Abstract

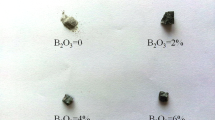

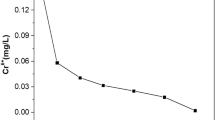

The effects of basicities and equilibrium temperatures on the enrichment of chromium in different mineral phases of synthesized argon–oxygen decarburization slags were investigated to understand the Cr concentrating behavior into Mg(Cr,Al)2O4 spinel phase and to determine the leaching stability of Cr-containing slag. The results showed that when the basicity decreased from 1.0 to 0.6 and temperatures decreased from 1600 to 800 °C, the Cr content of amorphous phase and crystalline phase gradually decreased, with a subsequent increase in the Cr content of spinel phase. The range of Cr enrichment in spinel of slags S1, S2, and S3 is 92.03–96.89, 91.63–96.36, and 90.67–95.42, respectively. The mass fraction and the size of spinel increased with the decreasing equilibrium temperatures, and the Cr leaching values decreased simultaneously. Therefore, the trend of the amount of Cr-related ions in the leachate was consistent with the trend of Cr in the amorphous phase, diopside, and akermanite. The results suggest that the lower basicity and equilibrium temperatures could be conducive to stabilizing Cr into spinel phase to minimize Cr leaching into the environment.

Similar content being viewed by others

References

J. Guo, Y. Bao, M. Wang, Waste Manag. 78 (2018) 318–330.

Z. Huawei, H. Xin, Resour. Conserv. Recycl. 55 (2011) 745–754.

S. Zhang, Y. Zhang, Z. Qu, J. Alloy. Compd. 805 (2019) 1106–1116.

S. Zhang, Y. Zhang, Z. Qu, Ceram. Int. 45 (2019) 11216–11225.

K. Cui, Y. Zhang, T. Fu, S. Hussain, T.S. Algarni, J. Wang, X. Zhang, S. Ali, Coatings 11 (2021) 234.

S. Zhang, Y. Zhang, T. Wu, Ceram. Int. 44 (2018) 10119–10129.

Z. Wang, I. Sohn, Ceram. Int. 46 (2020) 903–912.

S. Kawanishi, T. Yoshikawa, ISIJ Int. 60 (2020) 2123–2128.

X. He, L. Wang, K. Chou, Ceram. Int. 47 (2021) 12476–12482.

M. Leuchtenmüller, J. Antrekowitsch, S. Steinlechner, Metall. Mater. Trans. B 50 (2019) 2221–2228.

S. Zhang, Y. Zhang, J. Gao, Z. Qu, Z. Zhang, J. Eur. Ceram. Soc. 39 (2019) 4283–4291.

W. Song, J. Cao, Z. Wang, X. Geng, J. Lu, J. Hazard. Mater. 403 (2021) 123598.

Z. Wang, I. Sohn, J. Am. Ceram. Soc. 103 (2020) 6012–6024.

G. Kim, I. Sohn, J. Hazard. Mater. 359 (2018) 174–185.

Y. Lin, B. Yan, T. Fabritius, Q. Shu, Metall. Mater. Trans. B 51 (2020) 763–775.

Q. Zhao, C. Liu, L. Cao, M. Jiang, B. Li, H. Saxén, R. Zevenhoven, ISIJ Int. 59 (2019) 583–589.

D. Mombelli, S. Barella, A. Gruttadauria, C. Mapelli, G.L. Saout, E. Garcia-Diaz, Appl. Sci. 9 (2019) 121.

F. Jiang, Y. Li, L. Zhao, D. Cang, Appl. Clay Sci. 143 (2017) 199–204.

F. Engström, D. Adolfsson, Q. Yang, C. Samuelsson, B. Björkman, Steel Res. Int. 81 (2010) 362–371.

L. Wang, S. Seetharaman, Metall. Mater. Trans. B 41 (2010) 946–954.

S. Mostafaee, A study of EAF high-chromium stainless steelmaking slags characteristics and foamability, KTH Royal Institute of Technology, Stockholm, Sweden, 2011.

G.J. Albertsson, L. Teng, B. Björkman, Miner. Process. Extr. Metall. 123 (2014) 116–122.

L.H. Cao, C.J. Liu, Q. Zhao, M.F. Jiang, J. Iron Steel Res. Int. 24 (2017) 258–265.

Q. Zhao, C. Liu, L. Cao, X. Zheng, M. Jiang, Minerals 8 (2018) 445.

J. Yang, B. Liu, S. Zhang, A.A. Volinsky, J. Alloy. Compd. 688 (2016) 709–714.

S.G. Zhang, J. Yang, B. Liu, D.A. Pan, C.L. Wu, A.A. Volinsky, J. Iron Steel Res. Int. 23 (2016) 220–224.

C. Zou, J. Cao, M. Zhao, Z. Wang, J. Lu, J. Eur. Ceram. Soc. 39 (2019) 4979–4987.

J. Ma, Y. Shi, H. Zhang, S. Ouyang, L. Deng, H. Chen, M. Zhao, Y. Du, Mater. Chem. Phys. 261 (2021) 124213.

W. Li, X. Xue, Ironmak. Steelmak. 45 (2018) 929–936.

Y. Shi, B.W. Li, M. Zhao, M.X. Zhang, J. Am. Ceram. Soc. 101 (2018) 3968–3978.

M. Nath, P. Kumar, S. Song, Y. Li, H.S. Tripathi, Ceram. Int. 45 (2019) 12411–12416.

Y. Sugimoto, S. Kitamura, K. Maeda, Refractories 58 (2006) 133–142.

R.G. Burns, Mineralogical applications of crystal field theory, Cambridge University Press, Cambridge, UK, 1993.

B. Warren, W. Lawrence Bragg, Zeitschrift für Kristallographie-Crystalline Materials 69 (1929) 168–193.

M. Kimata, N. Ii, N. Jb. Miner. Abh. 144 (1982) 254–267.

V. Simonet, F. Hippert, M. Audier, R. Bellissent, Phys. B 315 (2002) 187–200.

Acknowledgements

This work was supported by the National Key R&D Program of China (2019YFC1905701) and the National Natural Science Foundation of China (U1960201).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Sw., Zhang, Yl. & Zhang, S. Chromium enrichment in different crystalline phases of Cr-containing slag under various basicities and equilibrium temperatures. J. Iron Steel Res. Int. 29, 1412–1422 (2022). https://doi.org/10.1007/s42243-021-00737-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00737-5