Abstract

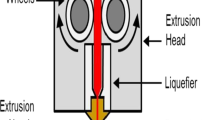

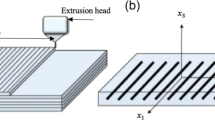

Eco-friendly manufacturing processes have been the focus of recent research in engineering and biomedical sciences. The filament fusion fabrication (FFF) technique of bio-based polymeric parts is a promising additive manufacturing process with low environmental impact. This work investigates the optimised manufacturing parameters to produce bidirectional PLA plates under tensile loads. A full factorial design investigates the effect of layer angle, layer height, print speed, and sample thickness on tensile strength and stiffness. Layer height is the most predominant factor over tensile modulus and strength, while raster angle and print speed factors lead to small changes in the mechanical properties of 3D-printed structures. PLA samples oriented at ± 45° and 0/90° using low layer height achieve greater mean tensile strength and stiffness, respectively. The statistical design indicates interaction effects, which combine printing parameters and geometry capable of increasing the mechanical response of printed structures.

Similar content being viewed by others

Availability of data and material

The experimental data are available under request.

Code availability

Not applicable.

References

ASTM International ASTM F2792 - 12 (2012) Standard terminology for additive manufacturing technologies. https://doi.org/10.1520/F2792-12

Yao T, Zhang K, Deng Z et al (2020) A novel generalised stress invariant-based strength model for inter-layer failure of FFF 3D printing PLA material. Mater Des 193:108799. https://doi.org/10.1016/j.matdes.2020.108799

Ye J, Yao T, Deng Z et al (2021) A modified creep model of polylactic acid (PLA -max) materials with different printing angles processed by fused filament fabrication. J Appl Polym Sci 138:50270. https://doi.org/10.1002/app.50270

Grünewald J, Parlevliet P, Altstädt V (2017) Manufacturing of thermoplastic composite sandwich structures. J Thermoplast Compos Mater 30:437–464. https://doi.org/10.1177/0892705715604681

Garlotta D (2001) A Literature Review of Poly(Lactic Acid). J Polym Environ 9:63–84. https://doi.org/10.1023/A:1020200822435

Patra S, Young V (2016) A review of 3d printing techniques and the future in biofabrication of bioprinted tissue. Cell Biochem Biophys 74:93–98. https://doi.org/10.1007/s12013-016-0730-0

Wolfs RJM, Bos FP, Salet TAM (2018) Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem Concr Res 106:103–116. https://doi.org/10.1016/j.cemconres.2018.02.001

Antony S, Cherouat A, Montay G (2020) Fabrication and characterisation of hemp fibre based 3D printed honeycomb sandwich structure by FDM process. Appl Compos Mater 27:935–953. https://doi.org/10.1007/s10443-020-09837-z

Brischetto S, Torre R (2020) Honeycomb sandwich specimens made of PLA and produced via 3D FDM Printing Process: An Experimental Study. J Aircr Spacecr Technol 4:54–69. https://doi.org/10.3844/jastsp.2020.54.69

Ayrilmis N, Nagarajan R, Kuzman MK (2020) Effects of the face/core layer ratio on the mechanical properties of 3D printed wood/polylactic acid (PLA) green biocomposite panels with a gyroid core. Polymers (Basel). https://doi.org/10.3390/polym12122929

Song Y, Li Y, Song W et al (2017) Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater Des 123:154–164. https://doi.org/10.1016/j.matdes.2017.03.051

Zhao Y, Chen Y, Zhou Y (2019) Novel mechanical models of tensile strength and elastic property of FDM AM PLA materials: Experimental and theoretical analyses. Mater Des 181:108089. https://doi.org/10.1016/j.matdes.2019.108089

Ezeh OH, Susmel L (2019) Fatigue strength of additively manufactured polylactide (PLA): effect of raster angle and non-zero mean stresses. Int J Fatigue 126:319–326. https://doi.org/10.1016/j.ijfatigue.2019.05.014

Algarni M (2021) The influence of raster angle and moisture content on the mechanical properties of PLA parts produced by fused deposition modeling. Polymers (Basel). https://doi.org/10.3390/polym13020237

Ferreira RTL, Amatte IC, Dutra TA et al (2017) Experimental characterisation and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos B Eng 124:88–100. https://doi.org/10.1016/j.compositesb.2017.05.013

Zhang X, Chen L, Mulholland T et al (2019) Effects of raster angle on the mechanical properties of PLA and Al/PLA composite part produced by fused deposition modeling. Polym Adv Technol 30:2122–2135. https://doi.org/10.1002/pat.4645

Shilpesh R. Rajpurohit, Harshit K. Dave (2018) Tensile Properties Of 3D Printed Pla Under Unidirectional And Bidirectional Raster Angle: A Comparative Study. https://doi.org/10.5281/zenodo.1315615

ASTM International ASTM D3039 - Test Method for Tensile Properties of Polymer Matrix Composite Materials

3D-Lab (N/A) Filamento PLA: como imprimir com esse filamento (in Portuguese). https://3dlab.com.br/como-imprimir-com-filamento-pla/. Accessed 01st July 2021

R Core Team (2020) R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria

Montgomery DC (2009) Design and analysis of experiments, 7th edn. Wiley, Hoboken, NJ

Khosravani MR, Berto F, Ayatollahi MR, Reinicke T (2022) Characterisation of 3D-printed PLA parts with different raster orientations and printing speeds. Sci Rep 12:1016. https://doi.org/10.1038/s41598-022-05005-4

Sousa AM, Pinho AC, Piedade AP (2021) Mechanical properties of 3D printed mouthguards: Influence of layer height and device thickness. Mater Des 203:109624. https://doi.org/10.1016/j.matdes.2021.109624

Dou H, Cheng Y, Ye W et al (2020) Effect of process parameters on tensile mechanical properties of 3D printing continuous carbon fiber-reinforced PLA composites. Materials (Basel). https://doi.org/10.3390/ma13173850

Funding

The authors would like to thank the financial support provided by CNPq/Brazil (Conselho Nacional de Desenvolvimento Científico e Tecnológico)-GDE-290224/2017–9 and PQ-309885/2019–1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pereira, R.B.D., Pereira, E.B., Oliveira, P.R. et al. The effect of printing parameters on the tensile properties of bidirectional PLA structures: a statistical approach. Prog Addit Manuf 8, 519–527 (2023). https://doi.org/10.1007/s40964-022-00345-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-022-00345-z