Abstract

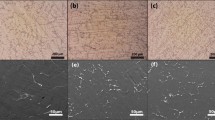

The indirect squeeze casting process has been used to cast a 7050 (Al-6.2Zn-2.3Cu-2.3Mg) wrought Al alloy to near-net shape with excellent die replication. Defects which occur with gravity casting, in particular (1) shrinkage pipe, (2) macro-porosity and (3) hot-tearing, are largely removed by squeeze casting, although regions of macro-porosity can re-appear when thick sections are fed through substantially thinner sections. Squeeze casting results in a considerable refinement of microstructure compared to gravity casting due to a marked decrease in solidification time. The decrease in solidification time is caused by intimate contact between the pressurised melt and the die, which leads to an increase in the heat transfer coefficient. Decreasing the section thickness also results in a refinement of the microstructure due to a reduction in solidification time.

Similar content being viewed by others

References

G. A. Chadwick and T. M. Yue, Met. Mater. 5 (1989) 6.

“Product Design and Specifications for Squeeze Casting” (ELM International Inc., East Lansing, Michigan, USA, 1994).

M. Gallerneault, G. Durrant and B. Cantor, Met. Trans. A 27A (1996) 4121.

J. Campbell, “Castings” (Butterworth-Heinemann Ltd., Oxford, UK, 1991).

D. L. Zhang, C. Brindley and B. Cantor, J. Mater. Sci. 28 (1993) 2267.

H. G. Kang, H. I. Lee, P. R. G. Anderson and B. Cantor, in “Proc. Process and Fabrication of Advanced Materials IV,” edited by T. S. Srivatsan and J. J. More (TMS, Warrendale, Pensylvania, 1996).

S-W Kim, G. Durrant and B. Cantor, J. Mats. Synth. and Proc. 6(1998) 75.

M. F. Flemmings, “Solidification Processing” (McGraw-Hill, London, UK, 1974).

J. A. Sekhar, G. J. Abbaschian and R. Mehrabian, Mater. Sci. Eng. 40 (1979) 105.

D. L. Zhang and B. Cantor, Modelling Simul. Mater. Sci. Eng. 3 (1995) 121.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, SW., Durrant, G., Lee, JH. et al. The effect of die geometry on the microstructure of indirect squeeze cast and gravity die cast 7050 (Al-6.2Zn-2.3Cu-2.3Mg) wrought Al alloy. Journal of Materials Science 34, 1873–1883 (1999). https://doi.org/10.1023/A:1004531830333

Issue Date:

DOI: https://doi.org/10.1023/A:1004531830333