Abstract

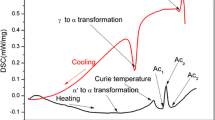

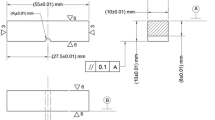

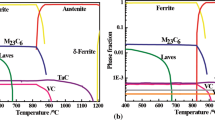

The tempering behavior of a Cr-W-V steel was investigated in this research. This new alloy with the composition of Fe-4.5Cr-2W-0.25V-0.1C was austenitized at 1000 °C for 30 min and tempered at 600 and 700 °C for different time up to 100 h. An OM analysis of the microstructure of air cooled and water quenched specimens before tempering showed that although under both conditions fully martensitic matrix formed, finer structure had formed in the water quenched specimens. The XRD and TEM results showed that the most stable carbides formed during tempering of the steel were M23C6 and M7C3, respectively. Other carbides such as M3C and M2C, formed in the first stages of tempering, and stable MC were also observed. The results showed that when the tempering time, temperature and cooling rate were increased, mass percent of extracted precipitates was increased. In addition, the formation rate of the stable carbides such as M23C6 and dissolution rate of the metastable carbides such as M3C and M2C were increased.

Similar content being viewed by others

References

Carian Y de, Murugananth M, Sourmail T, et al. Design of New Fe-9CrWV Reduced Activation Martensitic Steels for Creep Properties at 650 °C [J]. J Nucl Mater, 2004, 329–333: 238.

Zinkle S J. Advanced Materials for Fusion Technology [J]. Fusion Eng Des, 2005, 74: 31.

Jones R H, Heinisch H L, McCarthy K A. Low Activation Materials [J]. J Nucl Mater, 1999, 271–272: 518.

Ioltukhovskiy A G, Blokhin A I, Budylkin N I, et al. Material Science and Manufacturing of Heat-Resistant Reduced-Activation Ferritic-Martensitic Steels for Fusion [J]. J Nucl Mater, 2000, 283–287: 652.

Chen Z, Shan Z W, Wu N Q, et al. Fine Carbide-Strengthened 3Cr-3WVTa Bainitic Steel [J]. Metall Mater Trans A, 2004, 35(4): 1281.

Robson J D, Bhadeshia H K D H. Modelling Precipitation Sequences in Power Plant Steels Part 2—Application of Kinetic Theory [J]. Mater Sci Tech, 1997, 13: 640.

Gustafson P. A Thermodynamic Evaluation of the C-Cr-Fe-W System [J]. Metall Mater Trans A, 1988, 19(10): 2547.

Kim S H, Ryu W S, Kuk H H. Microstructure and Mechanical Properties of Cr-Mo Steels for Nuclear Industry Applications [J]. J Korean Nucl Soc, 1999, 31(6): 561.

Fujita N, Bhadeshia H K D H. Modelling Simultaneous Alloy Carbide Sequence in Power Plant Steels [J]. ISIJ Int, 2002, 42 (7): 760.

Klueh R L. Heat Treatment Behavior and Tensile Properties of Cr-W Steels [J]. Metall Trans A, 1989, 20: 463.

Janovec J, Vyrostkva A, Svoboda M. Influence of Tempering Temperature on Stability of Carbide Phases in 2.6Cr-0.7Mo-0.3V Steel With Various Carbon Content [J]. Metall Trans A 1994, 25: 267.

Miyata K, Sawaragi Y. Effect of Mo and W on the Phase Stability of Precipitates in Low Cr Heat Resistant Steels [J]. ISIJ Int, 2001, 41(3): 281.

Klueh R L, Alexander D J, Kenik E A. Development of Low-Chromium, Chromium-Tungsten Steels for Fusion [J]. J Nucl Mater, 1995, 227: 11.

Jayaram R, Klueh R L. Microstructural Characterization of 5–9% Cr-2% W-V-Ta Martensitic Steels [J]. Metall Mater Trans A, 1998, 29: 1551.

Klueh R L, Alexander D J. Sokolov M A. Effect of Chromium, Tungsten, Tantalum, and Boron on Mechanical Properties of 5-9Cr-WVTaB Steels [J]. J Nucl Mater, 2002, 304: 139.

Asakura K, Kohyama K, Yamada T. Mechanical Properties 3Cr-2W-V-Ti Ferritic and Microstructure Changes of Low-activation Steels [J]. ISIJ Int, 1990, 30(11): 947.

Cullity B D. Elements of X-Ray Diffraction [M]. 2nd ed. Massachusetts: Addison Wesley, 1978.

Hasegawa T, Abe Y R, Tomita Y, et al. Microstructural Evolution During Creep Test in 9Cr-2W-V-Ta Steels and 9Cr-1Mo-V-Nb Steels [J]. ISIJ Int, 2001, 41(8): 922.

Klueh R L. Elevated Temperature Ferritic and Martensitic Steels and Their Application to Future Nuclear Reactors [J]. Int Mater Rev, 2005, 50(5): 287.

Cai G J, Andren H O, Svensson F L E. Microstructural Change of a 5% Cr Steel Weld Metal During Tempering [J]. Mater Sci Eng A, 1998, 242(1/2): 202.

Leonteva-Smirnova M V, Ioltukhovskiy A G, Arutiunova G A, et al. Investigation of Heat Treatment Conditions on the Structure of 12% Chromium Reduced Activation Steels [J]. J Nucl Mater, 2002, 307–311: 466.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asadabad, M.A., Kheirandish, S. & Novinrooz, A.J. Tempering Behavior of 4.5Cr-2W-0.25V Steel. J. Iron Steel Res. Int. 17, 57–62 (2010). https://doi.org/10.1016/S1006-706X(10)60184-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60184-7