Abstract

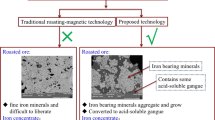

A fluidized-bed magnetizing roasting–magnetic separation process was selected to treat this type of material. Phase transformations and microstructural changes in the product resulting from magnetizing roasting under different reducing gases (CO, H2, CO + H2) were clarified by vibrating sample magnetometry, X-ray diffraction, scanning electron microscopy, and energy-dispersive X-ray spectroscopy. The results indicated that the conversion ratio and saturation magnetization of samples roasted in a mixed gas of CO and H2 were higher than those of samples produced under CO or H2 alone. This indicated that synergy of the combined CO and H2 gas had a positive effect on the fluidized-bed magnetizing roasting process. The mechanism and kinetics of the improved magnetizing roasting of a siderite–hematite iron ore mixture under this synergistic CO–H2 system were investigated under isothermal conditions. The results indicated that the apparent activation energies of the reactions of the iron oxides decreased from 37.7 and 17.9 to 15.9 kJ/mol when the roasting atmosphere was changed from pure H2 or CO to a gas mixture of CO and H2, respectively. The mixed CO–H2 gas promoted the conversion ratio of hematite and siderite to magnetite, thereby improving the conversion ratio in the fluidized-bed magnetizing roasting process.

Similar content being viewed by others

References

V.P. Ponomar, N.O. Dudchenko, A.B. Brik, Miner. Eng. 122 (2018) 277–284.

E. Tekin, B. Varol, Z. Ayan, M. Satir, N. Jb. Miner. Monat. 2002 (2002) 289–318.

S.N. Rychagov, A.A. Nuzhdaev, I.I. Stepanov, Geochem. Int. 52 (2014) 131–143.

O.B. Apukhtina, V.S. Kamenetsky, K. Ehrig, M.B. Kamenetsky, R. Maas, J. Thompson, J. McPhie, C.L. Ciobanu, N.J. Cook, Econ. Geol. 112 (2017) 1531–1542.

S.J. Bai, M. Wu, C. Lü, S.M. Wen, J. Iron Steel Res. Int. 23 (2016) 891–899.

L. Tankosić, P. Tančić, S. Sredić, Z. Nedić, Minerals 8 (2018) 119.

T. Brachaniec, A. Wieczorek, Carnets Geol. 16 (2016) 349–354.

S. Song, S. Lu, A. Lopez-Valdivieso, Miner. Eng. 15 (2002) 415–422.

D.N. Obiora, M.N. Ossai, F.N. Okeke, A.I. Oha, J. Geol. Soc. India 88 (2016) 654–667.

O.V. Avchenko, I.L. Zhulanova, K.V. Chudnenko, A.A. Karabtsov, Russ. J. Pac. Geol. 12 (2018) 174–189.

T. Umadevi, K. Abhishek, R. Sah, K. Marutiram, Miner. Metall. Process. 35 (2018) 35–45.

F. Lagroix, Y. Guyodo, Front. Earth Sci. 5 (2017) 61.

H.Q. Hao, L.X. Li, Z.T. Yuan, J.T. Liu, J. Mol. Liq. 254 (2018) 349–356.

S.J. Bai, S.M. Wen, D.W. Liu, W.B. Zhang, Y.J. Xian, ISIJ Int. 51 (2011) 1601–1607.

Y.H. Zhang, J. Zhang, Y.J. Zhang, H.C. Li, P. Zhao, J. Wuhan Univ. Technol. 35 (2013) No.3, 116–119.

T.J. Chun, D.Q. Zhu, J. Pan, Miner. Process. Extr. Metall. Rev. 36 (2015) 223–226.

C. Li, H.H. Sun, J. Bai, L.T. Li, J. Hazard. Mater. 174 (2010) 71–77.

Z.J. Su, Y.B. Zhang, J. Chen, B.B. Liu, G.H. Li, T. Jiang, Sep. Sci. Technol. 51 (2016) 1900–1912.

K. Zhang, X.L. Chen, W.C. Guo, H.J. Luo, Z.J. Gong, B.W. Li, W.F. Wu, PLoS One 12 (2017) e0186274.

G.G.O.O. Uwadiale, Miner. Process. Extr. Metall. Rev. 11 (1992) 1–19.

J.W. Yu, Y.X. Han, Y.J. Li, P. Gao, Int. J. Miner. Process. 168 (2017) 102–108.

V.I. Matyukhin, S.G. Melamud, V.V. Shatsillo, O.V. Matyukhin, A.V. Matyukhina, Izvestiya Vysshikh Uchebnykh Zavedenij. Chernaya Metallurgiya 58 (2015) 652–657.

V.I. Matyukhin, V.V. Shatsillo, A.V. Kuznetsov, D.V. Rybakin, A.F. Krokhalev, Metallurgist 61 (2017) 3–11.

X.H. Wang, Z.H. Wang, J. Liu, F.P. Xiang, J.H. Zhou, K.F. Cen, J. Zhejiang Univ. Eng. Sci. 47 (2013) 675–679.

R.F. Wei, S.H. Feng, H.M. Long, J.X. Li, Z.S. Yuan, D.Q. Cang, C.B. Xu, Energy 140 (2017) 406–414.

J. Tang, M.S. Chu, Z.W. Ying, F. Li, C. Feng, Z.G. Liu, Metals 7 (2017) 153.

W. Li, G.Q. Fu, M.S. Chu, M.Y. Zhu, J. Iron Steel Res. Int. 24 (2017) 34–42.

Y.L. Sui, Y.F. Guo, T. Jiang, X.L. Xie, S. Wang, F.Q. Zheng, Int. J. Miner. Metall. Mater. 24 (2017) 10–17.

S.Y. Luo, C.J. Yi, Y.M. Zhou, Renew. Energ. 36 (2011) 3332–3336.

Y.L. Sui, Y.F. Guo, T. Jiang, G.Z. Qiu, J. Alloy. Compd. 706 (2017) 546–553.

Y. Li, Basic research on gas-based reduction of Indonesia ironsand oxidized pellets, University of Science and Technology Beijing, Beijing, China, 2015.

H. Ono-Nakazato, T. Yonezawa, T. Usui, ISIJ Int. 43 (2003) 1502–1511.

Z.Q. Guo, D.Q. Zhu, J. Pan, F. Zhang, Minerals 7 (2017) 98.

Z.Q. Guo, D.Q. Zhu, J. Pan, C.C. Yang, Powder Technol. 329 (2018) 55–64.

Acknowledgements

The authors would like to express their thanks to the National Natural Science Foundation of China (No. 5157041410) for the financial support of this research.

Author information

Authors and Affiliations

Contributions

Qiang Zhao conducted the experimental work and prepared the manuscript; Ji-lai Xue directed the research work and modified the manuscript; Wen Chen participated in the design of the research work at different stages.

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Q., Xue, Jl. & Chen, W. Mechanism of improved magnetizing roasting of siderite–hematite iron ore using a synergistic CO–H2 mixture. J. Iron Steel Res. Int. 27, 12–21 (2020). https://doi.org/10.1007/s42243-019-00242-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00242-w