Abstract

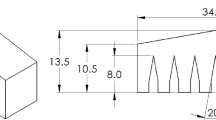

Electroslag surfacing with liquid metal (ESSLM) is an excellent method for producing high-quality bimetallic compound rollers. The quality of each compound roller is primarily determined by the metallurgical quality of the combined interface. A GCr15/40Cr compound roller is produced using an ESSLM non-consumable electrode electroslag heating method. The temperature and electric fields produced by the ESSLM system are calculated. As the roller core moves downward in the mold, it passes through five sections: the preheating section, the rapid heating section, the temperature homogenizing section, the bimetal fusing section and the cooling section which listed from the top to bottom of the mold, respectively. The temperature distribution and the degree of the surface temperature fluctuation in the roller core are different for each section. Near the combined interface, four layers are found from the roller core to the cladding layer: the remelting layer, the fusion layer, the interface solidification layer and the chilling layer, respectively. Among these, the fusion and interface solidification layers are the key transition zones that greatly influence the combination quality. The surface temperature of the roller core prior to cladding is mainly determined by the drawing velocity, and the thickness of the transition layer increases as the drawing velocity decreases. A transition layer that is too thick or too thin will reduce the mechanical properties at the combined interface. Therefore, the drawing velocity should be limited to a moderate range to produce a satisfactory bimetallic compound roller.

Similar content being viewed by others

References

H. C. Li, Z. Y. Jiang, A. K. Tieu, W. H. Sun, D. B. Wei, Wear 271 (2011) 2500–2511.

R. D. Mercado-Solisa, J. Talamantes-Silva, J. H. Beynon, M. A. L. Hernandez-Rodriguez, Wear 263 (2007) 1560–1567.

H. G. Fu, Foundry 58 (2009) 690–697.

M Pellizzari, D. Cescato, M. G. De Flora, Wear 267 (2009) 467–475.

M Pellizzari, A. Molinari, G. Straffelini, Wear 259 (2005) 1281–1289.

Y. L. Bai, Y. K. Luan, N.N. Song, X. H. Kang, D. Z. Li, Y. Y. Li, J. Mater. Sci. Technol. 28 (2012) 853–858.

E.I. Marukovich, A.M. Branovitsky, Y. S. Na, J. H. Lee, K. Y. Choi, Mater. Des. 27 (2006) 1016–1026.

K. G. Bang, J. K. Choi, H. S. Kim, D. G. Lee, H. S. Jeon, Compos. Struct. 38 (1997) 321–328.

H. G. Fu, Q. Xiao, J. D. Xing, Mater. Sci. Eng. A 479 (2008) 253–260.

H. G. Fu, X. Qiang, J. D. Xing, Mater. Sci. Eng. A 474 (2008) 82–87.

K. G. Hwang, S. H. Lee, H. C. Lee, Mater. Sci. Eng. A 254 (1998) 282–295.

B. F. Wang, W. Chen, J. Li, Z. L. Liu, X. B. Zhu, Mater. Des. 47 (2013) 74–79.

M. J. Feng, E. G. Wang, J. G. Wang, C. M. Luo, K. Wang, J. C. He, J. Iron Steel Res. 20 (2008) No. 9, 36–41.

K. Z. Shao, S. Z. Wei, R. Long, Y. M. Liu, S. C. Wang, T. Peng, C.W. Xu, Foundry 55 (2006) 160–163.

Z. H. Jiang, The Physical Chemistry and Transport Phenomena in Electroslag Metallurgy, Northeastern Unversity Publishers, Shenyang, 2000.

Y. W. Dong, Z. H. Jiang, Z. B. Li, J. Iron Steel Res. Int. 14 (2007) No. 5, 7–12.

Z. H. Wang, J. Xu, G. D. Bao, J. Zhang, X. F. Fang, T. B. Liu, J. Mater. Process. Technol. 182 (2007) 588–592.

Z. H. Jiang, Y. W. Dong, X. M. Zang, X. Geng, H. B. Li, Q. Yu, Journal of Materials and Metallurgy 10 (2011) No. 3, 14–20.

H. E. Mir, A. Jardy, J. P. Bellot, P. Chapelle, D. Lasalmonie, J. Senevat, J. Mater. Process. Technol. 210 (2010) 564–572.

Z.H. Jiang, L. Medovar, G. Stovpchenko, Y. W. Dong, X. M. Zang, F. B. Liu, J. Iron Steel Res. 25 (2013) No. 3, 1–7.

W. L. Chen, Y. C. Yang, Appl. Therm. Eng. 30 (2010) 1247–1254.

D.J. Lee, D.H. Ahn, E. Y. Yoon, S.I. Hong, S. H. Lee, H. S. Kim, Scripta Mater. 68 (2013) 893–896.

D. Benasciutti, E. Brusa, G. Bazzaro, Procedia Engineering 2 (2010) 707–716.

J. L. Wang, F. M. Wang, Y. Y. Zhao, J. M. Zhang, W. Ren, Int. J. Miner. Metall. Mater. 16 (2009) 640–645.

W. M. Li, Z.H. Jiang, Y. W. Dong, H. Liu, L. C. Zheng, Journal of Materials and Metallurgy 10 (2011) 77–80.

Y. H. Liu, H. F. Liu, S. R. Yu, Chinese Journal of Mechanical Engineering 36 (2000) No. 7, 81–85.

Z. Ignaszak, M. Hajkowski, J. Hajkowski, J. Mater. Sci. 12 (2006) 124–128.

F. B. Liu, X. M. Zang, Z. H. Jiang, X. Geng, M. Yao, Int. J. Miner. Metall. Mater. 19 (2012) 303–311.

J. H. Kim, B. O. Lee, C. B. Lee, S. H. Jee, Y. S. Yoon, J. Rare. Earth. 30 (2012) 599–603.

M. Nilsson, M. Olsson, Wear 307 (2013) 209–217.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51165030)

Rights and permissions

About this article

Cite this article

Rao, L., Wang, Sj., Zhao, Jh. et al. Experimental and Simulation Studies on Fabricating GCr15/40Cr Bimetallic Compound Rollers Using Electroslag Surfacing with Liquid Metal Method. J. Iron Steel Res. Int. 21, 869–877 (2014). https://doi.org/10.1016/S1006-706X(14)60155-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(14)60155-2