Abstract

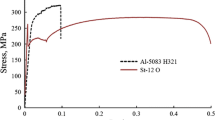

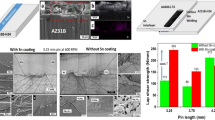

The friction spot extrusion brazing of Cu and AISI 304 stainless plates was carried out with a pure Zn interlayer medium to prevent Cu-Fe reaction by changing the tool shoulder surfaces from smooth to scrolled shoulder. The metallurgical and mechanical characterizations and fracture behaviors of the as-welded joints were studied. The change in tool shoulder surface had no significant effect on the chemical composition and the formation of interlocked or the plastically deformed material flow zone of the joint at an unchanged processing parameter setting. The kernel average misorientation fraction, high angle grain boundaries, and dislocation density are slightly higher at the stir zone of the smooth shoulder-produced welds owing to the higher heat input in the scroll shoulder-produced counterparts. The change of the tool from a smooth shoulder to a scroll shoulder tool produced a slightly more flash (non-uniform), increased peak temperature (409–459 °C), caused a rise in the average grains (6.58–7.73 µm) and promoted the fracture load (1359–2249 N) of the welds. Because there is no upper sheet bulging-induced interfacial gap at the brazed zone the tensile result of the scroll shoulder-produced joint has improved.

Similar content being viewed by others

References

Kumar Dinda S, Kar J, Gopal Roy G, Kockelmann W, Srirangam P. Texture mapping in electron beam welded dissimilar copper-stainless steel joints by neutron diffraction. Vacuum. 2020;181:109668.

Aghaee Attar M, Ghoreishi M, Malekshahi Beiranvand Z. Prediction of weld geometry, temperature contour and strain distribution in disk laser welding of dissimilar joining between copper & 304 stainless steel. Optik. 2020;219:165288.

Cheng Z, Liu H, Huang J, Ye Z, Yang J, Chen S. MIG-TIG double-sided arc welding of copper-stainless steel using different filler metals. J Manuf Process. 2020;55:208–19.

Li J, Cai Y, Yan F, Wang C, Zhu Z, Hu C. Porosity and liquation cracking of dissimilar Nd: YAG laser welding of SUS304 stainless steel to T2 copper. Opt Laser Technol. 2020;122:105881.

Gladkovsky SV, Kuteneva SV, Sergeev SN. Microstructure and mechanical properties of sandwich copper/steel composites produced by explosive welding. Mater Charact. 2019;154:294–303.

Varanasi D, Koncz-Horvath D, Sycheva A, Baumli P, Kaptay G. Cracking of copper brazed steel joints due to precipitation of MnS upon cooling. J Mater Eng Perform. 2020;29:8183–93.

Mangla V, Sharma JD, Kumar S, Dinesh Kumar P, Agarwal A. Joining of stainless steel (SS304) and OFE copper by vacuum brazing. Mater Today: Proc. 2020;26:724–7.

Wang Y, Luo J, Wang X, Xu X. Interfacial characterization of T3 copper/35CrMnSi steel dissimilar metal joints by inertia radial friction welding. Int J Adv Manuf Technol. 2013;68:1479–90.

Vyas HD, Mehta KP, Badheka V, Doshi B. Friction welding of dissimilar joints copper-stainless steel pipe consist of 0.06 wall thickness to pipe diameter ratio. J Manuf Process. 2021;68:1176–90.

Imani Y, Besharati MK, Guillot M. Improving friction stir welding between copper and 304L stainless steel. Adv Mat Res. 2012;409:263–8.

Luo J, Xiang J, Liu D, Li F, Xue K. Radial friction welding interface between brass and high carbon steel. J Mater Process Technol. 2012;212:385–92.

Shen Z, Chen Y, Haghshenas M, Nguyen T, Galloway J, Gerlich AP. Interfacial microstructure and properties of copper-clad steel produced using friction stir welding versus gas metal arc welding. Mater Charact. 2015;104:1–9.

Jafari M, Abbasi M, Poursina D, Gheysarian A, Bagheri B. Microstructures and mechanical properties of friction stir welded dissimilar steel-copper joints. J Mech Sci Technol. 2017;31:1135–42.

Sahlot P, Nene SS, Frank M, Mishra RS, Arora A. Towards attaining dissimilar lap joint of CuCrZr alloy and 316L stainless steel using friction stir welding. Sci Technol Weld Join. 2018;23:715–20.

Guo G, Shen Y, Cui C, Gao A, Wang B, Yin J. Interfacial properties of friction stir lap welded 430/304 stainless steels using Cu interlayer. Mater Lett. 2021;284:129027.

Paidar M, Memon S, Samusenkov VO, Babaei B, Ojo OO. Friction spot extrusion welding-brazing of copper to aluminum alloy. Mater Lett. 2021;285:129160.

Paidar M, Mohanavel V, Ojo OO, Mehrez S, Rajkumar S, Ravichandran M. Dieless friction stir extrusion-brazing (DFSE-B) of AA2024-T3 aluminum alloy to Copper with Zn interlayer. Results Phys. 2021;24:104101.

Fan G, Paidar M, Mehrez S, Ojo OO, Liu M, Dai Y, Mahariq I. Influence of shoulder diameter on interfacial microstructure and mechanical behavior in dieless friction stir riveting of CP-Copper to 321 stainless steel. Vacuum. 2022;197:110809.

Paidar M, Bokov D, Mehrez S, Nasution MKM, Ojo OO, Zain AM. The influence of the backing plate materials on microstructure and mechanical properties of friction spot extrusion brazing of AA2024-T3 aluminum alloy and Brass sheets. J Manuf Process. 2022;74:28–39.

Saju TP, Narayanan RG. Dieless friction stir lap joining of AA 5050–H32 with AA 6061–T6 at varying pre-drilled hole diameters. J Manuf Process. 2020;53:21–33.

Han J, Paidar M, Vaira Vignesh R, Mehta KP, Heidarzadeh A, Ojo OO. Effect of shoulder features during friction spot extrusion welding of 2024–T3 to 6061–T6 aluminum alloys. Arch Civ Mech Eng. 2020;20:84.

Oladimeji OO, Taban E, Kaluc E. Understanding the role of welding parameters and tool profile on the morphology and properties of expelled flash of spot welds. Mater Des. 2016;108:518–28.

Saju TP, Ganesh Narayanan R, Saha Roy B. Effect of pinless tool shoulder diameter on dieless friction stir extrusion joining of AA 5052–H32 and AA 6061–T6 aluminum alloy sheets. J Mech Sci Technol. 2019;33:3981–97.

Tong L, Xie J, Liu L, Chang G, Ojo OO. Microscopic appraisal and mechanical behavior of hybrid Cu/Al joints fabricated via friction stir spot welding-brazing and modified friction stir clinching-brazing. J Mater Res Technol. 2020;9:13239–49.

Ahmad S. Presence of golden ratio relationships in Fe–Fe3C, Cu–Zn and Cu–Sn alloy systems. Int J Des Nat Ecodyn. 2015;10:174–81.

Paidar M, Ashraff Ali KS, Mohanavel V, Mehrez S, Ravichandran M, Ojo OO. Weldability and mechanical properties of AA5083-H112 aluminum alloy and pure copper dissimilar friction spot extrusion welding-brazing. Vacuum. 2021;187:110080.

Paidar M, Mehrez S, Ojo OO, Mohanavel V, Babaei B, Ravichandran M. Modified friction stir clinching of AA6061-T6/AA5754-O joint: effect of tool rotational speed and solution heat treatment on mechanical, microstructure, and fracture behaviors. Mater Charact. 2021;173:110962.

Paidar M, Elveny M, Mehrez S, Ravi S, Babaei B, Ravichandran M. Influence of material positioning during modified friction stir clinching brazing of Al/Zn/Cu welds. Mater Lett. 2021;301:130250.

Paidar M, Kazemi A, Mehrez S, Ojo OO, Matyuso Nasution MK, Nikolaevich Mironov S. Investigation of modified friction stir clinching-brazing process of AA2024 Al/AZ31 Mg: metallurgical and mechanical properties. Arch Civil Mech Eng. 2021;21:115.

Paidar M, Tahani K, Vaira Vignesh R, Ojo OO, Ezatpour HR, Moharrami A. Modified friction stir clinching of 2024–T3 to 6061–T6 aluminum alloy: effect of dwell time and precipitation-hardening heat treatment. Mater Sci Eng A. 2020;791:139734.

Acknowledgements

This work is supported by the Scientific Research Program Funded by Shaanxi Provincial Education Department (No. 20JC001).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval

We confirm that this work is original and has not been published elsewhere, nor it is currently under consideration for publication elsewhere. All authors have approved the manuscript and have agreed with its submission to your journal.

Rights and permissions

About this article

Cite this article

Bai, J., Paidar, M., Mehrez, S. et al. Friction spot extrusion brazing of copper to AISI 304 stainless steel with Zn interlayer: effect of shoulder surface modification. Archiv.Civ.Mech.Eng 22, 62 (2022). https://doi.org/10.1007/s43452-022-00386-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00386-9