Abstract

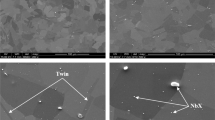

The effects of aging temperature on the microstructure and mechanical properties of a newly designed martensitic precipitation hardening stainless steel, which is 1.8Cu-15.9Cr-7.3Ni-1.2Mo-low C, N steel, for improving the toughness, ductility and corrosion resistance of stainless steel of 1000 MPa grade tensile strength were experimentally investigated. The specimen aged at 753 K for 14.4 ks has a typical lath martensitic structure with about 12% interlath austenite, while the specimens aged at 813 K and 853 K for 14.4 ks have the lamellar duplex microstructure of the reverted austenite and the aging hardened martensite. The formation process of reverted austenite is controlled by diffusion of Ni in martensite. The mean size of precipitates which are enriched with Cu increases with rising aging temperature, however, it is about 30 nm even after aging at 853 K for 14.4 ks. The specimens aged at 813 K and 853 K for 14.4 ks, in which the reversion of martensite to austenite is observed, have the excellent combinations of strength, ductility and toughness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

D. Peckner and I. M. Bernstein, “Handbook of Stainless Steel” (McGraw-Hill Book Co., New York, 1977) p. 7.13, 20.32.

H. Nakagawa and T. Miyazaki, J. Mater. Sci. submitted. 2252

B. Sundman, B. Jansson and J. O. Andersson, CALPHAD 9 (1985) 153.

M. Hillert and C. Qui, Metall. Trans. A 21A (1990) 1673.

M. J. Dickson, J. Appl. Cryst. 2 (1969) 176.

V. Seetharaman, M. Sundararaman and R. Krishnan, Mater. Sci. Eng. 47 (1981) 1.

T. Maki, H. Morimoto and I. Tamura, Trans. ISIJ 20 (1980) 700.

U. K. Viswanathan, S. Banerjee and R. Krishnan, Mater. Sci. Eng. A104 (1988) 181.

B. V. N. Rao, Metall. Trans. A 10A (1979) 645.

G. Thomas, ibid. 9A (1978) 439.

Y. Katz, H. Mathias and S. Nadiv, ibid. 14A (1983) 801.

B. P. J. Sandvik and C. M. Wayman, ibid. 14A (1983) 809.

L. T. Shiang and C. M. Wayman, Metallography 21 (1988) 425.

S. J. Kim and C. M. Wayman, Mater. Sci. Eng. A128 (1990) 217.

P. J. Othen, M. L. Jenkins and G. D. W. Smith, Phil. Mag. A 70 (1994) 1.

W. M. Garrison, Jr. and J. A. Brooks, Mater. Sci. Eng. A149 (1991) 65.

J. Burke, “The Kinetics of Phase Transformations in Metals” (Pergamon Press Ltd., Oxford, 1965) p. 36.

J. W. Christian, “The Theory of Transformations in Metals and Alloys” (Pergamon Press Ltd., Oxford, 1965) p. 475.

K. Hirano, M. Cohen and B. L. Averbach, Acta Metall. 9 (1961) 440.

W. Sha, A. Cerezo and G. D. W. Smith, Metall. Trans. A 24A (1993) 1221.

G. R. Speich, Trans. Met. Soc. AIME 227 (1963) 1436.

P. P. Sinha, D. Sivakumar, N. S. Babu, K. T. Tharian and A. Natarajan, Steel Res. 66 (1995) 490.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nakagawa, H., Miyazaki, T. & Yokota, H. Effects of aging temperature on the microstructure and mechanical properties of 1.8Cu-7.3Ni-15.9Cr-1.2Mo-low C, N martensitic precipitation hardening stainless steel. Journal of Materials Science 35, 2245–2253 (2000). https://doi.org/10.1023/A:1004778910345

Issue Date:

DOI: https://doi.org/10.1023/A:1004778910345