Abstract

India is the fifth-largest apple producer in the world with more than 2 MT per year. Mechanical damage such as bruises of apples (Malus domestica Borkh.), which can result in considerable wastage and decline in quality, is a major problem of the apple industry. On-site investigations of apple orchard management strategies to reduce bruises in Northern India were conducted by the first author in collaboration with the University of Bonn. The apple industry including the farmers is in a continuous process of reducing losses caused by mechanical damage. Apple bruises can develop along the whole value chain. Orchard management offers countermeasures to reduce bruise susceptibility of the apples. At harvest, bruises can be caused by impact and compression forces due to unsuitable practices. This review explains the formation and development of bruises, followed by the causes of mechanical damage and orchard management measures to reduce or avoid bruises, with particular regard to India. The orchard management measures include crop load management, fruit water status and nutrient composition, maturity stage, harvest time later in the day, gentle harvest methods, packing into soft, padded bins and careful transport of the apple bins out of the orchard.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Apple production and demand in India

As part of work at the University of Bonn to reduce food waste, particularly in apple production systems (Blanke 2015), the cultivation in Northern India was investigated. Annual apple production in India exceeds 2 MT, i.e. twice the apple yield in Germany, making it the fifth-largest apple producer worldwide (FAO 2019). For the Indian apple growing states Jammu & Kashmir, Himachal Pradesh and Uttarakhand, apple production is of significant economic importance and contributes to a healthy diet. The growth in economy as well as population in India led to a continuous rise in demand for apples (De Pablo Valenciano et al. 2018). The market potential for apples in India ranks as the largest in the world and exceeds inland production by far (Arora 2018).

The demand for high quality apples is increasing, especially in upper income segments of the population, who are willing to pay a high price; this demand exceeds domestic supply (Golombek and Blanke 2020). The import of foreign high quality apples with a good reputation, amounts to only 8–14% (since 2014) of the Indian apple consumption of 2–3 MT/year (Golombek and Blanke 2020). Apples with slight damages are accepted by lower income groups because of the lower fruit price. To meet the demand for high quality fruit and thereby increase the income of Indian apple farmers and stakeholders of the supply chain, a further rise in fruit quality is desirable, which also allows storage and profitable supply long after harvest season. The objective of this review is to explain the causes of bruise formation and to present opportunities to reduce or avoid bruises, with particular regard to India.

Causes of bruising

Impact of mechanical damage and infection risks

By their nature, apples are vulnerable to mechanical damage especially during harvest and post-harvest management. Significant losses may occur by mechanical damage resulting spoilage, so that any reduction of only few percent would result in a larger amount of better fruit in the market and improve the economic gain along the whole value chain.

Mechanical damages can be bruises, cuts, puncture, split and abrasion (Opara and Pathare 2014); bruises result in damaged epidermal and hypodermal tissue without rupture of the skin (Fig. 1), comprising living and dead cells (Mitsuhashi-Gonzalez et al. 2010; Opara and Pathare 2014). Indian consumers judge fruit quality predominantly on size and appearance; minor visible damages result in price and quality downgrading and reduce the financial returns. Additionally, mechanical damages may induce physiological disorders, which can lead to off-flavour, loss of nutritional value, decay and spoilage (Opara and Pathare 2014). Even minor injuries can enable bacterial and fungal infection, which may shorten the shelf-life of the apples (Van Zeebroeck et al. 2007). Predominantly gray mold (Botrytis cinerea) and blue mold (Penicillium spp.), but also other microorganisms, enter the apple fruit mainly through bruises. These infections play a major role in the wastage of apples (Kumari et al. 2018) and may spread throughout the packing box, making mechanically damaged fruit a potential source of infection throughout the value chain. Therefore, mechanically damaged apples are not suitable for storage and transport over long distances.

Forces causing bruises and minimum drop height

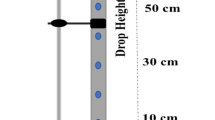

Excessive impact, compression, and/or vibration forces can cause bruises (Fig. 1). Impact forces result from dropping an apple onto a solid surface or against each other (Opara and Pathare 2014; Opara and Fadiji 2018; Scheffler et al. 2018). The minimum dropping height, which causes bruising, depends on the elasticity of the surface material, on which the apple drops (concrete, wood, cardboard or polyethylene foam) (Table 1). For wood and concrete as target material, the minimal dropping height of apples, which caused bruises was only 1–1.3 cm (or converted into Newton meter: 0.02 N m), for cardboard 3–4 cm (0.06 N m) and for polyethylene foam 8–9 cm (0.14–0.15 N m). The minimal drop height of an apple against another apple to avoid bruising should be less than 3 cm for apples of the NZ cultivar ‘Jazz’ according to Fu et al. (2020). These data show that the minimal dropping height, which causes bruising, is very low. With a larger drop height onto surfaces of different materials (concrete, wood, cardboard, concrete, polyethylene foam), the bruise volume within the fruit increases (Jung and Watkins 2009; Kormanicki et al. 2017; Stopa et al. 2018; Stropek and Gołacki 2013).

Apples are exposed to compression forces (a) by the fingers of the picker in the orchard, (b) when the size of the apples exceeds the pocket size of the tray, (c) excessive fruit stacking (Fig. 2), (d) collapse of the cardboard boxes, or (e) an operator forcing cartons into a tight spot (Fadiji et al. 2017; Opara and Fadiji 2018). Vibration forces during motorised transportation (Opara and Pathare 2014) may cause bruises.

Role of physico-textural characteristics for bruise susceptibility

The bruise susceptibility of apples depends on their mechanical properties, which include peel and flesh firmness, water content (‘turgor’), elasticity, fruit shape and size (Hussein et al. 2018; Stopa et al. 2018; Stropek and Gołacki 2015). During the ripening process of the apple, the degradation of cell wall components, including pectin, hemicellulose, and cellulose leads to less firm fruit (Ortiz et al. 2011; Win et al. 2019), which is promoted by ethylene and synthesis of cell wall degrading enzymes (Ireland et al. 2014), so that ethylene inhibitors such as 1-MCP would be suitable to reduce bruises. Decreasing firmness of apples makes them more susceptible to bruises (Garcı́a et al. 1995; Hussein et al. 2018, 2019; Opara 2007), which can be explained by cell wall properties and a loss in cell-to-cell adhesion, rounder cells and larger intercellular spaces (Iwanami et al. 2005; Johnston et al. 2002).

The water content (exactly: turgidity) of the apple fruits directly affects their bruise susceptibility. A slight dehydration results in lower stiffness, thereby reducing the risk/susceptibility to bruising (Iwanami et al. 2008; Garcı́a et al. 1995). Baritelle and Hyde (2001) measured that a mass loss of 2–3% due to slight dehydration reduced the bruise susceptibility by doubling the bruise threshold, i.e. the minimum force causing bruises.

Delay in bruise visibility

Bruises on apples do not become instantly visible (Fig. 1) until several hours after the impact (Zhang and Li 2018). The damaged tissues may soften, become brownish or dry (Zhang and Li 2018). As a consequence of the delay between impact and bruise visibility, bruises may become visible at a later stage of the value chain. Bruises are more visible on green (e.g. Granny Smith; Fig. 1) or yellow (e.g. Golden Delicious) apples, as the red (e.g. in Red Delicious, Gala) fruit colour often masks bruises (Ferrari et al. 2015).

Orchard management—tips for farmers and farm managers

Effect of crop load on the apple tree and water availability on bruise susceptibility

The crop load on the tree influences fruit firmness and can be manipulated by bloom thinning and pruning to achieve the optimum fruit load for fruit firmness (Table 2). Excessive crop load can reduce both the firmness and size of the apples (Musacchi and Serra 2018). The interaction of crop load and water availability in their effect on bruise susceptibility or firmness had been investigated. Opara (2007) found a higher bruise susceptibility and lower fruit size when the crop load of ‘Gala’ was increased under well-watered conditions. Under water deficit, increasing crop load of ‘Gala’ had no effect on bruise susceptibility, but decreased fruit size. Opara (2007) reported that water deficit decreased bruise susceptibility and fruit size only under high crop load. In contrast to Opara (2007), Mpelasoka et al. (2001) could not detect an interaction of water availability with crop load regarding fruit firmness; deficit irrigation during early or late fruit developmental stages of the cultivar ‘Braeburn’ increased fruit firmness associated with a smaller fruit size at harvest independent of crop load. Similarly, apple cultivars ‘Fuji’ and ‘Gala’ responded to deficit irrigation with firmer and smaller fruit (Fallahi et al. 2018; Opara et al. 1997). Overall, crop load management (CLM) by bloom thinning or pruning integrates fruit size, colour, firmness and other fruit quality parameters, and can enable an acceptable yield without alternate bearing.

Role of plant nutrition such as calcium, potassium and nitrogen for bruise development

Calcium stabilizes cell walls by cross-linking adjacent pectins (Hocking et al. 2016), ensures fruit firmness and helps to reduce physiological disorders like bitter pit and lenticel breakdown. Hence, pre-harvest foliar calcium sprays such as calcium chloride and/or calcium nitrate promoted firmness of ‘Red Delicious’ (Ranjbar et al. 2020) and ‘Idared’ (Murtic et al. 2019) and of average size apples of ‘Golden Delicious’ (Siddiqui and Bangerth 1995) at harvest. The fruit size has an effect on the calcium content. As fruit size increases, its calcium concentration is diluted (with more risk of bitter pit) in susceptible apples (Kalcsits et al. 2017; Neilsen and Neilsen 2003).

Potassium and calcium are competitors during nutrient uptake from the soil solution into the roots. Hence, an increase of potassium (K) in the soil solution can decrease the calcium (Ca) uptake into the roots and finally into the fruits. Further, the relation between potassium and calcium in the apple fruit is of importance for the firmness, bruise susceptibility and the development of physiological disorders. Therefore, a negative correlation between the K/Ca ratio of the apple and the firmness in ‘Golden Delicious’ as well as the bruise resistance in the cv. ‘Aroma’ was observed (Dilmaghani et al. 2005; Tahir et al. 2007). Depending on the growing region, K/Ca ratios of the fruit below 25:1 up to 30:1 have been recommended for calcareous soils in Iran for a favourable firmness and storage potential and to prevent physiological disorders (Dilmaghani et al. 2005).

In the majority of soils of the Indian apple growing regions of Himachal Pradesh and Kashmir the content of the available calcium is sufficient and the content of the available potassium medium to high (Block fertility map of HP of the Himachal Pradesh Agricultural University; Soil maps of the Department of Agriculture Kashmir 2015); there are only few areas in the Indian apple regions with low available calcium or potassium in the soil.

Oversupply of nitrogen can retard fruit maturation and lead to softer fruit with more bruise susceptibility (Musacchi and Serra 2018; Neilsen and Neilsen 2003; Tahir et al. 2007). Tahir et al. (2007) showed that an increase in nitrogen to moderate or excess levels increased fruit weight, fruit N and K content, while decreasing Ca content and therefore increased the bruise susceptibility at harvest.

Harvest management—tips for farmers and farm managers

Optimum harvest date (OHD) (Maturity stage)—an important factor influencing bruise susceptibility

OHD is determined by the marketing intention, where long-term storage requires an early harvest but immediate consumption needs late picking. The Streif index is a common testing tool to determine the optimum picking date (OHD) for apples and includes fruit firmness. The range of the Streif index (immediate consumption—long-term storage) is e.g. for Gala 0.13–0.3, Fuji 0.04–0.08, and Golden Delicious 0.05–0.10. Progressive apple growers and traders can easily and quickly measure apple firmness with an affordable, hand-held penetrometer. During maturation, apple firmness declines and other quality parameters such as sugar and organic acid contents and skin colour improve (Ganai et al. 2018; Garcı́a et al. 1995; Musacchi and Serra 2018). An important factor influencing the bruise susceptibility of apples is the maturity stage at harvest (Table 3). With decreasing firmness, apples become often more susceptible to bruises (Hussein et al. 2018; Garcı́a et al. 1995).

Harvest time during the day—a decline in water content reduces the bruise susceptibility

Because the water content of the fruit decreases during the day, apples harvested later in the day are less susceptible to bruising than those harvested in the morning (Abbott et al. 2010), particularly after severe overnight rainfall. Overnight water refill, dew in the morning as well as fog and rain raise the water content of the fruit and therefore increase bruise susceptibility and depends on the extent to which the region is influenced by the monsoon during the harvest. There are apple growing areas in the South slopes of the Himalayas which are exposed to the monsoon at fruit maturation near harvest, as for instance the district Shimla. Other apple growing areas lie in the rain shadow of the Himalayas, like in the regions Kinnaur and Lahaul and Spiti, with dry climate and glacial water supply. Again in other regions apples are harvested when the monsoon has ceased, like in Shopian. The harvest of wet, fairly turgescent apples increases their bruise susceptibility significantly. Delaying harvest until the late morning, when moisture/humidity and risk of bruises have decreased, might get the farmers a fair reputation of good quality fruit with fewer bruises.

Harvest method—a major key to reduce bruises

The harvest procedure is a crucial stage to reduce bruises. Apple picking can cause compression damage to the fruit, when pickers grasp the fruit too tight (Li and Thomas 2014). Pickers need to be trained to pick the apples gently by use of a whole hand grip and an upward bending movement to detach the fruit with the stalk (Knee and Miller 2002) and pick the apples with their stalk. They should not hold more than one apple in the hand at a time and should not wear jewellery on the fingers. In India, apples are picked usually into bags or padded baskets (Fig. 3a). Padding of the baskets decreases the risk of bruises. To prevent bruising, the fruit should not be dropped, but to lay them gently into bags and baskets. If the harvest is performed by climbing in the trees with a harvest bag, care should be taken not to bump the harvest bag against the tree.

The fruit bags or baskets should be emptied slowly and gently into bins like plastic crates or panniers (Figs. 2 and 3b). Dumping the apples into the bins, as it can often be observed, should be avoided to prevent the formation of bruises. The training of the picker and, if possible, supervision, is beneficial. The plastic crates should be padded to avoid bruises during filling and the transport out of the orchard (Fig. 3b), often they are not. The pannier, a traditional/universal bin for the transport of agricultural products on the back of a person, allows a stacking height, which often leads to bruising of the apples by compression and vibration during transport (Fig. 2). Bruise damage increases gradually from the upper layers to the bottom layers.

In the case the freshly harvested apples are too turgescent, their bruise susceptibility can be reduced by transporting the apple bins out of the orchards only after the apples have dehydrated slightly in the shade (Baritelle and Hyde 2001; Bollen 2005). Then the bins should be transported without much time delay into a cool room for better storability.

Transport of the apple boxes out of the orchard—a potential source for bruises

The long-winded transport of the filled plastic boxes on rough terrain out of the orchard can be another potential source for bruises. In hilly orchards, as it is often the case in the apple growing regions of India, apple boxes are carried out of the orchard on the back of porters (Fig. 4). To avoid exposure to the sun and unnecessary warming, the apple boxes should be covered before and during transport (Nissen et al. 2018). Shaking and swinging of the boxes should be avoided if possible, because it might cause a sequence of collisions leading to bruises (Van Zeebroeck et al. 2007). The boxes should be set down with care to minimize further compression damage of the fruit, which can be overcome by training the porters (Fig. 4).

Apples fallen to the ground are collected separately and packed with other poor quality apples into sacks in India. These sacks are collected by transporters of processing industries for the production of e.g. juice, squash, jelly, jams, cider and vinegar. They should be stored in the shade to avoid unnecessary warming of the fruit and expansion of the bruises, and separately from apples of higher quality, because a part of these apples might be infested by pathogens.

Conclusion and future prospects

In this review, options to reduce bruises on apples are described along all orchard processes with particular regard to the situation in India. Impact, compression and/or vibration forces cause mechanical damages. Fruit firmness plays an important role in bruise susceptibility. Orchard management can reduce the bruise susceptibility by increasing the fruit firmness with the measures: obtaining an optimal crop load and K/Ca fruit ratio without nitrogen oversupply. Proper harvest management can diminish bruise susceptibility by choosing the optimum harvest date (OHD) according to final destination, possibly a later harvest time during the day when fruit dehydration started and by appropriate harvest methods. Gentle picking, preventing bumps of the harvest bag against the tree, placing apples gently into padded harvest devices and moderate stacking height are measures (Fig. 4) to reduce impact und compression damages. During transport of the apple boxes out of the orchard, shaking, swinging, and rough handling should be avoided (Fig. 5).

In the future, further education of all persons involved in orchard management measures important for the development of bruises would be of benefit. The Horticulture Departments of Indian universities and governments and the ‘Horticulture Mission for North East and Himalayan States’ are already offering measures like training, information, recommendations, online-tools, and technology transfer to improve the apple cultivation.

Because there are also many factors causing apple bruises along the Indian apple value chain from the transport out of the farm until reaching the consumer, these factors will be reviewed in a further article. A decline of mechanical damage would meet the increasing demand for more high quality apples and improve the income of Indian apple farmers and stakeholders along the whole supply chain. A quality which also allows storage and profitable supply long after harvest season is desirable and would also allow a better competition with foreign apples.

References

Abbott B, Holford P, Golding JB (2010) Comparison of “Cripps Pink” apple bruising. Acta Hortic 880:223–229

Arora T (2018) Case study India: potential of apple imports. Invited paper presented at the INTERPOMA, November 2018, Bozen, Italy

Baritelle AL, Hyde GM (2001) Commodity conditioning to reduce impact bruising. Postharvest Biol Technol 21:331–339. https://doi.org/10.1016/S0925-5214(00)00154-X

Blanke M (2015) Challenges of reducing fresh produce waste in Europe - from farm to fork. Agriculture 5:389–399. https://doi.org/10.3390/agriculture5030389

Block Fertility Map of HP (2015) Himachal Pradesh Agricultural University, Palampur. Available at http://www.hillagric.ac.in/research/dr/BlockFertilityMap/index.html. Accessed 17 Oct 2020

Bollen AF (2005) Major factors causing variation in bruise susceptibility of apples (Malus domestica) grown in New Zealand. New Zeal J Crop Hort 33:201–210. https://doi.org/10.1080/01140671.2005.9514351

De Pablo VJ, Giacinti Battistuzzi MA, Tassile V, García JM (2018) Analysis of trade: import of apples in India. Indian J Agric Econ 73:216–228

Dilmaghani M, Malakouti M, Neilsen G, Fallahi E (2005) Interactive effects of potassium and calcium on K/Ca ratio and its consequences on apple fruit quality in calcareous soils of Iran. J Plant Nutr 27:1149–1162. https://doi.org/10.1081/PLN-120038541

Fadiji T, Berry TM, Coetzee CJ, Opara LU (2017) Investigating the mechanical properties of paperboard packaging material for handling fresh produce under different environmental conditions: experimental analysis and finite element modelling. J Appl Packing Res 9:20–34

Fallahi E, Fallahi B, Kiester MJ (2018) Evapotranspiration-based irrigation systems and nitrogen effects on yield and fruit quality at harvest in fully mature ‘Fuji’ apple trees over four years. Hortic Sci 53:38–43

FAO (2019) Crops statistics for 2018. http://www.fao.org/faostat/en/#data/QC. Accessed 13 Oct 2020

Ferrari C, Foca G, Calvini R, Ulrici A (2015) Fast exploration and classification of large hyperspectral image datasets for early bruise detection on apples. Chemometr Intell Lab 146:108–119. https://doi.org/10.1016/j.chemolab.2015.05.016

Fu H, Karkee M, He L, Duan J, Li J, Zhang Q (2020) Bruise patterns of fresh market apples caused by fruit-to-fruit impact. Agronomy 10:59. https://doi.org/10.3390/agronomy10010059

Ganai SA, Ahsan H, Tak A, Mir MA, Rather AH, Wani SM (2018) Effect of maturity stages and postharvest treatments on physical properties of apple during storage. J Saudi Soc Agric Sci 17:310–316. https://doi.org/10.1016/j.jssas.2016.07.001

Garcia JL, Ruiz-Altisent M, Barreiro P (1995) Factors influencing mechanical properties and bruise susceptibility of apples and pears. J Agric Eng Res 61:11–17. https://doi.org/10.1006/jaer.1995.1025

Golombek S, Blanke M (2020) Apple supply chain in the Himalayas [Vom Fuße des Himalaya – Wertschöpfungskette Äpfel in Indien]. Erwerbs-Obstbau 62:377–387. https://doi.org/10.1007/s10341-020-00515-9

Hocking B, Tyerman SD, Burton RA, Gilliham M (2016) Fruit calcium: transport and physiology. Front Plant Sci. https://doi.org/10.3389/fpls.2016.00569

Hussein Z, Fawole OA, Opara UL (2018) Preharvest factors influencing bruise damage of fresh fruits—a review. Sci Hortic 229:45–58. https://doi.org/10.1016/j.scienta.2017.10.028

Hussein Z, Fawole OA, Opara UL (2019) Harvest and postharvest factors affecting bruise damage of fresh fruits. Hortic Plant J 6:1–13. https://doi.org/10.1016/j.hpj.2019.07.006

Ireland HS, Gunaseelan K, Muddumage R, Tacken EJ, Putterill J, Johnston JW, Schaffer RJ (2014) Ethylene regulates apple (Malus × domestica) fruit softening through a dose × time-dependent mechanism and through differential sensitivities and dependencies of cell wall-modifying genes. Plant Cell Physiol 55:1005–1016. https://doi.org/10.1093/pcp/pcu034

Iwanami H, Moriya S, Kotoda N, Takahashi S, Abe K (2005) Influence of mealiness on the firmness of apples after harvest. HortScience 40:2091–2095

Iwanami H, Moriya S, Kotoda N, Abe K (2008) Turgor closely relates to postharvest fruit softening and can be a useful index to select a parent for producing cultivars with good storage potential in apple. HortScience 43:1377–1381

Johnston JW, Hewett EW, Hertog MLATM (2002) Postharvest softening of apple (Malus domestica) fruit: a review. New Zeal J Crop Hort 30:145–160. https://doi.org/10.1080/01140671.2002.9514210

Jung S-K, Watkins CB (2009) 1-Methylcyclopropene treatment and bruising of different apple cultivars during storage. J Hortic Sci Biotech 84:143–148. https://doi.org/10.1080/14620316.2009.11512495

Kalcsits L, Van der Heijden G, Reid M, Mullin K (2017) Calcium absorption during fruit development in ‘Honeycrisp’ apple measured using 44Ca as a stable isotope tracer. HortScience 52:1804–1809

Knee M, Miller AR (2002) Mechanical injury. In: Knee M (ed) Fruit quality and its biological basis. Sheffield Academic Press Ltd, Sheffield, UK, pp 157–179

Komarnicki P, Stopa R, Szyjewicz D, Kuta Ł, Klimza T (2017) Influence of contact surface type on the mechanical damages of apples under impact loads. Food Bioprocess Technol 10:1479–1494. https://doi.org/10.1007/s11947-017-1918-z

Kumari N, Sharma JN, Singh D, Thakur AK (2018) Major storage rots of apple: occurrence and distribution. Int J Econ Plants 5:46–52

Li Z, Thomas C (2014) Quantitative evaluation of mechanical damage to fresh fruits. Trends Food Sci Tech 35:138–150. https://doi.org/10.1016/j.tifs.2013.12.001

Mitsuhashi-Gonzalez K, Pitts MJ, Fellman JK, Curry EA, Clary CD (2010) Bruising profile of fresh apples associated with tissue type and structure. Appl Eng Agric 26:509–517

Mpelasoka BS, Behboudian MH, Green S (2001) Water use, yield and fruit quality of lysimeter-grown apple trees: Responses to deficit irrigation and to crop load. Irrigation Sci 20:107–113. https://doi.org/10.1007/s002710100041

Murtic S, Drkenda P, Music O, Oglecevac A (2019) Quality parameters and distribution of calcium in Idared apples under different fertilizer treatments. J Cent Eur Agric 20:1126–1134. https://doi.org/10.5513/JCEA01/20.4.2437

Musacchi S, Serra S (2018) Apple fruit quality: overview on pre-harvest factors. Sci Hortic 234:409–430. https://doi.org/10.1016/j.scienta.2017.12.057

Neilsen GH, Neilsen D (2003) Nutritional requirements of apple. In: Ferree DC, Warrington IJ (eds) Apples: botany, production and uses. CABI Publishing, UK, pp 267–302

Nissen R, Bound S, Adhikari R, Cover I (2018) Factors affecting post-harvest management of apples: A guide to optimising quality. National Library of Australia Cataloguing-in-Publication entry. https://www.utas.edu.au/__data/assets/pdf_file/0011/1186436/FGT-Post-Harvest-Manual-2018-Web.pdf

Opara LU (2007) Bruise susceptibilities of ‘Gala’ apples as affected by orchard management practices and harvest date. Postharvest Biol Technol 43:47–54. https://doi.org/10.1016/j.postharvbio.2006.08.012

Opara UL, Fadiji T (2018) Compression damage susceptibility of apple fruit packed inside ventilated corrugated paperboard package. Sci Hortic 227:154–161. https://doi.org/10.1016/j.scienta.2017.09.043

Opara UL, Pathare PB (2014) Bruise damage measurement and analysis of fresh horticultural produce—a review. Postharvest Biol Technol 91:9–24. https://doi.org/10.1016/j.postharvbio.2013.12.009

Opara LU, Studman CJ, Banks NH (1997) Physico-mechanical properties of ‘Gala’ apples and stem-end splitting as influenced by orchard management practices and harvest date. J Agric Eng Res 68:139–146. https://doi.org/10.1006/jaer.1997.0190

Ortiz A, Graell J, Lara I (2011) Cell wall-modifying enzymes and firmness loss in ripening ‘Golden Reinders’ apples: a comparison between calcium dips and ULO storage. Food Chem 128:1072–1079. https://doi.org/10.1016/j.foodchem.2011.04.016

Ranjbar S, Ramezanian A, Rahemi M (2020) Nano-calcium and its potential to improve “Red Delicious” apple fruit characteristics. Hortic Environ Biotechnol 61:23–30. https://doi.org/10.1007/s13580-019-00168-y

Scheffler OC, Coetzee CJ, Opara UL (2018) A discrete element model (DEM) for predicting apple damage during handling. Biosyst Eng 172:29–48. https://doi.org/10.1016/j.biosystemseng.2018.05.015

Siddiqui S, Bangerth F (1995) Effect of pre-harvest application of calcium on flesh firmness and cell-wall composition of apples - influence of fruit size. J Hortic Sci 70:263–269. https://doi.org/10.1080/14620316.1995.11515296

Soil maps of the Department of Agriculture Kashmir, Government of Jammu & Kashmir. Available at http://diragrikmr.nic.in/Soil_Maps.html. Accessed 17 July 2020

Stopa R, Szyjewicz D, Komarnicki P, Kuta Ł (2018) Determining the resistance to mechanical damage of apples under impact loads. Postharvest Biol Technol 146:79–89. https://doi.org/10.1016/j.postharvbio.2018.08.016

Stropek Z, Gołacki K (2013) The effect of drop height on bruising of selected apple varieties. Postharvest Biol Technol 85:167–172. https://doi.org/10.1016/j.postharvbio.2013.06.002

Stropek Z, Gołacki K (2015) A new method for measuring impact related bruises in fruits. Postharvest Biol Technol 110:131–139. https://doi.org/10.1016/j.postharvbio.2015.07.005

Tahir II, Johansson E, Olsson ME (2007) Improvement of quality and storability of apple cv. Aroma by adjustment of some pre-harvest conditions. Sci Hortic 112:164–171. https://doi.org/10.1016/j.scienta.2006.12.018

Van Zeebroeck M, Van Linden V, Ramon H, De Baerdemaeker J, Nicolaï BM, Tijskens E (2007) Impact damage of apples during transport and handling. Postharvest Biol Technol 45:157–167. https://doi.org/10.1016/j.postharvbio.2007.01.015

Win NM, Yoo J, Kwon S-I, Watkins CB, Kang I-K (2019) Characterization of fruit quality attributes and cell wall metabolism in 1-Methylcyclopropene (1-MCP)-treated ‘Summer King’ and ‘Green Ball’ apples during cold storage. Front Plant Sci. https://doi.org/10.3389/fpls.2019.01513

Zhang M, Li G (2018) Visual detection of apple bruises using AdaBoost algorithm and hyperspectral imaging. Int J Food Prop 21:1598–1607. https://doi.org/10.1080/10942912.2018.1503299

Acknowledgements

Jagjit Singh Chauhan (BSc hort), Smitra Orchards, village Rukhla, district Shimla, is thanked for many explanations, discussions and demonstrations. We are grateful to several apple farmers of Himachal Pradesh for providing valuable information.

Funding

Open Access funding enabled and organized by Projekt DEAL. There was no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Golombek, S.D., Blanke, M.M. Orchard management strategies to reduce bruises on apples in India: a review. Vegetos 35, 1–8 (2022). https://doi.org/10.1007/s42535-021-00326-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42535-021-00326-7