Abstract

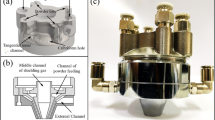

The slot plug is an important functional element for bottom-injection technology of powders and greatly influences the smooth operation of this technology. The mixing chamber is an important part of the slot plug, and its diffusion angle strongly affects the transmitting stability of powders. The two-fluid model and the two-phase k-ε turbulence model were used to describe the two-phase flow of CaC2 powders in a mixing chamber and to study how the angle of the conical section affects the pressure in the mixing chamber. In addition, the concentration and velocity distribution of the CaC2 powders were analyzed. The results show that, if the angle of the conical section is 45°, the gas-powder transmission pressure is stable, and the powder concentrates mainly around the central axis of the mixing chamber. If the angle of the conical section is 45° or 90°, the powder moves around the outlet and then passes smoothly through the slits.

Similar content being viewed by others

References

J. A. Zhou, M. Y. Zhu, S. S. Pan, J. Iron Steel Res. 19 (2007) No. 9, 14–16.

J. A. Zhou, Study on the Desulfurization Process of Furnace Bottom, Metallurgical Industry Press, Beijing, 2008.

S. S. Pan, M. Y. Zhu, Metal Technology 43 (2007) 553–556.

S. S. Qi, Z. Q. Xu, D. L. Xie, Chinese Journal of Scientific Instrument (2014) S2, 159–162.

Y. Xu, Z. W. Yu, T. Zhang, G. Li, Journal of Mechanical Engineering 44 (2008) No. 12, 105–110.

J. A. Zhou, M. Y. Zhu, S. S. Pan, Steelmaking 23 (2007) No. 1, 18–20.

Y. Q. Xiong, J. Chem. Ind. Eng. 55 (2004) 1638–1643.

Y. Tsuji, T. Kawaguchi, Power technol. 77 (1993) 79–87.

K. W. Chu, A. B. Yu, Powder Technol. 179 (2008) 104–114.

Y. L. Lai, Y. Q. Tai Y Q, D. S. Ren, Chem. Eng. Sci. 59 (2004) 4637–4651.

K. Luo , J. Yan, J. R. Fan, Sci. China Ser. E 51 (2008) 386–396.

Y. Lu, L. Qian, W. Q. Zhong, B. S. Jin, Journal of Engineering Thermophysics (2015) No. 7, 1481–1486.

P. Gao, S. Y. Gu, S. Q. Zhong, Y. M. Jin, Y. Cao, Energy Chem. Industry (2015) No. 3, 66–70.

J. A. Zhou, C. M. Liu, Z. Q. Liu, J. Univ. Sci. Technol. Beijing 36 (2014) 1348–1358.

J. A. Zhou, Z. J. Sun, D. P. Zhan, J. Northeast. Univ. 33 (2012) 90–93.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Ja., Wei, K., Li, Zq. et al. Numerical simulation of gas-powder flow in a slot-plug mixing chamber. J. Iron Steel Res. Int. 22 (Suppl 1), 24–29 (2015). https://doi.org/10.1016/S1006-706X(15)30133-3

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30133-3