Abstract

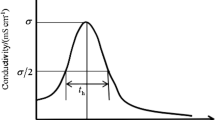

A detailed mathematical procedure of the optimization of the fluid flow in a tundish water model with and without flow control devices (weir and dam) was carried out using the commercial CFD code FLUENT 6. 0. The (k-ε) two-equation model was used to model turbulence. The residence time distribution (RTD) curves were used to analyze the behavior of the flow in tundish. The location of flow control devices in the tundish was studied. The results show that the flow modifiers play an important role in promoting the floatation of nonmetallic inclusions in steel. Comparing the three geometric configurations that are considered (bare tundish, weir, weir + dam), the tundish equipped with the arrangement (weir+dam) is a best and optimal geometric configuration of tundish.

Similar content being viewed by others

References

ZHANG Li-feng. Validation of the Numerical Simulation of Fluid Flow in the Continuous Casting Tundish [J]. J Univ Sci Technol Beijing, 2005, 12(2): 116.

Lee S M, Koo Y S, Kang T, et al. Mathematical and Physical Modelling of 3-D Fluid Flow in a Tundish With Dam and Weir [A]. Proceedings of the Sixth International Iron and Steel Congress [C]. Nagoya: ISIJ, 1990. 239.

Damle Chandrashekhar, Sahai Yogeshwar. The Effect of Tracer Density on Melt Flow Charaterization in Continuous Casting Tundishes—A Modelling Study [J]. ISIJ International, 1995, 35(2): 163.

Chakraborty S, Sahai Y. Mathematical Modelling of Transport Phenomena in Continuous Casting Tundishes. Part 1 Transient Effects During Ladle Transfer Operations [J]. Ironmaking and Steelmaking, 1992, 19(6): 479.

Kumar A, Koria S C, Mazumdar D. An Assessment of Fluid Flow Modelling and Residence Time Distribution Phenomena in Steelmaking Tundish Systems [J]. ISIJ International, 2004, 44 (8): 1334.

Sahai Y, Ahuja R. Fluid Flow and Mixing of Melt in Steelmaking Tundishes [J]. Ironmaking and Steelmaking, 1986, 13(5): 241.

Sahai Y, Emi T. Melt Flow Characterization in Continuous Casting Tundishes [J]. ISIJ International, 1996, 36(6): 667.

Levenspeil O. Chemical Reaction Engineering [M]. 2nd ed. New York; John Wiley and Sons, 1972.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bensouici, M., Bellaouar, A. & Talbi, K. Numerical investigation of the fluid flow in continuous casting tundish using analysis of RTD curves. J. Iron Steel Res. Int. 16, 22–29 (2009). https://doi.org/10.1016/S1006-706X(09)60022-4

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(09)60022-4