E. WILLIAMS, Corr. Science 33(3) (1992) 457.

M. A. BAKER and J. E. CASTLE, ibid. 33(8) (1992) 1295.

M. CARBUCICCHIO, G. PALOMBARINI, M. RATEO and G. SAMBOGNA, Hyperfine Interactions 112 (1998) 19.

H. STAMM, U. HOLZWARTH, D. J. BOERMAN, F. DOS SANTOS MARQUES, A. OLCHINI and R. ZAUSCH, Fat. Fract. Engng. Mater. Struct. Interactions 19(8) (1996) 985.

K. MUDALI, R. DAYAL, J. GNAMOORTHY, S. KANETKAR and S. OGALE, Materials Transactions, JIM 33(9) (1991) 845.

R. DAYAL, Surface Engineering 13(4) (1997) 299.

K. MUDALI, R. DAYAL and G. GOSWAMI, Anticorrosion Meth. & Mat. 45(3) (1998) 181.

K. MUDALI, M. PUJAR and R. DAYAL, JMEPEG 7(2) (1998) 212.

Q. PAN, W. HANG, R. SONG, Y. ZHOU and G. ZHANG, Surface & Coating Technology 102 (1998) 245.

C. KWOK, H. MAN and F. CHENG, ibid. 99 (1998) 295.

Y. NAKAO, K. NISHIMOTO and W. ZHANG, Transactions of the Japan Welding Society 241(1) (1993).

F. KLOCKE, A. DEMMER and A. ZABOLICKI, Lasers In Materials Processing, SPIE Conference, Vol. 3097, edited by L. Beckmann (1997) p. 592.

J. LAWRENCE and J. LI, J. Phys. D: Appl. Phys 32 (1999) 2311.

Les aciers inoxydables”, Les éditions de Physique (Fr), edited by G. Béranger and B. Baroux (1990).

P. PEYRE, X. SCHERPEREEL, L. BERTHE, C. CARBONI, R. FABBRO, G. BÁRANGER and C. LEMAITRE, Materials Sciences and Engineering A 280 (2000) p. 294.

C. CARBONI, P. PEYRE, M. FREGONESE, H. MAZILLE, G. BÁRANGER and C. LEMAITRE, in “Surface Modifications Technologies XIV, ” edited by T. Sudarshan and M. Jeandin, to be published.

A. L. SCHAEFFLER, Met. Prog. 56 (1949) 680.

G. MAEDER, Materiaux Techniques (Fr) 5 (1988).

T. SHIBATA and T. TAKEYAMA, Corrosion N. A. C. E. 33(7) (1977) 243.

ABAQUS Standard 5.7 software, Hibbitt, Karlsson and Sorensen Ed, 1995.

B. CULLITY, “Elements of X-ray diffraction” (Addison Wesley, New York, 1978) p. 411.

E. M. GUTMAN, “Mechanochemistry of Solid Surfaces” (Ed. World Scientific Publishing, 1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Carboni, C., Peyre, P., Béranger, G. et al. Influence of high power diode laser surface melting on the pitting corrosion resistance of type 316L stainless steel. Journal of Materials Science 37, 3715–3723 (2002). https://doi.org/10.1023/A:1016569527098

Issue Date:

DOI: https://doi.org/10.1023/A:1016569527098