Abstract

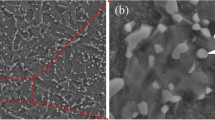

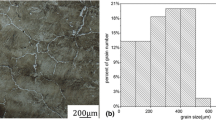

H13-mod steel developed after optimizing the composition and heat treatment process exhibits good hardness and impact toughness and can be used as a shield machine hob. Based on the Avrami equation, the dynamic recrystallization (DRX) behaviour of H13-mod steel during hot compression was studied in the temperature of 900–1150 °C and strain rate ranges of 0.01–10 s−1. A DRX model and finite element software were used to study DRX behaviour of H13-mod steel. Significant DRX was found at both low and high strain rates. Electron backscatter diffraction and optical microscopy analyses found different DRX nucleation mechanisms at low and high strain rates under different deformations. At a low strain rate, the nucleation was dominated by the strain-induced grain boundary migration, whereas the subgrain coalescence mechanism was dominant at a high strain rate. Moreover, dynamic recovery occurred in both processes. In addition, it was easier to obtain small and uniform equiaxed grains at high strain rates than at low strain rates.

Similar content being viewed by others

References

J.J. Jonas, T. Sakai, Acta Metall. 32 (1984) 189–209.

C.M. Li, Y. Liu, Y.B. Tan, F. Zhao, Metals 8 (2018) 846.

S.L. Wang, M.X. Zhang, H.C. Wu, B. Yang, Mater. Charact. 118 (2016) 92–101.

M. Irani, M. Joun, Comput. Mater. Sci. 142 (2018) 178–184.

C.M. Li, Y.B. Tan, F. Zhao, Mater. Res. Express 6 (2019) 026578.

Z. Wan, Y. Sun, L. Hu, H. Yu, Mater. Des. 122 (2017) 11–20.

Y.C. Lin, L.T. Li, Y.C. Xia, Y.Q. Jiang, J. Alloy. Compd. 550 (2013) 438–445.

Y. Yang, Z. Xie, Z. Zhang, X. Li, Q. Wang, Y. Zhang, Mater. Sci. Eng. A 615 (2014) 183–190.

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, J.J. Jonas, Prog. Mater. Sci. 60 (2014) 130–207.

K. Huang, R.E. Logé, Mater. Des. 111 (2016) 548–574.

Z. Yanushkevich, A. Belyakov, R. Kaibyshev, Acta Mater. 82 (2015) 244–254.

H. Yamagata, Y. Ohuchida, N. Saito, M. Otsuka, Scripta Mater. 45 (2001) 1055–1061.

P. Cizek, Acta Mater. 106 (2016) 129–143.

Q.Y. Zhao, F. Yang, R. Torrens, L. Bolzoni, Mater. Des. 169 (2019) 107682.

A. Dehghan-Manshadi, M.R. Barnett, P.D. Hodgson, Mater. Sci. Eng. A 485 (2008) 664–672.

F. Zhu, H. Wu, S. Lee, M. Lin, D. Chen, Mater. Sci. Eng. A 640 (2015) 385–393.

Y.C. Lin, X. Wu, X. Chen, J. Chen, D. Wen, J. Zhang, L. Li, J. Alloy. Compd. 640 (2015) 101–113.

D. He, Y.C. Lin, J. Chen, D. Chen, J. Huang, Y. Tang, M. Chen, Mater. Des. 154 (2018) 51–62.

A. Momeni, K. Dehghani, Mater. Sci. Eng. A 527 (2010) 5467–5473.

Y.C. Lin, J. Huang, D. He, X. Zhang, Q. Wu, L. Wang, C. Chen, K. Zhou, J. Alloy. Compd. 795 (2019) 471–482.

A. Saboori, M. Pavese, S. Biamino, P. Fino, M. Lombardi, J. Alloy. Compd. 757 (2018) 1–7.

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, M. He, Mater. Des. 57 (2014) 568–577.

H. Wang, D. Liu, J.G. Wang, H.P. Wang, Y. Hu, H.D. Rao, J. Iron Steel Res. Int. 27 (2020) 807–819.

Z.Q. Yang, Z.D. Liu, X.K. He, S.B. Qiao, C.S. Xie, J. Iron Steel Res. Int. 25 (2018) 1189–1197.

L. Cheng, H. Chang, B. Tang, H. Kou, J. Li, J. Alloy. Compd. 552 (2013) 363–369.

R. Ding, Z.X. Guo, Acta Mater. 49 (2001) 3163–3175.

E.I. Galindo-Nava, P.E.J. Rivera-Diaz-del-Castillo, Int. J. Plast. 47 (2013) 202–221.

P.D. Hodgson, R.K. Gibbs, ISIJ Int. 32 (1992) 1329–1338.

L.X. Kong, P.D. Hodgson, B. Wang, J. Mater. Process. Technol. 89–90 (1999) 44–50.

A. Laasraoui, J.J. Jonas, ISIJ Int. 31 (1991) 95–105.

H. Sun, Y. Sun, R. Zhang, M. Wang, R. Tang, Z. Zhou, Mater. Des. 64 (2014) 374–380.

B. Carlsson, J. Mater. Process. Technol. 73 (1998) 1–6.

S. Guo, D. Li, H. Pen, Q. Guo, J. Hu, J. Nucl. Mater. 410 (2011) 52–58.

A.M.S. Hamouda, J. Mater. Process. Technol. 124 (2002) 209–215.

R.L. Goetz, S.L. Semiatin, J. Mater. Eng. Perform. 10 (2001) 710–717.

M.C. Mataya, V.E. Sackschewsky, Metall. Mater. Trans. A 25 (1994) 2737–2752.

K.A. Babu, S. Mandal, C.N. Athreya, B. Shakthipriya, V.S. Sarma, Mater. Des. 115 (2017) 262–275.

G. Xiao, L.X. Li, T. Ye, Chin. J. Nonferrous Met. 24 (2014) 1268–1274.

X.M. He, Force-saving forming method and microstructure controlling of 1Cr12Ni3Mo2VN extra-large blade of nuclear power, China Academy of Machinery Science and Technology, Beijing, China, 2017.

J. Li, C. Gong, L. Chen, H. Zuo, Y. Liu, Acta Metall. Sin. 50 (2014) 1063–1070.

C.M. Sellars, G.J. Davies, Hot Working and Forming Processes: Proceedings of an International Conference on Hot Working and Forming Processes, The Society, London, UK, 1980.

M. Zhao, L. Huang, R. Zeng, D. Wen, H. Su, J. Li, Mater. Sci. Eng. A 765 (2019) 138300.

A. Belyakov, H. Miura, T. Sakai, Mater. Sci. Eng. A 255 (1998) 139–147.

E. Bruenger, X. Wang, G.B. Gottstein, Scripta Mater. 38 (1998) 1843–1849.

Y.S. Hao, J. Li, W.C. Liu, W.A. Zhang, Z.Y. Liu. J. Iron Steel Res. Int. 26 (2019) 1080–1087.

M.R. Rokni, A. Zarei-Hanzaki, H.R. Abedi, Mater. Sci. Eng. A 532 (2012) 593–600.

H.R. Abedi, A.Z. Hanzaki, Z. Liu, R. Xin, N. Haghdadi, P.D. Hodgson, Mater. Des. 114 (2017) 55–64.

B. Eghbali, Mater. Sci. Eng. A 527 (2010) 3402-3406.

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant No. 51571066) and Guizhou Science and Technology Project (Grant Nos. 20165654 and 20162326).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Cm., Tan, Yb. & Zhao, F. Dynamic recrystallization behaviour of H13-mod steel. J. Iron Steel Res. Int. 27, 1073–1086 (2020). https://doi.org/10.1007/s42243-020-00462-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00462-5