Abstract

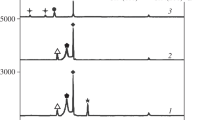

N-doped TiO2 (N-TiO2) coatings were obtained by oxidation of titanium nitride coatings, which were prepared by the plasma surface alloying technique on stainless steel (SS). The microstructure of N-TiO2 coatings was characterized by X-ray diffraction (XRD), glow discharge optical emission spectrometry (GDOES), X-ray photoelec-tron spectroscopy (XPS) and scanning electron microscopy (SEM), respectively. Ball-on-disc sliding wear was applied to test and compare the tribological behaviors of the coatings and substrate. XRD patterns showed that anatase type TiO2 existed in the coatings after oxidation. GDOES showed that the resultant coatings had a layered structure, comprising of N-TiO2 layer at the top and a diffusion-type interface. Such a hybrid coatings system showed good adhesion with the substrate. According to XPS, residual N atoms partially occupied O atom sites in the TiO2 lattice. Uniform, continuous and compact coatings were observed by SEM images of coatings after oxidation. Under a load of 7. 6 N, the coefficient of friction was in the range of 0. 27–0. 38 for the N-TiO2/Al2O3 systems and the wear rate of the coatings was only one-fourteenth of that for untreated 316L SS. N-TiO2 coatings displayed much better wear resistance and antifriction performance than SS substrate.

Similar content being viewed by others

References

Oldfield J W, Todd B. Technical and Economic Aspects of Stainless Steels in MSF Desalination Plants [J]. Desalination, 1999, 124(1/2/3): 75.

Olivares R, Rodil S E, Arzate H. In Vitro Studies of the Biomineralization in Amorphous Carbon Films [J]. Surface and Coatings Technology, 2004, 177-178: 758.

Fini M, Nicoli Aldini N, Torricelli P, et al. A New Austenitic Stainless Steel With Negligible Nickel Content: An in Vitro and in Vivo Comparative Investigation [J]. Biomaterials, 2003, 24(27): 4929.

Disegi J A, Eschbach L. Stainless Steel in Bone Surgery [J]. Injury, 2000, 31(S4): D2.

Kowandy C, Mazouz H, Richard C. Isolation and Analysis of Articular Joints Wear Debris Generated in Vitro [J]. Wear, 2006, 261(9): 966.

Sun Y, Bell T. Sliding Wear Characteristics of Low Temperature Plasma Nitrided 316 Austenitic Stainless Steel [J]. Wear, 1998, 218(1): 34.

Tabet N, Allam I, Yin R C. X-Ray Photoelectron Spectroscopy Investigation of the Carburization of 310 Stainless Steel [J]. Applied Surface Science, 2003, 220(1/2/3/4): 259.

Siva Rama Krishna D, Sun Y. Thermally Oxidised Rutile-TiOa Coating on Stainless Steel for Tribological Properties and Corrosion Resistance Enhancement [J]. Applied Surface Science, 2005, 252(4): 1107.

Gusmano G, Montesperelli G, Rapone M, et al. Zirconia Primers for Corrosion Resistant Coatings [J]. Surface and Coatings Technology, 2007, 201(12): 5822.

Lampke Th, Leopold A, Dietrich D, et al. Correlation Between Structure and Corrosion Behaviour of Nickel Dispersion Coatings Containing Ceramic Particles of Different Sizes [J]. Surface and Coatings Technology, 2006, 201(6): 3510.

Hamdy A S, Butt D P, Ismail A A. Electrochemical Impedance Studies of Sol-Gel Based Ceramic Coatings Systems in 3. 5% NaCl Solution [J]. Electrochimica Acta, 2007, 52(9): 3310.

Yao Z P, Jiang Z H, Wang F P. Study on Corrosion Resistance and Roughness of Micro-Plasma Oxidation Ceramic Coatings on Ti Alloy by EIS Technique [J]. Electrochimica Acta, 2007, 52(13): 4539.

Shan C X, Hou X H, Choy K L. Corrosion Resistance of TiO2 Films Grown on Stainless Steel by Atomic Layer Deposition [J]. Surface and Coatings Technology, 2008, 202(11): 2399.

Shen G X, Chen Y C, Lin C J. Corrosion Protection of 316 L Stainless Steel by a TiO2 Nanoparticle Coating Prepared by Sol-Gel Method [J]. Thin Solid Films, 2005, 489(1/2): 130.

Dai W W, Ding C X, Li J F, et al. Wear Mechanism of Plasma-Sprayed TiO2 Coating Against Stainless Steel [J]. Wear, 1996, 196(1/2): 238.

LI Hong-mei, LIU Min, ZENG Yang-su, et al. Coexistence of Antiferromagnetic and Ferromagnetic in Mn-Doped Anatase TiO2 Nanowires [J]. Journal of Central South University of Technology, 2010, 17(2): 239.

Xu Z, Fang B H, Zheng W N, et al. A Novel Plasma Surface Metallurgy: Xu-Tec Process [J]. Surface and Coatings Technology, 1990, 43-44(Part 2): 1065.

Zhang H J, Wen D Z. Antibacterial Properties of Sb-TiO2 Thin Films by RF Magnetron Co-Sputtering [J]. Surface and Coatings Technology, 2007, 201(9/10/11): 5720.

Dan Z G, Ni H W, Xu B F, et al. Microstructure and Antibacterial Properties of AISI 420 Stainless Steel Implanted by Copper Ions [J]. Thin Solid Films, 2005, 492(1/2): 93.

Kwok S C H, Zhang W, Wan G J, et al. Hemocompatibility and Anti-Bacterial Properties of Silver Doped Diamond-Like Carbon Prepared by Pulsed Filtered Cathodic Vacuum Arc Deposition [J]. Diamond and Related Materials, 2007, 16(4/5/6/7): 1353.

Baghery P, Farzam M, Mousavi A B, et al. Ni-TiO2 Nano-composite Coating With High Resistance to Corrosion and Wear [J]. Surface and Coatings Technology, 2010, 204(23): 3804.

Author information

Authors and Affiliations

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50771070); Project Innovation of Graduate Students of Shanxi Province of China (20093038)

Rights and permissions

About this article

Cite this article

Wang, Hf., Tang, B. & Li, Xy. Microstructure and Wear Resistance of N-Doped TiO2 Coatings Grown on Stainless Steel by Plasma Surface Alloying Technology. J. Iron Steel Res. Int. 18, 73–78 (2011). https://doi.org/10.1016/S1006-706X(11)60094-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(11)60094-0