Abstract

Purpose

This paper investigates experimentally the aerodynamic performance and forced response characteristics of two rotors (baseline and optimized design) under the influence of frequency mistuning effects.

Method

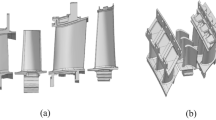

The optimized rotor blade was obtained by a multidisciplinary optimization framework, in which the aerodynamic performance and vibration characteristics were improved numerically. From steady-state aerodynamic measurements, the total pressure ratios at different operating conditions of the baseline and optimized blade were measured and validated. The optimized blade demonstrated a 0.5% improvement in total pressure ratio and a consistent shift of the performance curve towards higher mass flow rates. Ten modified cylinders were uniformly installed circumferentially in front of the rotor to serve as the excitation source, so the forced response of both baseline and optimized blade during the acceleration process was observed and measured by using the blade tip-timing technique.

Results

Blade tip-timing data analysis revealed that the rotor blades exhibited relatively strong responses at engine order (EO) 10 and 12, which was caused by the coupling effect of the upstream cylinder and downstream outlet stator. A detailed analysis and evaluation were required because they were found to be close to the design speed. Compared with the baseline blade, the maximum vibration amplitude decreased by 7.3% for EO = 10, and the amplitude magnification factor reduced from 1.56 to 1.47, approximately 5.7%. Similarly, for EO = 12, the maximum amplitude and amplitude magnification factor of optimized blade also decreased by 18% and 3.5% respectively. Furthermore, an improved fundamental mistuning model (FMM) was employed to predict the vibration amplitudes of all blades. The average predicted vibration amplitudes exhibited good agreement with the measured values in the deterministic analysis. Especially for the case of EO = 12, the relative error of the averaged amplitude was less than 1%. However, accurately predicting the maximum amplitude remains challenging due to the complex structural and aerodynamic coupling. The maximum relative error exceeded 16%.

Conclusion

Even so, both experimental and numerical results indicated that the amplitude magnification factor of optimized blade was smaller than that of the baseline.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during this study.

Abbreviations

- AMM:

-

Asymptotic mistuning model

- BTT:

-

Blade tip-timing

- CFD:

-

Computational fluid dynamics

- LE:

-

Leading edge

- TE:

-

Trailing edge

- EO:

-

Engine order

- HCF:

-

High cycle fatigue

- HB:

-

Harmonic balance

- FMM:

-

Fundamental mistuning model

- MP:

-

Measurement plane

- ND:

-

Nodal diameter

- OPR :

-

Once per revolution

- \({K}_{G}\) :

-

The correction coefficient of inlet boundary layer

- \({T}_{0}\) :

-

The environmental temperature

- \({P}_{0}\) :

-

The environmental pressure

- \({P}_{BS}\) :

-

The static pressure of inlet wall surface

- \(G\) :

-

The inlet mass flow rate

- \({\varphi }_{G}\) :

-

The flow coefficient

- \({\psi }_{P}\) :

-

The total pressure coefficient

- \(\pi \) :

-

Total Pressure ratio

- \({d}_{i,j}\) :

-

The blade displacement of blade i measured by probe j

- \(\mu \) :

-

The mean of Gaussian distribution of forced response

- \(\sigma \) :

-

The standard deviation of Gaussian distribution of forced response

- \(\omega \) :

-

The excitation frequency

- \([{\Lambda }^{^\circ }]\) :

-

Modal stiffness matrix

- \(\mathbf{D}\) :

-

Complex modal displacements expressed in physical coordinates

- \(\left[\text{E}\right]\) :

-

The discrete Fourier transformation matrix

- \({\mathbf{F}}_{\text{external}}\) :

-

The modal force vector due to external excitations

- \({\mathbf{F}}_{\text{vibration}}\) :

-

The modal force vector due to blade vibration

- \([\text{I}]\) :

-

Modal mass matrix

- \([\Delta \text{K}]\) :

-

Stiffness matrix perturbation due to mistuning

- \([\Delta \text{M}]\) :

-

Mass matrix perturbation due to mistuning

- \(\mathbf{Y}\) :

-

Complex modal displacements expressed in traveling wave coordinates

References

Li J, Aye-Addo N, Kormanik IN, Matthews D, Key N, Kielb R (2017) Mistuned higher-order mode forced response of an embedded compressor rotor: Part I—steady and unsteady aerodynamics. Turbo Expo: Power for Land, Sea, and Air 50930: V07BT36A021

Yang J, Zhang W (2023) Forced response analysis of the rotor blade rows with the ROM-based aeroelastic model. Aerosp Sci Technol 139:108366

Pinelli LBC, Ignesti M et al (2023) Forced response in a multi-stage aeroderivative axial compressor with acoustic excitations: Method validation with field data. Aerosp Sci Technol 138:108305

Pan T, Yan Z, Lu H, Li Q (2021) Numerical investigation on the forced vibration induced by the low engine order under boundary layer ingestion condition. Aerosp Sci Technol 115:106802

Xu K, Yan X, Du D, Sun W (2021) Control of mistuning level using hard coating for blisks based on mistuning identification technique. Aerosp Sci Technol 111:106526

Whitehead DS (1966) Effect of mistuning on the vibration of turbo-machine blades induced by wakes. J Eng Mech Eng Sci 8(1):15–21

Martel C, Sánchez-Álvarez JJ (2017) Maximum mistuning amplification of the forced response vibration of turbomachinery rotors in the presence of aerodynamic damping. J Sound Vibr 397(1):108–122

Martel C, Sánchez-Álvarez JJ (2018) Intentional mistuning effect in the forced response of rotors with aerodynamic damping. J Sound Vibr 433(1):212–229

Figaschewsky F, Kühhorn A (2015) Analysis of mistuned blade vibrations based on normally distributed blade individual natural frequencies. Turbo Expo Power Land Sea Air. https://doi.org/10.1115/GT2015-43121

Fulayter RD (2004) An experimental investigation of resonant response of mistuned fan and compressor rotors utilizing NSMS. PhD's Thesis, Purdue University, USA

Besem FM, Kielb RE, Galpin P, Zori L, Key NL (2016) Mistuned forced response predictions of an embedded rotor in a multistage compressor. J Turbomach 138(6):061003

Moffatt S, He L (2003) Blade forced response prediction for industrial gas turbines. Part 1: methodologies. Turbo Expo Power Land Sea Air 36878:407–414

W. Ning SM, Y. Li and R. G. Wells, et al (2003) Blade forced response prediction for industrial gas turbines. part 2: verification and application. Turbo Expo Power Land Sea Air 36878:415–422

He L, Ning W (1998) Efficient approach for analysis of unsteady viscous flows in turbomachines. AIAA J 36(11):2005–2012

Rahmati MT, He L, Wang DX, Li YS, Wells RG, Krishnababu SK (2012) Non-linear time and frequency domain methods for multi-row aeromechanical analysis. Turbo Expo Power Land Sea Air 44731:1473–1485

Frey C, Ashcroft G, Kersken HP, Voigt C (2014) A harmonic balance technique for multistage turbomachinery applications. Turbo Expo Power Land Sea Air. https://doi.org/10.1115/GT2014-25230

Marco E, Michel A, Jeschke P (2011) Analysis of rotor-stator-interaction and blade-to-blade measurements in a two stage axial flow compressor. J Turbomach 133:011027

Smith RN, William LMI, Nicole LK (2016) Considerations for measuring compressor aerodynamic excitations including rotor wakes and tip leakage flows. J Turbomach 138(3):031008

Fan C, Wu Y, Russhard P, Wang A (2020) An improved blade tip-timing method for vibration measurement of rotating blades during transient operating conditions. J Vib Eng Technol 1(2):1–10

Przysowa R (2014) The analysis of synchronous blade vibration using linear sine fitting. J KONBIN 30(1):5–19

Battiato G, Firrone CM, Berruti TM (2015) A benchmark for tip timing measurement of forced response in rotating bladed disks. Proceedings of the 11th International Conference on Engineering Vibration 1–13

Stargardter H (1977) Optical determination of rotating fan blade deflections. J Eng Gas Turbines Power 99(2):204–209

Georgiev V, Holík M, Kraus V, Krutina A, Kubín Z, Liška J, Poupa M (2011) The blade flutter measurement based on the blade tip timing method. International Conference on Systems 270–275

Freund O, Montgomery M, Mittelbach M, Seume JR (2014) Non-contact test set-up for aeroelasticity in a rotating turbomachine combining a novel acoustic excitation system with tip-timing. Meas Sci Technol 25(3):1–13

McCarty PE, Thompson JW (1980) Performance evaluation of a prototype noninterference technique for measurement of turbine engine compressor blade stress. Arnold Engineering development Center, USA AEDC-TR-80-5

Baumgartner M, Kameier F, Hourmouziadis J (1995) Non-engine order blade vibration in a high pressure compressor. Twelfth International Symposium on Airbreathing Engines

Holzinger F, Wartzek F, Jüngst M, Schiffer HP, Leichtfuss S (2016) Self-excited blade vibration experimentally investigated in transonic compressors: rotating instabilities and flutter. J Turbomach 138(4):1–12

García I, Zubia J, Durana G, Aldabaldetreku G, Illarramendi MA, Villatoro J (2015) Optical fiber sensors for aircraft structural health monitoring. J Sens 15(7):15494–15519

Li J, Aye-Addo N, Kielb R, Key N (2018) Mistuned higher-order mode forced response of an embedded compressor rotor—part II: mistuned forced response prediction. J Turbomach 140(3):031006

Hegde S, Mao Z, Pan T, Zori L, Campregher R, Kielb R (2019) Separation of up and downstream forced response excitations of an embedded compressor rotor. J Turbomach 141(9):091013

Miura T, Sakai N, Kanazawa N, Nakayama K (2021) Forced response excitation due to the stator vanes of two and three compressor stages away. J Eng Gas Turbines Power 143(11):111018

Fan C, Adjei RA, Ye Z, Cui J (2023) Investigation on aeroelastic characteristics of mistuned low-speed axial compressor rotor: numerical methodology and optimization. Aerosp Sci Technol 143:108735

Kadhem AA, Wahab NIA, Aris I, Jasni J, Abdalla AN (2017) Computational techniques for assessing the reliability and sustainability of electrical power systems: a review. Renew Sustain Ener Rev 80:1175–1186

Navid A, Khalilarya S, Abbasi M (2018) Diesel engine optimization with multi-objective performance characteristics by non-evolutionary Nelder-Mead algorithm: Sobol sequence and Latin hypercube sampling methods comparison in DoE process. J Fuel 228:349–367

Ebbs-Picken T, Da Silva CM, Amon CH (2023) Design optimization methodologies applied to battery thermal management systems: a review. J Energ Storag 67:107460

Feiner DM, Griffin JH (2002) A fundamental model of mistuning for a single family of modes. J Turbomach 124(4):597–605

Deb K, Jain H (2014) An evolutionary many-objective optimization algorithm using reference-point-based nondominated sorting approach, Part I: solving problems with box constraints. IEEE Trans Evol Comput 18(4):577–601

Blair GP, Cahoon WM (2006) Special investigation: design of an intake bellmouth. Race Engine Technol 17:34–41

Bell S (2001) A beginner's guide to uncertainty of measurement. Measurement Good Practice Guide No. 11 (Issue 2)

Paul ARURR, Jain A (2011) A novel calibration algorithm for five-hole pressure probe. Int J Eng Sci Technol. https://doi.org/10.4314/ijest.v3i2.68136

Fan C, Wu Y, Russhard P, Ruan C, Wang A (2020) A blade tip-timing method without once-per-revolution sensor for blade vibration measurement in gas turbine engines. Trans Can Soc Mech Eng 1(2):1–12

Russhard P (2010) Development of a blade tip timing based engine health monitoring system. PhD's Thesis, University of Manchester, UK

Jousselin OR, P.; Bonello, P. (2012) A method for establishing the uncertainty levels for aero-engine blade tip amplitudes extracted from blade tip timing data. In Proceedings of the 10th International Conference on Vibrations in Rotating Machinery 211–220

Mohamed ME, Bonello P, Russhard P (2020) Determination of simultaneous steady-state movements using blade tip timing data. J Vib Acoust 142(1):011017

Joung KK, Kang SC, Paeng KS, Park NG, Choi HJ, You YJ, Von Flotow A (2006) Analysis of vibration of the turbine blades using non-intrusive stress measurement system. In Asme Power Confer 42053:391–397

Przysowa R, Russhard P (2019) Non-contact measurement of blade vibration in an axial compressor. J Sens 20(68):1–18

Zucca S, Di Maio D, Ewins DJ (2012) Measuring the performance of underplatform dampers for turbine blades by rotating laser Doppler vibrometer. Mech Syst Signal Process 32(1):269–281

Murray WL III, Key NL (2015) Experimental investigation of a forced-response condition in a multistage compressor. J Propul Power 31(5):1320–1329

T Miyakozawa RE Kielb KC Hall 2009 The effects of aerodynamic asymmetric perturbations on forced response of bladed disks 131 4 1 12

Acknowledgements

The first author would like to thank Shanghai Jiao Tong University for supporting this research in blade tip-timing measurement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fan, C., Wu, Y., Adjei, R.A. et al. Experimental Investigation on Forced Response of Mistuned Axial Compressor Rotors. J. Vib. Eng. Technol. 13, 75 (2025). https://doi.org/10.1007/s42417-024-01633-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42417-024-01633-4