Abstract

The multifarious relationships between nitrogen application, energy consumption and GHG emissions are still not well understood in irrigated potato production system. There is a need to ensure that N and energy use are closely considered to provide useful options for adaptation and to build resilience at the farm level. A field experiment was conducted during the winter (November–March) of 2012–2013 and 2013–2014 at the District Seed Farm, Adisaptagram, Hooghly, West Bengal, India (23°26′N latitude and 88°22′E longitude with an altitude of 12 m above mean sea level), under sub-humid subtropical climatic condition of West Bengal, India. The objective of the study was to assess environmental and economic sustainability in potato cultivation as influenced by nitrogen fertilization. This paper examines nitrogen application and energy consumption relationships for irrigated potato production system in eastern India. Results showed that net energy gain was the highest with the supply of 225 kg N/ha for both Kufri Himalini and Kufri Jyoti and 150 kg N/ha for Kufri Shailja. However, maximum values of energy ratio, specific energy and energy intensiveness were recorded with 300 kg N/ha for all three tested cultivars. Total estimated GHG emission per ha increased with the increase in N level from 0 to 300 kg N/ha, regardless of cultivars. Net benefit of potato cultivation was observed to increase with increasing levels of N application up to 300 kg N/ha (for K. Himalini) and up to 225 kg N/ha (for K. Shailja and K. Jyoti). The highest GRF for K. Himalini was observed at 300 kg N/ha, while for K. Shailja and K. Jyoti the maximum GRF was associated with 150 and 250 kg N application per hectare, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Although West Bengal accounts for one-third of the country’s total potato production, potato growers for the last few years have been facing fundamental setbacks mainly due to lack of knowledge about new cultivar and appropriate doses of fertilizers (Mozumder et al. 2014). Introduction of improved cultivars with better yield potential supported by judicious nutrient management may improve such situation (Banerjee et al. 2015). The new potato hybrids ‘Kufri Himalini’ and ‘Kufri Shailja’ have primarily been developed with higher level of resistance to late blight and exhibited higher yield potentials than existing popular variety of the region (Kufri Jyoti).

Nitrogen is the most important nutrient for potato growth and yield, and without its application, tuber yield reduction can reach up to 70% (Banerjee et al. 2016). Application of N can increase the size and number of tubers that ultimately enhance total yield (Kumar et al. 2007). In addition, under- or oversupply of N may affect total number of tubers. Excessive N application leads to delayed maturity, poor tuber quality and occasional reduction in tuber yield (Alva 2004). In order to optimize the crop production and minimize the risk of N leaching into groundwater, modern fertilizer management practices involve optimization of N. Potato cultivars differ in their growth behaviour and yield potential, and therefore, it is important to evaluate each genotype for its growth and yield attributes.

Understanding the energetics may provide additional information for identification of a better and efficient crop management practice (Ganajaxi et al. 2011; Tzanakakis et al. 2012). Agricultural output is proportional to the management of energy inputs such as seed, fertilizers, pesticides and irrigation. Crops supply food, feed and fibre through the process of photosynthesis, the process of harnessing solar energy into plant biomass (Alam et al. 2005). In order to boost up crop production, optimum use of different energy inputs is essential. While human labour and animal power are not enough for harnessing better crop yield, the use of machinery, irrigation and fertilizers can lead to increased productivity from limited land resources. Energy budgeting, the relationship between energy input and output (Gezer et al. 2003), could be an important tool for intensification of potato cultivation in smallholder farmers’ fields. To augment resilience at the farm level, the optimum situation envisaged by an irrigated potato production system can minimize N and energy use when reducing GHG emissions.

Recently, global warming has become an important challenge for agriculture, which contributes to nearly 20% of the GHG emissions (Pathak and Wassman 2007). The estimation of GHG emissions from crop fields has been carried out mostly for developed countries, which seldom reflects the situations of developing countries. For example in India, direct (during cultivation and harvesting) and indirect (through fertilizers, pesticides) emissions of GHGs from agriculture are estimated to be around 17% of the net CO2eq emissions (Wood and Cowie 2013). Thus, identification of C-efficient alternatives through a better understanding of the emissions from different farm operations is essential (Lal 2004). However, there are certain factors, such as different efficiencies of plants, different mechanisms controlling emissions, raw materials used and the variation in assumptions made by the analysts, contribute to variations of emission factors for similar fertilizer products. Estimation of emissions, which includes both direct and indirect emissions from farm operations (Wood and Cowie 2013), has been conducted in this study.

Energy budgeting, estimation of GHG emission and economic analysis of potato production have hardly been undertaken in the eastern Indo-Gangetic plains (IGPs) in a backdrop where risk and uncertainty associated with indiscriminate use of N fertilizer by small and marginal farmers are notable. The objective of this study was to estimate the effect of energy inputs on potato yield, GHG emissions and profitability in potato cultivation.

2 Materials and methods

2.1 Location and growth conditions

The field experiment was conducted at the District Seed Farm, Adisaptagram, Hooghly, during the winter (November–March) of 2012–2013 and 2013–2014. The research field is situated in sub-humid subtropical climate region of West Bengal, India, at an altitude of 12 m above mean sea level and is intersected by latitude of 23°26′N and longitude of 88°22′E. The soil of the experimental site is loamy in texture, composed of 44% sand, 30% silt and 26% clay with a slightly acidic pH 6.34, EC of 0.25 dS/m and 0.60% organic carbon in the upper soil layer (0–30 cm). The available N, P and K recoveries were 183.3, 24.1 and 614.03 kg/ha, respectively, before initiation of the experiment. Climate of the experimental site remained dry throughout the crop season.

2.2 Experimental design, treatments and crop management practices

The experiment was laid out in a factorial randomized block design with combinations of three potato cultivars (V) as the main-plot factor and five nitrogen levels as the subplot factor. Potato cultivars used were Kufri Himalini, Kufri Shailja and Kufri Jyoti, and levels of nitrogen were 0, 75, 150, 225 and 300 kg/ha, respectively. The experimental design was replicated four times in 5 m × 3 m plots of each treatment. Tubers weighing 30–40 g each were hand-planted in last week of November to a density of about 83,333 plants/ha. All plants were arranged in rows with 20-cm spacing between the plants along furrows. The total amount of N was applied as urea. Half of nitrogen was broadcasted as basal, and rest half of nitrogen was top dressed at 30 days after planting (DAP) followed by earthing up. All treatments received the same amount of phosphorus (150 kg P2O5/ha through single super phosphate) and potash (150 kg K2O/ha through muriate of potash). Pre-emergence application of Sencor (metribuzin) at 0.75 kg a.i./ha was done at 3 DAP followed by one hand weeding at 20 DAP to promote early crop growth. Irrigation was withdrawn 15 days before tuber lifting, and dehaulming was done in last week of February. Lifting of potato tubers was done manually at the end of growing season on 10 March (100 DAP) when all plants reached physiological maturity.

2.3 Energy budgeting and estimation of energy indices

For determining the energy budget of potato production, the amount of each input [tractor, disc harrow, diesel, human labour, bullock, potato seed, fertilizer (N, P and K), water for irrigation, insecticide and sprayer] was considered for common energy input. Cultivar and fertilizer (as per treatment) were considered for treatment energy input, while output energy was calculated considering the economic produce, i.e. seed. For estimating the energy value, quantity of different inputs and output was converted to energy by multiplying the respective energy equivalents (Table 1). The machine energy was calculated as per Devasenapathy et al. (2009) with some changes as follows:

where ‘ME’ is the machine (tractor, disc harrow, water lifting pump and sprayer) energy (MJ/ha); ‘W’ the weight of machine (kg); ‘E’ the energy equivalent (MJ/ha); ‘T’ the time of operation (hours); and ‘L’ the life span of machine. The following energy indices were calculated for each treatment combination as per Banaeian and Zangeneh (2011) and Ghahderijani et al. (2013):

where NEG is net energy gain (MJ/ha); ER is energy ratio; SE is specific energy (MJ/kg); EP is energy productivity (Kg/MJ); EI is energy intensiveness (MJ/US$); E o is energy output (MJ/ha); E i is energy input (MJ/ha); Y t is tuber yield (kg/ha); and C P is total cost of productiSon (US$/ha).

Source-wise energy input (E i) was categorized into direct and indirect forms (Mandal et al. 2002; Singh et al. 2003). In this study, the direct energy sources were human labour, bullock (renewable), diesel fuel and electricity (non-renewable), while indirect energy sources were seed (renewable), and machinery, fertilizer (N, P and K) and insecticide (non-renewable).

2.4 Estimation of CO2 equivalents of GHGs

The GHG emissions of different inputs of production [machinery/tractor, diesel, electricity, fertilizer (N, P2O5 and K2O) and insecticide] per unit area were estimated from the CO2 emission coefficients (Table 2) multiplied by the application rate of inputs.

2.5 Economic analysis

Net returns from the production system were calculated over direct as well as indirect costs. The cost of production included human labour, tractor use, inputs such as tillage, planting, seed, fertilizer, irrigation, pesticide and harvesting. The cost of human labour, used for tillage (twice), cutting of seed tuber, planting, earthing up (once), irrigation (7 times), fertilizer application (twice), spraying of fungicides/pesticides (4 times), weeding (twice), dehaulming and harvesting of crop was calculated in man-days/ha. The time (h) required to complete each field operation was recorded and expressed as man-days/ha, considering 8 h to be equivalent to 1 man-day. The cost of labour was calculated using the minimum wage rate as per the State labour law. Similarly, the time required by a tractor drawn machine/implement to complete land preparation was recorded and expressed as hours/ha. Cost of irrigation was calculated by multiplying time required to irrigate one hectare area, diesel consumption by the pump and price of diesel. All these costs were summed up to obtain the total cost of production. Economic benefits were then assessed by:

where GR is gross revenue (US$/ha); NB is net benefit (US$/ha); GRF is gross return above fertilizer cost (US$/ha); Y t is tuber yield (t/ha); P t is minimum support price of potato (US$/t); C p is total cost of production (Rs./ha); and C f is fertilizer cost (US$/ha). All economic data were converted into US$ using an exchange rate of 1 US$ = 60 Indian rupees (INR).

3 Results and discussion

3.1 Energy budgeting

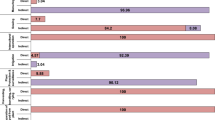

Energy used for raising different potato cultivars was computed to augment energy budgeting. The energy inputs (E i) against each field operation were classified as direct energy (that release the energy directly) and indirect energy (those do not release energy directly but release it by conversion process) (see Fig. 1). Both direct and indirect sources of energy were grouped into renewable (direct in nature but can be subsequently replenished) and non-renewable sources (not replenished in due course of time). In the present study, the direct sources of energy include human, animal and diesel, of which human and animal were categorized as renewable direct energy sources, while the only non-renewable direct energy source was diesel. On the other hand, the indirect sources of energy include seed, chemical fertilizers and machinery, of which only seed was categorized as renewable indirect energy source, while the non-renewable indirect energy sources were chemical fertilizer and machinery. For most of the field operations, the involvement of direct sources of energy was greater than that of indirect sources, while the trend was reverse for sowing, plant protection and surveillance operations (Fig. 1). More specifically, the per cent sharing of direct energy was 100 (total renewable source) for intercultural operations, dehaulming, harvesting and carrying. But in case of other field operations like land preparation and irrigation, the major energy input was from direct non-renewable resources (84.1 and 85.2%, respectively). Involvement of indirect energy sources was greater than direct sources for sowing, plant protection and surveillance operations. More specifically, 100% share of indirect energy in plant protection and surveillance operation was from non-renewable sources. On the other hand, the major share of indirect energy in sowing operation was from renewable sources (89.7%).

In the present study, energy output increased with increasing level of N for each potato cultivar. The supply of 225 kg N/ha recorded better energy output (E o) for K. Shailja and K. Jyoti, but for K. Himalini the E o was higher with 300 kg N/ha (Table 3). This trend is similar to that of yield since the E o is dependent on economic part of the crop (Ganajaxi et al. 2011). Estimated energy indices (Table 4) revealed that net energy gain (NEG) was the highest with the supply of 225 kg N/ha for both K. Himalini and K. Jyoti and 150 kg N/ha for K. Shailja. However, maximum values of energy ratio (ER), specific energy (SE) and energy intensiveness (EI) were recorded with 300 kg N/ha for all three tested cultivars. Therefore, application of 300 kg N/ha was considered as the most energy-intensive treatment with the lowest energy productivity (EP).

As depicted in Fig. 2, N level and energy use efficiency (ratio between energy output and energy input per hectare) were highly correlated. It was revealed that energy use efficiency (EUE) increased with the increase in N application up to certain level (150 kg N/ha) and thereafter declined till 300 kg N/ha. From the regression equation, the optimum level of N (Nopt) was derived as 131.25 kg N/ha to achieve optimum EUE (3.44). Therefore, applying N fertilizers more than what actually need results in less energy-efficient production system. According to Gupta et al. (2007), energy ratio and energy productivity exhibited phenomenal decrease with increment in N level from 75 to 125% of recommended dose (RD). This is due to lesser inputs used at lower fertility levels as compared to higher fertility level, which corroborates with earlier study of Billore et al. (1994), who opined that higher energy input resulted in lower energy ratio and energy productivity. According to Tzanakakis et al. (2012), agronomic practices with greater differences between energy output and input leading to higher net energy gain and energy ratio have potential to be used as a bio-energy management indicating its environmental and economic sustainability. Thus, as the cultivar showed higher response to N fertilization with respect to tuber yield, the present level of energy input use (other than fertilizers sources) should be substantially reduced by using energy-efficient machinery (not worn-out tractors), adopting some conservation measures (like mulching), less pressurized irrigation system and more use of diesel in place of electricity.

3.2 Greenhouse gas (GHG) emissions

Common inputs that contribute much in GHG emission from potato production are shown in Fig. 3. The highest GHG emissions were associated with diesel fuel with a share of 85.8% of total emission, and the rest is contributed by the emissions from machinery (8.25%) and herbicide (5.95%). Estimated total GHG emissions in terms of CO2 equivalents (CO2-eq) were varying with N management strategies (Fig. 4). Total estimated GHG emission per ha increased with increase in N levels from 75 to 300 kg N/ha, regardless of cultivars. Application of 300 kg N/ha remained responsible for the highest GHG emission (450 kg CO2-eq/ha) sharing 60.4% of the total emission. This study showed that higher N doses led to adverse environmental impacts. Our suggestion is to adopt lower effluent application rate of nitrogen, preferably 225 kg N/ha, which contributed comparatively less to total GHG emission (352.54 kg CO2-eq/ha with share of 54.5%). This option may lead to reduction in the yield suggesting that more land is required to compensate the losses. This might be infeasible, particularly in areas with high needs in food crops. To mitigate the losses in crop yield and reduce the adverse environmental impacts from N, additional practices should be developed. Options may include more intense pre-treatment particularly with respect to N to meet crop needs, early planting, adjustment of planting density and optimization of irrigation schedule (Tzanakakis et al. 2012).

3.3 Assessment of economic benefits

Potato cultivars K. Himalini and K. Shailja outperformed K. Jyoti in respect of gross revenue (GR) and net benefit (NB). Irrespective of N levels, K. Himalini paid the highest NB as well as gross return above fertilizer cost (GRF) (Table 5). Higher productivity of K. Himalini was mainly responsible for higher return from this cultivar. Nitrogen nutrition exerted positive effect on GR, NB and GRF in potato production. NB of potato cultivation was observed to increase with increasing levels of N application up to 300 kg N/ha (for K. Himalini) and up to 225 kg N/ha (for K. Shailja and K. Jyoti). The highest GRF for K. Himalini was observed at 300 kg N/ha, while for K. Shailja and K. Jyoti the maximum GRF was associated with 150 and 250 kg N application per hectare, respectively. The present study also demonstrated that the profitability of K. Himalini cultivation was more than K. Shailja and K. Jyoti because K. Himalini with 300 kg N/ha gave highest NB (US$ 2419/ha) and GRF (US$ 3679/ha). Next best NB (US$ 2323/ha) and GRF (US$ 3583/ha) were recorded with the same variety receiving 225 kg N/ha. The negative response in both NB and GRF was recorded in plots treated with zero-N that might be due to poor growth and low productivity of the crop (Baishya et al. 2013). These results are in partial agreement with the finding of Love et al. (2005), which reported that net returns were relatively low without N, increased to a highest level at some intermediate N rate, and then decreased again at the highest N rates. Higher economic returns and GRF were obtained at higher N doses because of increased marketable and total tuber yield realized at higher N application (Kumar et al. 2007).

4 Conclusions

The present study emphasizes the need to optimize N fertilization of potato to ensure an energy-efficient and profitable production system. From both energy ratio (output : input) and GRF point of view, cultivation of Kufri Himalini is more profitable than Kufri Shailja and Kufri Jyoti. Regardless of cultivar, 225 kg N/ha increased tuber yield, energy use efficiency and profitability as compared to farmers’ practice. The over-application of N fertilizer to potato contributed to high GHG emissions and soil–water pollution. However, further validation of these findings in terms of energy budgeting and GHG emission mitigation may be necessary. This strategy makes the best use of N, minimizes the quantity and investment in urea (N fertilizer) required by the potato growers.

References

Alam MS, Alam MR, Islam KK (2005) Energy flow in agriculture: Bangladesh. Am J Environ Sci 1:213–220

Alva A (2004) Potato nitrogen management. J Veg Crop Prod 10(1):97–130

Baishya LK, Kumar M, Ghosh M, Ghosh DC (2013) Effect of integrated nutrient management on growth, productivity and economics of rainfed potato in Meghalaya hills. Int J Agric Environ Biotechnol 6(1):69–77

Banaeian N, Zangeneh M (2011) Estimating production function of walnut production in Iran using Cobb-Douglas method. Agricultura Tropica et Subtropica 44:177–189

Banerjee H, Ray K, Sarkar S, Puste AM, Mozumder M, Rana L (2015) Impact of nitrogen nutrition on productivity and nutrient use efficiency of potato (Solanum tuberosum L.) in an inceptisol of West Bengal, India. SAARC J Agric 13(2):141–150

Banerjee H, Rana L, Ray K, Sarkar S, Bhattacharyya K, Dutta S (2016) Differential physiological response in potato (Solanum tuberosum L.) upon exposure to nutrient omissions. Indian J Plant Physiol 21(2):129–136

Billore SD, Singh K, Singh AP, Bargale M (1994) Energy productivity of sorghum-wheat sequence through long-term use of chemical fertilizers. Indian J Agron 39(2):198–202

Devasenapathy P, Senthilkumar G, Shanmugam PM (2009) Energy management in crop production. Indian J Agron 54:80–90

Dyer JA, Desjardins RL (2003) Simulated farm fieldwork, energy consumption and related greenhouse gas emissions in Canada. Biosyst Eng 85(4):503–513

Dyer JA, Desjardins RL (2006) Carbon dioxide emissions associated with the manufacturing of tractors and farm machinery in Canada. Biosyst Eng 93:107–118

Ganajaxi HSI, Hiremath SM, Chittapur BM (2011) Productivity, profitability and energy use efficiency of different cropping sequences in northern transition zone of Karnataka. Indian J Agric Sci 81(10):921–926

Gezer I, Acaroglu M, Haciseferogullari H (2003) Use of energy and labour in apricot agriculture in Turkey. Biomass Bioenergy 24:215–219

Ghahderijani M, Komleh SHP, Keyhani A, Sefeedpari P (2013) Energy analysis and life cycle assessment of wheat production in Iran. Afr J Agric Res 8:1929–1939

Gupta M, Bali A, Sharma S, Dixit AK (2007) Potential role and influence of zero tillage technology on energy saving in rice (Oryza sativa L.)-wheat (Triticum aestivum) system. Indian J Agric Sci 77(10):657–659

Jackson TM, Hanjra MA, Khan S, Hafeez MM (2011) Building a climate resilient farm: a risk based approach for understanding water, energy and emissions in irrigated agriculture. Agric Syst 104:729–745

Kumar P, Pandey SK, Singh BP, Singh SV, Kumar D (2007) Effect of nitrogen rate on growth, yield, economics and crisps quality of Indian potato processing cultivars. Potato Res 50(2):143–155

Lal R (2004) Carbon emissions from farm operations. Environ Int 30:981–990

Love SL, Stark JC, Salaiz T (2005) Response of four potato cultivars to rate and timing of nitrogen fertilizer. Am J Potato Res 82:21–30

Mandal KG, Saha KP, Ghosh PK, Hatik M, Bandyopadhyay KK (2002) Bio-energy and economic analysis of soybean-based crop production systems in central India. Biomass Bioenergy 23:337–345

Mittal VK, Mittal JP, Dhawan KC (1985). Research digest on energy requirements in agricultural sector. Co-ordinating cell, AICRP on energy requirements in agricultural sector. Punjab Agricultural University, Ludhiana, India, p 42

Mozumder M, Banerjee H, Ray K, Paul T (2014) Evaluation of potato (Solanum tuberosum) cultivars for productivity, N requirement and eco-friendly indices under different nitrogen levels. Indian J Agron 59(2):327–335

Pathak H, Wassman R (2007) Introducing greenhouse gas mitigation as a development objective in rice-based agriculture: I. generation of technical coefficients. Agric Syst 94:807–825

Sadorsky P (2006) Modeling and forecasting petroleum futures volatility. Energy Econ 28:467–488

Singh H, Mishra D, Nahar NM, Ranjan M (2003) Energy use pattern in production agriculture of a typical village in arid zone India: part II. Energy Convers Manag 44:1053–1067

Tzanakakis VA, Chatzakis MK, Angelakis AN (2012) Energetic environmental and economic assessment of three tree species and one herbaceous crop irrigated with primary treated sewage effluent. Biomass Bio-energy 47:115–124

Wood S, Cowie A (2013) A review of greenhouse gas emission factors for fertilizer production, pp. 1–20. www.ieabioenergy-task38.org. Accessed: 22 May 2015

Acknowledgements

The financial support extended by the Indian Council of Agricultural Research (ICAR), New Delhi, through Project Directorate for All India Coordinated Research Project on Potato, Shimla (Himachal Pradesh), for the study is gratefully acknowledged. Special thanks to anonymous reviewers for their useful comments and Dr. Kallol Bhattacharyya (Bidhan Chandra Krishi Viswavidyalaya) for final editing of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Banerjee, H., Sarkar, S. & Ray, K. Energetics, GHG emissions and economics in nitrogen management practices under potato cultivation: a farm-level study. Energ. Ecol. Environ. 2, 250–258 (2017). https://doi.org/10.1007/s40974-017-0058-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40974-017-0058-7