Abstract

Anaerobic digestion of the organic fraction from municipal solid waste offers the possibility of producing alternative energy from the produced biogas. Currently, there are eight biogas plants in Poland, where municipal waste is the feedstock for the fermentation process, but in the future, it is likely that much more will be built. For this reason, it is very important to characterise the sources of odour emissions in the plants in order to prevent complaints from residents of the region. The paper presents results of preliminary research in the field of identification and characteristic of odour sources in two selected biogas plants processing municipal waste in Poland: Wólka Rokicka-WR and Stalowa Wola-SW. The basic sources of odour were identified in relation to the biological treatment process and the pre-treatment of waste. The odour intensity and the concentration of odour and leading impurities were analysed. Results of the research of various technological solutions carried out in biogas plants were compared. The majority of big concentrations of odour and odorants are related to the operation of the biological part of both plants. The study revealed a strong dependency between the applied operation procedures, technological regime and the obtained measurement results. The highest correspondence between the results was obtained in both tested installations in the case of odour intensity and odour concentration, and in the case of concentration of NH3 and VOC.

Similar content being viewed by others

1 Introduction

Biogas plants processing municipal waste are environmentally friendly investments. Problems related to public health, land use, resource loss and climate change result in stringent rules on organic waste disposal, and more searches are being undertaken to increase reduction, recycling and recovery of useful materials from waste. A key element that is technically and economically viable for recovery is energy from organic waste fractions of municipal solid waste [1]. Municipal solid waste management is one of the most current challenges also from the point of view of sustainable economy for future generations [2,3,4]. Waste management is an extremely difficult undertaking due to the origin of the waste, which has a significant impact on the morphological composition of the waste [4,5,6,7]. In addition, food consumption and changes in chemical composition [4, 8] due to technological progress in the following areas in the food industry make the treatment of municipal solid waste a very important issue [9], which can be solved by various methods: thermal [4, 10] and more sustainable biological methods with energy recovery [4, 11].

Analysed biogas plants constitute a part of mechanical–biological municipal waste treatment installations and fulfil an important function in sustainable development of urban infrastructures [12]. There are a few different fermentation techniques. In order to accurately assess the most appropriate one, a thorough knowledge of the composition of the waste is essential since particular fractions have different degrees of degradation and biogas efficiency [13].

Eight biogas stations processing municipal waste currently function in the territory of Poland. They will certainly be more numerous in the future, because the investments perfectly correspond with the assumptions of the circular economy. The discussed plants particularly deal with processing biodegradable waste mechanically separated from the stream of mixed waste. The planned introduction of changes resulting from implementation acts to the act on waste [14] will favour the modification of the fermentation chamber feedstock to biodegradable waste from selective collection. Pursuant to the act of renewable energy sources on 20 February 2015 [15], a biogas plant processing this type of waste constitutes a renewable energy source.

Next to unquestioned benefits from waste management and production of biogas further transformed into electricity and heat energy, biogas installations also cause nuisances resulting from their functioning—odour emissions and emissions of process gasses containing abundant compounds: organic (volatile fatty acids, aldehydes, ketones, alcohols) and inorganic (hydrogen sulphide, ammonia) [16,17,18]. Such compounds become important pollution sources of urban odour nuisance that threatens public health and environmental safety [18,19,20]. Raised concerns over the implementation of new investments constituting a potential source of odours have been observed in many countries over the recent years [21].

A review of the literature allows to state that biogas installations have so far been studied mainly in terms of their energy efficiency. Much less attention was paid to odour problems. In addition, research work in this area focuses primarily on agricultural biogas plants and sludge fermentation [22] (in wet fermentation conditions). Much less attention was devoted to odour problems in anaerobic treatment of municipal waste. The process itself usually takes place under different conditions—using dry fermentation. Moreover, it is accompanied by completely different technological treatments as a part of pre-treatment of waste—also generating odour nuisance. Identification of these different odour sources and linking the concentration of odorants to technological operations deserve special attention [23].

The paper presents and analyses study results regarding the identification and characteristic of odour sources in plants equipped with a mechanical–biological municipal waste treatment installation, applying methane fermentation in the biological part.

2 Methodology

This paper covers pilot research at two biogas plants processing municipal waste, located in the towns of Wólka Rokicka and Stalowa Wola in the territory of Poland. Before commencing the research, local visions were performed at the plants, aimed at the identification of sources of odour emission, simultaneously constituting measurement sites during the implementation of the research [24]. In Fig. 1, there is the diagram presenting the steps of the procedure used in the study.

The research covered odour measurements including determination of odour intensity by means of sensory assessment on a 6-level scale (0–5) in accordance with Table 1 and measurement of the multitude of dilution of contaminated air with treated air (D/T) by means of a dynamic olfactometer Nasal Ranger. Based on read D/T parameters, odour concentrations were calculated at each of the study receptors.

The olfactometer Nasal Ranger permits the determination of the value of the dilution to threshold ratio (D/T), equivalent to the ratio of a stream of treated gas to contaminated gas. During the measurement, the contribution of the gas stream omitting filters embedded in the device should be gradually increased until the moment of obtaining perceptibility of odour. After the adaptation of the sense of smell to treated air (position BLANK), i.e. air passing through the filters entirely, available settings of the ratio of the stream of treated gas to contaminated gas should be selected in the following order: 500, 400, 300, 200, 100, 60, or 60, 30, 15, 7, 4, 2 (with transitional BLANK setting). The measurement is completed at the moment of determination of a difference in the evaluated odour and the BLANK setting. The D/T value provides the basis for the calculation of odour concentration (ou/m3) [25, 27].

The research covered also chemical tests including determination of odorants concentrations—measurement of ammonia (NH3) and volatile organic compounds (VOC) by means of a gas detector MultiRae Pro and measurement of hydrogen sulphide and dimethyl sulphate (DMS) by means of a portable gas chromatograph Photovac Voyager.

The measurement of ammonia and volatile organic compounds employed a portable gas detector MultiRAE Pro. The device permits simultaneous, continuous control of the analysed compounds. Concentrations are read in real time at any location. Measurement of hydrogen sulphide and dimethyl sulphate involves the application of a portable wireless gas chromatograph Photovac Voyager with embedded PID detector.

The range of operation of the devices and odour perceptibility thresholds for selected chemical compounds is presented in Table 2.

The studied objects were located in the Lubelskie Voivodeships (waste management plant in Wólka Rokicka-WR) and Podkarpackie Voivodeships (mechanical–biological waste treatment plant in Stalowa Wola-SW).

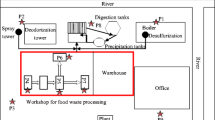

Both of the analysed installations are composed of a mechanical and biological part. The objective of the mechanical part is the separation of useful fractions (waste raw materials) from the stream of mixed municipal waste both in a mechanical and manual way. They are then directed to recovery processes. The so-called subscreen fraction is also sorted here. It mainly contains biodegradable waste, further directed to the fermentation process (after appropriate preparation).

Technological systems used at the analysed plants show both similarities and certain differences. At the plant in Wólka Rokicka, dewatering of fermented residue is not performed, because it is not required by the applied system of dry, static garage fermentation. Dewatering of fermented residue is performed at the plant in Stalowa Wola. This unitary procedure is required by the applied technology (semi-dry fermentation in dynamic conditions). Biological processing in anaerobic conditions in both of the analysed installations lasts approximately 21 days. At both plants, biogas produced in the fermentation process is captured, stored and treated for further use in energy engineering, fermented residue is subject to oxygen stabilisation, and green waste is subjected to composting. Both plants are equipped with deodorising installations in the form of a chemical scrubber and biofilter. Their task is to treat process air from halls where mechanical and biological processing of waste takes place. The plant in Wólka Rokicka additionally has an anti-odour barrier [31, 32].

3 Results and discussion

On 28 and 30 August 2018 measurement was performed at two biogas stations processing municipal waste, first in Wólka Rokicka, and then in Stalowa Wola. At both plants, the research covered similar measurement sites (the odour sources). Differences in their nomenclature result from the differences in the technological systems of both installations, and a bigger number of measurement sites in the case of the plant in Stalowa Wola—from a bigger number of identified sources of odour nuisance.

Tables 3 and 4 present measurement results from the waste treatment plant in Wólka Rokicka.

Tables 5 and 6 present measurement results from the mechanical–biological waste treatment plant in Stalowa Wola.

The analysis of obtained results (included in Tables 3, 4, 5, 6) shows that the biggest odour concentration at the plant in Wólka Rokicka occurs in the biological part at the fermentation chamber (WR 5)—during its opening. It is worth emphasising that the chambers are opened regularly (each time) after the completion of the fermentation process. It is required by the garage technology applied at the plant (dry fermentation in static conditions), where after the completion of anaerobic processing, fermented residue is unloaded and transported by loaders to the oxygen stabilisation yard. The aforementioned procedures, however, entail considerable odour emission. In the case of the plant in Stalowa Wola, the biggest odour concentrations also occur in the biological part of the installation—in the hall where dewatering of fermented residue takes place (SW 4) and in the fermented residue oxygen stabilisation chamber (SW 5). The fermentation technology applied at the plant (semi-dry, dynamic) does not require opening the fermentation chamber. The feedstock is supplied in a continuous manner (after homogenisation in the mixer), and then (after the completion of the fermentation process), it is dewatered.

The analysis of the obtained results of odorant concentrations shows that big concentrations of volatile organic compounds (VOC) are recorded both in the mechanical and biological part of the installations. In Wólka Rokicka, this concerns the preliminary waste processing hall (WR 2) and fermented residue oxygen stabilisation chamber (WR 5). Similar situation was observed in Stalowa Wola where big concentrations of VOC were met in the hall of feedstock preparation and storage for fermentation chambers (SW 3) and in the fermented residue oxygen stabilisation chamber (SW 5). At this plant, the fermented residue dewatering station is also an important source of VOC (SW 4). Big VOC concentration in the preliminary waste processing hall in Wólka Rokicka suggests the commencement of uncontrolled processes of decomposition of biodegradable substances contained in the supplied waste. Such a situation may result from excessively long storage of waste supplied to the plant. The biggest concentration of NH3 recorded in both analysed plants is shown in Fig. 2.

The biggest ammonia concentrations at both of the analysed plants are related to the operation of the biological part of the installations. In Wólka Rokicka, this concerns fermented residue oxygen stabilisation chambers (WR 3)—at the moment of their opening, and in Stalowa Wola—fermented residue dewatering station (SW 4).

The big concentrations of hydrogen sulphite at both of the analysed plants are related to post-fermentation residues. In Wólka Rokicka, this concerns fermentation chambers (WR 4)—after their opening—which is an expected result, and in Stalowa Wola—fermented residue oxygen stabilisation (SW 10)—which probably suggests irregularities in the performance of this technological process. Moreover, measurement sites where the biggest hydrogen sulphite concentrations were recorded proved to be biogas storage and processing objects in Wólka Rokicka (WR 8) and the hall of preparation and storage of feedstock for the fermentation process in Stalowa Wola (SW 3).

Results of odorant concentrations recorded on the surface of the biofilter at the mechanical–biological waste treatment plant in Stalowa Wola (SW 11)—big ammonia and hydrogen sulphite concentrations—deserve particular attention. They indicate the malfunctioning of the biofiltration installation and the need for exchanging the filter bed. Moreover, the high ammonia concentration (14 ppm) suggests ineffective operation of the chemical scrubber used for ammonia reduction (before biofilter)—as a part of process gases pre-treatment before biofiltration. This is confirmed by the results obtained in another biogas plant (in Jarocin) [24], where a similar level of ammonia concentration was recorded on the biofilter surface (13 ppm) when the chemical scrubber was not used as a part of the deodorisation installation (before biofilter). The presented results underline the significant role of a deodorant installation (both its type and proper functioning) among odour sources in municipal waste treatment plants. The biggest concentration of hydrogen sulphite and ammonia recorded in both analysed plants is shown in Figs. 3 and 4, respectively.

The highest correspondence between the presented results was obtained in both tested installations in the case of odour intensity and odour concentration, and in the case of concentration of NH3 and VOC what was illustrated in Figs. 5, 6, 7 and 8.

Data included in Table 2 are reflected in the observation of measurement points at the analysed plants and in the obtained concentration values of particular compounds. The odour perceptibility threshold of ammonia was exceeded in objects related to the fermentation process (in the garage technology), oxygen stabilisation, in the fermented residue dewatering station, and on the surface of the biofilter. The odour perceptibility threshold of hydrogen sulphate was exceeded in the fermentation chamber (at the moment of its opening for the purpose of unloading in the case of the garage technology), in the hall of preparation of feedstock for the fermentation process (in the case of the semi-dry dynamic technology), on the surface of the biofilter, and in the vicinity of biogas storage and processing objects. The odour perceptibility threshold of hydrogen sulphate was also exceeded at one of the plants in the case of second-degree fermented residue oxygen stabilisation, which is probably related to failure to observe the technological regime for the process. The odour perceptibility threshold of dimethyl sulphate was exceeded at many measurement sites, both in the mechanical and biological parts at both plants.

4 Conclusions

The paper presents the effects of local visions at two mechanical–biological waste treatment plants (with the methane fermentation process applied in the biological part), involving the identification of the basic sources of odour emissions. Based on own observations, as well as literature data, a methodology of analyses was determined, applied during the pilot research at two plants: in Wólka Rokicka and Stalowa Wola.

The innovation potential is the identification of odour sources in biogas installations processing municipal waste both in relation to the biological treatment process and the pre-treatment of waste. Since previous research concerned a different type of biogas installations, in this work, a special attention was paid to the relationship between the applied technological processes and operation procedures and the concentrations of odours and odorants. This is important in relation to both the proper designing of the installations and the prevention of odour nuisance during operation.

The odour sources were identified both in the mechanical and biological part of the analysed installations, as well as in places of storage of waste and waste raw materials, in the vicinity of objects related to biogas storage and processing, and deodorising installations. The majority of big concentrations of odour and odorants, however, are related to the operation of the biological part of both plants.

The study revealed a strong dependency between the applied fermentation technology and the obtained measurement results. The fermentation process conducted in static conditions (so-called garage technology) entails the necessity of periodical opening of fermentation chambers. Such a procedure is a significant source of odours. Dewatering of fermented residue in the semi-dry dynamic technology is accompanied by both big odour concentrations and considerable VOC and ammonia concentrations. Conducting the methane fermentation process based on the semi-dry dynamic method results in an additional source of emission in the form of dewatering of fermented residue. Biological processing itself is in this case less strenuous due to full airtight sealing (encapsulation) of the fermentation chamber.

The research also showed a significant dependency between the applied operation procedures and technological regime and the obtained measurement results. Irregularities related to the operation of deodorising installations are the cause of bigger than average concentrations of leading impurities. Lack of control over the time of storage of raw municipal waste can consequently lead to bigger than average VOC concentrations in the mechanical part of the MBT installation. Big hydrogen sulphate concentrations recorded during fermented residue oxygen stabilisation suggest errors in the conducting of the technological process.

The highest correspondence between the presented results was obtained in both tested installations in the case of odour intensity and odour concentration, and in the case of concentration of VOC and NH3.

The obtained results suggest that the applied technological solutions and operation procedures affect the emission of odorants from biogas plants processing municipal waste. They encourage further research for the purpose of more accurate determination of the dependency between the applied technologies, technological regime, but also meteorological conditions. The obtained results would offer a change for minimising odour emissions at the existing plants and would be helpful in designing new ones.

References

Tyagia VK, Fdez-Güelfo LA, Zhou Y, Álvarez-Gallego CJ, Romero Garcia LI, Ng WJ (2018) Anaerobic co-digestion of organic fraction of municipal solid waste (OFMSW): progress and challenges. Renew Sustain Energy Rev 93:380–399. https://doi.org/10.1016/j.rser.2018.05.051

Karak T, Bhagat RM, Bhattacharyya P (2012) Municipal solid waste generation, composition, and management: the world scenario. Crit Rev Environ Sci Technol 42:1509–1630. https://doi.org/10.1080/10643389.2011.569871

Pires A, Martinho G, Chang N-B (2011) Solid waste management in European countries: a review of systems analysis techniques. J Environ Manag 92:1033–1050. https://doi.org/10.1016/j.jenvman.2010.11.024

Migliori M, Catizzone E, Giordano G, Le Pera A, Sellaro M, Lista A, Zanardi G, Zoia L (2019) Pilot plant data assessment in anaerobic digestion of organic fraction of municipal waste solids. MDPI Processes 7:54. https://doi.org/10.3390/pr7010054

Khandelwal H, Dhar H, Thalla AK, Kumar S (2019) Application of life cycle assessment in municipal solid waste management: a worldwide critical review. J Clean Prod 209:630–654. https://doi.org/10.1016/j.jclepro.2018.10.233

Rodrigues AP, Fernandes ML, Rodrigues MFF, Bortoluzzi SC, Gouvea da Costa SE, Pinheiro de Lima E (2018) Developing criteria for performance assessment in municipal solid waste management. J Clean Prod 186:748–757. https://doi.org/10.1016/j.jclepro.2018.03.067

Eriksson O, Carlsson Reich M, Frostell B, Björklund A, Assefa G, Sundqvist J-O, Granath J, Baky A, Thyselius L (2005) Municipal solid waste management from a systems perspective. J Clean Prod 13:241–252. https://doi.org/10.1016/j.jclepro.2004.02.018

Baldino N, Gabriele D, Migliori M (2010) The influence of formulation and cooling rate on the rheological properties of chocolate. Eur Food Res Technol 6:821–828. https://doi.org/10.1007/s00217-010-1334-3

Hartmann H, Ahring BK (2006) Strategies for the anaerobic digestion of the organic fraction of municipal solid waste: an overview. Water Sci Technol 53:7–22. https://doi.org/10.2166/wst.2006.231

Lu X, Jordan B, Berge ND (2012) Thermal conversion of municipal solid waste via hydrothermal carbonization: comparison of carbonization products to products from current waste management techniques. Waste Manag 32:1353–1365. https://doi.org/10.1016/j.wasman.2012.02.012

Sosnowski P, Wieczorek A, Ledakowicz S (2003) Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid wastes. Adv Environ Res 7:609–616. https://doi.org/10.1016/S1093-0191(02)00049-7

Wiśniewska M, Lelicińska K (2018) The effectiveness of the mechanical treatment of municipal waste using the example of a selected installation, E3S web of conferences, 45. https://doi.org/10.1051/e3sconf/20184500102

Ayodele TR, Ogunjuyigbe ASO, Alao MA (2018) Economic and environmental assessment of electricity generation using biogas from organic fraction of municipal solid waste for the city of Ibadan, Nigeria. J Clean Prod 203:718–735. https://doi.org/10.1016/j.jclepro.2018.08.282

Ustawa z dnia 14 grudnia 2012 r. o odpadach (tekst jednolity Dz.U. z 2018, poz. 992 z późniejszymi zmianami) [act of 14 December 2012 on waste (consolidated text Journal of Laws of 2018, item 992 with further amendments)]

Ustawa z dnia 20 lutego 2015 r. o odnawialnych źródłach energii (tekst jednolity Dz. U. z 2018, poz. 2389) [act of 20 February 2015 on renewable energy sources (consolidated text Journal of Laws of 2018, item 2389)]

Orzi V, Cadena E, D’Imporzano G, Artola A, Davoli E, Crivelli M, Adani F (2010) Potential odour emission measurement in organic fraction of municipal solid waste during anaerobic digestion: relationship with process and biological stability parameters. Bioresour Technol 101:7330–7337. https://doi.org/10.1016/j.biortech.2010.04.098

Scaglia B, Orzi V, Artola A, Font X, Davoli E, Sanchez A, Adani F (2011) Bioresource Technology Odours and volatile organic compounds emitted from municipal solid waste at different stage of decomposition and relationship with biological stability. Bioresour Technol 102(7):4638–4645. https://doi.org/10.1016/j.biortech.2011.01.016

Cheng Z, Sun Z, Zhu S, Lou Z, Zhu N, Feng L (2019) The identification and health risk assessment of odor emissions from waste landfilling and composting. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2018.08.230

Capelli L, Sironi S, Del Rosso R, Céntola P, Rossi A, Austeri C (2011) Odour impact assessment in urban areas: case study of the city of Terni. Procedia Environ Sci 4:151–157. https://doi.org/10.1016/j.proenv.2011.03.018

De Feo G, De Gisi S, Williams ID (2013) Public perception of odour and environmental pollution attributed to MSW treatment and disposal facilities: a case study. Waste Manag 33(4):974–987. https://doi.org/10.1016/j.wasman.2012.12.016

Huimin Ch, Yan Z, Haobo T, Wenjing L, Hongtao W (2019) Parameter sensitivity to concentrations and transport distance of odours compounds from solid waste facilities. Sci Total Environ 651:2158–2165. https://doi.org/10.1016/j.scitotenv.2018.10.134

Chernicharo CAL, van Lier JB, Noyola A, Bressani Ribeiro T (2015) Anaerobic sewage tratment: state of the art, constraints and challenges. Rev Environ Sci Biotechnol 14:649–661. https://doi.org/10.1007/s11157-015-9377-3

Laor Y, Parker D, Page T (2014) Measurement, prediction, and monitoring of odor in the environment: a critical review. Rev Chem Eng 30:139–166. https://doi.org/10.1515/revce-2013-0026

Wiśniewska M, Kulig A, Lelicińska-Serafin K (2018) Identification and preliminary characteristics of odour sources in biogas plants processing municipal waste, SHS web of conferences, vol 57. https://doi.org/10.1051/shsconf/20185702016

Barczak R (2014) Analiza porównawcza olfaktometrii terenowej z innymi metodami badawczymi w ocenie oddziaływania zapachowego oczyszczalni ścieków, Rozprawa doktorska, Politechnika Warszawska (Comparative analysis of field olfactometry with other research methods in the assessment of the odour impact of sewage treatment plants. Dissertation, Warsaw University of Technology)

Kulig A (2004) Metody pomiarowo-obliczeniowe w ocenach oddziaływania na środowisko obiektów gospodarki komunalnej (Measurement and modelling based methods applicable in environmental impact assessment of municipal utilities), Warszawa

Szulczyński B, Dymerski T, Gębicki J, Namieśnik J (2018) Instrumental measurement of odour nuisance in city agglomeration using electronic nose, E3S web of conferences, vol 28. https://doi.org/10.1051/e3sconf/20182801012

Amoor JA, Hautala E (1983) Odour as an aid to chemical safety. JAT 3:272–290

Kośmider J, Mazur-Chrzanowska B, Wyszyński B (2012) Odory [odours]. Wydawnictwo Naukowe PWN, Warszawa

Eui-Chan J, Hyun-Keun S, Jae-Hwan S (2009) Emission characteristics and factors of selected odorous compounds at a wastewater treatment plant. Sensors 9:311–326. https://doi.org/10.3390/s90100311

Marshall of Lubelskie Voivodeship (2016) Decision no. RŚ-V.7222.2.2016.ILU for the waste management plant in Wólka Rokicka

Marshall of Podkarpackie Voivodeship (2016) Decision no. OS.I.7222.52.35.2017.MD for the waste management plant in Stalowa Wola

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wiśniewska, M., Kulig, A. & Lelicińska-Serafin, K. Comparative analysis of preliminary identification and characteristic of odour sources in biogas plants processing municipal waste in Poland. SN Appl. Sci. 1, 550 (2019). https://doi.org/10.1007/s42452-019-0534-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0534-0