Abstract

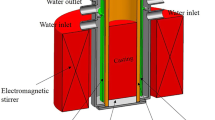

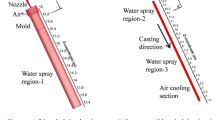

A 3D/2D hybrid multi-physical-field mathematical model, which takes into consideration the thermosolutal buoyance, was developed to predict the macrosegregation of gear steel 20CrMnTi continuously cast by a curved billet caster with size of 160 mm × 160 mm, and investigated the effect of final electromagnetic stirring (F-EMS) on the fluid flow, heat transfer and solute distribution in the liquid core of continuously cast steel. The results show that the application of F-EMS eliminates the effect of thermosolutal buoyancy on the asymmetric distribution of carbon concentration in the cross section of billet and accelerates the final solidification of resident molten steel in the liquid core of strand, but promotes the negative carbon segregation near the billet center. When the gear steel 20CrMnTi is cast at the temperature of 1803 K and speed of 1.7 m/min, the solidification end advances forward from 9.84 to 9.72 m, and center carbon segregation ratio of billet decreases from 1.24 to 1.17 with the increase in current density of F-EMS from 0 to 350 A.

Similar content being viewed by others

References

M.C. Flemings, ISIJ Int. 40 (2000) 833–841.

G. Krauss, Metall. Mater. Trans. B 34 (2003) 781–792.

A. Ludwig, M. Wu, A. Kharicha, Metall. Mater. Trans. A 46 (2015) 4854–4867.

M.C. Flemings, G.E. Nereo, Trans. Met. Soc. AIME 239 (1967) 1449–1461.

M.C. Flemings, R. Mehrabian, G.E. Nereo, Trans. Met. Soc. AIME 242 (1968) 41–49.

M.C. Flemings, G.E. Nereo, Trans. Met. Soc. AIME 242 (1968) 50–55.

V. Ludlow, A. Normanton, A. Anderson, M. Thiele, J. Ciriza, J. Laraudogoitia, W. van der Knoop, Ironmak. Steelmak. 32 (2005) 68–74.

K. Ayata, H. Mori, K. Taniguchi, H. Matsuda, ISIJ Int. 35 (1995) 680–685.

P. Sivesson, C.M. Raihle, J. Konttinen, Mater. Sci. Eng. A 173 (1993) 299–304.

P. Sivesson, G. Hällén, B. Widell, Ironmak. Steelmak. 25 (1998) 239–246.

C.H. Yim, J.K. Park, B.D. You, S.M. Yang, ISIJ Int. 36 (1996) S231-S234.

S. Luo, M.Y. Zhu, C. Ji, Y. Chen, Ironmak. Steelmak. 37 (2010) 140–146.

S. Luo, M. Zhu. C. Ji, Ironmak. Steelmak. 41 (2014) 233–240.

D.B. Jiang, W.L. Wang, S. Luo, C. Ji, M.Y. Zhu, Int. J. Heat Mass Transfer 122 (2018) 315–323.

R. Guan, C. Ji, C.H. Wu, M.Y. Zhu, Int. J. Heat Mass Transfer 141 (2019) 503–516.

K. Ayata, T. Mori, T. Fujimoto, T. Ohnishi, I. Wakasugi, Trans. ISIJ 24 (1984) 931–939.

S. Luo, F.Y. Piao, D.B. Jiang, W.W. Wang, M.Y. Zhu, J. Iron Steel Res. Int 21 (2014) 51–55.

H.B. Sun, L.J. Li, J.H. Wang, X.W. Cheng, F. Zhou, Ironmak. Steelmak. 45 (2018) 708–713.

H. Mizukami, M. Komatsu, T. Kitagawa, K. Kawakami, Trans. ISIJ 24 (1984) 923–930.

K.I. Suzuki, Y. Shinsho, K. Murata, K. Nakanishi, M. Kodama, Trans. ISIJ 24 (1984) 940–949.

K.S. Oh, Y.W. Chang, ISIJ Int. 35 (1995) 866–875.

J.C. Li, B.F. Wang, Y.L. Ma, J.Z. Cui, Mater. Sci. Eng. A 425 (2006) 201–204.

W.D. Du, K. Wang, C.J. Song, H.G. Li, M.W. Jiang, Q.J. Zhai, P. Zhao, Ironmak. Steelmak. 35 (2008) 153–156.

Y. Wan, M.H. Li, L.J. Chen, Y.C. Wu, J. Li, H.B. Pan, W. Zhong, Metals 9 (2019) 665.

D.B. Jiang, M.Y. Zhu, Steel Res. Int. 86 (2015) 993–1003.

Q.P. Dong, J.M. Zhang, Q. Liu, Y.B. Yin, Steel Res. Int. 88 (2017) 1700067.

W.X. Jiang, M.J. Long, T. Liu, D.F. Chen, H.B. Chen, J.S. Cao, H.L. Fan, S. Yu, H.M. Duan, JOM 70 (2018) 2059–2064.

H. Sun, J. Zhang, Metall. Mater. Trans. B 45 (2014) 1133–1149.

H. Sun, L. Li, X. Cheng, W. Qiu, Z. Liu, L. Zeng, Ironmak. Steelmak. 42 (2015) 439–449.

H. Sun, L. Li, D. Ye, X. Wu, Metall. Mater. Trans. B 49 (2018) 1909–1918.

D. Jiang, M. Zhu, Metall. Mater. Trans. B 47 (2016) 3446–3458.

D. Jiang, M. Zhu, Metall. Mater. Trans. B 48 (2017) 444–455.

Y.M. Won, B.G. Thomas, Metall. Mater. Trans. A 32 (2001) 1755–1767.

B.E. Launder, D.B. Spalding, Comput. Method. Appl. M 3 (1974) 269–289.

S. Luo, M.Y. Zhu, S. Louhenkilpi, ISIJ Int. 52 (2012) 823–830.

W.J. Zhang, S. Luo, Y. Chen, W.L. Wang, M.Y. Zhu, Metals 9 (2019) 66.

Acknowledgements

The authors gratefully acknowledge the financial support of the National Key Research and Development Plan (Nos. 2017YFB0304100 and 2016YFB0300105), National Natural Science Foundation of China (Nos. 51674072, 51704151, and 51804067) and Fundamental Research Funds for the Central Universities (Nos. N182504014, N170708020, and N172503013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, Sk., Luo, S., Zhang, Wj. et al. Numerical simulation of macrosegregation in continuously cast gear steel 20CrMnTi with final electromagnetic stirring. J. Iron Steel Res. Int. 28, 424–436 (2021). https://doi.org/10.1007/s42243-020-00490-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00490-1