Abstract

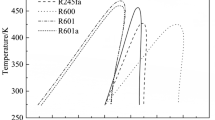

In the current study, simulations based on the engineering equation solver (EES) software are performed to determine the suitable working fluid for the simple organic Rankine cycle system in different temperature ranges. Under the condition of various temperatures and a constant thermal power of the flue gas, the influence of different organic working fluids on the efficiency of the subcritical organic Rankine cycle power generation system is studied, and its efficiency and other parameters are compared with those of the regenerator system. It is shown that the efficiency of the subcritical organic Rankine cycle system is the best when the parameters of the working fluid in the expander inlet are in the saturation state. And for the organic Rankine cycle, the R245fa is better than other working fluids and the efficiency of the system reaches up to 10.2% when the flammability, the toxicity, the ozone depletion, the greenhouse effect and other factors of the working fluids are considered. The R601a working fluid can be used for the high-temperature heat source, however, because of its high flammability, new working fluid should be investigated. Under the same condition, the efficiency of the organic Rankine cycle power generation system with an internal heat exchanger is higher than that of the simple system without the internal heat exchanger, but the efficiency is related to the properties of the working fluid and the temperature of the heat source.

Similar content being viewed by others

References

HUNG T. C., SHAI T. Y. and WANG S. K. A review of organic rankine cycles (ORCs) for the recovery of low grade waste heat[J]. Energy, 1997, 22(7): 661–667.

SALEH B., KOGLBAUE G. and WENDLAND M. et al. Working fluids for low-temperature organic Rankine cycles[J]. Energy, 2007, 32(7): 1210–1221.

GAO Dong-ming, SHI Xiao-jun. Analysis of reclaiming residual heat of the flue gas of gas-fired boiler with a condensing air heat exchanger[J]. Industrial Boiler, 2005, (6): 1–6(in Chinese).

NGUYEN V. M., DOHERTY P. S. and RIFFAT S. B. Development of a prototype low temperature Rankine cycle electricity generation system[J]. Applied Thermal Engineering, 2001, 21(2): 169–181.

SAITOH T., YAMADA N. and WAKASHIMA S. Solar rankine cycle system using scrollexpander[J]. Journal of Energy and Engineering, 2007, 2(4): 708–718.

HUSBAND W. W., BEYENE A. Low-grade heat-driven Rankine cycle, a feasibility study[J]. International Journal of Energy Research, 2008, 32(15):1373–1382.

CHEN H., YOGI GOSWAMI D. and MUHAMMAD M. A supercritical Rankine cycle using zeotropic mixture working fluids for the conversion of low-grade heat into power[J]. Energy, 2010, 36(1): 549–555.

TCHANCHE B. F., PAPADAKIS G. and LAMBRINOS G. et al. Fluid selection for a low-temperature solar organic rankine cycle[J]. Applied Thermal Engineering, 2009, 29(11–12): 2468–2476.

CAO Bin-bin. Analysis of screw expander surplus heat recovery system[D]. Doctoral Thesis, Tianjin, China: Tianjin university, 2007(in Chinese).

ZHU Jiang, LU Yuan-wei and MA Chong-fang et al. Working fluid selection for organic rankine cycle (ORC) in low temperature geothermal power generation system[J]. Renewable Energy Resources, 2009, 27(2): 76–79(in Chinese).

SUN J., LI W. Operation optimization of an organic rankine cycle (ORC) heat recovery power plant[J]. Applied Thermal Engineering, 2011, 31(11–12): 2032–2041.

SHI Shuo, LIU Zheng-gang and DU Guang-sheng et al. Study of errors in ultrasonic heat meter measurements caused by impurities of water based on ultrasonic attenuation[J]. Journal of Hydrodynamics, 2015, 27(1): 141–149.

GU Wei, WENG Yi-wu and CAO Guang-yi. The latest research findings concerning low-temperature heat ene-rgy-based power generation and its development trend[J]. Journal of Engineering for Thermal Energy and Power, 2007, 22(2): 115–119(in Chinese).

YAN Jia-lu. Thermodynamic principles and formulas for choosing working fluids and parameters in designing power plant of low temperature heat[J]. Journal of Engineering Thermophysics, 1982, 3(1): 1–7(in Chinese).

ANGELINO G., COLONNA DI PALIANO P. Multicomponent working fluids for organic Rankine cycles (ORCs)[J]. Energy, 1998, 23(6): 449–463.

ANGELINO G., COLONNA DI PALIANO P. Organic Rankine cycles (ORCs) for energy recovery of molten carbonate fuel cells[C]. 35th Intersociety Energy Conversion Engineering. Las Vegas, USA, 2000.

CAO Deng-sheng, SHI Lin. Refrigerant using manual[M]. Beijing, China: Metallurgical Industry Press, 2007(in Chinese).

ISSN 1041-2336. Designation and safety classification of refrigerants[S]. ANSI/ASHRAE Standard 34, 2007.

Author information

Authors and Affiliations

Corresponding author

Additional information

Biography: LI Dian-xun (1974-), Male, Ph. D. Candidate

Rights and permissions

About this article

Cite this article

Li, Dx., Zhang, Ss. & Wang, Gh. Selection of organic Rankine cycle working fluids in the low-temperature waste heat utilization. J Hydrodyn 27, 458–464 (2015). https://doi.org/10.1016/S1001-6058(15)60504-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1001-6058(15)60504-2