Abstract

Wearable piezoresitive sensors have exhibited promising potentials for applications in motion detection and human-computer interactions. Herein, we reported a facile sol-gel followed by hydrothermal reduction approach to prepare polypyrrole/reduced graphite oxide aerogel (PPy@rGA) film, which is more oriented to flexible wearable piezoresistive sensors as compared with traditional cylindrical reduced graphene oxide (rGO) aerogel. The strong π-π interactions between rGO and PPy enhance the interfacial strength and help to maintain the integrity of the composite aerogel film. Meanwhile, the PPy nanoparticles anchoring on the edges and defects of rGO sheets create more electrically conductive paths when an external pressure is applied, and therefore give rise to significant changes in the resistance value and thus excellent piezoresistive sensing performance. The PPy2@rGA film (pyrrole monomer: graphene oxide is 2:1 wt%)–based piezoresistive sensor exhibits a high sensitivity of 0.9 kPa−1 in a linear range that is of 0 to 1 kPa, a short response time of 165 ms, and a short relaxation time of 132 ms, and is able to withstand 10,000 cycles. Moreover, the wearable sensor is capable of detecting large as well as small human motion. This study shows the feasibility of fabricating wearable piezoresitive sensors from rGO aerogel films reinforced by intrinsically conductive polymers.

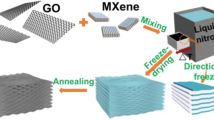

Graphical abstract

In this polypyrrole/reduced graphite oxide aerogel film which is more oriented to flexible wearable piezoresistive sensors, PPy nanoparticles anchor adjacent rGO sheets via strong π-π interfacial forces and meanwhile serve as nano-spacers that contribute to an enhanced piezoresistive sensing performance.

Similar content being viewed by others

References

Jing X, Li H, Mi H-Y, Liu Y-J, Feng P-Y, Tan Y-M, Turng L-S (2019) Highly transparent, stretchable, and rapid self-healing polyvinyl alcohol/cellulose nanofibril hydrogel sensors for sensitive pressure sensing and human motion detection. Sensor Actuat B-Chem 295:159–167. https://doi.org/10.1016/j.snb.2019.05.082

Li X-P, Li Y, Li X, Song D, Min P, Hu C, Zhang H-B, Koratkar N, Yu Z-Z (2019) Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets. J Colloid Interface Sci 542:54–62. https://doi.org/10.1016/j.jcis.2019.01.123

Tian G, Deng W, Gao Y, Xiong D, Yan C, He X, Yang T, Jin L, Chu X, Zhang H, Yan W, Yang W (2019) Rich lamellar crystal baklava-structured PZT/PVDF piezoelectric sensor toward individual table tennis training. Nano Energy 59:574–581. https://doi.org/10.1016/j.nanoen.2019.03.013

Deng W, Yang T, Jin L, Yan C, Huang H, Chu X, Wang Z, Xiong D, Tian G, Gao Y, Zhang H, Yang W (2019) Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy 55:516–525. https://doi.org/10.1016/j.nanoen.2018.10.049

Chu J, Cai J (2020) Flexible pressure sensors with a highly pressure- and strain-sensitive layer based on nitroxyl radical-grafted hollow carbon spheres. Nanoscale 12(17):9375–9384. https://doi.org/10.1039/d0nr01192d

Park H, Kim JW, Hong SY, Lee G, Kim DS, Oh Jh, Jin SW, Jeong YR, Oh SY, Yun JY, Ha JS (2018) Microporous polypyrrole-coated graphene foam for high-performance multifunctional sensors and flexible supercapacitors. Adv Funct Mater 28 (33). https://doi.org/10.1002/adfm.201707013

Chhetry A, Sharma S, Yoon H, Ko S, Park JY (2020) Enhanced sensitivity of capacitive pressure and strain sensor based on CaCu3Ti4O12 wrapped hybrid sponge for wearable applications. Adv Funct Mater :1910020. https://doi.org/10.1002/adfm.201910020

Zhao W, Shi Z, Hu S, Yang G, Tian H (2018) Understanding piezoelectric characteristics of PHEMA-based hydrogel nanocomposites as soft self-powered electronics. Adv Compos Hybrid Mater 1(2):320–331. https://doi.org/10.1007/s42114-018-0036-3

Su Y-F, Han G, Kong Z, Nantung T, Lu N (2020) Embeddable piezoelectric sensors for strength gain monitoring of cementitious materials: the influence of coating materials. Engnieered Sci 11:66–75. https://doi.org/10.30919/es8d1114

Lou M, Abdalla I, Zhu M, Wei X, Yu J, Li Z, Ding B (2020) Highly wearable, breathable, and washable sensing textile for human motion and pulse monitoring. ACS Appl Mater Interfaces 12(17):19965–19973. https://doi.org/10.1021/acsami.0c03670

Li Y, Wang W, Liao K, Hu C, Huang Z, Feng Q (2003) Piezoresistive effect in carbon nanotube films. Chin Sci Bull 48(2):125–127. https://doi.org/10.1360/03tb9024

Lu Y, Tian M, Sun X, Pan N, Chen F, Zhu S, Zhang X, Chen S (2019) Highly sensitive wearable 3D piezoresistive pressure sensors based on graphene coated isotropic non-woven substrate. Compos Part A-Appl S 117:202–210. https://doi.org/10.1016/j.compositesa.2018.11.023

Meyer JC, Geim AK, Katsnelson MI, Novoselov KS, Booth TJ, Roth S (2007) The structure of suspended graphene sheets. Nature 446(7131):60–63. https://doi.org/10.1038/nature05545

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183. https://doi.org/10.1038/nmat1849

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56. https://doi.org/10.1038/354056a0

Zhou K, Chen C, Lei M, Gao Q, Nie S, Liu X, Wang S (2020) Reduced graphene oxide-based highly sensitive pressure sensor for wearable electronics via an ordered structure and enhanced interlayer interaction mechanism. RSC Adv 10(4):2150–2159. https://doi.org/10.1039/c9ra08653f

Wu J, Li H, Lai X, Chen Z, Zeng X (2020) Conductive and superhydrophobic F-rGO@CNTs/chitosan aerogel for piezoresistive pressure sensor. Chem Eng J 386 https://doi.org/10.1016/j.cej.2019.123998

Iurchenkova AA, Fedorovskaya EO, Asanov IP, Arkhipov VE, Popov KM, Baskakova KI, Okotrub AV (2020) MWCNT buckypaper/polypyrrole nanocomposites for supercapasitor application. Electrochim Acta 335 https://doi.org/10.1016/j.electacta.2020.135700

Li H, Yin J, Meng Y, Liu S, Jiao T (2020) Nickel/Cobalt-containing polypyrrole hydrogel-derived approach for efficient ORR electrocatalyst. Colloid Surface A 586 https://doi.org/10.1016/j.colsurfa.2019.124221

Fan Y, Bai W, Mu P, Su Y, Zhu Z, Sun H, Liang W, Li A (2020) Conductively monolithic polypyrrole 3-D porous architecture with micron-sized channels as superior salt-resistant solar steam generators. Sol Energ Mat Sol C 206 https://doi.org/10.1016/j.solmat.2019.110347

Zhao P, Zhang R, Tong Y, Zhao X, Tang Q, Liu Y (2020) All‐Paper, All‐organic, cuttable, and foldable pressure sensor with tuneable conductivity polypyrrole. Adv Electron Mater 6(8). https://doi.org/10.1002/aelm.201901426

Chen J, Zhu Y, Guo Z, Nasibulin AG (2020) Recent progress on thermo-electrical properties of conductive polymer composites and their application in temperature sensors. Engnieered Sci. https://doi.org/10.30919/es8d1129

Huang H, Han L, Wang Y, Yang Z, Zhu F, Xu M (2019) Tunable thermal-response shape memory bio-polymer hydrogels as body motion sensors. Engnieered Sci 9:60–67. https://doi.org/10.30919/es8d812

Xue J, Chen J, Song J, Xu L, Zeng H (2017) Wearable and visual pressure sensors based on Zn2GeO4@polypyrrole nanowire aerogels. J Mater Chem C 5(42):11018–11024. https://doi.org/10.1039/c7tc04147k

Huang J, Li D, Zhao M, Ke H, Mensah A, Lv P, Tian X, Wei Q (2019) Flexible electrically conductive biomass-based aerogels for piezoresistive pressure/strain sensors. Chem Eng J 373:1357–1366. https://doi.org/10.1016/j.cej.2019.05.136

Wan Y, Qin N, Wang Y, Zhao Q, Wang Q, Yuan P, Wen Q, Wei H, Zhang X, Ma N (2020) Sugar-templated conductive polyurethane-polypyrrole sponges for wide-range force sensing. Chem Eng J 383 https://doi.org/10.1016/j.cej.2019.123103

Hummers WS, Offeman RE (1958) Preparation of Graphitic Oxide. J Am Chem Soc 80(6):1339. https://doi.org/10.1021/ja01539a017

Kim J, Cote LJ, Kim F, Yuan W, Shull KR, Huang J (2010) Graphene oxide sheets at interfaces. J Am Chem Soc 132(23):8180–8186. https://doi.org/10.1021/ja102777p

Guyard L, Hapiot P, Neta P (1997) Redox chemistry of bipyrroles: further insights into the oxidative polymerization mechanism of pyrrole and oligopyrroles. J Phys Chem B 101(29):5698–5706. https://doi.org/10.1021/jp9706083

Bai H, Sheng K, Zhang P, Li C, Shi G (2011) Graphene oxide/conducting polymer composite hydrogels. J Mater Chem 21(46):18653–18658. https://doi.org/10.1039/C1JM13918E

Moon IK, Lee J, Ruoff RS, Lee H (2010) Reduced graphene oxide by chemical graphitization. Nat Commun 1:73. https://doi.org/10.1038/ncomms1067

Chen C, Yang Q-H, Yang Y, Lv W, Wen Y, Hou P-X, Wang M, Cheng H-M (2009) Self-assembled free-standing graphite oxide membrane. Adv Mater 21(29):3007–3011. https://doi.org/10.1002/adma.200803726

Liu Z, Robinson JT, Sun X, Dai H (2008) PEGylated nanographene oxide for delivery of water-insoluble cancer drugs. J Am Chem Soc 130(33):10876–10877. https://doi.org/10.1021/ja803688x

Xu Y, Sheng K, Li C, Shi G (2010) Self-assembled graphene hydrogel via a one-step hydrothermal process. ACS Nano 4(7):4324–4330. https://doi.org/10.1021/nn101187z

Sahoo S, Karthikeyan G, Nayak GC, Das CK (2011) Electrochemical characterization of in situ polypyrrole coated graphene nanocomposites. Synth Met 161(15):1713–1719. https://doi.org/10.1016/j.synthmet.2011.06.011

Zhong J, Gao S, Xue G, Wang B (2015) Study on enhancement mechanism of conductivity induced by graphene oxide for polypyrrole nanocomposites. Macromolecules 48(5):1592–1597. https://doi.org/10.1021/ma502449k

Amarnath CA, Hong CE, Kim NH, Ku B-C, Kuila T, Lee JH (2011) Efficient synthesis of graphene sheets using pyrrole as a reducing agent. Carbon 49(11):3497–3502. https://doi.org/10.1016/j.carbon.2011.04.048

Jin Z, Yao J, Kittrell C, Tour JM (2011) Large-scale growth and characterizations of nitrogen-doped monolayer graphene sheets. ACS Nano 5(5):4112–4117. https://doi.org/10.1021/nn200766e

Chen W, Li S, Chen C, Yan L (2011) Self-assembly and embedding of nanoparticles by in situ reduced graphene for preparation of a 3D graphene/nanoparticle aerogel. Adv Mater 23(47):5679–5683. https://doi.org/10.1002/adma.201102838

Wan Y, Wang Y, Guo CF (2017) Recent progresses on flexible tactile sensors. Mater Today Phys 1:61–73. https://doi.org/10.1016/j.mtphys.2017.06.002

Yang T, Xie D, Li Z, Zhu H (2017) Recent advances in wearable tactile sensors: materials, sensing mechanisms, and device performance. Mater Sci Eng R-Reports 115:1–37. https://doi.org/10.1016/j.mser.2017.02.001

Yoon JI, Choi KS, Chang SP (2017) A novel means of fabricating microporous structures for the dielectric layers of capacitive pressure sensor. Microelectron Eng 179:60–66. https://doi.org/10.1016/j.mee.2017.04.028

Chen S, Zhuo B, Guo X (2016) Large area one-step facile processing of microstructured elastomeric dielectric film for high sensitivity and durable sensing over wide pressure range. ACS Appl Mater Interfaces 8(31):20364–20370. https://doi.org/10.1021/acsami.6b05177

Kim K-H, Hong SK, Jang N-S, Ha S-H, Lee HW, Kim J-M (2017) Wearable resistive pressure sensor based on highly flexible carbon composite conductors with irregular surface morphology. ACS Appl Mater Interfaces 9(20):17499–17507. https://doi.org/10.1021/acsami.7b06119

Lan L, Zhao F, Yao Y, Ping J, Ying Y (2020) One-step and spontaneous in situ growth of popcorn-like nanostructures on stretchable double-twisted fiber for ultrasensitive textile pressure sensor. ACS Appl Mater Interfaces 12(9):10689–10696. https://doi.org/10.1021/acsami.0c00079

Chen J, Zhu Y, Jiang W (2020) A stretchable and transparent strain sensor based on sandwich-like PDMS/CNTs/PDMS composite containing an ultrathin conductive CNT layer. Compos Sci Technol 186 https://doi.org/10.1016/j.compscitech.2019.107938

Haniff MASM, Hafiz SM, Huang NM, Rahman SA, Wahid KAA, Syono MI, Azid IA (2017) Piezoresistive effect in plasma-doping of graphene sheet for high-performance flexible pressure sensing application. ACS Appl Mater Interfaces 9(17):15192–15201. https://doi.org/10.1021/acsami.7b02833

Lee K, Lee J, Kim G, Kim Y, Kang S, Cho S, Kim S, Kim J-K, Lee W, Kim D-E, Kang S, Kim D, Lee T, Shim W (2017) Rough-surface-enabled capacitive pressure sensors with 3D touch capability. Small:1700368. https://doi.org/10.1002/smll.201700368

Li X, Huang W, Yao G, Gao M, Wei X, Liu Z, Zhang H, Gong T, Yu B (2017) Highly sensitive flexible tactile sensors based on microstructured multiwall carbon nanotube arrays. Scr Mater 129:61–64. https://doi.org/10.1016/j.scriptamat.2016.10.037

Wang L, Jackman JA, Tan E-L, Park JH, Potroz MG, Hwang ET, Cho N-J (2017) High-performance, flexible electronic skin sensor incorporating natural microcapsule actuators. Nano Energy 36:38–45. https://doi.org/10.1016/j.nanoen.2017.04.015

Funding

This work is financially supported by National Natural Science, Foundation of China (51703162). Dr. Huige Wei also received support from Young Elite Scientists Sponsorship Program by Tianjin (TJSQNTJ-2018-03).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wei, H., Li, A., Kong, D. et al. Polypyrrole/reduced graphene aerogel film for wearable piezoresisitic sensors with high sensing performances. Adv Compos Hybrid Mater 4, 86–95 (2021). https://doi.org/10.1007/s42114-020-00201-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-020-00201-0